Types

480,481, & 489

instrument signal. thus giving stable

and accurate response to a change in

controlled conditions.

Upon receiving a decreasing instru-

ment signal, the reverse of the above

actlo” takes place. The bellows con-

tracts and the beam pivots, restricting

the nozzle of relay “B” and

uncovering the nozzle of relay “A”.

Through relay action. the pressure be-

low the actuator piston increases and

the pressure above the piston decreases

to move the piston upward.

Types 481 and 489..

ISee Figure 21. Operation of either

a Type 481 or a Type 489 is similar to

a Type 480 in so far as basic piston

movement is concerned. However, the

manners of loading the respective

pistons are less complex. On the Type

489 actuators. the 3579 solenoid

manifold acts to alternately load and

exhaust full supply pressure to op-

posite sides of the piston in response

to electrical signals from an outside

power source. The 481, used most

frequently for on/off service, must

have an external switching device

attached to divert supply pressure

from one side of the piston to the

other.

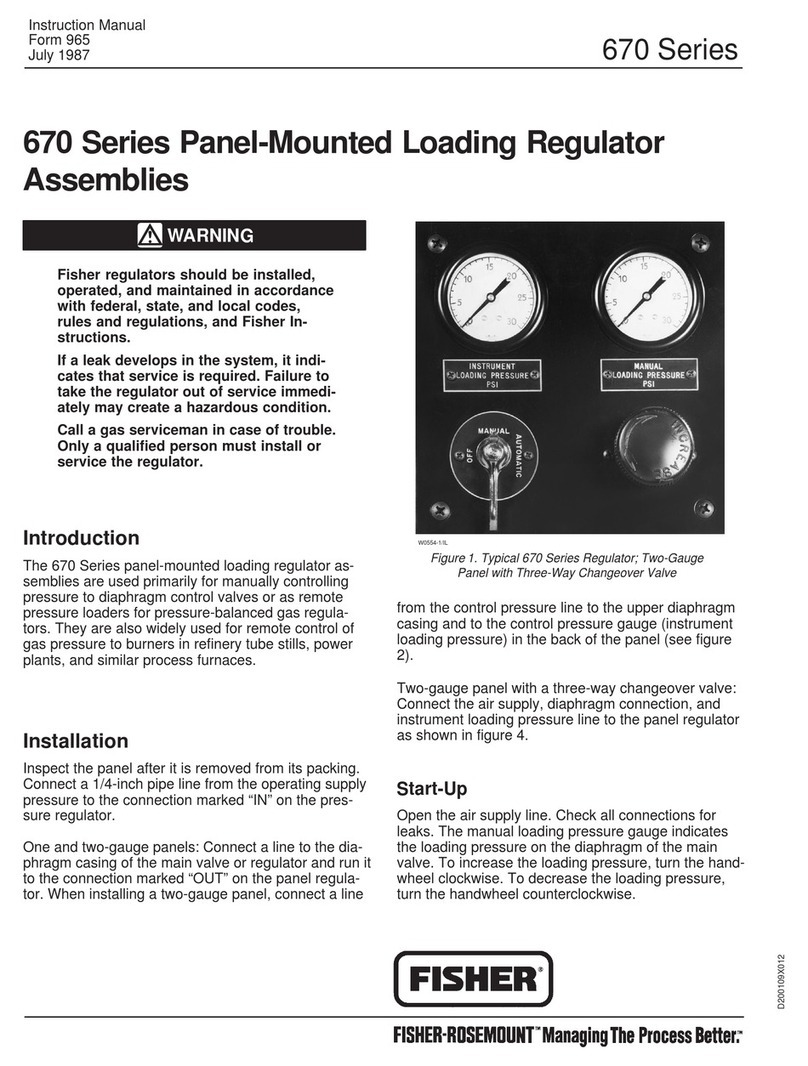

Figure 2 ///ustra don of a Type 3579 manifold asserr~bly.

Pressure Connections

Type 48%.

The Type 3570 positioner, an ins

tegral part of Type 480 actuator units,

is factory-assembled to the actuator.

Two connections, “Supply” and

“Instrument”. remain to be made after

valve installation. Both are 114” NPT

holes in the positioner and are label-

led. Minimum supply pressure is 35

psig. but for optimum performance,

supply pressure should be held as near

as possible to the 150 psig maximum.

Supply pressure air or gas should be

clean and dry, as well as non-corrosive.

Use of a Fisher Type 254 filter is rep

commended.

The positioner case should al-

ways be vented to prevent pressure

buildup. If the valve is installed with

the actuator below the pipeline, pro-

vide a new vent location in the lowest

part of the case by removing the

cadmium plated pipe plug from the

case and screwing it into the standard

vent location. This also serves as a

drain hole to prevent accumulationof

condensate.

Types 481 and 489..

The Type 481 and Type 489

actuators also require l/4” NPT male

Supply pressure piping. The 3579

solenoid manifold used or the Type

489 has three external connections.

Supply air enters the side of the ~nant~

fold. Depending on the controller

signal to the solenoid YBIYBS. the XIII-

ply air is directed either straight down

to the top side of the piston. or out

the bottom cylinder connection lin

side of manifold adjacent to supply

port) and through tubing to the lower

side of the piston. During loading of

piston, the air on the opposite side of

the piston is exhausted through the w

haust port of the manifold.

The Type 481 has only a pressure

tap cover on top of the cylinder. Sups

ply air pressure must be connected to

it. and also to the lower cylinder con-

nection located near the cylin-

der/cylinder flange joint. An external

four-way valve or other switching de-

we must be provided between the

maw supply pressure line and these

two actuator pressure connect,ons.

Adjustments

All three adjustments on the Type

480 actuator are on the Type 3570

positioner. For further information on

the positioner, such as Adjustments.

Maintenance. Reversing. and Relay

Operation, refer to the Type 3570 Ins

structions and Parts List, Form 1837.

Types 481 and 489 require no ad-

justments.