CONTENTS

Arm

Feed

Cord

Stringing

............

cece

cece

cece

eee

e

cece

cnet

e

ee

en

tent

ee

en

eneeeneneeenes

2

SpeCitiCavOnS-sicctiwkcicessncte

ca

dese

ue

lave

noore

vosdpe

vainseeabadeh

enero

bateee

eanuiaers

3

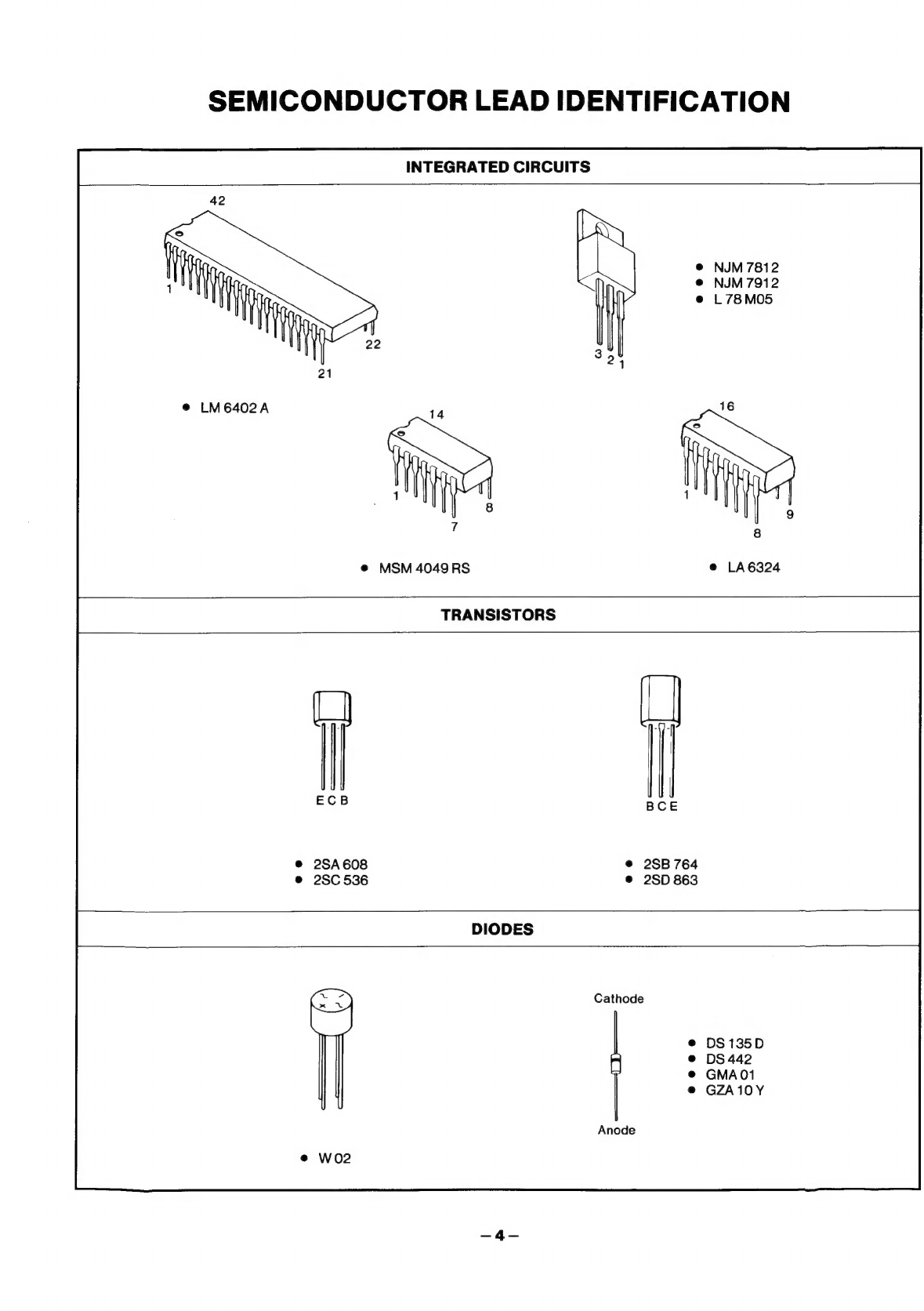

Semiconductor

Lead

identification

............

0...

ccc

cece

cece

eee

e

nee

e

eee

e

ee

eee

eens

4

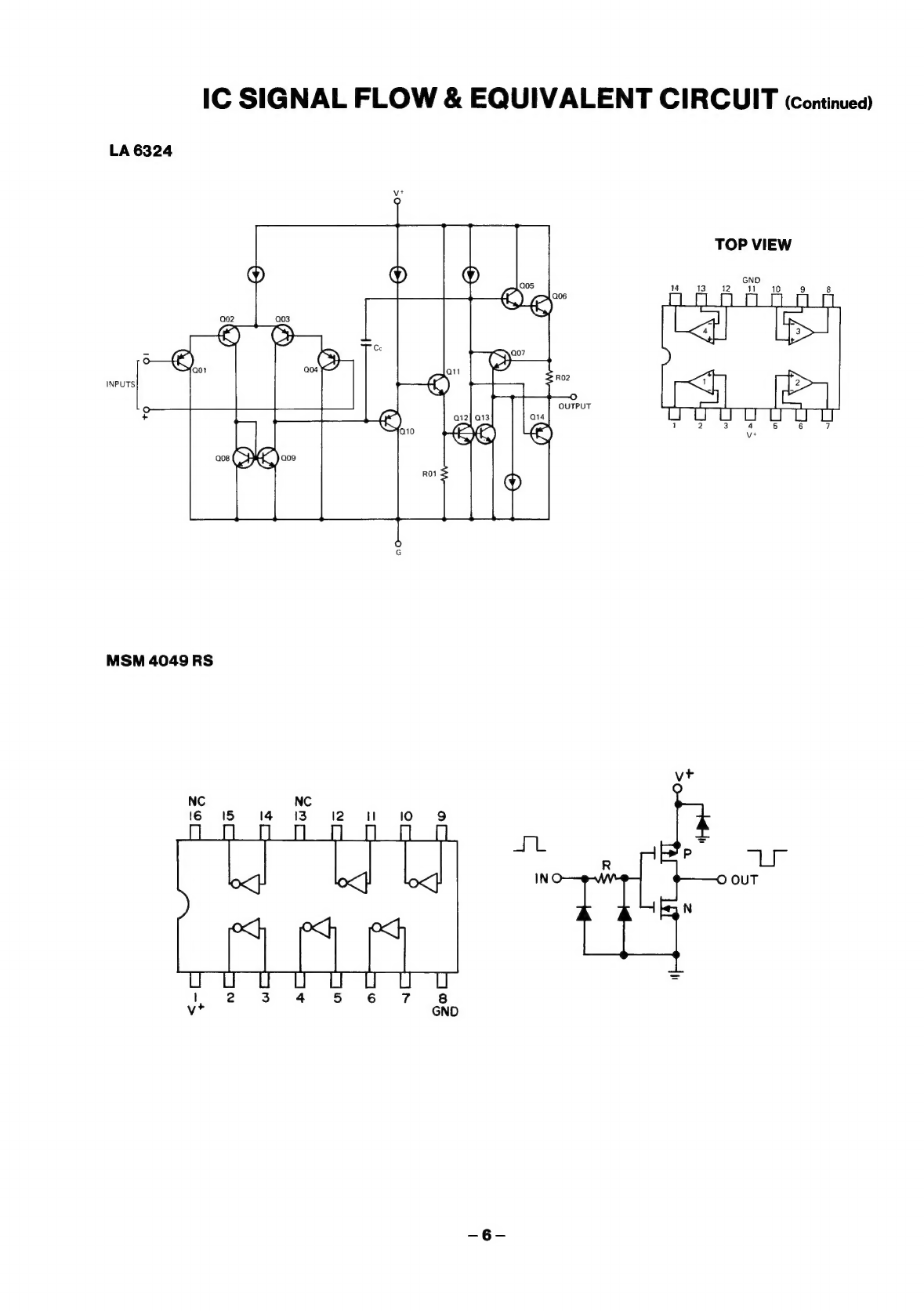

IC

Signal

Flow

&

Equivalent

Circuit

..........0....

ccc

ccc

cece

een

eens

5,6

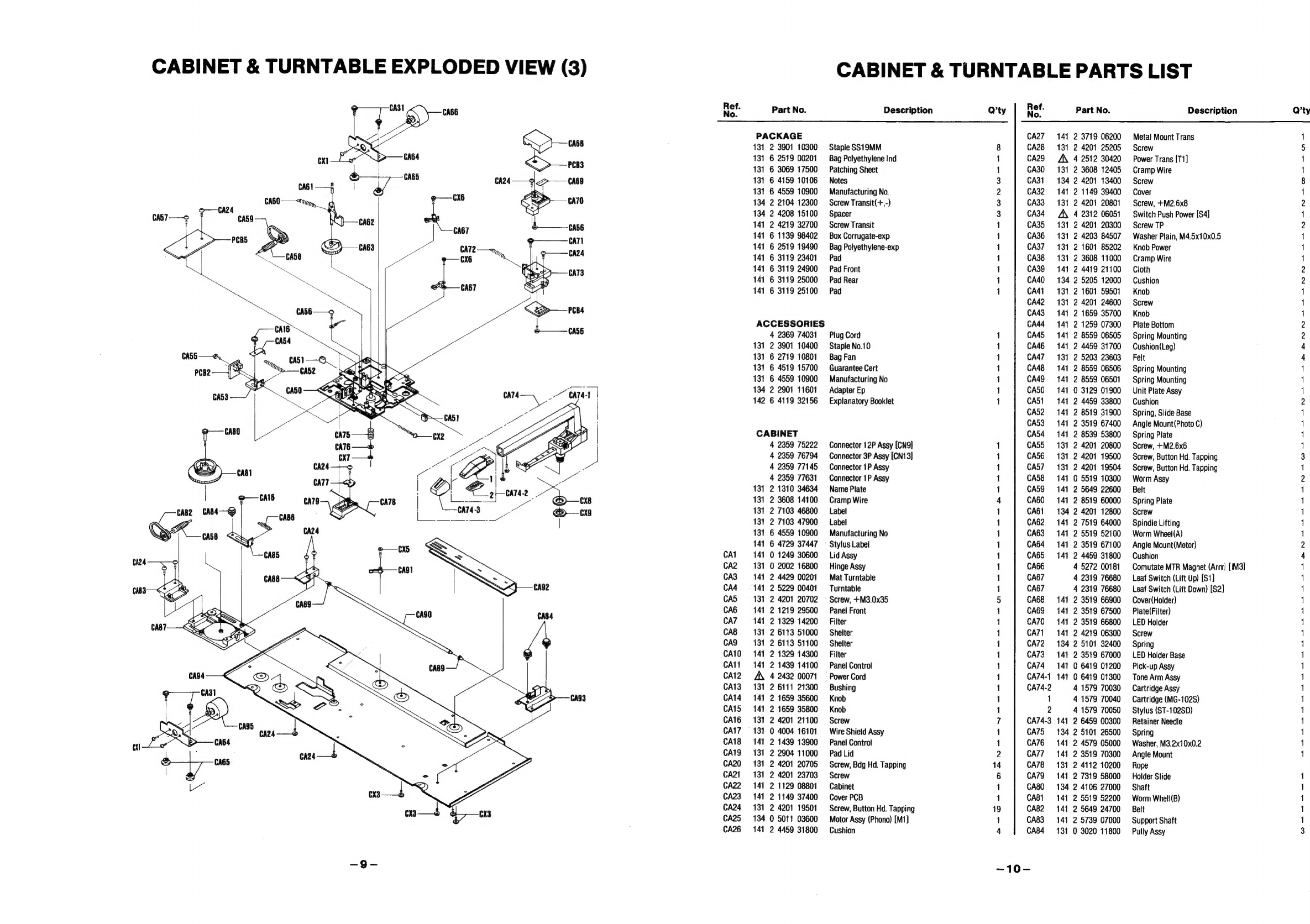

Cabinet

&

Turntable

Exploded

View

..............

0c

cece

cece cece

een

e

tee

eeeeeeenenes

7,8,9

Cabinet

&

Turntable

Parts

List

..............

0...

c

cece

cece

cece

eee

ene

eee

eeeeeeeeeee

10,11

Functional

Description

...............c

cee

cece

eee

e

ene

e

nee

e

eee

ener

enn

ene

en

eeeeee

12,13,14

Adjustment

Procedures

..........

0.

ccc

eee

ete

e

eee

e

erence

een

ene

n

en

ees

15,16,17

P.C.Board

Parts

List

............ccccccenccccccccncacacenccnesencusecurccscesusvecs

18,19,20

Printed

Circuit

Board

(Bottom

View)

...............c

cece

cece ence

ee

ee

21,22,23,24,25,26

Schematic

Diagram

.............:

ccc

cece

cece

cece

eee

ete

eee

en

eee

tere

e

ee ne

nena

27,28

Point

to

Point

Wiring

Diagram

.............

cc

cece

e

eee

eee

ee

n

eee

e

een

een

eee

e

es

29,30

Motor

Assy

Schematic

Diagram

...............

cece

cece

cece

eee

e

ete

e

eee

eee

ee

aee

31

Motor

Assy

P.C.Board

(Bottom

VieW)

...........

0c

cece

cece

cece

nnen

eee

eeeeeenneees

31

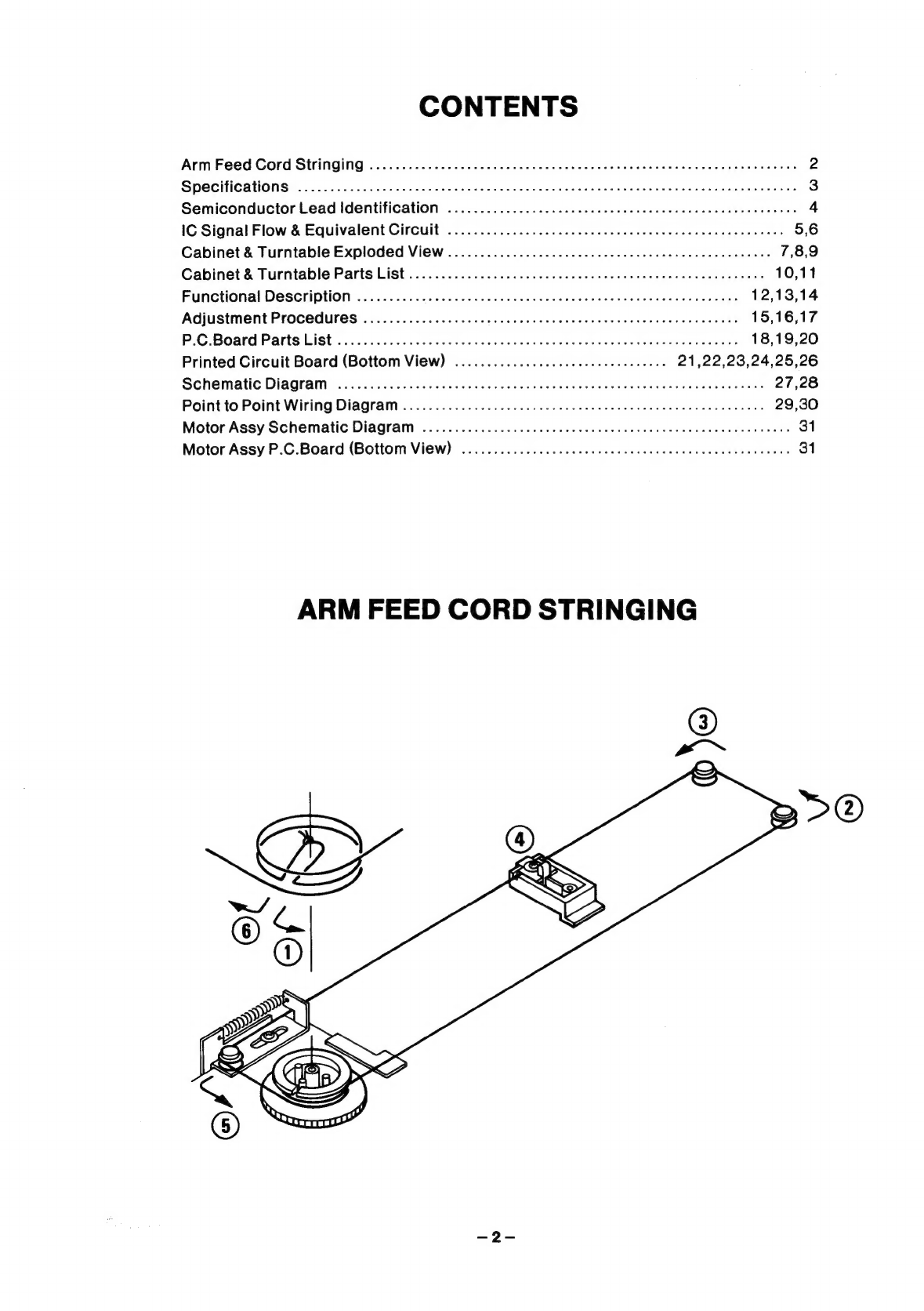

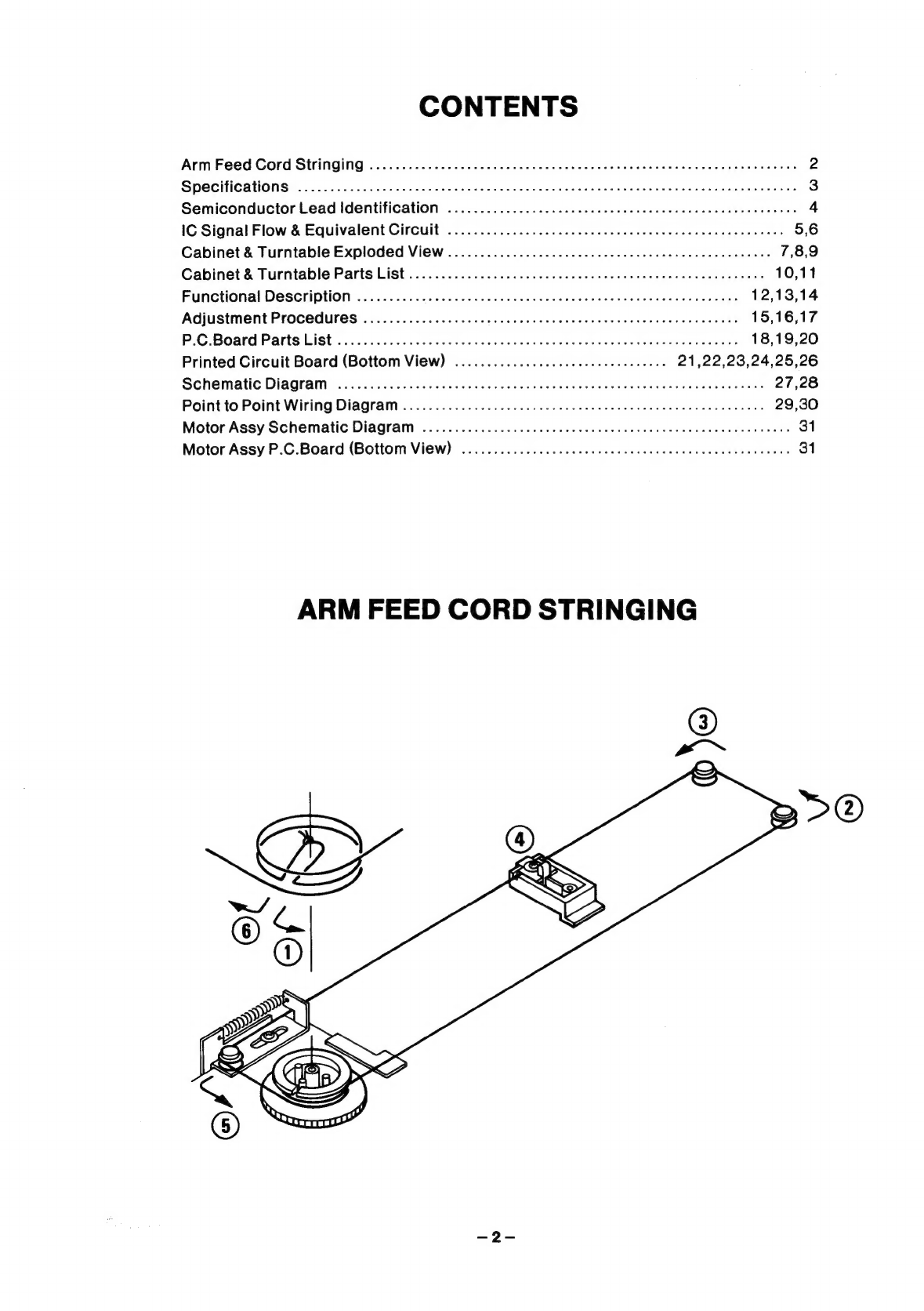

ARM

FEED

CORD

STRINGING