Safety Instructions

● When workin with the CPCI-PN-DEV follow the instructions below and read the manual carefully to protect yourself

from injury and the CPCI-PN-DEV from dama e.

● The device is a built-in component. It is essential to ensure that the device is mounted in a way that cannot lead to

endan erin or injury of persons or dama e to objects.

● The device has to be securely installed in the control cabinet before commissionin .

● Protect the CPCI-PN-DEV from dust, moisture and steam.

● Protect the CPCI-PN-DEV from shocks and vibrations.

● The CPCI-PN-DEV may become warm durin normal use. Always allow adequate ventilation around the CPCI-PN-

DEV and use care when handlin .

● Do not operate the CPCI-PN-DEV adjacent to heat sources and do not expose it to unnecessary thermal radiation.

Ensure an ambient temperature as specified in the technical data.

● Do not use dama ed or defective cables to connect the CPCI-PN-DEV.

● In case of dama es to the device, which mi ht affect safety, appropriate and immediate measures must be taken, that

exclude an endan erment of persons and domestic animals and property.

● Current circuits which are connected to the device have to be sufficiently protected a ainst hazardous volta e (SELV

accordin to EN 60950-1).

● The CPCI-PN-DEV may only be driven by power supply current circuits, that are contact protected.

A power supply, that provides a safety extra-low volta e (SELV or PELV) accordin to EN 60950-1, complies with this

conditions.

DANGER

Hazardous Voltage - Risk of electric shock due to unintentional contact with uninsulated live parts with hi h

volta es inside of the system into which the CPCI-PN-DEV is to be inte rated. Disconnect all hazardous

volta es (mains volta e) before you install the CPCI-PN-DEV into the system.

NOTICE

Electrostatic discharges may cause damage to electronic components.

To avoid this, please perform the steps described on pa e 8 before you touch the CPCI-PN-DEV, in order

to dischar e the static electricity from your body.

Qualified Personal

This documentation is directed exclusively towards personal qualified in control and automation en ineerin .

The installation and commissionin of the product may only be carried out by qualified personal, which is authorized to

put devices, systems and electric circuits into operation accordin to the applicable national standards of safety

en ineerin .

Conformity

The CPCI-PN-DEV is an industrial product and meets the demands of the EU re ulations and EMC standards printed in

the conformity declaration at the end of this manual.

Warning In a residential, commercial or li ht industrial environment the CPCI-PN-DEV may cause radio interferences

in which case the user may be required to take adequate measures.

Data Safety

This device is equipped with an Ethernet or other interface which is suitable to establish a connection to data networks.

Dependin on the software used on the device, these interfaces may allow attackers to compromise normal function, et

ille al access or cause dama e.

esd does not take responsibility for any dama e caused by the device if operated at any networks. It is the responsibility

of the device's user to take care that necessary safety precautions for the device's network interface are in place.

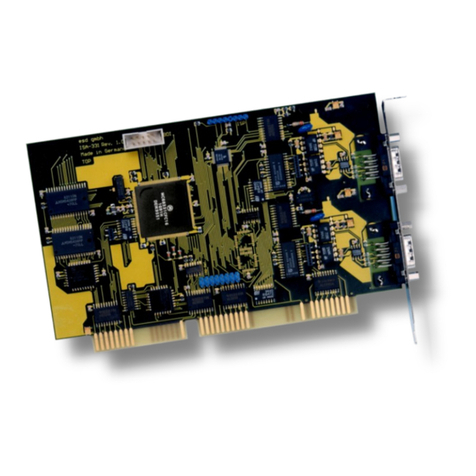

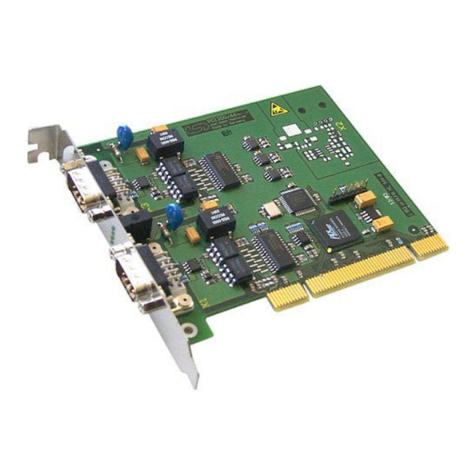

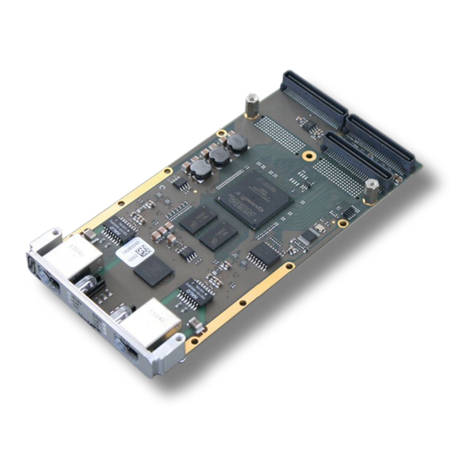

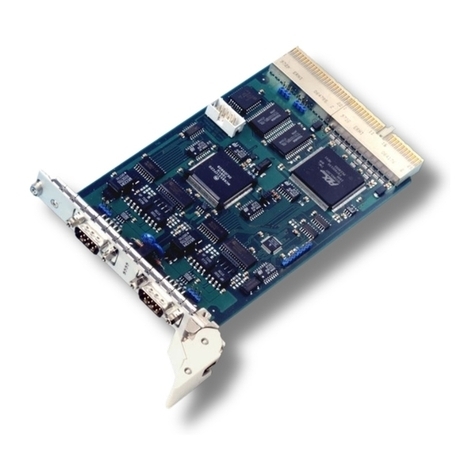

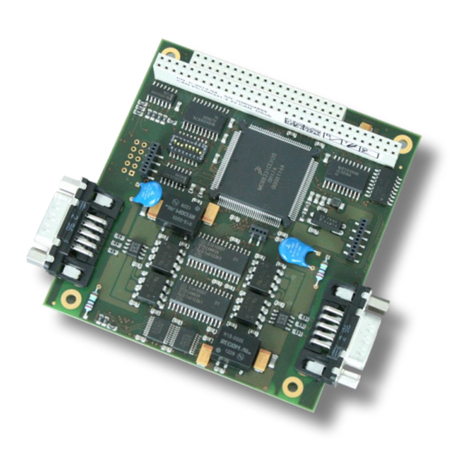

Intended Use

The intended use of the CPCI-PN-DEV is the operation as PROFINET® IO interface in a CompactPCI® system.

The uarantee iven by esd does not cover dama es which result from improper use, usa e not in accordance with

re ulations or disre ard of safety instructions and warnin s.

● The CPCI-PN-DEV is intended for installation in a CompactPCI-system only.

● The operation of the CPCI-PN-DEV in hazardous areas, or areas exposed to potentially explosive materials is not

permitted.

● The operation of the CPCI-PN-DEV for medical purposes is prohibited.

Service Note

The CPCI-PN-DEV does not contain any parts that require maintenance by the user. The CPCI-PN-DEV does not

require any manual confi uration of the hardware.

Disposal

Devices which have become defective in the lon run have to be disposed in an appropriate way or have to be returned

to the manufacturer for proper disposal. Please, make a contribution to environmental protection.

Pa e 4 of 30 Manual • Doc. No.: I.2329.21 / Rev. 1.3 CPCI-PN-DEV