Type 667 Size 30-76 & 87

9

control signal to the actuator. Be sure

the actuator cannot suddenly open or

close the valve.

DUse bypass valves or completely

shut off the process to isolate the valve

from process pressure. Relieve process

pressure from both sides of the valve.

Drain the process media from both sides

of the valve.

DVent the power actuator loading

pressure and relieve any actuator spring

pre-compression.

DUse lock-out procedures to be sure

that the above measures stay in effect

while you work on the equipment.

DThe valve packing box may contain

process fluids that are pressurized, even

when the valve has been removed from

the pipeline. Process fluids may spray

out under pressure when removing the

packing hardware or packing rings, or

when loosening the packing box pipe

plug.

The maintenance instructions are divided into several

sections: Actuator, Top-Mounted Handwheel Assem-

bly (Adjustable Down Travel Stop), Side-Mounted

Handwheel Assembly for Size 34 through 60 Actuators

(Manual Actuator), Side-Mounted Handwheel Assem-

bly for Size 70, 76 and 87 Actuators (Manual Actua-

tor), and Casing-Mounted Travel Stops.

Actuator

This procedure describes how the actuator can be

completely disassembled and assembled. When in-

spection or repairs are required, disassemble only

those parts necessary to accomplish the job; then,

start the assembly at the appropriate step.

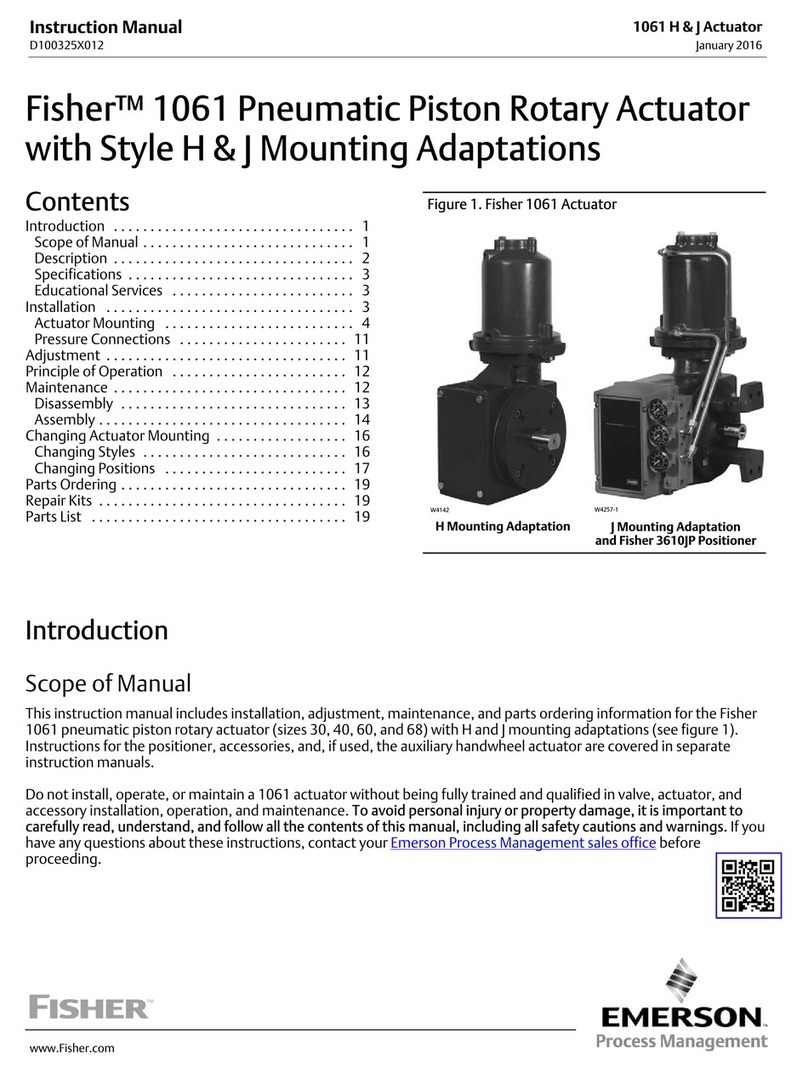

Key numbers are shown in figures 6, 7, or 8, unless

otherwise noted. Figure 6 shows the size 30 through

60 actuators, figure 7 shows the size 70 actuator, and

figure 8 shows the size 87 actuator.

Actuator Disassembly

Isolate the control valve from the line pressure, release

pressure from both sides of the valve body, and drain

the process media from both sides of the valve. Also

shut off all pressure lines to the power actuator, re-

lease all pressure from the actuator. Use lock-out pro-

cedures to be sure that the above measures stay in

effect while you work on the equipment.

1. Remove the tubing or piping from the connection in

the top of the yoke (key 73). For a top-loaded

construction, also remove the piping or tubing from the

connection in the upper diaphragm casing (key 1).

2. Turn the spring adjuster (key 74) counterclockwise

(toward the valve body) until all spring compression

is relieved.

WARNING

To avoid personal injury due to the sud-

den uncontrolled movement of parts, do

not loosen the stem connector cap

screws when the stem connector has

spring force applied to it.

3. If necessary, remove the actuator from the valve

body by separating the stem connector (key 31). Loos-

en the stem locknuts for the size 87 actuator, and re-

moving the stem connector nuts. For all other sizes,

separate the stem connector by loosening the stem

locknuts (keys 69 and 75) and unscrewing the two

stem connector cap screws.

4. Unscrew the spring adjuster (key 74) from the ac-

tuator stem (key 144). Also lift the spring seat and

spring (key 19 and 18) out of the yoke.

5. Remove the diaphragm casing cap screws and

nuts (keys 13 and 14), and lift off the upper diaphragm

casing (key 1).

6. Remove the following connected parts: the dia-

phragm (key 3), upper diaphragm plate (key 4), spacer

(key 2), cap screw (key 12), lower diaphragm plate

(key 71), and actuator stem (key 144). Be careful

when pulling the threads of the actuator stem through

the seal bushing (key 7) to avoid damaging the O-rings

(key 8).

7. Remove the cap screw (key 12) to separate the

parts of this assembly.

8. To remove the seal bushing, remove the snap ring

(key 72), and lift out the bushing. Inspect, and if neces-

sary, replace O-rings (8 and 9).

9. Remove cap screws (key 30), and take off the low-

er diaphragm casing (key 64) and the gasket (key 70,

size 30 through 60 and 76) or O-ring (key 70, size 70

or 87). If necessary, the down travel stops (key 77)

can be removed.

Actuator Assembly

1. Coat the O-rings (key 70, sizes 70 and 87) with lu-

bricant (key 237 or equivalent). Or, coat the gasket

with sealant (key 237 or equivalent). Place a new gas-

ket or O-ring (key 70) on the yoke (key 73). Position

the lower diaphragm casing (key 64) on the yoke, align

the holes, and insert and tighten the cap screws (key

30). If down travel stops (key 77) were removed, insert

and tighten them.

2. Coat the O-rings (keys 8 and 9) with lubricant (key

237 or equivalent) and place the O-rings in the seal

bushing (key 7).