Page 4

Contents

Quick Start 7

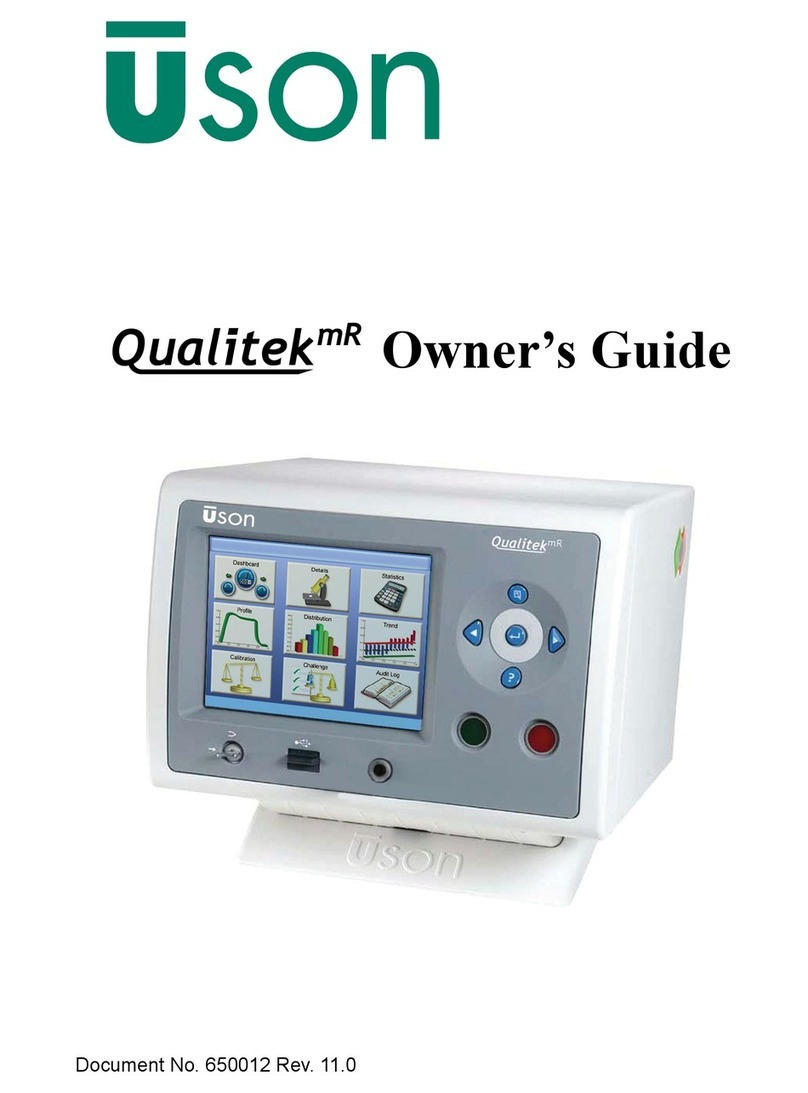

Front Panel Controls ................................................9

Back Components ..................................................10

Run Display ...........................................................12

Status Box Messages..............................................14

Decision Lights ......................................................16

Key Commands......................................................17

Test Parameters......................................................18

Troubleshooting ...................................................21

Air Supply..............................................................22

Full Setup 23

Standard vs. Optional Features ..............................24

How This Guide is Organized................................25

Turning On the Power............................................28

Switches and Buttons.............................................30

Setup Menus...........................................................34

Navigation..............................................................36

Parameters Menu ..................................................39

Test Pressure – Setting...........................................40

Coupling.................................................................42

Test Params – Sub-Parameter Menu .....................47

Vacuum Testing.....................................................53

How Sprint LC Works ...........................................54

Connections............................................................60

Run Display ..........................................................62

Units of Measure....................................................68

Serial Port...............................................................70

Input/Output...........................................................86