Installation

November 1999 2-3

Vent

WARNING

If a flammable, toxic, or reactive gas is

to be used as the supply pressure me-

dium, personal injury and property

damage could result from fire or ex-

plosion of accumulated gas or from

contact with toxic or reactive gas. The

digital valve controller/actuator as-

sembly does not form a gas-tight seal,

and when the assembly is in an en-

closed area, a remote vent line, ade-

quate ventilation, and necessary safe-

ty measures should be used. A re-

mote vent pipe alone cannot be relied

upon to remove all hazardous gas.

Vent line piping should comply with

local and regional codes and should

be as short as possible with adequate

inside diameter and few bends to re-

move exhaust gases to a ventilated

area.

The relay output constantly bleeds supply air into the

area under the cover. The vent opening at the back of

the housing should be left open to prevent pressure

buildup under the cover. If a remote vent is required,

the vent line must be as short as possible with a

minimum number of bends and elbows.

To connect a remote vent to Type DVC5010,

DVC5030, and DVC5040 digital valve controllers—

sliding-stem The Type DVC5040 digital valve

controller has no pipe fitting for the vent. The vent is

purged under the actuator cover. For the Type

DVC5010 and DVC5030 digital valve controllers,

remove the plastic vent. The vent connection is

1/4-inch NPT female. Typically, 3/8-inch (10 mm)

tubing is used to provide a remote vent.

To connect a remote vent to Type DVC5020 digital

valve controllers—rotary Replace the standard

mounting bracket with the vent-away mounting

bracket. Install a pipe plug in the vent-away mounting

bracket. Mount the digital valve controller on the

actuator as described in the mounting instructions

included with the mounting kit.

Electrical Connections

WARNING

To avoid personal injury or property

damage caused by fire or explosion,

remove power to the instrument be-

fore removing the terminal box cover

in an area which contains a potential-

ly explosive atmosphere or has been

classified as hazardous.

4 to 20 mA Loop Connections

The digital valve controller is normally powered by a

control system output card. The use of shielded cable

will ensure proper operation in electrically noisy

environments.

CAUTION

Do not connect the digital valve con-

troller directly to a voltage source

when implementing the point-to-point

wiring mode, or damage to the printed

wiring board assembly submodule

may result. In point-to-point wiring

mode, the digital valve controller may

only be connected to a 4–20 mA cur-

rent source.

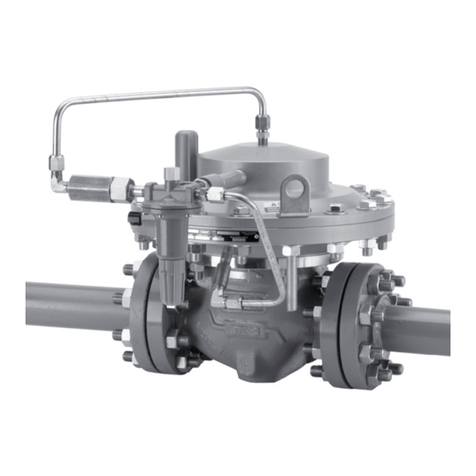

Wire the digital valve controller as follows, refer to

figure 2-3:

1. Remove the terminal box cap.

2. Bring the field wiring into the terminal box. When

applicable, install conduit using local and national

electrical codes which apply to the application.

Note

In the next step, note that the position

of the LOOP + and – terminals is differ-

ent than in previous units.

3. Connect the control system output card positive

wire ‘‘current output’’ to the LOOP + screw terminal in

the terminal box. Connect the control system output

card negative (or return) wire to the LOOP – screw

terminal in the terminal box.

2