CONTENTS

Page 6

Page 14

Page 9

Page 18

Page 25

1.PREFACE............................................................................................................................................

2.INSTALLATION....................................................................................................................................

3.ELECTRICAL WIRINGS......................................................................................................................

1.1 GENERAL SPECIFICATIONS

2.1 GENERAL DESCRIPTION

2.2 DIMENSIONS

2.3 PANEL CUT-OUT

2.4 ENVIRONMENTAL RATINGS

2.5 PANEL MOUNTING

2.6 INSTALLATION FIXING SCREWS

2.7 REMOVING FROM THE PANEL

3.1 TERMINAL LAYOUT AND CONNECTION INSTRUCTIONS

1.2 WARRANTY

1.3 MAINTENANCE

3.2 ELECTRICAL WIRING DIAGRAM

3.2.1 1-PHASE WIRING DIAGRAM

3.2.2 3-PHASE WIRING DIAGRAM

4.1 CABLE CONNECTION BETWEEN RS-232 TERMINAL OF THE DEVICE AND PC

4.2 CABLE CONNECTION BETWEEN RS-232 TERMINAL OF THE DEVICE AND MODEM

4.3 PC INTERFACE

4.3.1 TECHNICAL SPECIFICATIONS

4.3.2 INSTALLATION INSTRUCTIONS

4.3.2.1 MINIMUM SYSTEM REQUIREMENTS

4.3.3 INSTALLING SOFTWARE

4.3.4 USING OF COMMUNICATION SOFTWARE

4.3.5 DESCRIPTION

4.3.6 OBSERVATION WINDOW

4.3.7 OPERATOR PARAMETERS WINDOW

4.3.8 TECHNICIAN PARAMETERS WINDOW

4.3.9 MAIN MENU

4.3.9.1 FILE

4.3.9.2 PROGRAMMING

4.3.9.3 SETTINGS

4.3.10 ENTERING TO THE OPERATOR PARAMETERS WINDOW

4.3.11 ENTERING TO THE TECHNICIAN PARAMETERS WINDOW

4.3.12 ENTERING TO THE ADJUSTMENT WINDOW

4.3.13 LOAD THE CONFIGURATION FILE FROM DISC

4.3.14 SAVE THE CONFIGURATION FILE TO THE DISC

4.3.15 UPLOAD

4.3.16 DOWNLOAD

4. ...................

5.PARAMETERS.....................................................................................................................................

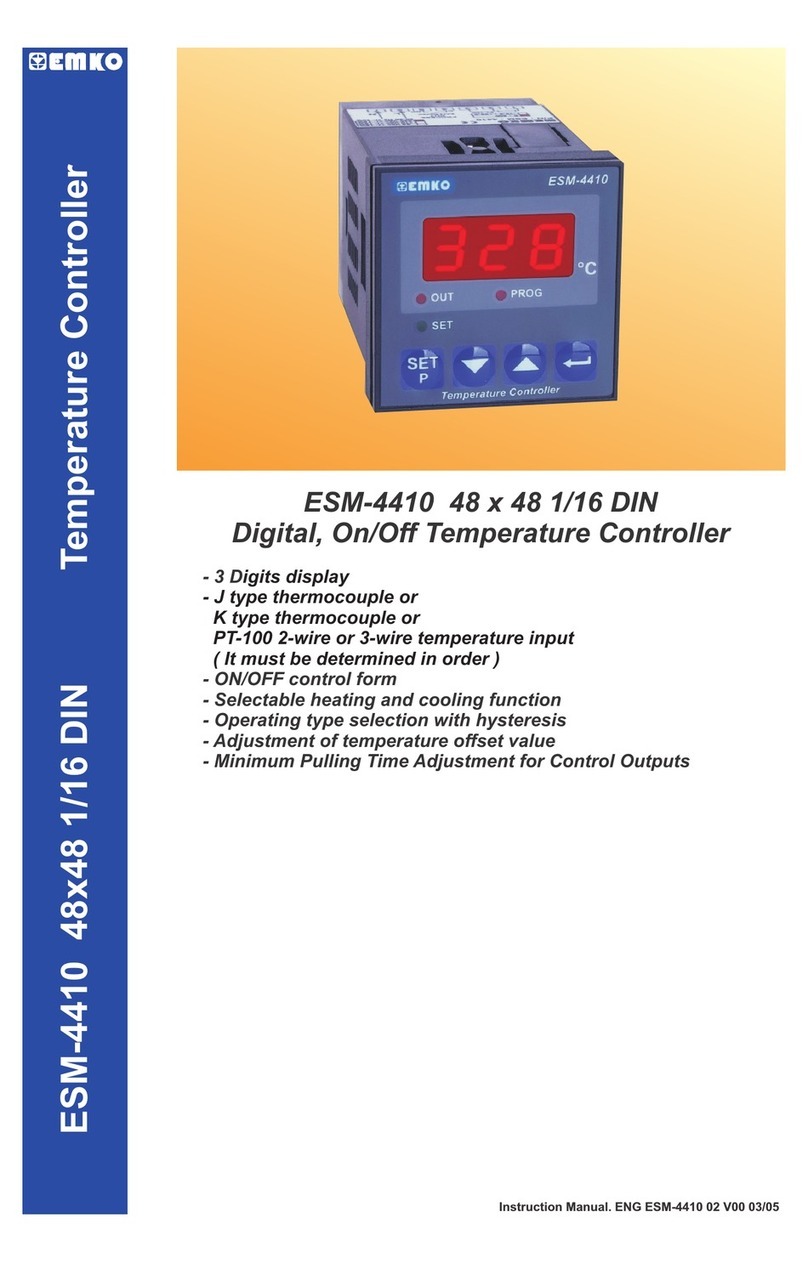

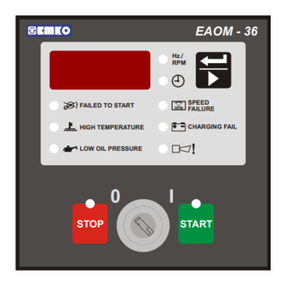

EAOM-72F

EAOM-72F

RS-232 SERIAL INTERFACE, PROGRAMMING THE DEVICE OVER PC OR MODEM

5.1.3 BATTERY VOLTAGE

5.1.4 OVER CURRENT LIMIT

5.1.5 MAINTENANCE INDICATION

5.1.11 STOP / FUEL SOLENOID SELECTION

5.1.12 STOP MAGNET ENERGISING TIME

5.1.13 ENGINE STARTED SIGNALS

5.1.14 ENGINE STARTING

5.1.15 OIL PRESSURE BYPASS TIME

5.1.16 CONTROL ON DELAY

5.1.17 ENGINE COOLING TIME

5.1.18 PREHEAT TIME

5.1. PROGRAM FUNCTIONS

5.1.1 ALTERNATOR VOLTAGE

5.1.2 ALTERNATOR FREQUENCY

5.1.6 REMOTE START TIME DELAY

5.1.7 REMOTE STOP TIME DELAY

5.1.8 WARM-UP TIME DELAY

5.1.9 CONTROL ON DELAY / FAST-LOADING SELECTION

5.1.10 SPEED SENSING

3