flamco Meibes A1CX Series Manual

GB

Technical information for installation and operation

Meibes Heat Interface Unit (HIU) A1CX Series

Installation in conjunction with a pre-plumbed unvented cylinder.

Standard Unit 20 kW, High Pressure Unit 20 kW and 30 kW

2

1. Safety instructions 3

2. Introduction 5

2.1 Product Usage 5

2.2 Unit Layout 5

2.3 Hydraulic Layout 6

2.4 Facts and Figures 7

3. Installation 8

3.1 Preparation 8

3.2 Positioning 8

3.3 Fitting 8

3.4 Connecting 8

3.4.1 Hydraulic Primary Circuit 8

3.4.2 Hydraulic Secondary Circuit 9

3.5 Electrical Connections 9

3.5.1 Electrical Diagram (for wiring centre fitted at the pre-plumbed unvented cylinder) 9

3.5.2 HIU - Heating Circuit 9

4. Service 10

4.1 Commissioning 10

4.2 Pressure Test 10

4.3 Flushing / Corrosion prevention 10

4.4 Service Check List 11

5. Heat Meter 12

6. Appendix A 13

7. Appendix B 16

8. Appendix C 17

9. Appendix D - Spare Parts 21

Contents

3

Please follow these safety instructions faithfully to eliminate hazards, personal injury and material damage.

Target group

These instructions are intended exclusively for authorised trained experts. Only trained experts or installers authorised

by the respective competent utility company are permitted to work on the heating system, the domestic water, gas and

electric circuits.

Regulations

When carrying out work, you must comply with:

• The statutory accident prevention regulations,

• The statutory environmental protection regulations,

• The pertinent safety requirements of DIN, EN, DVGW, TRGI and TRF

• ÖNORM, EN, ÖVGW-TR Gas, ÖVGW-TRF and ÖVE

• SEV, SUVA, SVGW, SVTI, SWKI and VKF

• and all new and regionally applicable regulations and standards

Instructions for working on the system and system parameters

• Disconnect the system from the mains and monitor it to ensure that no voltage is being supplied (e.g. at the

separate cut-out or a main switch).

• Secure the system against being restarted.

The unit may only be installed in:

–Dry and not potentially explosive environments

–Enclosed rooms with temperatures of 5-50°C (not condensing)

• The devices must be installed in enclosed, frost-free spaces

• Observe the safety areas in accordance with 60529 when designing and installing the system

• Device protection code in accordance with EN 60520 IP42

Note:

The device is installed inside a building in an upright position on the wall, in a convenient location with suicient frost

protection.

Potential equalisation or protective earthing in accordance with VDE:

The HIU must be protected by potential equalisation or protective earthing according to the applicable

regulations!

1. Safety instructions

4

This unit must be installed, commissioned and inspected/serviced qualified technical personnel in accordance with

national regulations and/or relevant local requirements.

The mains electrical supply must be isolated before making any connections. Electrical

work must comply with regulations BS7671. Ensure the power supply is isolated when

working on any electrical components in the HIU. All installation and system work must

comply with the relevant building regulations.

Please be aware that the unit weighs approximately 15 kg, and as such should be handled

in accordance with health and safety guidelines and regulations. The unit should be

attached to a structurally sound wall capable of bearing the weight of the unit.

Water temperatures higher than 50°C may cause severe burns. Components within the

unit may be hot, and care should be taken to avoid burns and scalds when installing,

commissioning or inspecting/servicing the unit.

Any unauthorised alterations on the unit or tampering with it in any way will void the warranty and certificates.

1. Safety instructions

5

Heat Interface Units (HIU) supply space heating and domestic hot water to an apartment or house. They are connected

on the primary side to a heat network which supplies energy in the form of hot water. The secondary side of the unit

supplies the house or the apartment. The unit is fully factory assembled and contains all necessary hydraulic and electrical

components. It is designed to be installed in conjunction with a pre-plumbed unvented cylinder.

2.1 Product Usage

This product is to be installed by trained installers only! Please follow the safety instructions as well as all applicable

technical regulations. These instructions are aimed exclusively at trained installers and service technicians. Electrical work

may only be carried out by qualified electricians.

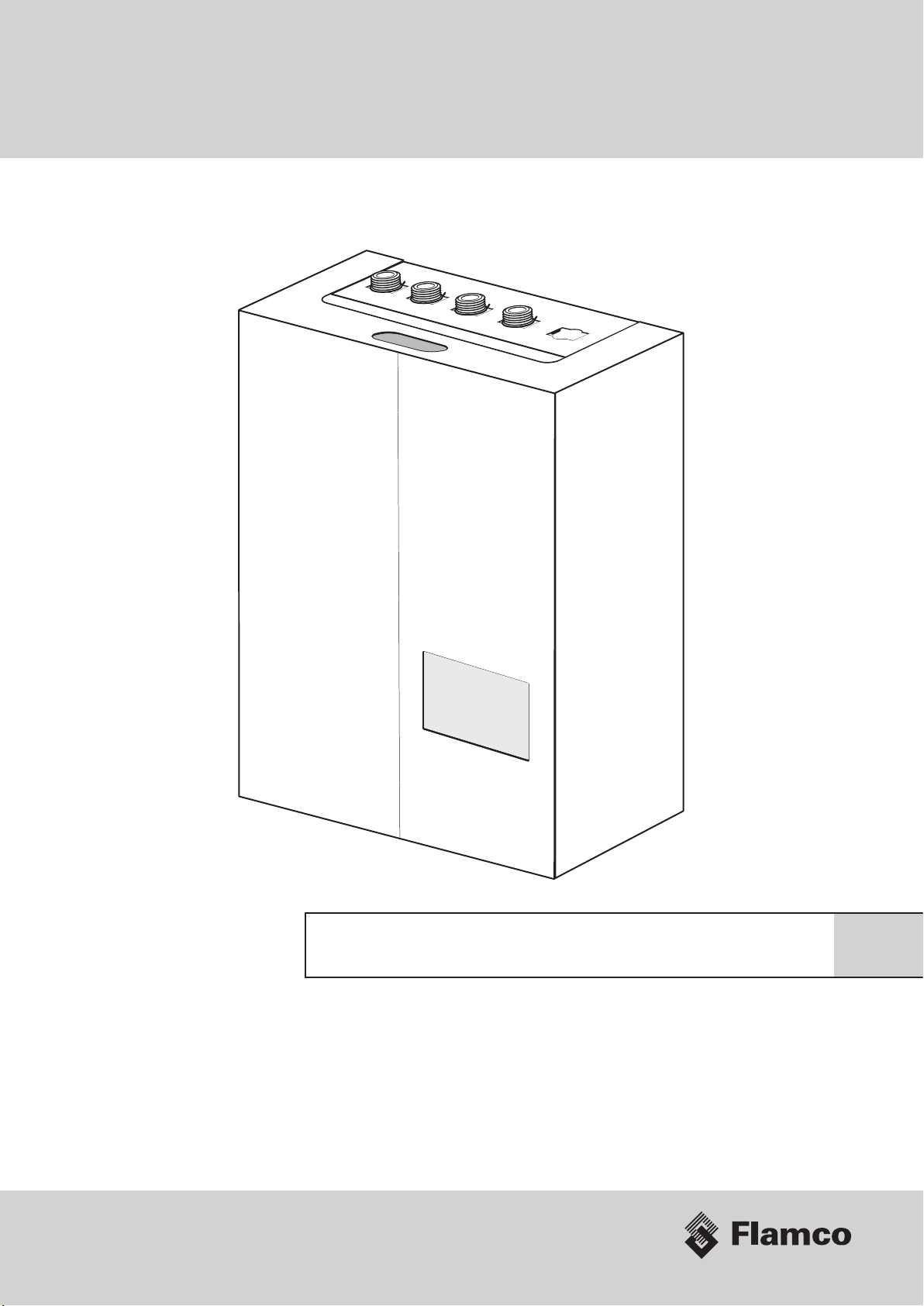

2.2 Unit Layout

Plate heat exchanger

Display Heat meter

Primary zone valve

Bleed points

Bleed points

Dierential pressure

control valve (DPCV)

Return Temperature

Limiter

Strainer

Test

points

SecondaryPrimary

2. Introduction

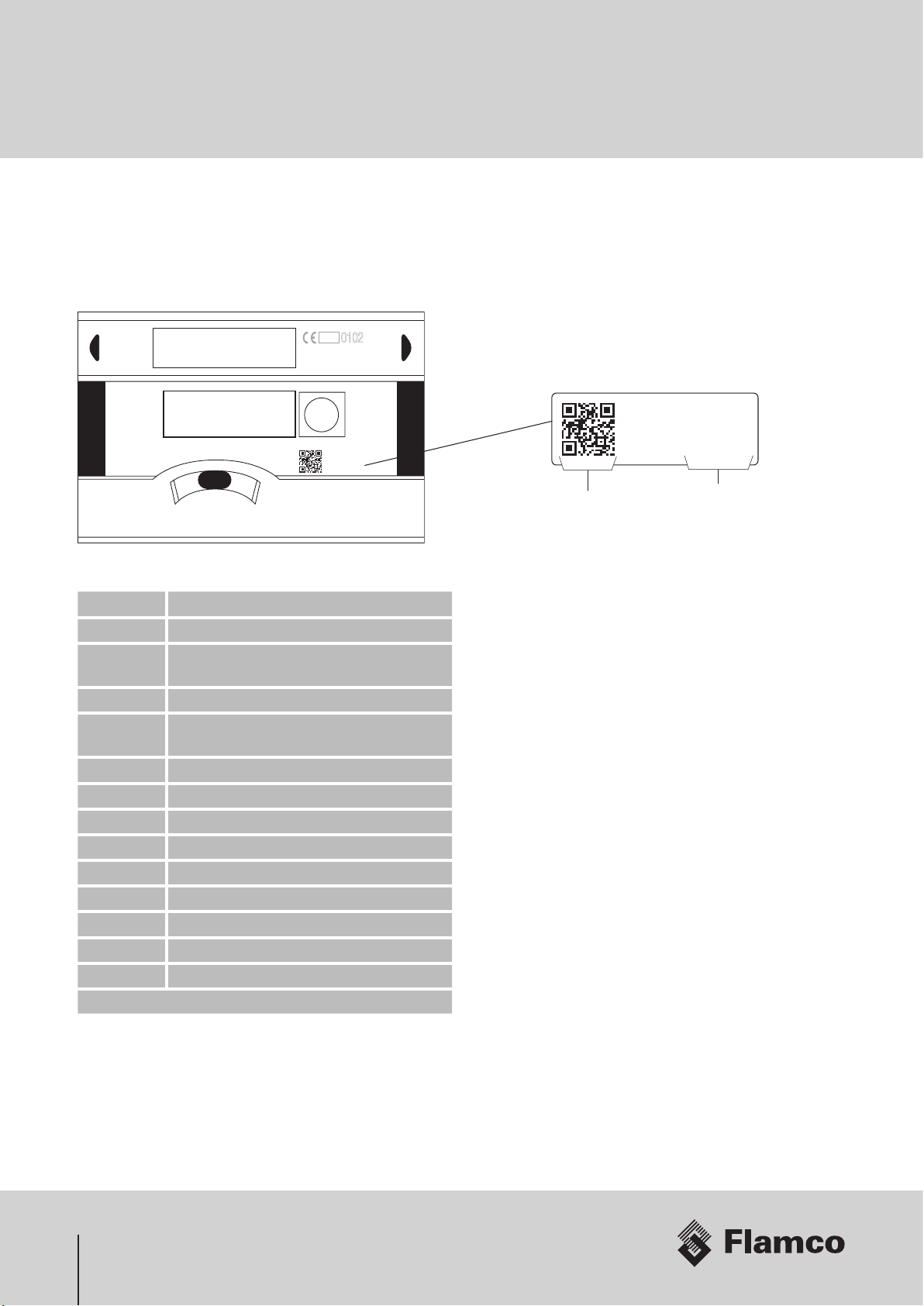

6 RAM40 1234 5678

Heat Meter

Quick Mode

Type 775

0102

LCD Loop3: Installation

Class 2

E2 / M2

IP 54

6

2.3 Hydraulic Layout

Diagram Parts Description

1. Test points

2. Strainer

3. Spool piece for heat

meter 3/4“x110mm

(removable)

4. Dierential pressure

control valve DPCV

(Balancer)

5. Zone valve

6. Plate heat exchanger

7. Bleed points

8. 3/4“ isolation ball valves

(not illustrated) Spool

piece for solenoid

valve 3/4“x110mm

(removable)

9. Return temperature

limiting valve (RTL).

Factory locked to 40°C

(Standard Unit), to 60°C

(High Pressure Unit).

Connections

A. Primary Flow

B. Primary Return

C. Secondary Flow

D. Secondary Return

370mm

465mm

1

3

4

5

6

3

7

7

2

9

AB CD

2. Introduction

6 RAM40 1234 5678

Heat Meter

Quick Mode

Type775

0102

LCD Loop3: Installation

Class 2

E2 / M2

IP 54

3

T

M

∑

1

1

27

77

9

6

4

A

B

C

D

5

7

2.4 Facts and Figures

Description Type District heating station to be installed in conjunction with a pre-plumbed unvented cylinder

Mounting Wall mounted with top or bottom connections

Size including case 400 x 180 x 500 mm (WxDxH)

Heating System 2 pipe flow

Construction Pipework Fully insulated flexible stainless steel pipe with brass fittings

Plate heat exchanger Fully insulated stainless steel

Casing White powder coated sheet steel cover with viewing window for the heat meter

Primary Fluid Low pressure hot water

Secondary Fluid Low pressure hot water

20kW Standard Unit 20 and 30kW High Pressure Unit

Duty (primary) Heat Transfer Capacity (P1; q1) 20 kW @ 30K ∆T (550 l/h) 20 kW @ 30K ∆T (550 l/h)

32 kW @ 30K ∆T (900 l/h)

Fluid Temperature flow (t11) 70°C (95º Max) 70°C (95º Max)

Fluid Temperature return (t12) - design (max.

temp. depends on RTL setting)

40°C 60°C

Pressure Primary max. pressure 6 bar 10 bar

Max. primary dierential pressure (∆p1) Depending to lowest value of components

Secondary max. pressure 6 bar 10 bar

Fittings

Primary side

Zone Valve Fitted with electrical actuator head, max.

dierential pressure 100 kPa (kvs=1.85)

Fitted with electrical actuator head, max.

dierential pressure 700 kPa (kvs=1.6)

Return Temperature Limiter 20 ... 65°C (Factory set fixed to 40°C), max. dp

= 150 kPa

25 … 70°C, (Factory set fixed to 60°C) max. dp

= 600 kPa

Strainer On primary flow

Test points Binder style test points

Sensor Pocket Primary Flow temperature sensor for heat meter

Heat Meter Rossweiner “HeatSonic“ M-Bus heat meter with permanent display. Battery or main power

available.

Dierential Pressure Control Valve (DPCV) Factory set (at 40 kPa), max. dp = 40 kPa 20 kW: at 13,5 kPa, max. 25 kPa

30 kW: at 40 kPa, max. dp = 40 kPa

Air Vents Manual

Connections All external connections 3/4” female ball valves 4x (not illustrated); optional “First Fix Rail” with or without flushing bypass

2. Introduction

Δp2

Δp1

t12

t11 t22

t21

q1q2

DH

∆p

q

t

P

= District Heating

= Differential Pressure (kPa)

= Flow Rate (l/s)

= Temperature (ºC)

= Power (kW)

Secondary

Primary (DH)

P2

P1

8

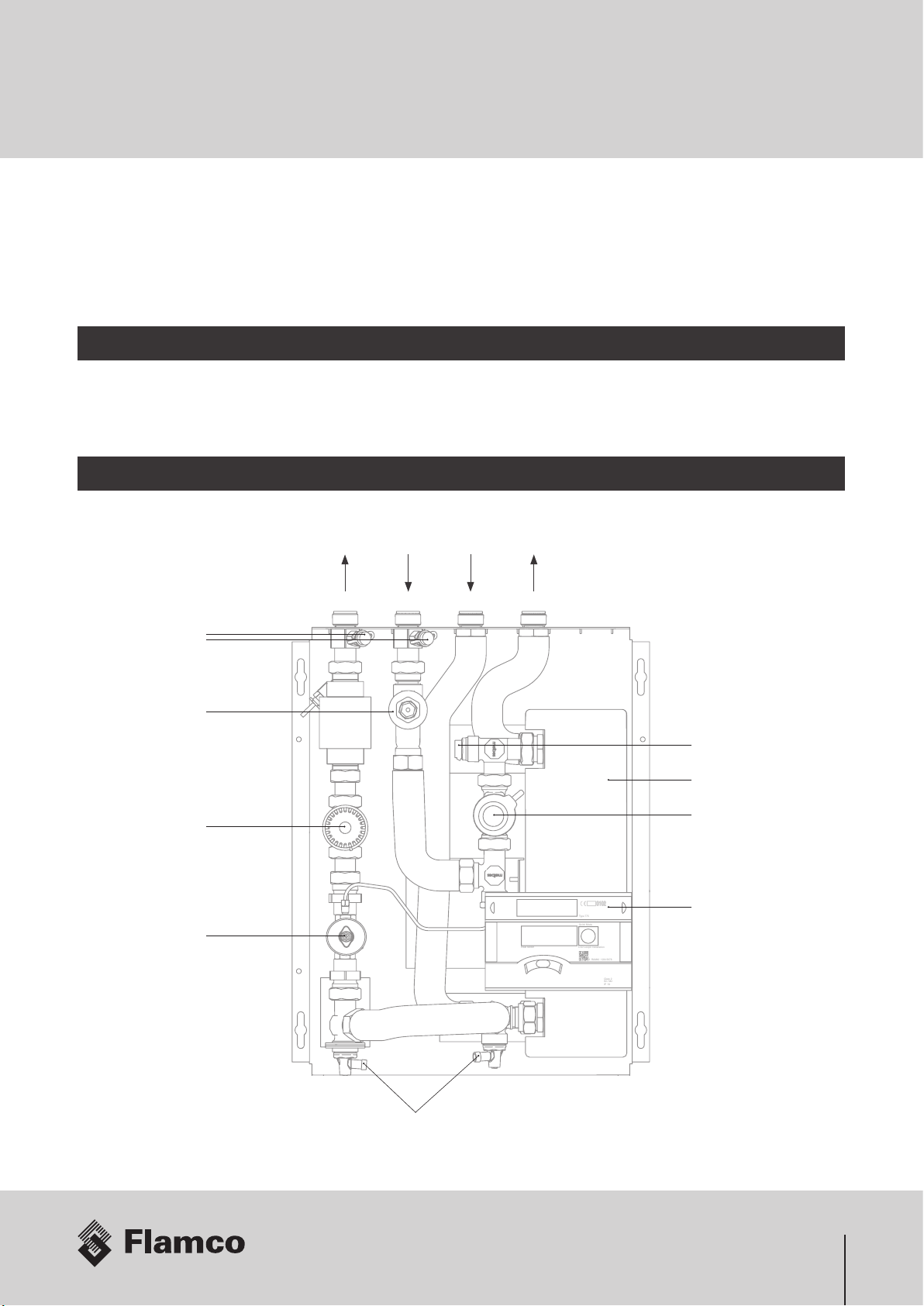

3.4 Connecting

All pipe connections are made to the isolating ball valves. These valves have standard 3⁄4” female BSP connections. Ensure

that the pipe material and size suits the system M&E specification. A safety pipe is part of pre-plumbed unvented cylinder

installation.

45 65 65 65 65

50

60

352

approx. 140

160

7

Ø12

The HIU must be installed inside a building. The location of the unit must be insulated against frost and easily accessible.

3.1 Preparation

Unpack the unit and read the installation manual to fully understand how the HIU is going to be fitted and connected.

Identify all hydraulic and electrical connections.

3.2 Positioning

The HIU needs to be fitted to a wall in an upright position with either isolating valves at the top or alternatively at the

bottom. The wall needs to be strong enough to support the unit. If the wall is of drywall construction make sure that there

is a supporting board (e.g. 18mm ply wood) installed to the supporting structure, which is strong enough to hold the unit.

While positioning the unit on the wall make sure that there is suicient space to run pipes and cables along the sides if

needed and leave suicient space underneath or above to connect the pipes to the isolating ball valves.

3.3 Fitting

The unit must be securely fitted using appropriate sized fittings. Ensure that the unit is mounted in an upright position. Fit

the First Fix Rail (FFR) to the wall using appropriate sized fittings as shown below. The external connections can be made

once the FFR is secured to the wall. The HIU can be hung at the FFR by sliding it onto the hanging points at any time but

must be secured to the structure using the 4 key hole shaped fixing points in the base plate of the unit.

3. Installation

9

3.5.2 HIU - Heating Circuit

The HIU has one 2-core cable which needs to be wired into the heating control. Connect the brown wire to the switched

live (call for heat) and the blue wire to neutral. No other wiring is required. If a prepayment meter is to be fitted refer to the

separate wiring diagram for the prepayment unit.

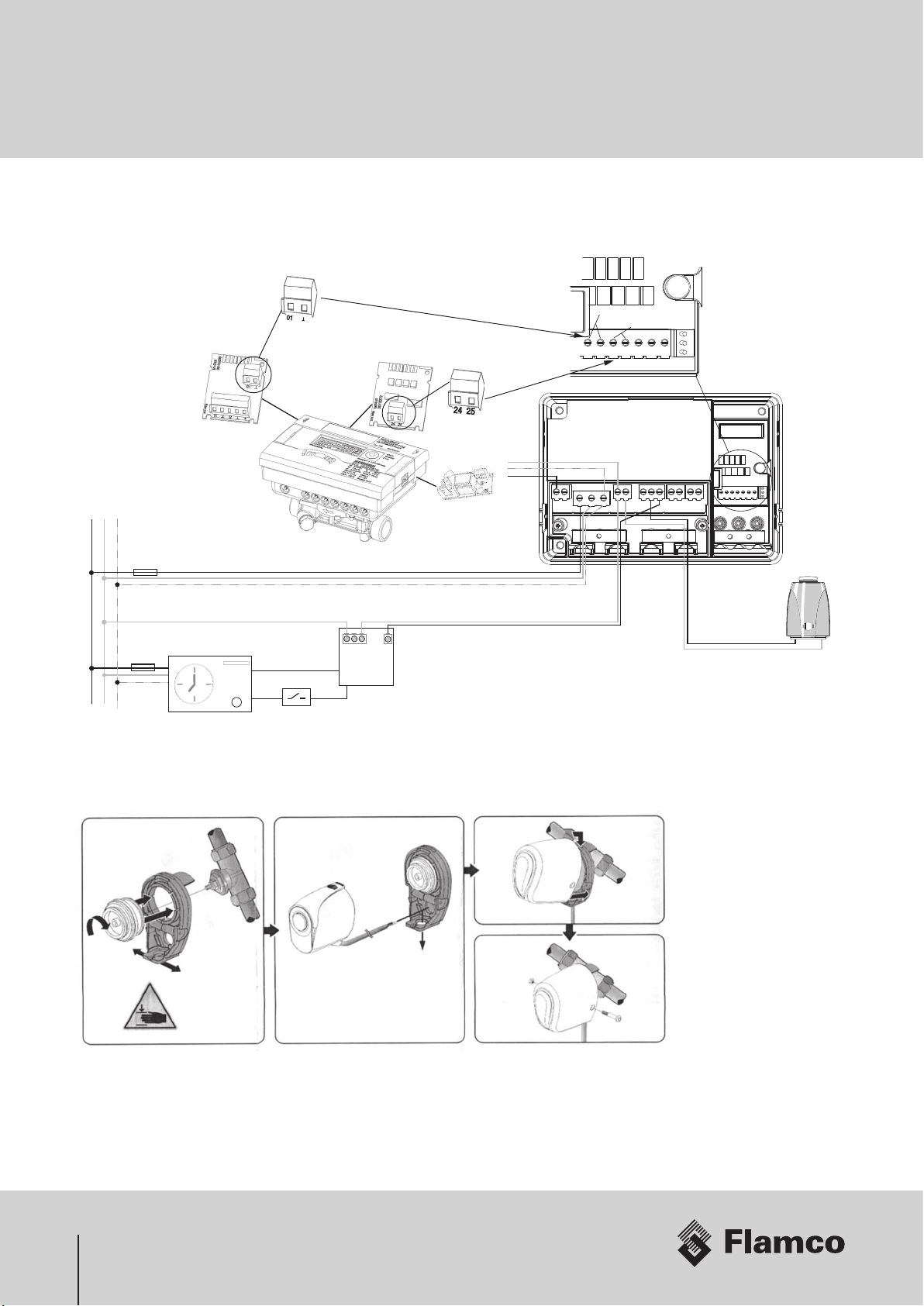

3.5.1 Electrical Diagram (for wiring centre fitted at the pre-plumbed unvented cylinder)

WIRING DIAGRAM 2 PORT ZONE VALVE (S-PLAN)

Key:

W=White, G=Grey,Bl=Blue,O =

Orange, G/Y = Green/Yellow, Br

= Brown, L = Live, N = Neutral,

C = Common Terminal, SW =

Switched Live, MV = Actuator

head of the primary zone valve

within the HIU

Note:

The mains supply for boiler

and programmer must be

taken from the “Wiring Centre”.

Br G

12 3

Bl

2 PORT (HTG) 2 PORT (DHW)CUTOUT (COMBINED) STAT

WIRING CENTRE

5A SUPPLY

ROOM STAT PROGRAMMER

BOILER

OC

1

1

2

2

LN

3

3

4

4

1234 LN SL

HTG

ON

DHW

ON

DHW

OFF

MV

BlBr

L

L PUMP

N

N

2

3

2

5

5

6

6

7

7

8

8

9

9

10

10

2C21

G YBr G

12 3

Bl O G Y

3.4.2 Hydraulic Secondary Circuit

There are 2 connections (flow and return) which need to be connected to the pre-plumbed unvented cylinder in the

apartment or house.

3.5 Electrical Connections

All wiring within the HIU must be supplied

from the same electrical circuit as the

controls for the heating system. This circuit

needs to be protected by a 5A fuse. The only

necessary connection within the HIU is the

2-core cable from the actuator head of the

motorised valve (MV) - see chapter “HIU

Heating Circuit”.

3. Installation

Blue Brown

Actuator

Head

Heat

Interface Unit

Wiring Centre of

Pre-Plumbed Cylinder

Fuse/Switch

Channel: Hot Water N

Boiler Call

230V

~

PE N

L

Room Thermostat

Channel: Space Heating

10

4.2 Pressure Test

The HIU and the installation must be pressure tested with 1.3 times the intended working pressure of the system (Refer M&E

specifications). If there are no leaks, the installation needs to be flushed. Both independent hydraulic systems need to be

tested in accordance to its own pressure rating. Please refer to the HIU specification.

4.3 Flushing/Corrosion prevention

All pipework that is to be connected to the units must be thoroughly cleaned and flushed out before the final connections

are made to the heat exchangers. Any debris or flux that could collect in the narrow channels of the heat exchangers will

be diicult to remove once they are installed. Remaining debris and flux could cause serious corrosion problems, as well

as restricting flow and reducing the eiciency of the units. Where soldered joints are used, it is preferable to employ fluxes

that are water miscible and do not contain chlorides (e.g. zinc or ammonium chloride), as these compounds are known

to be aggressive to stainless steel. It is also important to ensure that, where pipework installations are sterilised using

chemicals containing chlorine, safe levels are never exceeded if premature pitting corrosion is to be avoided. Any treatment

or cleaning should only be carried out by competent organisations that have the experience and technical resources to

monitor the installation during the chemical treatment process. Similarly, subsequent maintenance and water treatment

must follow accepted and approved practice.

For further guidance on water quality and treatment please refer to Appendix C.

The capillary tube of the

DPCV needs to be flushed

to ensure that there are no

air pockets le in the tube.

Carefully loosen the tube on

the valve body and bleed the

air. Re-assemble the tube

aerwards. Also check that

the valve is fully opened.

4.1 Commissioning

Before starting commissioning, please ensure that all connections are correctly fitted and tightened. When checking

connections, use 2 wrenches in order to counteract any torsion force within the rest of the assembly. Some threaded

connections (not union connections) may have been assembled using a glue like thread sealant. Make sure that these

connections are never rotated! Check the expansion vessel pressure (should be operating pressure of the secondary

heating system) and adjust if necessary. Standard operating pressure is 1.5 bar. The expansion vessel is part of the pre-

plumbed cylinder package and is not supplied with the HIU.

4. Service

11

• Close all isolation ball valves.

• Ensure the electricity supply is switched o.

• Check visually for leaks (union connections, ball valve

connections)

• Check all pipework connected to the unit is clean and free from

debris, flux or limescale.

• Check the strainer (2) for debris and swarf. Take extra care

when removing the strainer cap (sensor cable), then check the

gauze. The gauze should be clean, clean the gauze if necessary.

Reassemble all strainers, replace any damaged 0-rings or fibre

seals.

• Check the setting of the return temperature limiter (9). Please

refer to Appendix A - Locking temperature setting of the

thermostatic head.

• Check all cables for damage and make sure that they

are tied together in a safe place (e.g. M-Bus cable o

hot pipes) without any tension.

• Open the isolation ball valves and ensure there are

no visible leaks.

• Switch on the electricity supply.

• Check the functionality of the system. Turn up the

room thermostat and push the override button on

the timer to get a call for heat. This will activate the

HIU delivering heat to the radiators and/or the DHW

circuit. Make sure that at least one TRV on a radiator

circuit is open. It will take some minutes to start

heating the apartment/ cylinder.

• Also check the max. primary flow rate using the heat

meter (pos. 3). Adjust the flow rate if necessary at

the zone valve (9) by removing the actuator head as

shown and turning the flow restrictor (A).

230 V ~, 50Hz

LN

Timer

Room

Thermostat

e.g. Standard Unit:

Adjusting the temperature of

the thermostatic valve.

Setting range: 20 ... 65ºC

(Factory locked to 40°C).

Strainer (2)

4.4 Service Check List

4. Service

A

1

3

4

5

6

3

7

7

2

9

AB CD

6 RAM40 1234 5678

Heat Meter

Quick Mode

Type775

0102

LCD Loop3: Installation

Class 2

E2 / M2

IP 54

Service activity needs to be logged in the service record of the unit including

date, servicing company and service engineer‘s name. Any faults recorded

need to be rectified immediately. Perform a functional test of the unit before

proceeding to the next step. Record the findings and rectify any problems

before proceeding.

3

T

M

∑

1

1

27

77

9

6

4

A

B

C

D

5

12

Error code Description

C -1 Basic parameter error in flash or RAM

E1 Temperature range exeeded [-19.9 °C ... 199.9 °C] e.g. sensor

cable short circuit

E 3 ** Flow and return sensors inverted/confused

E4 Hardware fault in ultrasonic unit, e.g. transducer or trigger

faulty or short circuit

E5 Reading interval too short. No communication possible.

E 6 ** Wrong flow direction (flow sensor)

E7 Undetermined flow sensor reading (air, debris)

E8 No (mains) power supply, running on the backup battery

E9 Battery discharged

E A* leakage, broken pipe

Eb * leakage, heat meter

EC * leakage, pulse input 1

Ed * leakage, pulse input 2

* optional, ** application dependet

The Table shows the list of error codes which might be

shown on the display. “E-7“ is the general error that is

shown when the HIU has not been filled (air in flow sensor).

For further information please refer to the leaflet of the heat meter (Installation Guide) supplied with the HIU or refer to the

comprehensive manual for the heat meter.

The HIU‘s factory fitted heat meter is an MID class 2 (RHI certified), battery or mains powered ultrasonic heat meter with

M-Bus functionality. You can scroll through the menu shortly pressing the black button next to the display. The serial

number (8 digit number) can be found as shown in the picture.

5. Heat Meter

6 RAM40 1234 5678

Heat Meter

Quick Mode

Type 775

0102

LCD Loop3: Installation

Class 2

E2 / M2

IP 54

6 RAM40 1234 5678

Heat meter

serial number

QR code

13

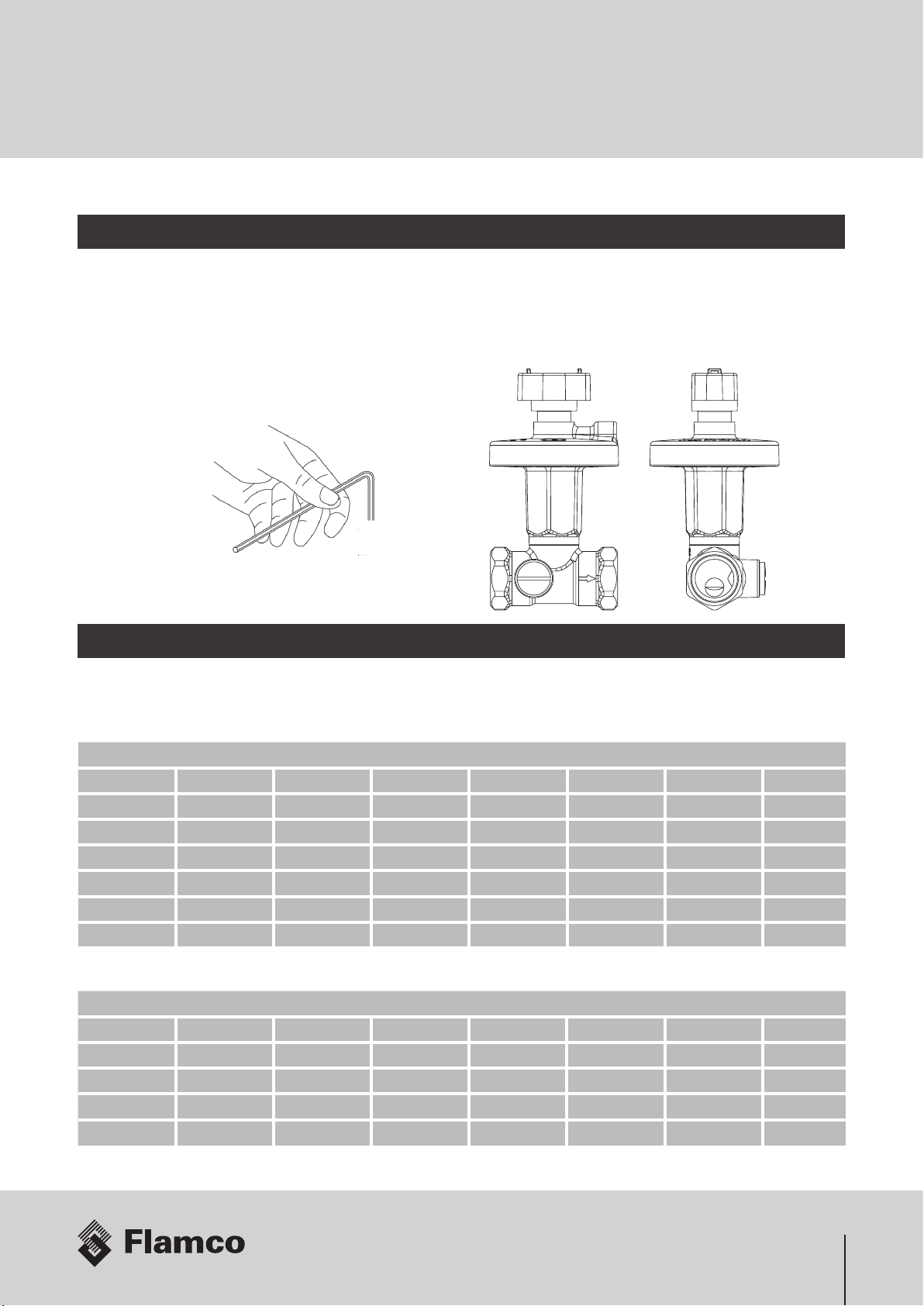

Adjusting the settings of the DPCV

Fitted into the HIU the DPCV has been set-up in the factory to 13,5 kPa (DN15) / 40 kPa (DN20). If this needs re-adjusting

do the following steps: Use the 3mm Allen key provided with the unit to turn the screw anti-clockwise until it is loosened.

According to the table below turn the key clockwise the number of rounds to the new required setting.

DN20 factory setting = 40 kPa (Standard Unit and 30 kW High Pressure Unit) 20 ... 40 kPa

Turns dp [kPa] Turns dp [kPa] Turns dp [kPa] Turns dp [kPa]

1 20.0 6 26.1 11 32.6 16 39.2

2 21.0 7 27.4 12 33.9 17 40.0

3 22.2 8 28.7 13 35.2

4 23.5 9 30.0 14 36.5

Dierential Pressure Control Valve (DPCV) - Ballorex® DN15, DN20

The DPCV fitted in the primary circuit of the HIU ensures that the pressure loss of the unit doesn‘t exceed DN15: 13,5 kPa,

DN 20: 40 kPa - factory setting. The valve itself is installed in the return. The pressure in the flow is received on top of the

membrane through the capillary tube. When the dierential pressure increases, the rising pressure on top of the internal

membrane forces the spring/spindle downwards closing the valve gradually, whereby constant pressure in the circuit is

obtained. The dierential pressure can be set between DN15: 5-25 kPa, DN 20: 20-40 kPa.

6. Appendix A

DN15 factory setting = 13,5 kPa (20 kW High Pressure Unit) 5... 25 kPa

Turns dp [kPa] Turns dp [kPa] Turns dp [kPa] Turns dp [kPa]

0 5.0 6 11.0 12 17.0 18 23.0

1 6.0 7 12.0 13 18.0 19 24.0

2 7.0 8 13.0 14 19.0 20 25.0

3 8.0 9 14.0 15 20.0

4 9.0 10 15.0 16 21.0

5 10.0 11 16.0 17 22.0

14

6. Appendix A

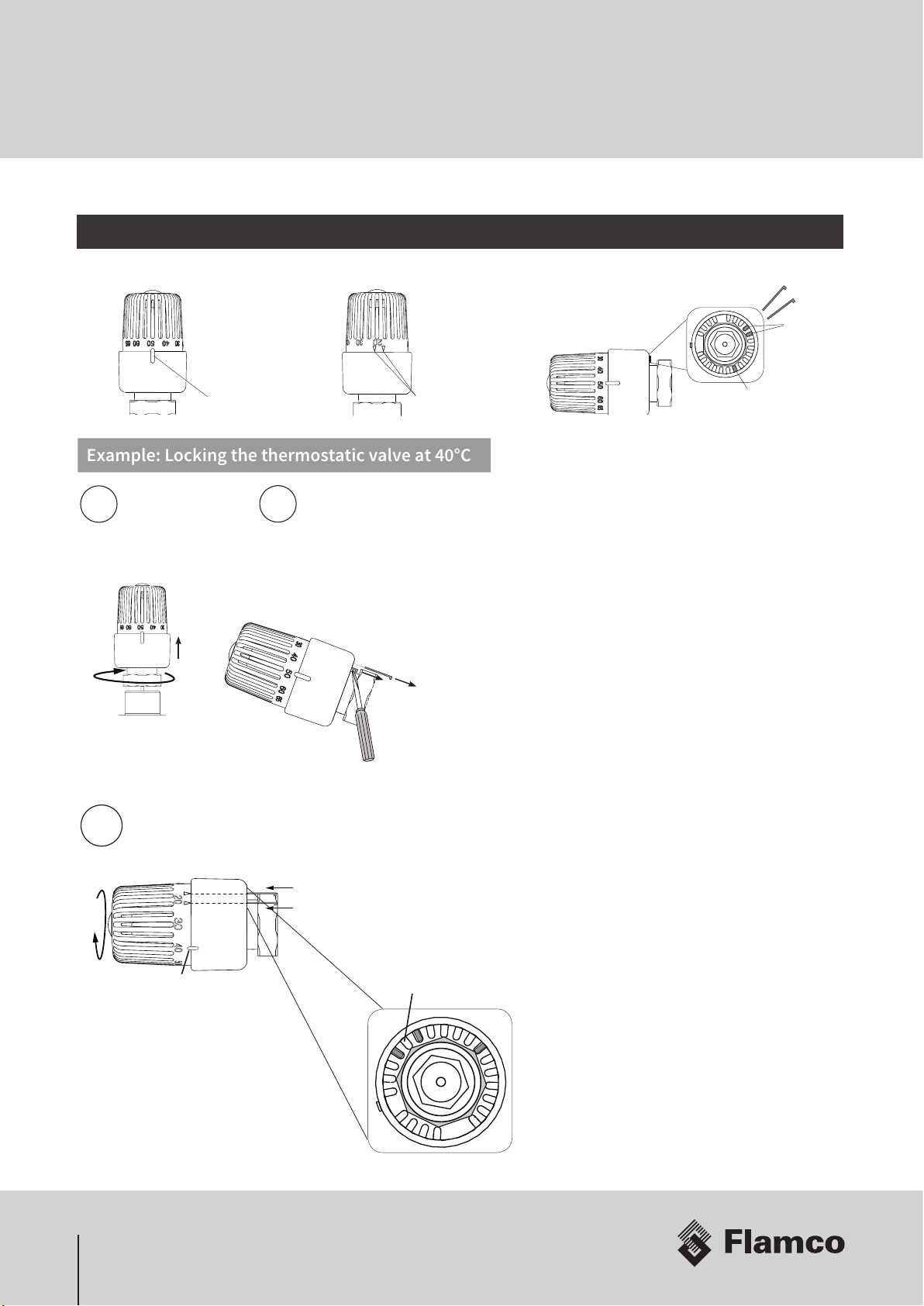

Locking the temperature setting

Set Temperature Index Alignment Marks

Metal Pins

Single Metal Pin

(not to be removed)

2x

Remove the two

metal pins using a

screw driver

12

Remove the thermostatic

head from the valve body

3

Select the temperature by

turning the head until the

index is pointing at 40ºC

To lock the head align the two

metal pins with the marks as

shown and push them back in

Make sure there is

a space between the two pins

Locking the Temperature Setting (Standard Unit)

Example: Locking the thermostatic valve at 40°C

15

Mains Supply

The mains supply needs to be protected by a 5A fuse and a double pole switch so that the unit can be safely disconnected

for servicing.

Fitting of the Heat Meter

The heat meter is optional and can be fitted by replacing the spool piece. Details will be found in the meter documentation.

System Testing

Finally test the system to ensure it is operating properly. This can only be done if the primary heat network is running

and the heating controls are wired in and switched on. Ensure that all isolation ball valves at the HIU are open as well as

one domestic hot tap. Hot water should be flowing from the tap in a very short time. To test the heating turn up the room

thermostat and push the override button on the timer get a call for heat. This will activate the HIU delivering heat to the

radiators or the underfloor heating circuit. Make sure that at least one TRV on a radiator or underfloor heating circuit is

open. It will take some minutes to start heating the apartment but the response of the unit can be checked immediately by

measuring the temperature of the primary and secondary flow pipes at the HIU.

Servicing

Service activity needs to be logged in the service record of the unit including date, servicing company and service

engineer‘s name. Any faults recorded need to be rectified immediately. Perfom a functional test of the unit before

proceeding to the next step. Record the findings and rectify any problems before proceeding.

Visual Check

Perform a visual check of the unit making sure all seals are water tight and there are no visible leaks. Any leaks need to be

fixed, union nuts tightened and seals replaced.

Cleaning the Strainers

Close all isolation ball valves and drain all circuits of the unit. Remove the strainer cap, then the strainer and clean the

strainer gauze. Reassemble all strainers, replacing any rubber or fibre seals. Then fill and bleed the entire unit ensuring

there are no leaks.

6. Appendix A

16

L2L1

N1 N2

R1 R2 R3

NO C NO C

NO NC C

N

N

L

PE

230V ~

Boiler Call

Fuse / Switch

Channel: Space Heating

Channel: Hot Water

brown blue

Room Thermostat

Wiring Centre of

Unvented Pre-plumbed Cylinder

Actuator Head

in HIU

Wiring Centre

Fuse

(non switched, 5A)

Heat Meter

M-Bus

Pulse

Pulse Inputs

Pulse Output

Pulse Module

M-Bus Module

24 25

01

24 25

2 core cable

2 core cable

L N PE

230V ~ Module

N

PE

L

Pre-Payment example (GURU System)

Securing Zone/Pre-Payment Actuator

7. Appendix B

17

The filter should be added to the requirements of the

“Operating and Maintenance” instructions handed over with

the system. If an advisory sticker is provided with the filter it

should be attached at a suitable location as to indicate the

presence within the system of the filter to ensure periodic

checking & servicing by any attending Service Engineer.

We would also recommend that these filters incorporate a

sight glass, particularly on the larger sizes to provide a visual

means of assessing corrosion without the need to disrupt

the operation of the system for checking.

Line Size Magnetic Field Strength

DN15 7500 gauss

DN20 9000 gauss

DN25 10500 gauss

DN35 21000 gauss

DN40 21000 gauss

DN50 52500 gauss

DN80 73500 gauss

DN100 73500 gauss

DN150 94500 gauss

Guidelines for System Conditioning of Heating Networks for Flamco Limited - Meibes Heat Interface Units (HIU)

Flamco Limited prides itself on bringing to the UK market a proven range of Heating Interface Units (HIU). To ensure that

our products deliver increased longevity and performance, these guidelines are specifically written to aid and ensure

both the primary and secondary side of the heat network are designed, installed and commissioned to realise the desired

heating comfort levels. These guidelines are not oered for use on potable, domestic, and water draw o side of

the system. Solely for the heating circuits ONLY. For further guidance on water treatment and water analysis

please refer to BSRIA BG29/2012, BG50/2013 and BS8552. Whilst not exhaustive, we oer these guidelines from

experience and a practical standpoint, in addition, as a check list to support design review. These guidelines are not

intended as mandatory or fixed in their approach; moreover they are intended as supporting documentation to highlight

good practise and methodology ensuring operation and maintenance activities are kept to a minimum post handover. We

are not specialists in the design, installation and or cleaning and subsequent treatment of water systems but, nevertheless,

contained in the sections below are importance aspects to consider.

1. System Design Considerations

• A review of the system should be undertaken post the design stage. The review should focus on the allocation,

location and capacity of strainers both fixed and temporary, air and gas removal devices, debris traps, isolation

valves to ensure that removal of debris from the system which was not removed in the commissioning activity is

managed and that sub sections can be economically isolated to permit maintenance.

• It should be considered at the design stage to include into the design a means ferrite removal. Poorly commissioned

and maintained systems exhibit corrosion. As the majority of systems contain products manufactured from iron, it is

the iron in the form of steel ferrite which creates the tell tale black sludge or blacked water which indicates corrosion

is taking place of components of the system. This corrosion if remaining unchecked, fouls water ways and controls,

erodes system components, reduces system performance and leads the production of hydrogen in the system

known as “Gassing”. This is also a tell tale sign of system corrosion.

• As over 90% of debris in systems is ferrous we recommend the installation of a rare earth, magnetic filter to both

remove the ferrite but act as a means of identifying corrosion is taking place and a prompt for remedial action.

• The removal device ideally, should have a first pass rate of 75% debris removal or greater, have incorporated into

it a static mixing function to open the system fluid to permit rapid removal of the debris, mounted in the common

return, main return pipe work. The filter shall be of adequate size and capacity to allow suicient flow rate and

debris capture for the system size (line size is recommended). Any such filter should have the following magnetic

field strength capacity as a minimum to ensure maximum ferrite removal.

8. Appendix C

18

2. Main Factors aecting corrosion and System performance

• “PH” or relative Acidity/ Alkalinity are of key importance in managing the production of system corrosion. It is

recommended that PH Level of the system water be between 7 and 8.5 (ideally 7.4/7.5). A Lower PH level than

recommended would be classed as acidic and corrode all metals. Alternatively, too high a PH level would be

alkaline and will corrode aluminium components within the wetted part of the system.

• When considering a chemical treatment product to add to the system, we recommend products which incorporate a

mix for buering, in order to control the PH level more eectively.

• Oxygen Ingress should be minimised by the use of closed systems and barrier pipe within the system design.

• Aggressive ions (such as flux residues) promote corrosion and, continue to do so unless neutralised or flushed out

completely. Wewould recommend a jointing approach that removes the need to use such compounds and adopt

the use of heat free systems.

• If traditional solder fittings are used then we would recommend the use of a recognised chemical treatment to flush

out and neutralise the system.

• The accumulation of sludge & debris can cause deposit corrosion which leads to pitting. We recommend the use

of a recognised chemical treatment to flush out and neutralise the system In addition, it is strongly advised to

contact the manufacturer of the chemical treatment to gain early involvement prior to treatment as to the correct

application and chemical to use.

3. Refurbishment and Improvement to existing systems

• It is vitally important that before commencing works on existing systems that a complete scan of the water quality

of the system be taken. If it is found that the system contains products of corrosion and/or PH levels in excess of

the required norms, it is recommended that the existing water is conditioned and treated to PRIOR to the work

commencing.

4. System commissioning (water quality) Water Treatment Chemicals

• We do not recommend the use of raw water for hydraulic testing due to the risk of corrosion of the water being le in

the system and potentially, the internals of the system being exposed to the air due to partial draining.

• Chemically dosed water should be in all filling in activities accordance with the chemical manufacturers’

recommendations and in accordance with BSRIA BG29 2012.

• Aer a suitable filling and flushing regime is used, relevant to the system material, all chemicals used to be suitable

for HIU must comply with EU norms DIN EN 12828 and current guidelines for heating systems. In addition, they

should also be non hazardous, non toxic and biodegradable.

• The use of correct cleaners and inhibitors is of primary, environmental concern. All chemicals used to treat the

system should not contain phosphates, sulphuric acid, nitrites. See BS7593:2006 Code of Practice for treatment of

water in domestic hot water central heating systems.

• Inhibitors should meet Buildcert as a minimum and preferably be recommended by the Energy Savings Trust (EST).

8. Appendix C

19

• Acid based cleaners are unsuitable for older systems as there is a risk of “pinholing” on radiators. They will also

require some form of neutralisation process before being discharged or require being tankered away for disposal.

5. Recommendations for system conditioning - (Basic process)

• The system must be flushed and inhibited in accordance with BS7593 and the Domestic Building Services

Compliance Guide.

• The chemicals used should contain the following aspects of their composition:

–Surfactants to reduce surface tension allowing chelating agents to attach to the residues.

–Chelating agents will then entrap the calcium carbonate within the solution.

–Dispersants are used to hold residues in suspension.

–The inhibitor then prevents corrosive attacks on metals during cleaning.

–PH Buers to maintain a neutral PH

–Chemicals shall be of a type suitable for disposal through a conventional sewer or foul drain (i.e. no requirement

for tankering or specialist disposal)

–Neutralisation

6. Site installation conditions – Installation of the system

It is recommended that:

–Water soluble flux should be used (no Chloride – COSSH).

–The area of installation should be free from gypsum dust, brick dust, screed or other possible contaminants.

7. Recommended aercare (HIU) Network Primary side

• Any relevant details of the installed units and system conditioning to be documented on the service record

• There should be clear notification of any chemical products added, dates etc placed on the HIU

• If there is a requirement for a partial drain down, the inhibitor should be topped up to the required level with full

details.

• We recommend that all servicing/inspection etc is fully adhered to.

• Any checklist sticker placed within the casing by the manufacturer must be completed. 8 Recommended aercare

(Network)

8. Appendix C

20

8. Recommended aercare (Network)

It is recommended that a regime of periodic inspection of the system be undertaken. The inspection shall take the form of:

Visual inspection

System visual inspection, exterior corrosion, water stains on the pipe work and equipment, suggesting a slow leak and

make up water entering the system thereby diluting the inhibitor concentrations.

Water Samples

Water samples shall be drawn from a suitable draw o point to ascertain the condition of the network, on the primary side

water.

The analysis of the water should include:

• Visual assessment – Note any discolouration away from clear as an indicator of possible corrosion

• Chemical assessment – PH value, hardness, precipitate composition and concentration of chemical treatment and type of

treatment contained within the water (A UKAS registered lab is recommended to be used in the system water analysis).

8. Appendix C

Table of contents