2We reserve the right to change designs and technical specifications of our products.GPA III manual - 20211008

Table of Content

Notes ������������������������������������������������������������������������������������������������������������������������3

1� Symbol description �������������������������������������������������������������������������������������������������4

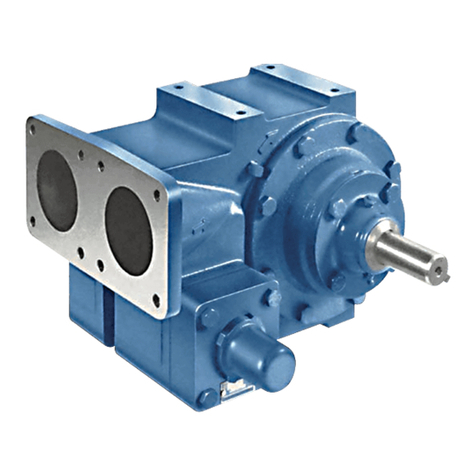

2.1. GPA III series circulating pump for water circulation... .............................................................. 4

2.2. Advantages of installation of the pump....................................................................................... 4

3� Service conditions���������������������������������������������������������������������������������������������������5

3.1. Ambient Temperature ................................................................................................................. 5

3.2. Relative humidity (RH) ................................................................................................................. 5

3.3. Media (conveying liquid) temperature ........................................................................................ 5

3.4. System Pressure ........................................................................................................................... 5

3.5. Protection Level ........................................................................................................................... 5

3.6. Inlet Pressure: .. ........................................................................................................................... 5

3.7. Pumping Liquid ........................................................................................................................... 5

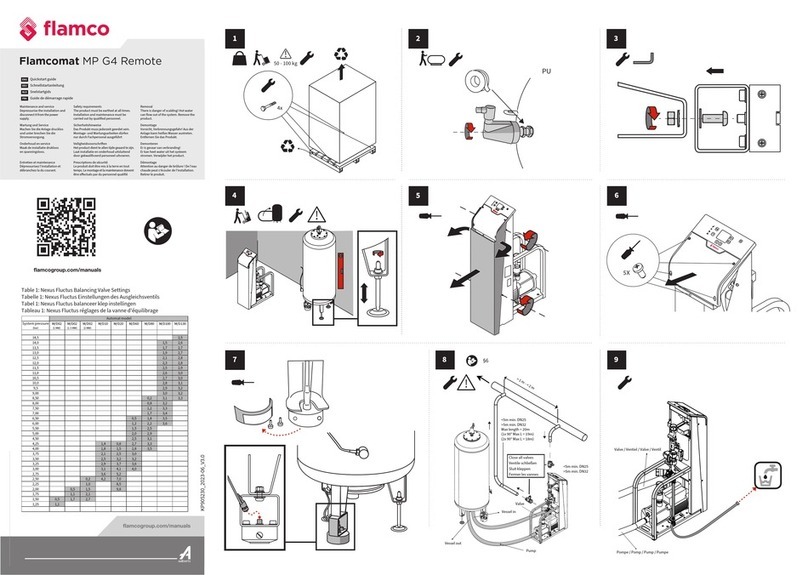

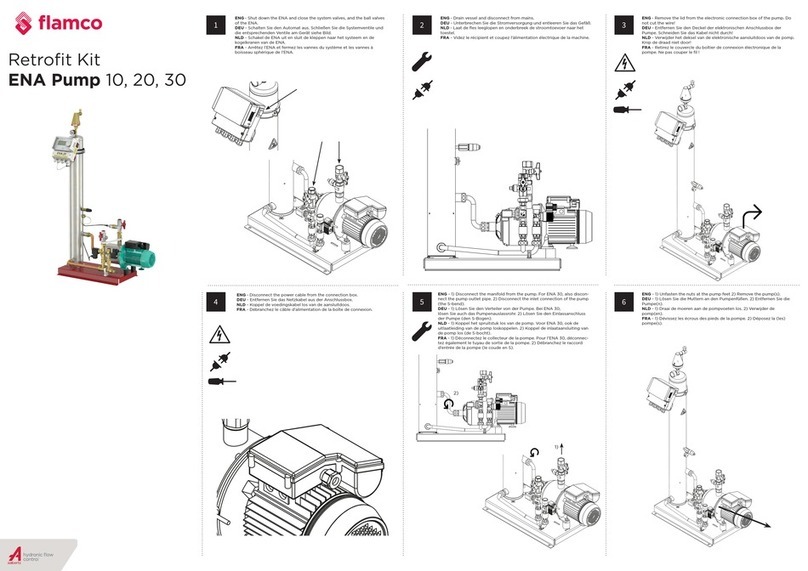

4� Installation�������������������������������������������������������������������������������������������������������������5

4.1 Installation..................................................................................................................................... 6

4.2 Position of Junction Box ............................................................................................................... 6

4.3 Position of junction box ................................................................................................................ 6

4.4 Thermal insulation of the pump body. ........................................................................................ 7

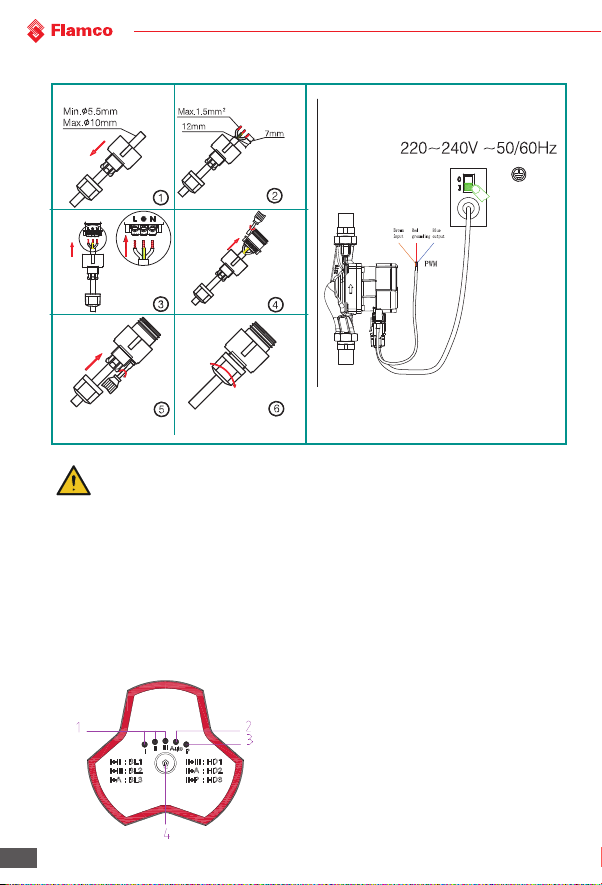

5� Electrical Connection ����������������������������������������������������������������������������������������������8

6� Control Panel����������������������������������������������������������������������������������������������������������8

6.1 Controls on Control Panel............................................................................................................. 8

6.3 Light area displaying the settings of the pump.... ....................................................................... 9

6.4 Button for selecting the pump settings........................................................................................ 9

7� Setting of the pump�����������������������������������������������������������������������������������������������10

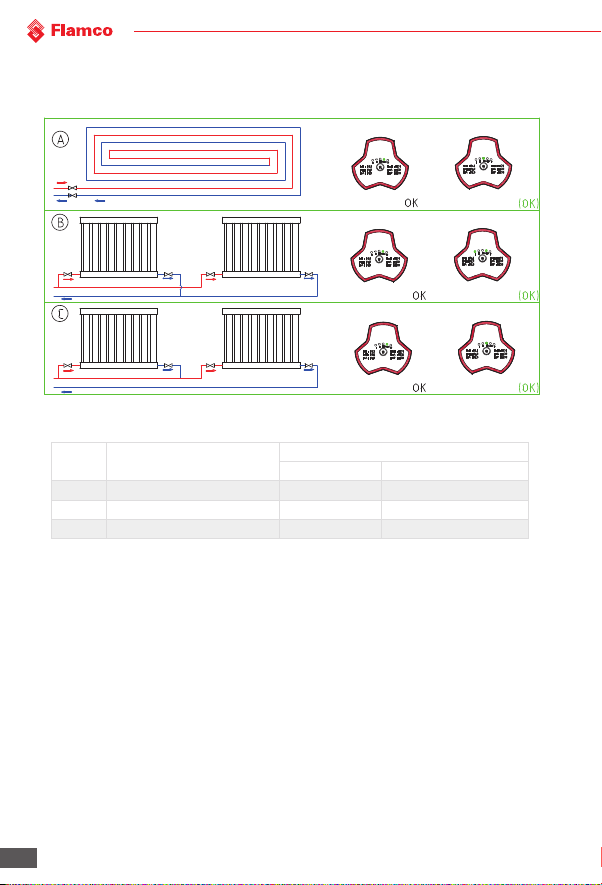

7.1 The pump should be set according to system type ...... ............................................................ 10

7.2 The control on the pump ............................................................................................................ 11

8� PWM Signal Control Mode �������������������������������������������������������������������������������������� 11

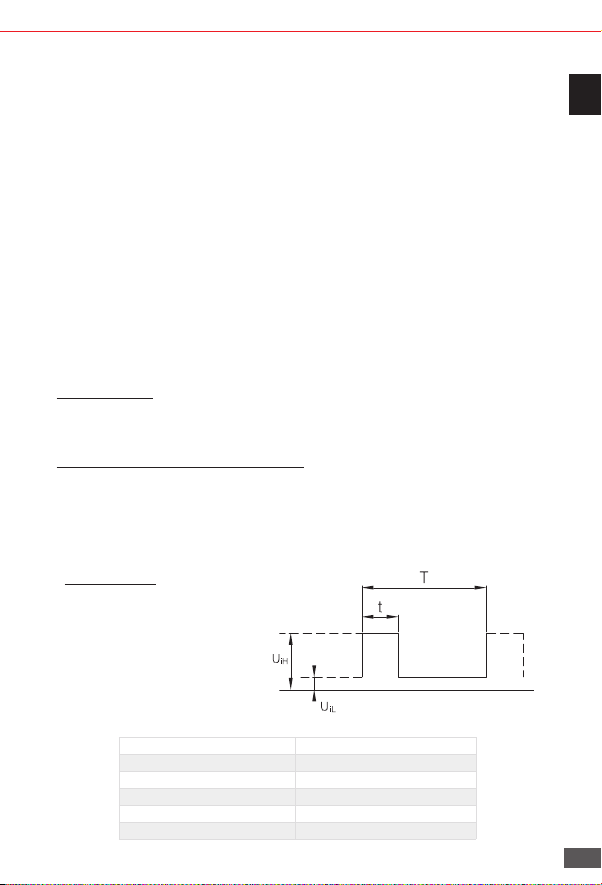

8.1 Control and Signal...... ................................................................................................................ 11

8.2 Interface....................................................................................................................................... 12

8.3 PWM Input Signal........ ................................................................................................................ 12

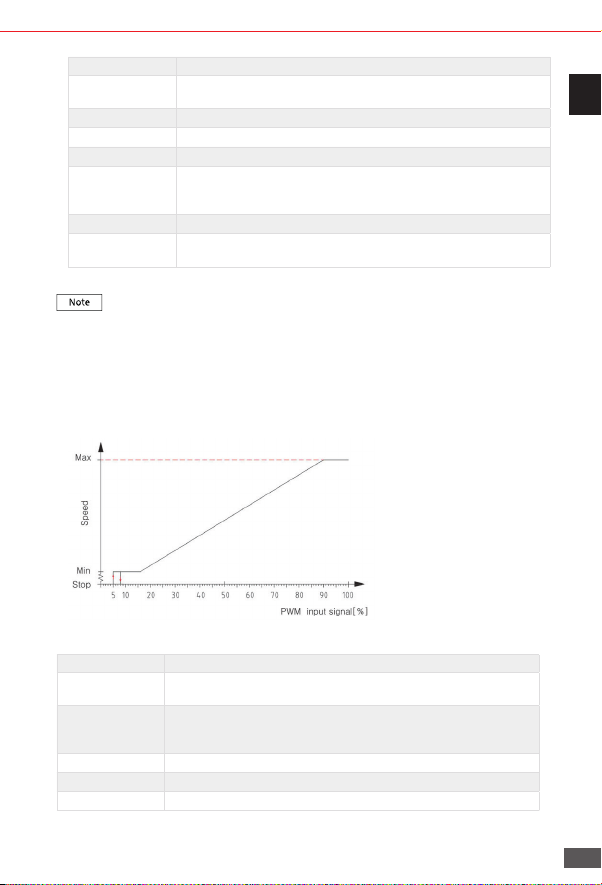

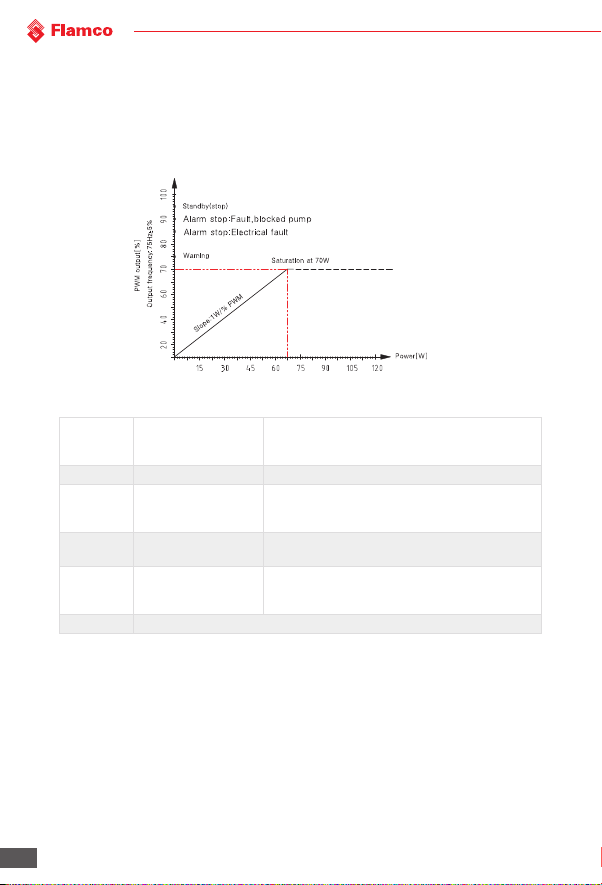

8.4 PWM PWM input signal profile PWM2(solar) .............................................................................. 13

8.5 PWM Feedback Signal ................................................................................................................ 14

8.5 How to use the signals ................................................................................................................ 14

9� Bypass Valve��������������������������������������������������������������������������������������������������������� 15

9.2 Manually-operated bypass valve ............................................................................................... 15

9.3 Automatic bypass valve (temperature control type) .... ............................................................ 15

10� Start up��������������������������������������������������������������������������������������������������������������16

10.1 Before Start Up ......................................................................................................................... 16

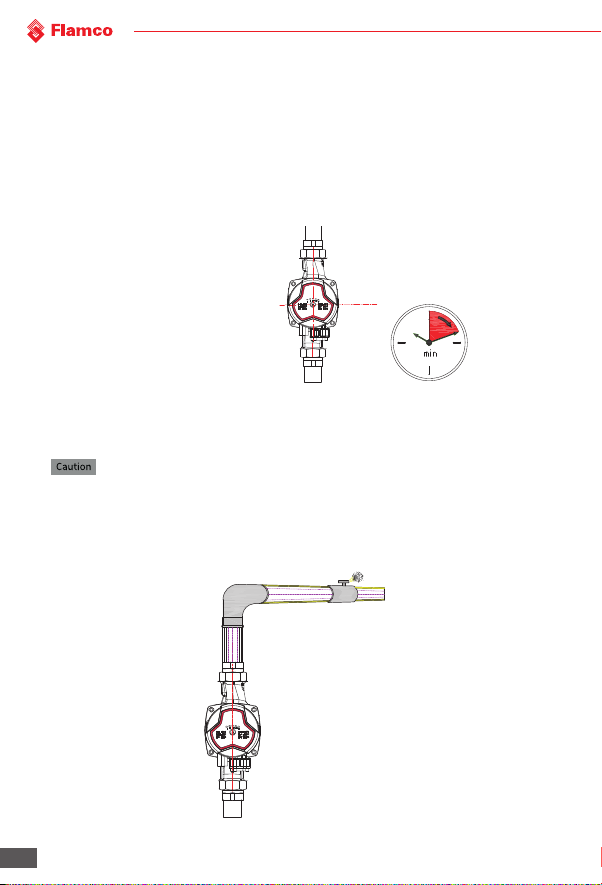

10.2 Exhaust the Motor Pump........................................................................................................... 16

10.3 Gas-exhausting of heating system..... ...................................................................................... 16

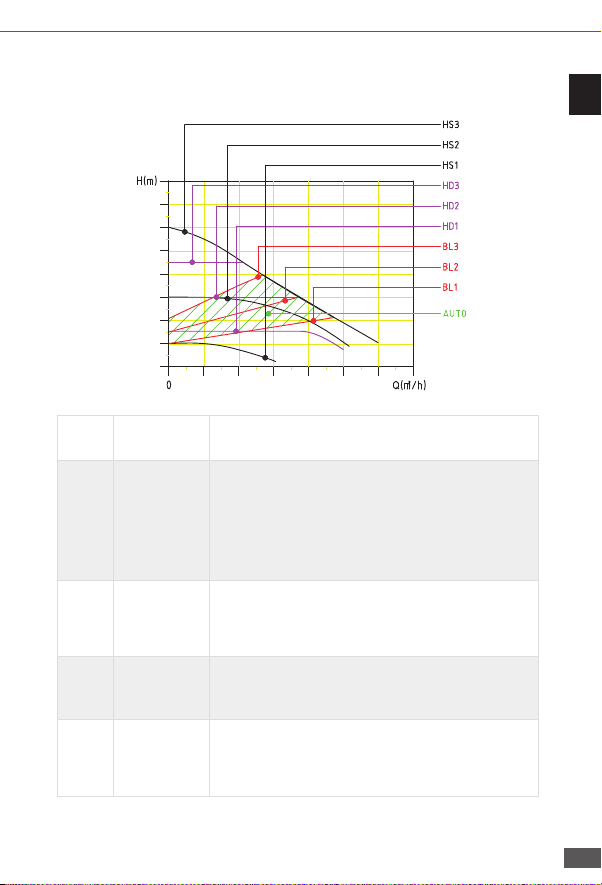

11� Settings and performance of pump �����������������������������������������������������������������������17

11.1 Relationship between pump settings and its performance .................................................... 17

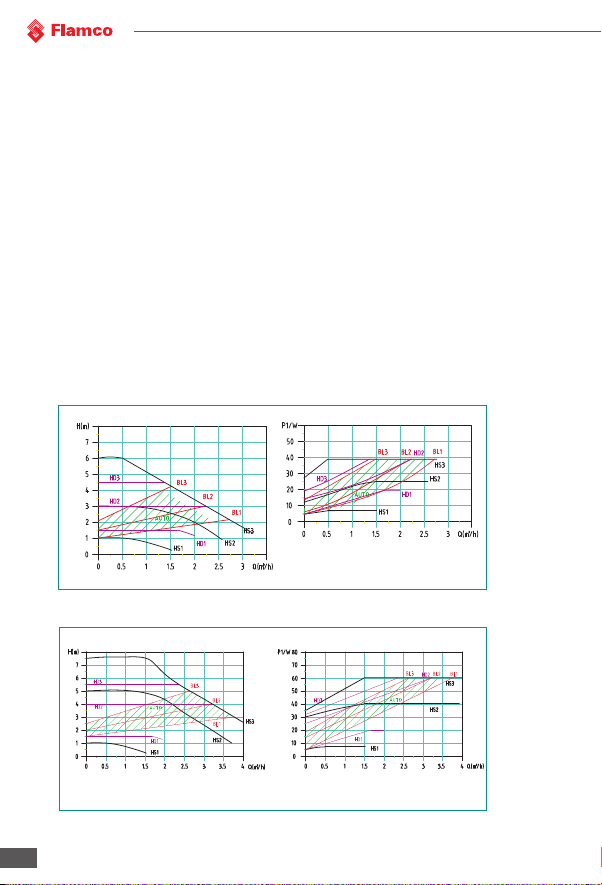

12� Performance Curve���������������������������������������������������������������������������������������������� 18

12.1 Performance curve guide ......................................................................................................... 18

12.2 Curve conditions....... ................................................................................................................ 18

12.3 Performance Curve... ................................................................................................................ 18

13� Characteristics����������������������������������������������������������������������������������������������������19

13.1 Description of nameplate.......................................................................................................... 19

13.2 Model explanation.... ................................................................................................................ 20

14� Technical Parameters and Installation Dimensions�������������������������������������������������� 20

14.1 Technical data.. ......................................................................................................................... 20

14.2 Installation Dimensions............................................................................................................. 21

15� Fault checklist ���������������������������������������������������������������������������������������������������� 22