flamco Logotherm LogoTronic Hub OTC User manual

www.flamcogroup.com/manuals

Logotherm LogoTronic Hub OTC

ENG Operating instructions

for communication with LogoTronic controllers

for electronically controlled interface stations (HIU)

Manual LogoTronic Hub OTC

2

Acronyms

HIU Heat Interface Unit (interface station)

RL Heating circuit return line

FL Heating circuit flow line

FLA Flashing

BT Wireless data transmission

FW Firmware

CW Domestic water, cold

RTU Remote Terminal Unit

GND Ground

AT External temperature sensor

We reserve the right to change designs and technical specifications of our products.

3

ENG

Table of contents

1. Safety instructions .................................................................................................... 4

1.1 EU declaration of conformity .............................................................................................. 4

1.1.1 General instructions ........................................................................................................................ 4

1.1.2 Alterations to the equipment .......................................................................................................... 4

1.2 Intended use ...................................................................................................................... 5

1.3 Warranty and liability ......................................................................................................... 5

1.4 Disposal and hazardous substances .................................................................................... 5

2. Description ............................................................................................................... 6

2.1 Technical data .................................................................................................................... 6

2.2 About the LogoTronic Hub OTC ........................................................................................... 6

2.3 Safety symbols and stickers................................................................................................ 7

3. Installation ............................................................................................................... 7

3.1 Electrical connections for the LogoTronic Hub OTC ............................................................. 8

4. Commissioning.......................................................................................................... 8

5. Servicing................................................................................................................... 9

5.1 Fuse ................................................................................................................................... 9

6. LogoTronic Hub OTC – operation ................................................................................. 9

6.1 Configuration ..................................................................................................................... 9

6.1.1 Keys A and B components ............................................................................................................. 10

6.1.2 LED displays 1...5 ........................................................................................................................... 11

7. LogoTronic Hub OTC – functions................................................................................ 12

7.1 Modbus – General overview ............................................................................................. 12

7.1.1 Remote Terminal Unit (RTU) mode ............................................................................................... 12

7.1.2 Protocol configuration ................................................................................................................... 13

7.1.2.1 Uni-/Broadcast transmission principles...................................................................................... 14

7.1.2.2 Function codes ............................................................................................................................. 14

7.1.2.3 Data/parameter scaling................................................................................................................ 14

7.1.2.4 CRC................................................................................................................................................ 14

7.1.2.5 Start/end....................................................................................................................................... 14

7.1.3 Transmission parameters................................................................................................................ 14

7.1.4 Modbus – properties ....................................................................................................................... 15

7.2 Modbus for LogoTronic Hub OTC and HIU controllers ........................................................ 15

7.2.1 Connection of the RS-485 interface on the circuit board ............................................................. 16

7.2.2 Setting the controller for the Modbus protocol ............................................................................ 16

7.2.3 RS-485 interface settings (notes for system integrators) ............................................................. 17

7.2.4 Example of a broadcast message (notes for system integrators) ................................................ 18

7.2.5 Client-server interconnection options in the Modbus network................................................... 19

7.2.6 Notes on components.................................................................................................................... 20

Manual LogoTronic Hub OTC

4

1. Safety instructions

Read the instructions carefully before installation and operation.

The LogoTronic Hub OTC only works in conjunction with corresponding electronically controlled

Flamco/Meibes interface stations.

1.1 EU declaration of conformity

By aixing the CE mark to the equipment, the manufacturer declares that the LogoTronic Hub OTC

iscompliant with the relevant provisions:

• Radio Equipment Directive (RED) 2014/53/EU

• Low Voltage Directive (LVD) 2014/35/EU

• Electromagnetic Compatibility Directive (EMCD) 2014/30/EU

• Restriction of hazardous substances (ROHS) 2011/65/EU.

1.1.1 General instructions

Please read!

These installation and operating instructions contain basic instructions and important information

concerning the safety, installation, commissioning, maintenance and optimal use of the equipment.

For this reason, the installer / specialist and operator of the system must thoroughly read and

observe them prior to installation, commissioning and operation of the equipment. The device is

an electric automatic control unit. This device may only be installed in dry spaces and under the

ambient conditions described in the "Technical data" section.

You must also observe the relevant accident prevention regulations, the regulations of the electrical

engineering association and your local energy supply company, the relevant DIN-EN standards and

the installation and operating instructions of any additional system components.

This device is in no way intended to replace any safety equipment that you may be required to

install!

Installation, connection to the electricity supply, commissioning and maintenance of the equipment

may be carried out only by an appropriately qualified specialist.

For the operator: You must ask the specialist to oer comprehensive training in the function and

operation of the equipment. Always keep these instructions close to the equipment.

The manufacturer will not be liable for any damage that may arise through the improper use of the

equipment or failure to follow these instructions!

1.1.2 Alterations to the equipment

• Alterations and additions to, and conversions of, the equipment require the written consent of the

manufacturer.

• The installation of components which have not been tested with the equipment is not permitted.

• If it should become apparent, for example through damage to the housing, that it is no longer

possible to operate the equipment without risk, the equipment must immediately be taken out

ofservice.

We reserve the right to change designs and technical specifications of our products.

5

ENG

• Any equipment parts and accessory parts which are not in perfect condition must be replaced

immediately.

• Use only original replacement parts and accessories of the manufacturer.

• You must not alter, remove or render illegible any labels on the equipment which have been

aixed by the manufacturer.

• Undertake only those adjustments to the equipment’s settings that are described in these

instructions.

1.2 Intended use

The components listed in the following instructions are intended for use in heating systems

according to DIN EN 12828.

The LogoTronic Hub OTC is an automatic regulation and control unit within the meaning of IEC60730-1.

It is used as a client for forwarding an outside temperature sensor value via Modbus to several

LogoTronic controllers (servers for electronically controlled interface stations).

The LogoTronic Hub OTC and associated peripherals may be used only for the control of thermal

systems. All the specifications described must be adhered to in its use. The LogoTronic Hub OTC may

be installed and set up only by a specialist. The installer must first have read and understood the

instructions. The installer must explain all the relevant functions to the operator. The housing must

be intact and sealed prior to operation.

1.3 Warranty and liability

The equipment has been produced and tested in compliance with high quality and safety requirements.

Excluded from warranty and liability are personal injury and damage to property which may, for example,

be attributed to one or more of the following causes:

• Failure to observe these installation and operating instructions

• Improper installation, commissioning, maintenance and operation

• Improperly executed repair work

• Any actions in contravention of the "Alterations to the equipment" section

• Improper use of the equipment

• Situations in which values below or in excess of the tolerances listed in the technical data occur

• Force majeure

1.4 Disposal and hazardous substances

The equipment complies with European RoHS Directive 2011/65/EU on the

restriction of the use of certain hazardous substances in electrical and electronic

equipment.

The equipment must not be disposed of with household waste. You may dispose

of the equipment only at approved collection facilities or by returning it to the

seller or the manufacturer.

The battery must be correctly and professionally disposed of. The battery must

not be disposed of with household waste (local legislation applies).

Manual LogoTronic Hub OTC

6

2. Description

2.1 Technical data

Model LogoTronic Hub OTC

Power supply 200 - 240VAC, 50 - 60Hz

Power consumption 5W (power supply unit with electronics)

Internal fuse 2A delayed

Theory of operation Type I

Degree of contamination II

Overvoltage category II

Permissible ambient conditions:

in operation 0⁰C – 40⁰C, maximum 85% relative air humidity at 25 ⁰C

in transport/storage 0°C – 70°C, no condensation permitted

Housing 3-part, plastic polycarbonate / ABS

Dimensions 250 mm x 175 mm x 48 mm

Display 5 LEDs

Operation 2 buttons for service personnel

2.2 About the LogoTronic Hub OTC

The LogoTronic Hub OTC is designed to transmit the outside temperature sensor value via Modbus to

electronically controlled heat interface units (HIU) in heating networks. The LogoTronic Hub OTC is

an end product and must be installed and connected professionally by the customer.

When connecting the LogoTronic Hub OTC, appropriate tensile loads must be provided for the cables.

We reserve the right to change designs and technical specifications of our products.

7

ENG

2.3 Safety symbols and stickers

The LogoTronic Hub OTC is marked with the following symbols:

1. in the lower le corner of the

transparent cover, the "High

voltage" symbol and the "Read

manual" symbol, see figure

2. on the inner cover plate to the

right of the fuse holder and the

word "FUSE": a sticker with the

inscription "2A T", see figure

3. Installation

The LogoTronic Hub OTC is supplied with a mains power cable which is connected to the LogoTronic

Hub OTC by a plug. The end of the cable to be attached to the mains is open and must be hard-wired.

The mains connection device is the three-pole connector, see Chapter 3.1 Item (A).

The mains connection device must be hard-wired. We recommend the use of a 3A fuse.

Manual LogoTronic Hub OTC

8

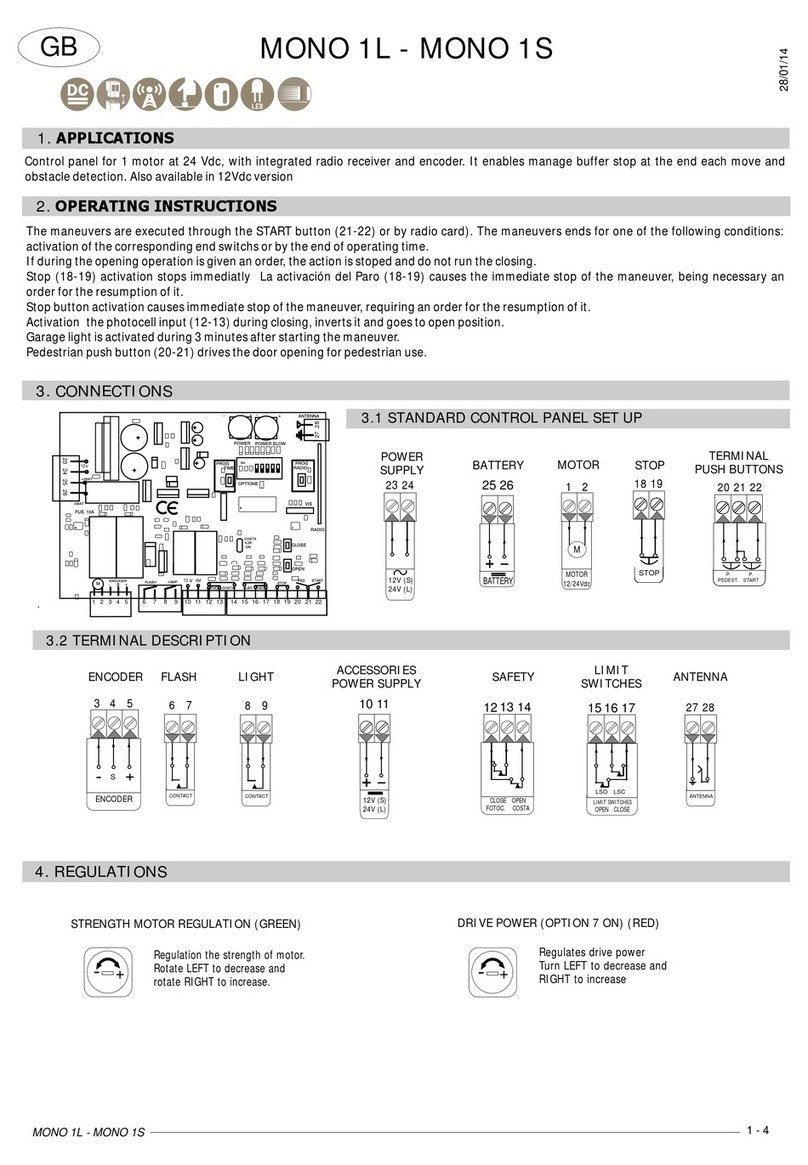

3.1 Electrical connections for the LogoTronic Hub OTC

Legend:

Pos. Identification Connection Comment Pin assignments

4 3 2 1

AL, N, PE, 230V Power supply Mains connection

device: AC 230V,

50Hz

- PE N L

BEXT. TEMP Outside

temperature

sensor (AT)

NTC, 10K resistor,

for type see

Chapter 7.2.6

- GND Temp

in

CRS 485 COM Modbus

connection*

or for e.g.

adapters for

flashing and

configuring

GND 24V DC RS485-B RS485-A

Note:

The connectors are labelled on the cover plate.

The connection cables for this must be assembled on site!

*for connecting the RS-485 interface: see also Chapter 7.2.1

4. Commissioning

The LogoTronic Hub OTC is tested during production. All settings are preset to ensure safe and

eicient operation.

If you want to change certain settings, then these changes will be made ex works.

The connections (see Chapter 3.1) to items (A), (B) and (C) must be made professionally by the

customer!

Example representations

We reserve the right to change designs and technical specifications of our products.

9

ENG

5. Servicing

The equipment must be disconnected from mains power before any servicing is carried out!

5.1 Fuse

A safety fuse is installed. The fuse installed is a 2A delayed fuse. The fuse type is: Glass fuse 5x 20mm.

Fuses may be changed only by specialist personnel once the equipment has been disconnected from

mains power.

6. LogoTronic Hub OTC – operation

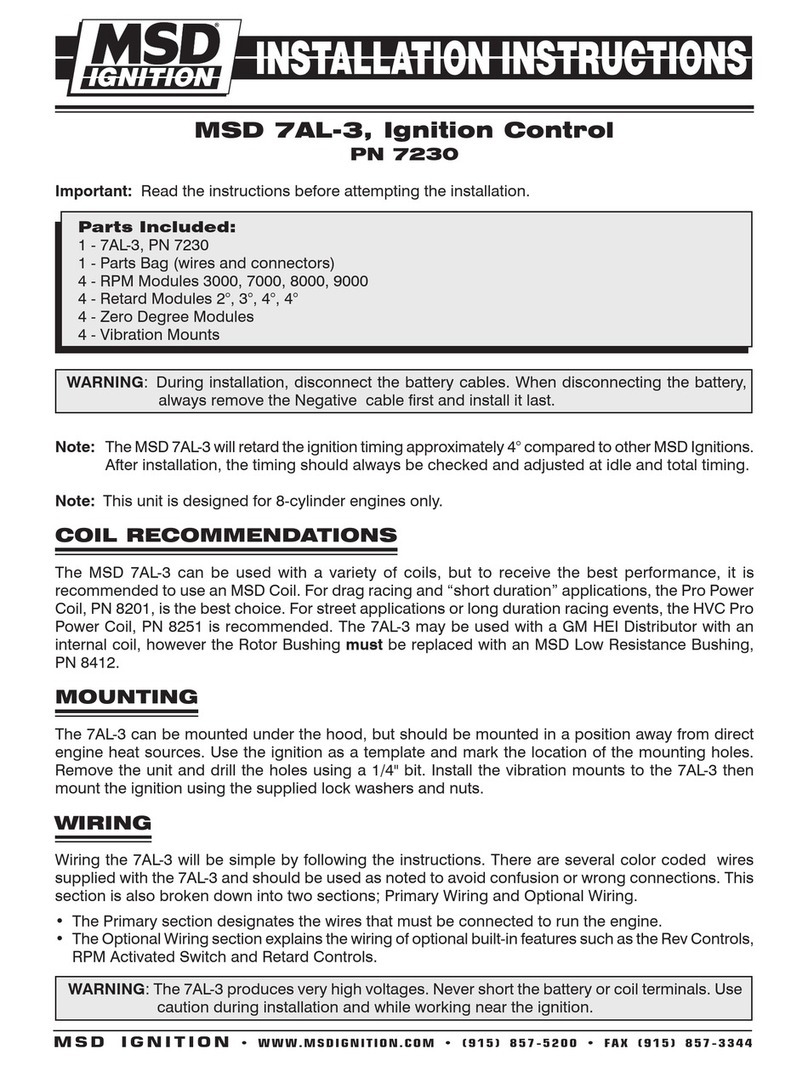

6.1 Configuration

(shown without front cover)

Mains connection device (L, N, PE): see also Chapter 3.1 Item (A)

The module has a built-in power supply unit and is supplied by it. The mains connection device must

therefore be 230V / 50Hz. This voltage is also switched through the output relays.

USB Key -A-

RTC battery

LED 1...5

Key -B-

Manual LogoTronic Hub OTC

10

6.1.1 Keys A and B components

Each key can be operated by pressing and letting go, pressing and holding, and pressing and holding

for a sustained period.

Incident table

Category Key -A- Key -B- Application mode Incident

USB Press and let go All states (not booting)

Prevents saving of the

transfer log onto a USB

stick (flush buer)

Press and let go All states (not booting)

Launches saving of the

transfer log onto a USB

stick

State Press and hold

for a sustained

period

Run/Test Activates test/run mode

Press and hold Test Launches with standard

configurations New

Press and hold

for a sustained

period

Press and hold

for a sustained

period

Run Restart

Press and hold

for a sustained

period

Press and hold

for a sustained

period

Restart/start

(byswitching on the

supply voltage)

Start firmware update

Notes:

Short-press means: Hold < 1s

Long-press means: Hold < 4s

Hold long-press means: Hold > 4s

We reserve the right to change designs and technical specifications of our products.

11

ENG

6.1.2 LED displays 1...5

The LEDs display the status.

Each LED can be either "OFF", "ON", "Flashing slowly" (FLS) or "Flashing fast" (FLF):

• Flashing slowly (FLS) means that the LED alternates between ON for 1 s and OFF for 1 s (flashing

frequency of 0.5 Hz).

• Flashing fast (FLF) means that the LED alternates between ON for 0.25s, OFF for 0.25s (flashing

frequency of 2 Hz).

LEDs 1 to 4 show the corresponding status of the LogoTronic controller in normal operating mode.

Status changes and LED indicators:

LEDs 12345

Possible display

Green

On/O/Flashing

(FLS/FLF)

Green

On/O/Flashing

(FLS/FLF)

Green

On/O/Flashing

(FLS/FLF)

Green

On/O/Flashing

(FLS/FLF)

Corresponding to

RGB colour or O

Function Status

Switched on (Run mode) Green

Switched on (Test mode) Magenta

Switched on (battery) Green FLF

BT connected Blue for 10s

USB transfer started

Yellow FLS 3s

USB transfer ended

Yellow for 3s

USB transfer error Red FLF 3s

An update procedure runs sequentially as follows:

Update started ON

Copy update FL 200ms ON

Unpack update FL 200ms ON ON

Validate update FL 200ms ON ON ON

Update error Red

Manual LogoTronic Hub OTC

12

7. LogoTronic Hub OTC – functions

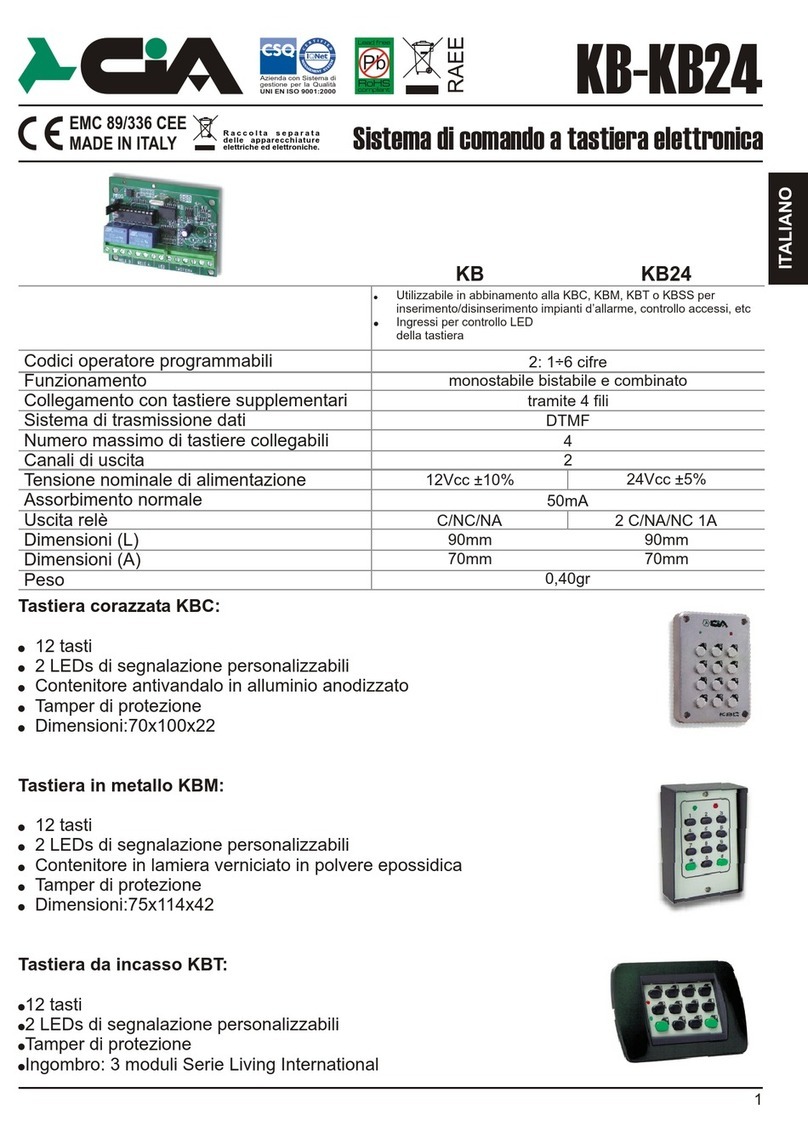

7.1 Modbus – General overview

Modbus is a serial communication protocol used to transport data via serial channels between

electronic devices. Modbus is an open protocol that can be used free of charge for commercial

applications. One client and up to 247 servers are possible in a Modbus network. The protocol uses,

for example, the RS-485 interface for data transmission. The protocol is based on a client-server

architecture.

Figure 7-1 Example: LogoMatic G2 stations and LogoTronic Hub OTC

AT

LogoTronic

Hub OTC

LogoMatic G2 with LogoTronic HIU

Modbus RTU

(via RS485)

CW

FL

RL

We reserve the right to change designs and technical specifications of our products.

13

ENG

7.1.1 Remote Terminal Unit (RTU) mode

Modbus protocol messages in Remote Terminal Unit (RTU) mode are transmitted in binary form from

the transmitter to the recipient as serial RS-485 communication, for example.

Client

(Master)

Transmitter Recipient

Server

(Slave)

Binary code, e.g.: 90 -> 01011010 (8 bits = 1 byte)

Recipient Transmitter

Note:

The maximum length of a message must not exceed 256 bytes.

7.1.2 Protocol configuration

A Modbus protocol message has defined start and end points. The receiving device recognises the

beginning of the message and reads out the server address. This allows a server to recognise whether

it has been addressed by the client and whether the message has been sent completely. If it has

arrived complete, the server uses error check bytes and parity bits to check the completeness of the

message. If the error check or parity fails, the message is discarded.

In RTU mode, the message starts with a silent interval of at least 3.5 characters. The first byte contains

the device address. Client and server devices continuously monitor the network, even during a silent

interval.

Aer the last transmitted byte, a silent interval of at least 3.5 characters indicates the end of the

message. Aer this silent interval, a new message can begin.

Protocol configuration

Start Application data unit End

Waiting

time

min. 3.5

characters

Address Protocol data unit CRC Error

Check Waiting

time

min. 3.5

characters

Function code Dates

1 byte 1 byte n byte

(0...252 byte) 2 byte (16 bits)

1 to 247* devices;

0 as broadcast

message 1…17 Checksum

* please note: up to 32 devices are possible without a Modbus repeater!

The entire message must be transmitted in one continuous flow. If a silence interval of more than

1.5 characters occurs before the completion of the message, the receiving device will discard the

incomplete message. Subsequently, the device assumes that the next byte contains the device

address of a new message.

Similarly, if a new message starts earlier than 3.5 characters aer the previous message. In this case, the

receiving device considers the message as a continuation of the previous message. Consequently, an

error occurs because the value of the combined message in the final CRC field (check field) is invalid!

Manual LogoTronic Hub OTC

14

7.1.2.1 Uni-/Broadcast transmission principles

In unicast mode, the client addresses an individual device which, aer receiving the message, processes

it and generates a response. The device address can vary from 1 to 247. A message always consists of a

request and a response. If no response is received within a specified time, timeout is detected.

In broadcast mode, the client sends a written command (request) to all participants on the bus, but they

do not generate a response. Address 0 is reserved for broadcast messages.

7.1.2.2 Function codes

The function code in a Modbus protocol message defines the action to be performed by the server. The

function codes are stored in an assignment table.

Assignment table:

The assignment table contains the function code, the data type, the register and information about the

register. With the information, a client can read out a register of a server via an RTU telegram.

7.1.2.3 Data/parameter scaling

Due to the limitations for integer data in the Modbus protocol, it is necessary to convert the parameters

before transmitting them. This is achieved by scaling, where a parameter containing a position aer a

decimal separator is multiplied by a factor so that a fractional value is no longer required. The scaling

factor to be applied can be taken from a corresponding table.

7.1.2.4 CRC

The CRC is a 16-bit value that is appended to the message. It is used to determine whether the

transmission of a message was detected without errors. Together with the parity check, all possible

transmission errors should be detected. If a parity error is detected when a message is received, no reply

message is generated by the device.

7.1.2.5 Start/end

The end identification of a message is specified as a rest situation on the Modbus with a length of 3.5

characters. Aer this time has elapsed, the earliest a server will begin its response or the earliest a client

will send out a new message.

The evaluation of a message can already begin when it is detected that the rest condition on the Modbus

has occurred for more than 1.5 characters. However, a response is started aer 3.5 characters at the

earliest.

7.1.3 Transmission parameters

Setting options for parity/

stop bit*

The parity bit can be used to check whether

a single error has occurred within a byte

during transmission.

No parity and 1 stop bit,

Same parity and 1 stop bit,

Unequal parity and 1 stop bit

Setting options for baud

rate*

The baud rate is a measure of the

transmission speed.

e.g. 2400, 4800, 9600, 19200, 38400,

57600, 115200 bits/s

* Factory setting options

Note: The transmission parameters must be set the same for all devices participating in a bus.

We reserve the right to change designs and technical specifications of our products.

15

ENG

7.1.4 Modbus – properties

Properties of Modbus RTU in the client-server network

Network topology

Linear bus with bus termination:

Cable with 120 Ohm resistance at both ends

Transmission medium

For connecting the devices, bus cables suitable for the respective

application must be used and laid professionally, the cross-section must

be AWG 26 (0.129mm²) or more. To increase transmission reliability, it is

recommended to use shielded bus cables twisted in pairs.

Cable lengths (without repeater)

A maximum cable length depends on the baud rate:

-at a baud rate of 9600 bits/s (factory setting), up to 1000m

physical interface

RS-485 with bus connector; connection can be mounted by the

customer, 2-wire and has a 2-screw terminal

Addressings

1 ... 247; the following must be observed:

32 devices in one segment, expandable to 247 with repeater, incl.

client, where address 0 goes as broadcast message to all servers.

Note:

The respective applicable regulations and standards must be taken into account for laying bus cables

inside buildings (inside/outside cabinets), laying cables outside buildings, potential equalisation,

minimum distances (such as measures against interference voltages), shielding of cables (e.g. shield

connection aer expected interference) as well as installation of terminating resistors!

When laying shielded cables, the shield may only be connected to ground at one point!

Work on electrical equipment and connection work is only permitted for authorised and qualified

electricians. The VDE guidelines and the provisions of the responsible energy utility company must

be observed.

The LogoTronic Hub OTC operates with mains voltage. Therefore, always ensure the system is

disconnected from the mains supply when carrying out any maintenance or repair work and secure

it against unauthorised activation

7.2 Modbus for LogoTronic Hub OTC and HIU controllers

These chapters describe the Modbus communication via RS-485 interface with the LogoTronic

controller for electronically controlled interface stations (HIU) that are prepared for communication

via the Modbus RTU client/server protocol.

The Modbus interface oers the following possibilities:

• User interface with restricted data access to registers

• Client-server communication between HIU controllers (passing on temperature values), whereby

they form a closed BUS system!

Manual LogoTronic Hub OTC

16

7.2.1 Connection of the RS-485 interface on the circuit board

Cable connection to RS-485:

The CON29 is marked in the controller as "RS-485 COM" and counts the pin numbers from right

(pin1) to le (pin 4), see also Chapter 3.1 Pin assignment

Pin description from right to le:

1) RS485-A

2) RS485-B

3) 24V DC supply output (to external devices)

4) GND (Ground)

The figure below shows the connection option, e.g. using a standard USB RS-485 cable connected

toa LogoTronic controller for electronically controlled interface stations.

7.2.2 Setting the controller for the Modbus protocol

Various protocols are available on the RS-485 interface. Currently, the HFC protocol (manufacturer's

own) and the open Modbus protocol are available. The protocol used on the RS-485 can be

changed using the keys on the controller (also see Chapter 6 LogoTronic Hub OTC operation and

configuration).

Interface mode (serial/Modbus):

In the factory setting, the controller operates in serial mode; this mode can be changed to Modbus

mode with the A and B keys.

Modbus mode (client/server):

The controller can be operated in client or server mode for Modbus communication. In the factory

setting, the controller operates in server mode; this mode can also be changed using the following

key combinations.

Key combination:

To change the interface or the Modbus mode, you must activate the service mode with key "B"

andselect the interface with key "A".

We reserve the right to change designs and technical specifications of our products.

17

ENG

Use the following key combination to activate the Modbus protocol or to change the interface

(RS-485 <-> Modbus):

1) Long-press key "B" to enter the service mode, LED 5 lights up light blue

2) Now press key "A" briefly several times to select the interface:

1 = RS-485

2 = Modbus as server (default setting)

3 = Modbus as client

Then, for example, only LED 2 is still lit (of the 4 available LEDs 1-4).

3) Long-press key "B" (to enter run mode), this saves the setting

and LED 5 lights up green again (or red if there is an error condition).

4)

The controller must be switched o and on again to activate the Modbus protocol.

Note (for system integrators) on the Modbus client on PC:

The program Flamco used to test the Modbus functionality is ModbusClientX

https://sourceforge.net/projects/modbusclientx-modbus-tool/

7.2.3 RS-485 interface settings (notes for system integrators)

The factory settings of the Modbus interface are set to (8, N, 1, 9600Baud) by default:

• 8 data bits

• No parity bit

• 1 start bit/1 stop bit

• Baud rate = 9600 bits/s

It is possible to preset the settings ex works to suit interface requirements.

7.2.4 Example of a broadcast message (notes for system integrators)

The external (outside) temperature can be transmitted via Modbus from a client to any LogoTronic

controller for electronically controlled interface stations (HIU) as a server. The easiest way is to

send the broadcast command to register 45002. The outside temperature should be written at least

every 10 minutes. The HIU controllers will invalidate the outside temperature value aer 15 minutes

without new data and reset it to the default value (-10°C).

The following example shows a complete telegram for a Modbus broadcast at address 0 for register

45002.

Manual LogoTronic Hub OTC

18

Send broadcast telegram: (Client -> server)

Telegram Hex RTU structure Value Description

1 0x00 Device address 0 Broadcast

2 0x10 Function code 16 Function code for writing multiple holding registers

30xAF Dates 45002 Modbus register for outside temperature

0xCA Dates

40x00 Dates 1 Number of registers to be read

0x01 Dates

5 0x02 Dates 2 Byte counter

60x08 Dates 2270 Value = 22.7C°

0xDE Dates

70x62 CRC check 25320 Checksum

0xE8 CRC check

Received broadcast telegram: (Server)

Telegram Hex RTU structure Value Description

1 0x00 Device address 0 Broadcast

2 0x10 Function code 16 Function code for writing multiple holding registers

30xAF Dates 45002 Register for outside temperature (via Modbus)

0xCA Dates

40x00 Dates 1 Number of registers to be read

0x01 Dates

5 0x02 Dates 2 Byte counter

60x08 Dates 2270 Value = 22.7C°

0xDE Dates

70x62 CRC check 25320 Checksum

0xE8 CRC check

We reserve the right to change designs and technical specifications of our products.

19

ENG

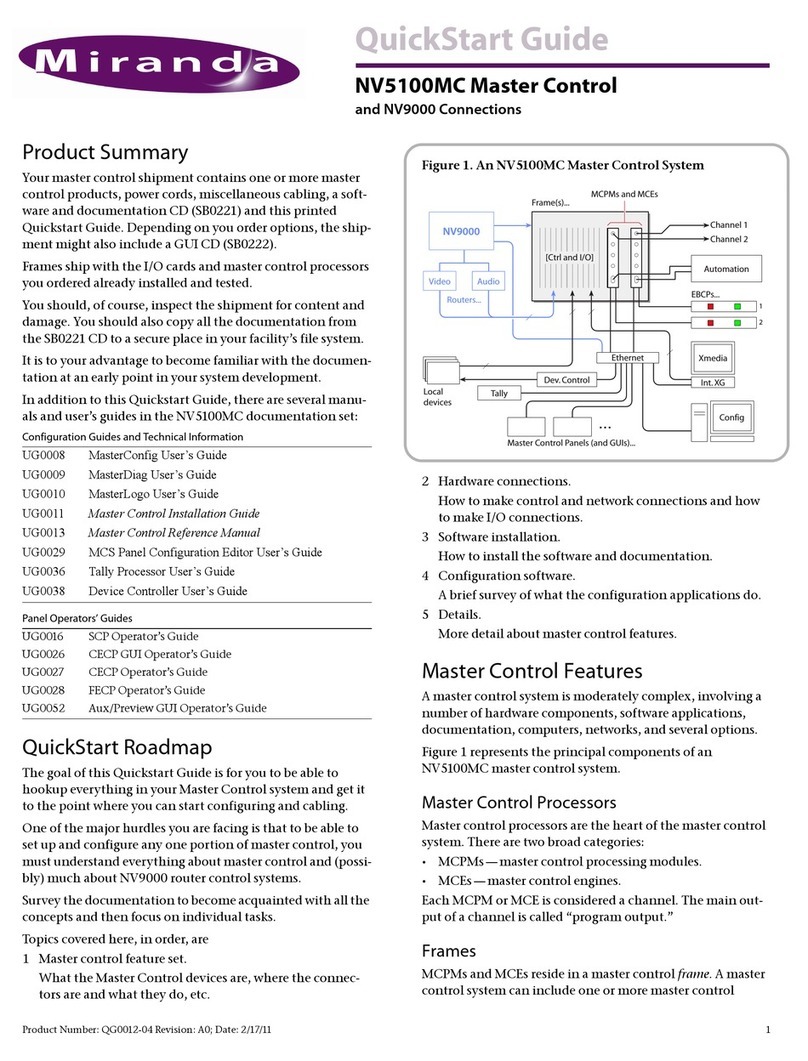

7.2.5 Client-server interconnection options in the Modbus network

1.

2.

Legend:

C Client, LogoTronic Hub OTC

S1…Sn Server, LogoTronic controller for electronically controlled interface stations (HIU)

AT Outside temperature sensor NTC 10K

120 Ohm – End resistors

corresponding connection cables – provided by the customer

Manual LogoTronic Hub OTC

20

7.2.6 Notes on components

Components Example fig.

To the outside temperature sensor:

• included in the scope of delivery of the

LogoTronic Hub OTC

• NTC 10k resistor, Honeywell AF10-B65

• Operating range -40...70°C, IP54

• Art. no.: M10560.53 (for a spare parts case)

Warning! The use of outside temperature sensors

with other temperature characteristics, such as

PT1000, is not possible here.

To terminating resistors 120 Ohm:

2 items are included in the scope of delivery of the

LogoTronic Hub OTC. As terminating resistors, they

can be directly connected to the ModBus cable.

Table of contents

Other flamco Control System manuals

Popular Control System manuals by other brands

Crystal Vision

Crystal Vision Indigo CoCo 3G user manual

Hindley Electronics

Hindley Electronics 105295-HEI installation instructions

Vertiv

Vertiv WSN Gateway Installer and user guide

heat-timer

heat-timer SMC Installation & operation manuals

Topline

Topline TEC4000 manual

Elka

Elka E 202 Installation and operating instructions