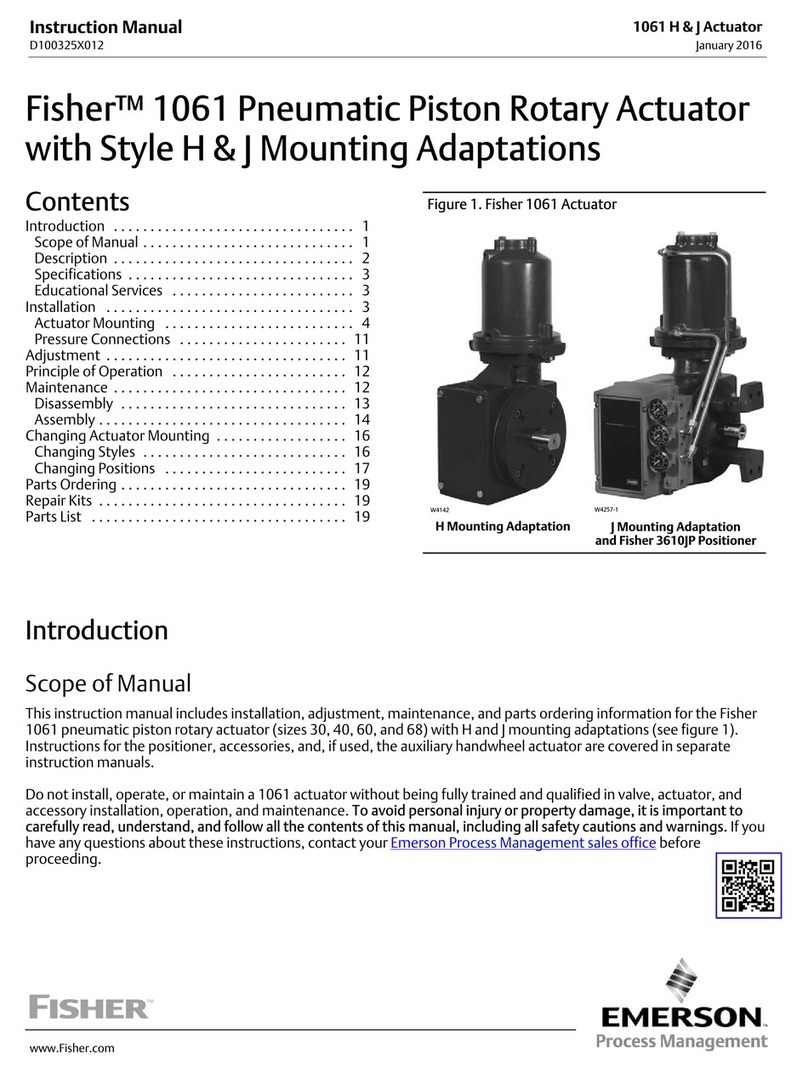

Type 1066 With H Mounting

Figure 4. Center of

Gravity Dimensions

operated equipment shaft, refer to the

changing positions procedure in the

Changlng Actuator Mounting section. This

procedure describes how the output shafi

can be repositioned to accommodate the

operated equipment shaft.

2. Attach an appropriate mounting bracket (not

provided) against the travel indicator scale(key21) inthe

desired orientation with the cap screws (key 20). See

figure 3 for mounting dimensions on the travel indicator

scale. Tighten the cap screws to 18 foot-pounds (25

N-m) for size 20 actuators and to 75 foot-pounds (102

Nom) for size 75 actuators.

3. Slide the actuator (with the user-provided mounting

bracket attached) into the user-provided coupling on the

operated shaft. Then, secure theactuatorto the operated

equipment in the desired mounting position with appre

priate fasteners, such as mounting cap screws. See

figure 3 for output shaft dimensions.

4. If necessary perform the adjustment procedure

before proceeding totheloadingconnectionsprocedure.

Loading Connections

1. Type 1066 actuators should have either a loading

solenoid, a four-way switching valve, or two threeway

switching valves connected tothe i/4-inch NPTpressure

connections located at the top and bottom of the actuator

cylinder.

2. Connecteither1/4-inch(6.4mm) or3/6-inch(9.5 mm)

tubing between the actuator pressure connections and a

controlling instrument Keep the length of tubing asshort

aspossibleto avoid transmission laginthe control signal.

3. When the actuator is completely installed and

connected to the instrument, check the actuator for

correct action (air-teopen or air-toclose) to match the

controlling instrument. For successful operation, the

piston rod (key 5) and equipment operating shaft must

move freely in response to loading pressure changes on

the piston (key 3).

Adjustment

Key numbers referenced in this section are shown in

figure 6.

Avoid personal injury or property damage

from a sudden release ot process pressure

or uncontrolled process fluid. Before

starting adjustment:

l

Isolate the valve or other operated

equipment from the process,

l

Release process pressure, and

l

Vent the actuator loading pressure.

TheTypel066 actuatorisfactorysetforafull90degrees

of operated shaft rotation unless otherwise specified by

thecustomer. Adjustmentsmay bemadeafterinstallation

by looseningthe self-sealing nuts(key37) and turning the

set screws(key 12).Top andbottom piston position limits

are set with the upper andlower setscrews, respectively.

If rotation of either set screw (key 12) seems difficult,

apply Lubriplate MAG-II11lubricant or equivalent (key35)

to the threads of each set screw as shown in figure 6.

4