flamco WMS 2-1 User manual

WMS 2-1

ENG Installation and operating instructions

Translation of the original operating instructions ––––––––––– 2

DEU Montage-und Betriebanleitung

Orginalbetriebsanleitung ––––––––––––––––––––––––––––––– 22

NLD Installatie- en bedieningsinstructies

Vertaling van de oorspronkelijke gebruiksaanwijzing ––––––– 42

FRA Installation et mode d’emploi

Traduction de la notice d’utilisation originale –––––––––––––– 62

2

English (ENG) Installation and Operating Instructions

Table of contents

1. About this operating manual 3

1.1 Layout of warning notices 3

2. Safety 3

2.1 Intended use 3

2.2 Foreseeable misuse 3

2.3 Safe handling 4

2.4 Staffqualications 4

2.5 Modicationoftheproduct 4

2.6 Liability 4

3. Product description 5

3.1 Function 6

3.2 Operating modes 7

4. Technical data 8

4.1 Permit, approval, registration 10

5. Transport and storage 10

6. Assembly and commissioning 10

6.1 Installing the sensor 10

6.2 Installing the signaling unit 11

6.3 Electrical connection 13

6.4 Starting up the product 15

6.5 Functional check 16

7. Operation 17

8. Maintenance 17

8.1 Maintenance intervals 17

8.2 Maintenance activities 17

9. Malfunctions 18

10. Decommissioning and disposal 19

11. Warranty 19

12. Copyright 19

13. Customer satisfaction 19

14. Addresses 19

15. Notes 20

15.1 Registration documents 20

15.2 EC Declaration of Conformity 21

ENG Installationandoperatinginstructions

Translationof the original operating instructions (DEU)

3

ENG

1. About this operating manual

This manual is part of the product.

fRead this manual before using the product.

fKeep this manual during the product’s service life, and keep it at hand for future

reference.

fPass on the operating manual to any subsequent owner or user of the product.

1.1 Layout of warning notices

Warning word This indicates the type and source of danger.

fThis indicates measures for avoiding the danger.

Warning instructions exist in three stages:

Warning word Explanation

DANGER Imminent danger!

Failure to observe will result in death or serious injury.

WARNING Potential imminent danger!

Failure to observe may result in death or serious injury.

CAUTION Dangerous situation!

Failure to observe so may result in minor or moderate injury, or

damage to property.

2. Safety

2.1 Intended use

The low water level protection system (WMS) is exclusively designed for monitoring water

levels in heating systems according to EN 12828. Low water levels (lack of water) are

detected and reported. Any other use is unintended.

2.2 Foreseeable misuse

The low water level protection system (WMS) must not be used in the following cases:

• Water temperature above 120 °C

• Water pressure above 10 bar

• Welding work on the sensor

• Areas with a risk of explosion

Incaseofoperationinareaswithariskofexplosion,sparkscancauseexplosions,resor

explosions.

4

ENG:Installationandoperatinginstructions

Translationoftheoriginaloperatinginstructions

2.3 Safe handling

This product is constructed in line with the current state of art and the current state of

recognized safety/engineering rules. Each product is tested before delivery to verify its

function and safety.

fThis product must only be operated in perfect condition, taking into account the

operating instructions, normal rules and regulations, and the applicable safety

regulations and accident prevention regulations.

WARNING Severe burns or death caused by mains voltage (230 V AC, 50 Hz) in the

signaling unit.

fAvoid contact between the signaling unit and water.

fBefore opening the signaling unit, or before maintenance and cleaning, disconnect the

power supply and safeguard against switching back on.

fDo not tamper with the signaling unit.

WARNING Severe burns to the body, especially the face and hands, due to heating

water escaping or spraying out.

The water in heating systems is under high pressure and can reach temperatures up to

100 °C.

fDo not tamper with the sensor and heating system.

fBefore opening the sensor, allow the heating water to drain or cool.

CAUTION Permanent damage to the sensor due to high water temperature or high

water pressure in the sensor.

fNever exceed the maximum permissible water temperature; see Table 1, Page 9.

fNever exceed the maximum permissible water pressure in the sensor; see Table 1,

Page 9.

2.4 Staff qualications

Installation, commissioning, operation, maintenance, decommissioning and waste

disposalmayonlybeperformedbyspeciallytrained,qualiedpersonnel.

Electricalworkmustbeperformedbyaqualiedelectricianinaccordancewiththe

applicable rules and regulations.

2.5 Modication of the product

Unauthorizedmodicationoftheproductcancausemalfunctionsandisprohibitedfor

safety reasons.

2.6 Liability

The manufacturer assumes no liability and provides no warranty for damage or

consequential damage caused by failure to observe the technical instructions, manuals

and recommendations.

The manufacturer and the distributor are not liable for any costs or damages incurred by

the user or a third party through the use of this product, especially in case of unintended

use of the product, misuse or malfunctions of the power supply, malfunction of the

5

ENG

product or connected products. Neither the manufacturer nor the distribution company

assume any liability for unintended use. The manufacturer assumes no liability for printing

errors.

3. Product description

The low water level protection system (WMS) consists of a fail-safe, self-monitoring

signaling unit with periodic self-test and a sensor.

The signaling unit and sensor are connected by a two-wire signal cable of up to 10 m in

length.

The product combination detects and reports low water levels (lack of water).

Sensor

Thesensorconsistsofametallicelectrodehousing,attedplasticcaseandanelectrode

rod that pulls out about 12 to 13 mm for functional testing.

The sensor is available in two versions:

fSensor DN 20:

Angledelectrodehousingwithtwo(DN20)weldedtting

(Øi=20mm,Øa=26.5mm)

1Electrode rod

2Plastic housing

3Electrode housing

4Union nuts G1", size 40

5Flange seal 30 x 21 x 2

6WeldedttingØ26.5

(DN20)

Fig. 1: Sensor DN 20

6

ENG:Installationandoperatinginstructions

Translationoftheoriginaloperatinginstructions

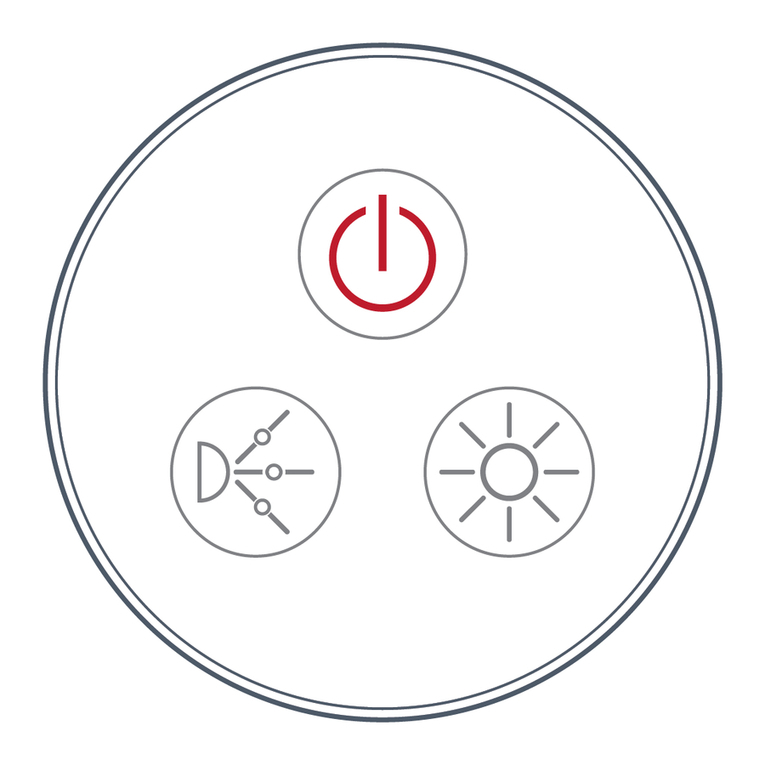

Signaling unit

The signaling unit contains indicators and controls in an impact-resistant plastic housing,

as well as all electronic components for evaluating and converting the sensor signal into a

digital output signal. The output is a zero potential relay contact.

The signaling unit is available in two versions:

fSignaling unit WMS 2-1:

With integrated power failure interlock; that is, after a power failure, the signaling unit

must be released.

aGreen operation lamp

bTest button

cRed alarm lamp

d

Release button

eWithout function

Fig. 2: Signaling unit

Type Signaling unit Sensor Component marking

WMS 2-1 WMS 2-1 DN 20 TÜV.WBH.14-345

3.1 Function

The WMS monitors water levels in heating systems. If the water level drops below

minimum, the low water level protection system alerts.

The operating principle of the low water level protection system relies on the conductivity

oftheheatingwater.Ifthereisaowofwaterthroughthesensor,thelowwaterlevel

protectionsystemindicatessufcientsupplyofheatingwater.Ifthereisnoowofwater

through the sensor, the signaling unit immediately alerts.

Sensor

The sensor consists of an outer electrode and an inner movable electrode. The two

electrodes are connected via a two-core cable to the signaling unit. The signaling unit

constantly monitors the conductivity (electrical resistance) between the two electrodes.

The inner movable electrode can be moved about 12 to 13 mm upwards from the water

7

ENG

for testing. As a result, the contact with the water is interrupted simulating a lack of water.

The signaling unit immediately alerts. An integrated spring returns the inner electrode back

to the starting position.

Signaling unit

The signaling unit constantly monitors the conductance of the water or the electrical

resistance between the two electrodes of the sensor. If the measured conductance greater

than20µS,orthemeasuredresistanceislessthan50kΩthesignalingunitindicatesa

sufficient supply of heating water and an error-free sensor circuit. The red alarm lamp is

unlit.Iftheconductanceislessthan20µS,ortheresistanceisgreaterthan50kΩ,thisis

interpreted as a lack of water, wire break or defective sensor circuit. The red alarm lamp is

lit.

The WMS is designed to be fail-safe and self-monitoring. The electronics in the signaling

unit check the entire low water level protection system several times a second.

Errors in the sensor circuit and signaling unit are displayed as alarms. The low water level

protection system can only be released if the entire low water level protection system is

error-free, a sufficient power supply is available, and the water level is above the minimum;

i.e., the red alarm lamp is unlit and the built-in relay is energized.

The green power light is lit when the low water level protection system is supplied with

mains voltage. The test button allows a functional check which simulates an alarm

condition.

3.2 Operating modes

The WMS 2-1 has an internal power failure interlock; that is, after a power failure, the

signaling unit must be released via the “Release” button or via an external release contact

8

ENG:Installationandoperatinginstructions

Translationoftheoriginaloperatinginstructions

4. Technical data

Table 1: Technical data, sensors

Parameters DN 20

General data

Housing dimensions (W x H x D) 130 x 270 x 44 mm

Space requirement (W x H x D) 100 x 300 x 150 mm

Weight 0.8 kg

Electrode housing Brass

Electrode rod Steel type 316

Resistance Boiler water

Mechanical connection Weldedtting

Ø i = 20 mm, Ø a = 26.5 mm

Operating pressure Max. 10 bar

Connecting cable:

Standard length:

Max. length

H05RN-F, 2 x 1 mm²

1.5 m

10 m (shielded)

Sensor voltage Max. 12 V

Operating temperature range

Environment 0°Cto+55°C

Medium Max.120°C

Storage -10°Cto+60°C

Electrical safety

Degree of protection IP 54

Table2:Technicalspecications,signalingunit

Parameters Value

General data

Housing dimensions (W x H x D) 100 x 188 x 65 mm

Weight 0.7 kg

delay time Approximately 1 second by default

Connections 1 output relay (switch)

1 external releasing device

Operating temperature range

Environment 0°Cto+55°C

9

ENG

Parameters Value

Storage -10°Cto+60°C

Voltage supply

Rated voltage AC 230 V ± 10%, 50Hz

Rated power 5 VA

Power supply fuse T50mA

Switching capacity output relay (1

zero-potential double throw switch)

Max. 250 V, 2 A resistive load

Electrical safety

Electrical safety EN60730

Protection class II EN 60730

Degree of protection IP 40 EN 60529

Electromagnetic compatibility (EMC)

As per EN 61000-6-3 EN 61000-6-3

As per EN 61000-6-2 EN 61000-6-2

Cable glands on the signaling unit

The middle grommet can be replaced by an M20 cable

gland.

Threaded cable glands Cable diameter

M16 4,0-8,8mm

M20 8,0-12,5mm

10

ENG:Installationandoperatinginstructions

Translationoftheoriginaloperatinginstructions

Fig. 3: Signaling unit and installation frame for installation in control panels; on the right: panel cut-out

4.1 Permit, approval, registration

WMS corresponds to the VdTÜV Bulletin “Water Level 100" (Edition 02.2010), the EMC

Directive (2004/108/EC), the Low Voltage Directive (2006/95 / EC) and the Pressure

Equipment Directive (97/23/EC).

5. Transport and storage

CAUTION DAMAGE TO THE PRODUCT DURING TRANSPORT.

fDo not throw or drop the product.

fProtect against moisture, humidity, dirt and dust.

CAUTION DAMAGE TO THE PRODUCT DUE TO IMPROPER STORAGE.

fStore only in a clean and dry environment.

fStore products only within the acceptable temperature range.

6. Assembly and commissioning

RDo not install the signaling unit and sensor in areas with a risk of explosion.

6.1 Installing the sensor

fInstall the sensor in a connection line between the water and steam chambers on the

boiler or parallel to the supply line between the boiler and the circulation pump.

If the boiler already has threaded sockets for the sensor, install it there.

fThere must not be a circulation pump with check valve and/or a shut off valve

between the sensor and the boiler.

fIt must be impossible to shut off the pipe to the sensor; it must have an internal

diameter of 20 mm (¾").

fInstall the sensor in accordance with this operating manual and using the supplied

gaskets.

11

ENG

fEnsure that the sensor installation position is protected against foam and high surface

water load.

fNosupplywaterowmustbeconnectedtothewater-sideconnectingpipesonthe

sensor housing with the boiler.

fEnsure that the permissible ambient temperature is not exceeded on the sensor

housing outside the boiler; see Chapter 4, Page 9.

fIn order to avoid false alarms due to air bubbles (particularly for larger systems) the

inside diameter of the pipe to the sensor must not be substantially smaller than that of

the supply pipe. The distances from the sensor to the supply pipe must be kept short

and gradually reduced to ¾”.

fThe sensor must be installed vertically to the extent possible. Deviations of up to

45 ° from the vertical are permissible in exceptional cases; please make sure that no

air bubbles can accumulate in the sensor.

fInstall the sensor so that the lower edge of the sensor is at least 100 mm above the

highest point of the boiler..

CAUTION PERMANENT DAMAGE TO THE SENSOR DUE TO WELDING ON THE

SENSOR.

fDo not weld on the sensor.

aBoiler, rear side,

separate bushes for

sensor

bBoiler

Fig. 4: Installing the DN 20 sensor

6.2 Installing the signaling unit

R Installthesignalingunitonaat,rmanddrywallateyelevel.

RThe signaling unit must be accessible and visible at all times.

RThe signaling unit must be installed out of reach of water or splash water.

RDo not mount the signaling unit in a wet area.

RMake sure that the permissible ambient temperature at the signaling is not

exceeded; see Table 2 , Page 9.

RProtect the signaling unit against direct weather exposure in outdoor

installations.

RWhen installing the signaling unit take the necessary steps to ensure touch

protection.

12

ENG:Installationandoperatinginstructions

Translationoftheoriginaloperatinginstructions

REnsure a minimum degree of protection of IP 44 as per EN 60529 In the boiler

installation room.

R Theriskofexposureduringexternalreaswellastrafc,windandearthquake

exposure depends on the installation location and the site of the pressure

equipment and, may need to be assessed separately where appropriate.

1. Open signaling unit.

2. Fasten signaling unit on the wall (Aor B).

A 1 Fasten screw to wall. BDrill fastening holes in lower part with

5 mm Ø drill bit.

Fasten lower part to wall using enclosed

screws.

2Mount signaling unit.

3Mount signaling unit.

13

ENG

2. Wire the electrical connection as per Chapter 6.3, Page 15.

3. Close signaling unit.

6.3 Electrical connection

RMains voltage is interrupted and secured against switching back on.

fCallinaqualiedelectriciantoperformtheelectricalinstallationwork.

fObserve VDE requirements, accident prevention regulations and operating instructions

for the WMS, boilers and burner.

RThe power supply cable for the boiler room must be equipped with a main

switch outside the boiler room that simultaneously isolates all ungrounded

conductors with at least a 3 mm contact gap.

Power supply

DenNetzanschlussmiteinerfestverlegtenLeitungz.B.NYM-O2x1,5mm²herstellen.

1. Route the power supply cable through the right-hand compression coupling in

the signaling unit.

2. Route the phase conductor to terminal L1 and the neutral conductor to terminal

N.

3. The supply cable to the signaling unit must be separately fused (max. 10 A).

14

ENG:Installationandoperatinginstructions

Translationoftheoriginaloperatinginstructions

Sensor

1. Route the sensor cable through the left compression coupling in the signaling unit.

2. Connect the sensor cable to the two terminals on the signaling unit labeled “Sensor”.

Polarity does not need to be observed.

3. If the 1.5 m sensor cable is not long enough, the sensor cable can be extended using

2 x 1.5 mm² shielded cable. The length of the connecting cable between the sensor

and the signaling unit must not exceed 10 m.

4. The connecting cable must be routed so as to avoid external interference.

5. Ensure a minimum degree of protection of IP 65 as per EN 60529.

External release

6. A pushbutton (normally open contact) for externally releasing the WMS can be

connected to the two terminals on the signaling unit labeled “Rel.” at a distance of up to

10 m. The maximum voltage at these terminals is 12 V.

7. The button connections must be potential free.

8. If you use an external release, use the following electrical circuit as per EN 50156-1.

Output

The output signal from the WMS can be tapped using a zero-potential relay contact

(double throw switch). This relay contact is used for the safety shutdown of the furnace.

9. Route the electrical wiring (maximum 10 m) so that the power to the furnace is

interrupted in the event of an alarm.

During normal operation, the relay contact is energized; in the event of an alarm, the

relay contact is in idle position.

10.The output contact of the low water level protection system must be protected with an

external fuse of max. M 2 A.

15

ENG

Anschluss-Beispiele

1Mains fuse F1

2Sensor

3Boiler

4External release

(optional)

5External alarm

(optional)

6Release contactor

7Supply voltage

Fig. 5: Wiring example WMS 2-1

CAUTION FUNCTIONAL IMPAIRMENT OF ELECTRICAL EQUIPMENT DUE TO

VOLTAGE SPIKES WHEN SWITCHING OFF INDUCTIVE LOADS.

fWire inductive loads with commercially available standard RC combinations, e.g.,

0.1µF/100ohms.

6.4 Starting up the product

RCheck that the signaling unit and sensor are installed as per Chapter 6, Page 11.

RCheck that the sensor is leak tight.

RCheck that heating water has been topped up.

RCheck the electrical connection was implemented as per Chapter 6.3, Page 15.

RCheck that the sensor is connected to the signaling unit.

RCheck that the output relay is connected (if appropriate).

RCheck that the external power failure interlock has been implemented.

RCheck that the mains connection is in place.

RCheck that the ribbon cable is connected to the circuit board.

RCheck that the signaling unit is closed and fastened.

16

ENG:Installationandoperatinginstructions

Translationoftheoriginaloperatinginstructions

If all conditions are met, the product is ready for operation.

1. Power on using the site-side mains fuse.

Ä The green power indicator and red alarm light up.

2. WMS 2-1 manually release using the “Release” button or via the external

releasing device.

Ä During normal operation the red alarm lamp is unlit and the burner starts up.

4. Perform a functional check; see Chapter 6.5, Page 18.

6.5 Functional check

A functional check is performed manually by reducing the water level below the trigger

threshold, or by pulling the inner, movable electrode upwards.

This functional check must be carried out at regular intervals.

fPerform the functional check 1 x per year and after any maintenance or repairs.

At the sensor

1. For the functional check, pull up the electrode rod to its upper limit for at least 1

second.

ÄThe electrode rod is no longer in the boiler water, which simulates a lack of

water.

Ä The red alarm lamp on the control unit is lit, and the burner automatically shuts off.

2. Press the release button on the control unit to return to normal operating state.

Ä The red alarm lamp is unlit and the burner is operational.

At the signaling unit

1. Press the test button for at least 1 second.

ÄThe connection to the sensor is interrupted and the red alarm lamp is lit.

ÄThe burner shuts off automatically.

2. Press the release button on the control unit to return to normal operating state.

ÄThe red alarm lamp is unlit and the burner is operational.

17

ENG

7. Operation

The WMS monitors water levels in heating systems. If the water level drops below

minimum, the WMS alerts and the burner is shut off. Operation of the WMS only involves

regular monitoring to ensure that

fthe green lamp is lit.

fThe red alarm lamp is unlit.

fThe burner is operational.

8. Maintenance

8.1 Maintenance intervals

Table 3: Maintenance intervals

When Activity

1 x annually fPerform a functional check;

see Chapter 6.5, Page 18

Regularly fMake sure that the low water level protection system

and its surroundings are always clean, accessible and

visible

fKeep the sensor free from soiling and deposits; if

necessary, clean the sensor.

Donotaddanylm-forming,adhesiveorwater

polluting substances to the heating water

Defective mains fuse fReplace the mains fuse F1;

see Chapter 8.2, Page 20

8.2 Maintenance activities

Replacing the mains fuse F1

R Mains voltage is interrupted and secured against switching back on.

1. Open the signaling unit; see Chapter 6.2, Page 13.

2. Remove the transparent cover from the mains fuse F1.

3. Replace the mains fuse F1; see Table 2, Page 9.

4. Latch the transparent cover onto the mains fuse F1.

5. Connect the ribbon cable to the connection plug board.

6. Close the signaling unit; see Chapter 6.2, Page 13.

7. Switch on the mains voltage.

8. Release the signaling unit.

18

ENG:Installationandoperatinginstructions

Translationoftheoriginaloperatinginstructions

9. Malfunctions

Wassermangelsicherungen sind Sicherheitseinrichtungen und dürfen im Schadensfall nur

vom Hersteller repariert werden.

ReparaturendürfenausschließlichvonfachspezischqualiziertemPersonalausgeführt

werden.

Table 4: Malfunctions

Problem Possible cause Troubleshooting

Green operation

lamp is not lit

Mains voltage interrupted fRestore mains voltage

Defective mains fuse fReplace the mains fuse

Ribbon cable is not

connected to the printed

circuit board

fConnect the ribbon cable to

the PCB

Red alarm lamp Lack of water fTop up with boiler water

fPress the release button

Sensor not connected fConnect the sensor

Red alarm lamp

permanently lit;

WMS cannot be

released

Wire break in the sensor,

sensor cable or signaling

unit

fCheck the wiring

Pressing the test

button has no effect

Signaling unit is defective fReplace the signaling unit

Pulling the electrode

rod has no effect

Sensor/wiring defective fReplace sensor

fCheck wiring

Burner does not

start up

Lack of water fCheck whether the red

alarm lamp is lit

Wiring/burner defect fCheck wiring

fCheck burner

Miscellaneous

malfunctions

–fSend product to the

manufacturer

19

ENG

10. Decommissioning and disposal

1. Switch off the supply voltage.

2. Remove the low water level protection system (see Chapter 6, Page 11; steps in

reverse order).

3. To protect the environment, this product must not be disposed of with unsorted

domestic waste. Dispose of the product according to local regulations.

This product consists of materials which can be recycled by recycling specialists. We have

designed the electronics to use easily separable materials.

If you do not have the opportunity to dispose of the used equipment properly, please

contact us to agree disposal or return.

11. Warranty

The manufacturer’s warranty is 24 months from the date of purchase for this product.

Claims can be made in any country in which this product is sold by the manufacturer or an

authorized reseller.

12. Copyright

The copyright for this operating manual remains with the manufacturer. Reproduction,

translation and reproduction, in whole or in part, without written approval is not permitted.

The technical details of this operating manual are subject to change with respect to

descriptions, information and illustrations.

13. Customer satisfaction

Customer satisfaction is our top priority. If you have any questions, suggestions, or

problems with your product, please contact us.

14. Addresses

Youwillndtheaddressesofourworldwideofcesontheinterneton

www.amcogroup.com.

20

ENG:Installationandoperatinginstructions

Translationoftheoriginaloperatinginstructions

15. Notes

15.1 Registration documents

Table of contents

Languages:

Other flamco Control System manuals