FJC 45125 User manual

.

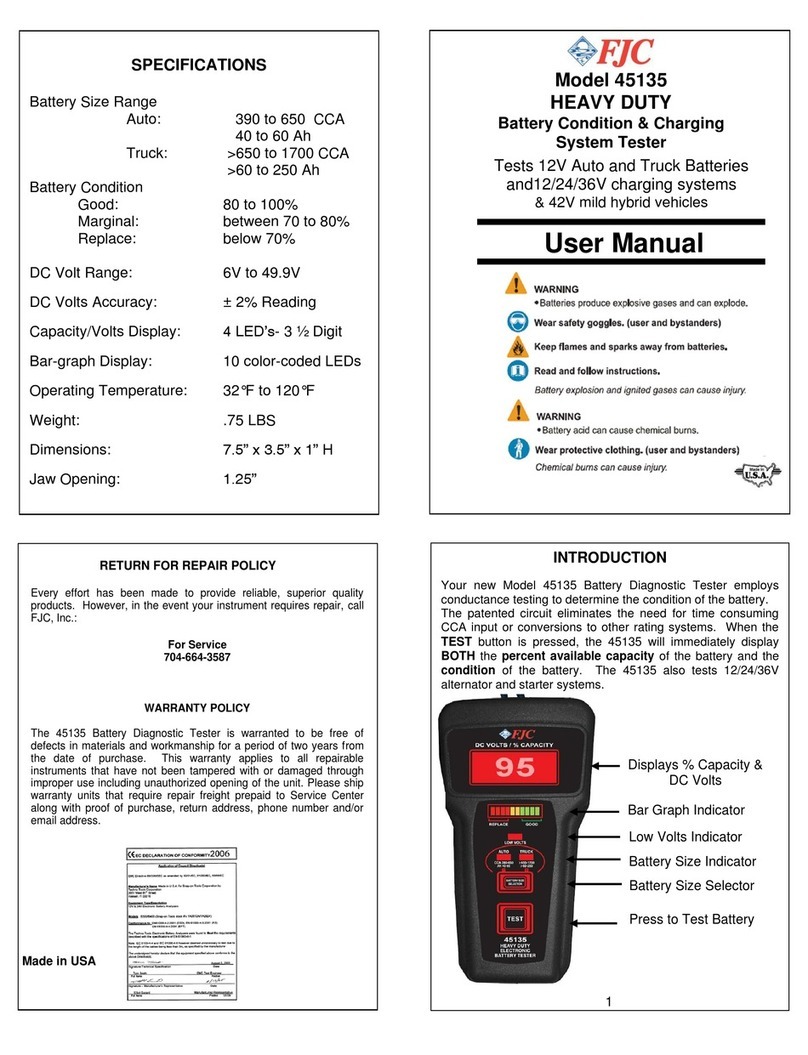

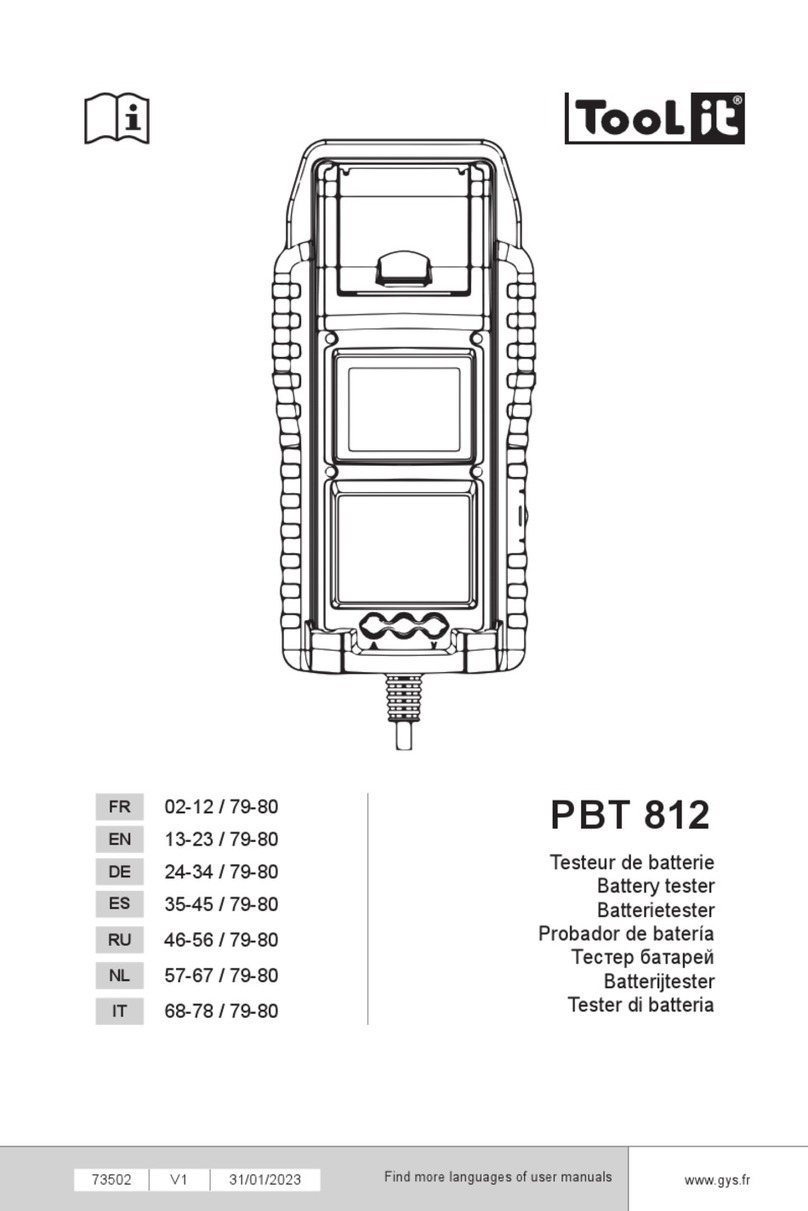

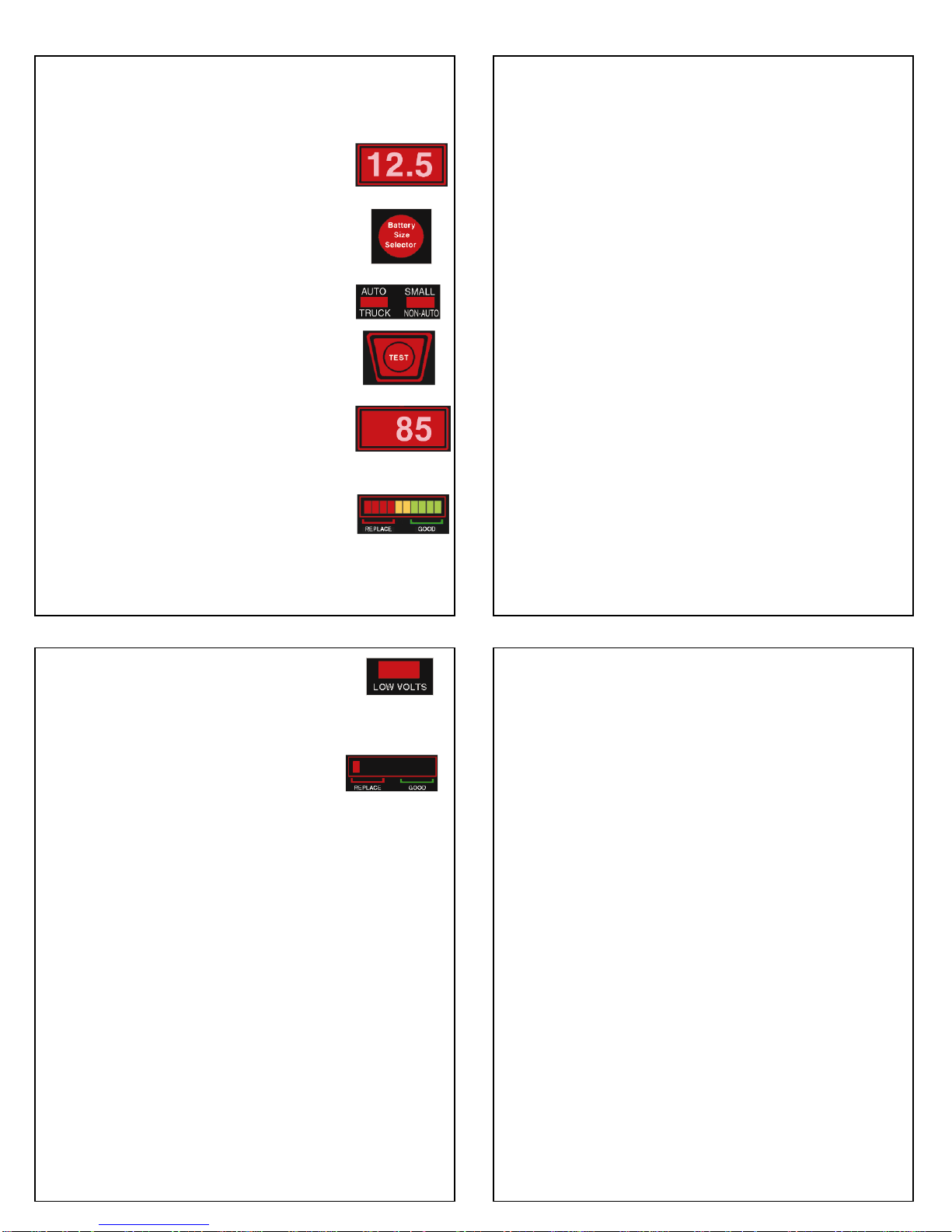

Displays % Capacity &

DC Volts

Bar Graph Indicator

Low Volts Indicator

Battery Size Selector

Press to Test Battery

Battery Size Indicator

1

YA2612A

User Manual

Model 45125

12V Battery Condition &

Charging System Tester

Tests 12V Auto/Truck and Non Auto

Batteries and 12V charging systems

SPECIFICATIONS

Battery Size Range

Auto/Truck: 390 to 1400 CCA

Small Non-Auto 6Ah to 33 Ah

Battery Condition

Good: 80 to 100%

Marginal: between 70 to 80%

Replace: below 70%

DC Volt Range: 7V to 19.9V

DC Volts Accuracy: ± 2% Reading

Capacity/Volts Display: 3 LED’s- 2 ½ Digit

Bar-graph Display: 10 color-coded LEDs

Operating Temperature: 32°F to 120°F

Weight: .75 LBS

Dimensions: 7.5” x 3.5” x 1” H

Jaw Opening: 1.25”

RETURN FOR REPAIR POLICY

Every effort has been made to provide reliable, superior

quality products. However, in the event your instrument

requires repair, call FJC, Inc.

For Service

704-664-3587

.

WARRANTY POLICY

The 45125 Battery Diagnostic Tester is warranted to be free of

defects in materials and workmanship for a period of two years

from the date of purchase. This warranty applies to all

repairable instruments that have not been tampered with or

damaged through improper use including unauthorized

opening of the unit. Please ship warranty units that require

repair freight prepaid to Service Center along with proof of

purchase, return address, phone number and/or email

address.

INTRODUCTION

Your new Model 45125 Battery Diagnostic Tester employs

conductance testing to determine the condition of the battery.

The patented circuit eliminates the need for time consuming

CCA input or conversions to other rating systems. When the

TEST button is pressed, the 45125 will immediately display

BOTH the percent available capacity of the battery and the

condition of the battery. The 45125 also tests 12V alternator

and starter systems

Checking Charging System

(Alternator)

CHARGING SYSTEM TEST

Note: Prior to performing this test, check the battery

condition to make sure it is in good condition. (See In

Vehicle Battery Test Instructions).

1. Check first for a loose, worn or broken alternator belt. If

okay, proceed to #2.

2. Connect the red clip to the positive battery terminal and the

black clip to the negative terminal and start engine.

3. With engine running, and lights on, the real time alternator

output voltage will be displayed. The reading should display

between 13.0 and 15.0 volts for 12V charging systems.

4. Low charging voltage: check belts for slippage. Check

connections from the alternator to the battery. If no problems

are found, replace the alternator.

5. High charging voltage: Check for loose connections

including the ground connection. If OK, replace the voltage

regulator. Newer alternators house the regulator inside. In this

case replacing the alternator is necessary.

4

STARTER TEST

Note: Check the battery condition to make sure it is in good

condition before performing this test. (See In-Vehicle Battery

Test Instructions page 3).

1. Connect the red clip to the positive battery terminal and the

black clip to the negative terminal.

2. Disengage the ignition. (Check manufacturer’s instructions).

Read the voltage displayed while cranking the starter.

3. Cranking Voltage is Normal: For 12V systems the normal

cranking voltage at the battery should be equal to or greater

than 9.6 volts*.

4. Cranking voltage is Low: If the cranking voltage is less

than 9.6 volts*, starting system has a problem. Check wires,

connections and starter.

* Check manufacturer’s specifications for 12V systems.

New Batteries:

Nearly all batteries will not reach full capacity until cycled 10-30 times. A

brand new battery will have a capacity of about 5-10% less than the

rated capacity.

Inactivity can be extremely harmful to a battery. New batteries that

have been on the shelf for many months may show “marginal” or

“replace” when tested, depending on the storage conditions. In that

case, always charge and retest the battery before replacing.

5

Checking Battery Condition

Out of Vehicle Testing

1. Connect the red clip to the positive battery

post and the black clip to the negative post. The

battery voltage will be displayed. Note: use post

adapters for side mount batteries or batteries with

top mount threaded studs (group 31). Connecting

to threaded studs will result in inaccurate

readings.

2. For Auto/Truck batteries (390 to 1400 CCA)

no size selection is necessary (default size).

The Auto/Truck size indicator LED will be on.

For Small/Non-Auto batteries (6 Ah to 33Ah)

press selector switch once. The LED indicator

will switch to the Small/Non-auto position.

3. Press and hold down the Test Button until

the final reading is displayed.

The digital display shows percent available

capacity. The Display and Bargraph will

automatically revert back to Volts after approx. 6

seconds, if the TEST Button is not released.

4. The color--coded LED BARGRAPH will show

GOOD (Green) MARGINAL (Yellow) or

REPLACE (Red).

Note: Some batteries may display above 100%. This means

that the available capacity is greater than the rated capacity

2

Low Volt Indicator

Batteries that test Marginal or (just below Marginal) when the

Low Volts LED indicator is on (below 12.3 Volts) should be

recharged and retested for more accurate results.

Bad Cell Indicator

Capacity displayed below 20% and only 1 red led on the bar-

graph indicates that the battery has a defective cell. Defective

battery cells are usually open or shorted and the battery must

be replaced.

In Vehicle Testing

(Checking Battery Condition)

1. Engine should be off. Turn off all accessory loads.

2. Remove surface charge (battery voltage is greater than 12.8

Volts) by turning on the headlights for 15 seconds.

3. Follow instructions for Out of Vehicle Testing (see Page 2).

Converting to CCA, DIN, JIS, Ah

If required, the available CCA, Ah, DIN, & JIS, can easily be

determined by multiplying the percent displayed times the

battery’s original rating. For example, a 600 CCA battery with

80% capacity available would have 480 CCA (.80 x 600)

available. A 20Ah battery with 80% would have 16 Ah available.

3

Other FJC Test Equipment manuals