Instruction Manual

D200137X012

3570 Positioners

September 2015

2

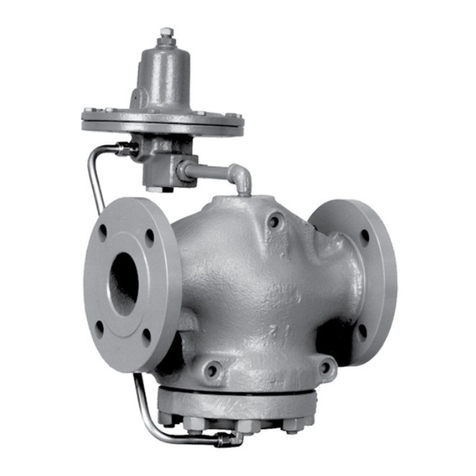

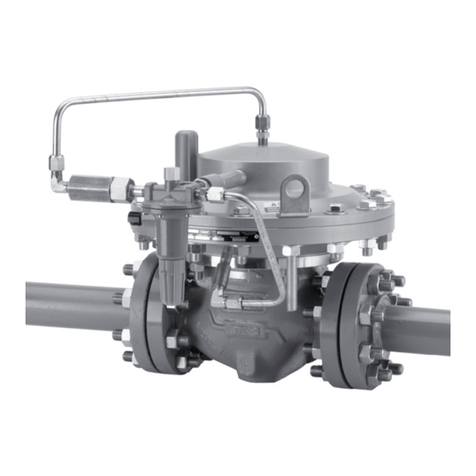

to figure 1 for a typical mounting of a 3570 positioner. Refer to separate instruction manuals for information

concerning the actuator, valve, and accessories.

Do not install, operate or maintain a 3570 positioner without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

Description

3570 pneumatic valve positioners are used with control valve assemblies to provide an accurate valve stem position

that is proportional to the input signal received from a control device. The input signal range can be 0.2 to 1.0 bar (3 to

15 psig), 0.4 to 2.0 bar (6 to 30 psig), or another pneumatic input signal range, as required.

These positioners are normally used with pneumatic piston actuators. However, product types within the 3570 family

can be used with pneumatic, long‐stroke, cylinder actuators or with pneumatic diaphragm actuators.

Valve Positioner Type Numbers

3570 — Pneumatic valve positioner with two relays for use with Fisher 470 and 480 pneumatic piston actuators. See

figure 4. The positioner includes three pressure gauges to monitor input signal, relay output pressure to the top of the

actuator cylinder, and relay output pressure to the bottom (piston underside) of the actuator cylinder.

The 3570 positioner is mounted on the top of the actuator cylinder. The actuator stem position feedback is provided

through extension of the range spring attached to the actuator piston rod.

3570C — Pneumatic valve positioner with automotive tire valves instead of pressure gauges. Tire valves can be used

for clip‐on test pressure gauges. The relay nozzles are locked in place with locknuts to resist unwanted nozzle

movement due to vibration.

3570P — Pneumatic valve positioner with two relays for use with Fisher 490 pneumatic piston actuators. The

positioner includes three pressure gauges to monitor input signal, relay output pressure to the top of the actuator

cylinder, and relay output pressure to the bottom (piston underside) of the actuator cylinder.

The 3570P positioner is mounted alongside the actuator cylinder. Actuator stem position feedback is provided from

the actuator‐valve stem connector through a cable and spool assembly.

3570PC — Pneumatic valve positioner with automotive tire valves instead of pressure gauges. Tire valves can be used

for clip‐on test pressure gauges. The relay nozzles are locked in place with locknuts to resist unwanted nozzle

movement due to vibration.

3571 (Discontinued)— Pneumatic valve positioner with two relays for use with long‐stroke cylinder actuators. The

positioner includes three pressure gauges to monitor input signal, relay output pressure to the top of the actuator

cylinder, and relay output pressure to the bottom (piston underside) of the actuator cylinder.

The 3571 positioner is bracket‐mounted to the side of the actuator. Actuator stem position feedback is provided

through a wire from the actuator‐valve stem connector.

3572 — Pneumatic valve positioner with one relay. The 3572 positioner is normally used on the 472 pneumatic piston

actuator mounted on valve bodies having push‐down‐to‐open (PDTO) action. The positioner includes two pressure

gauges to monitor input signal pressure and relay output pressure to the top of the actuator cylinder.

The 3572 positioner is mounted on the top of the actuator cylinder. Actuator stem position feedback is provided

through an extension of the actuator piston rod.