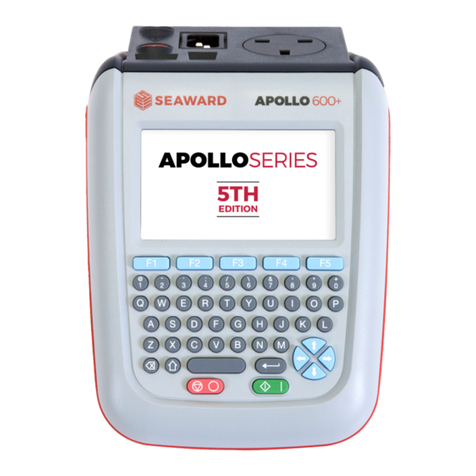

Flashcut CNC 401A Installation instructions

™

Computer Numerical Control for Windows

Model 401A

Motor Signal Generator

Hardware Guide

Z

Y

XA

LIMIT

ON

OFF

RXD TXD POWER

© 1998 FlashCut CNC, Inc.

1263 El Camino Real, Suite W, Menlo Park, CA 94025

Phone (650) 853-1444 •Fax (650) 853-1405 •www.flashcutcnc.com

Table of Contents

GETTING STARTED..........................................................................................................................................1

ABOUT THIS MANUAL..........................................................................................................................................1

SYSTEM SAFETY..................................................................................................................................................2

HARDWARE GUIDE..........................................................................................................................................3

OVERVIEW OF THE MOTOR SIGNAL GENERATOR...................................................................................................3

FRONT PANEL .....................................................................................................................................................3

REAR PANEL .......................................................................................................................................................3

TURNING OFF THE CONTROLLER ..........................................................................................................................6

FlashCut CNCFlashCut CNC SectionSection 11 Getting StartedGetting Started 11

1. Getting Started

About this Manual

FlashCut CNC is a unique application involving both hardware and software, so

you’ll need some instruction to get started.

Since automated machining is potentially dangerous, please take

the time to completely read through this manual and the Software

User’s Guide to understand the operation of the electronics,

software and machine before cutting a part.

Section

FlashCut CNCFlashCut CNC SectionSection 11 Getting StartedGetting Started22

System Safety

If you do not understand and agree with all of the above safety

guidelines, do not use this product.

1. Never let the machine run unattended.

2. Any person near a running machine tool must wear safety goggles.

3. Allow only trained people to operate the machine. Anyone

operating this machine must have:

•Knowledge of machine tool operation.

•Knowledge of personal computer operation.

•Knowledge of microsoft windows.

•Good common sense.

4. Place safety guards around the machine to prevent injury from

flying objects. FlashCut CNC highly recommends building a

plexiglass safety shield around the entire tool envelope.

5. A computer controlled machine tool is potentially dangerous.

Unexpected machine movement can occur at any time. Never

place any part of your body within the tool envelope while the

machine is online.

6. Be aware and on alert for computer crashes at all times.

7. Always keep the tool envelope tidy and free of any loose objects.

8. FlashCut CNC is not responsible for the safe installation and use

of this product. You and only you are responsible for the safety of

yourself and others during the operation of your CNC machine

tool. FlashCut CNC supplies this product but has no control over

how it is installed or used. Always be careful!

When running any machining operation, safety is of utmost

importance. For proper and safe use of the FlashCut CNC program

and your CNC machine, the following safety guidelines must be

followed:

FlashCut CNCFlashCut CNC SectionSection 22 Hardware GuideHardware Guide 33

2. Hardware Guide

Overview of The Motor Signal Generator

The Motor Signal Generator provides a flexible interface that controls up to 4

stepper motor drivers, 8 output lines and 8 input lines.

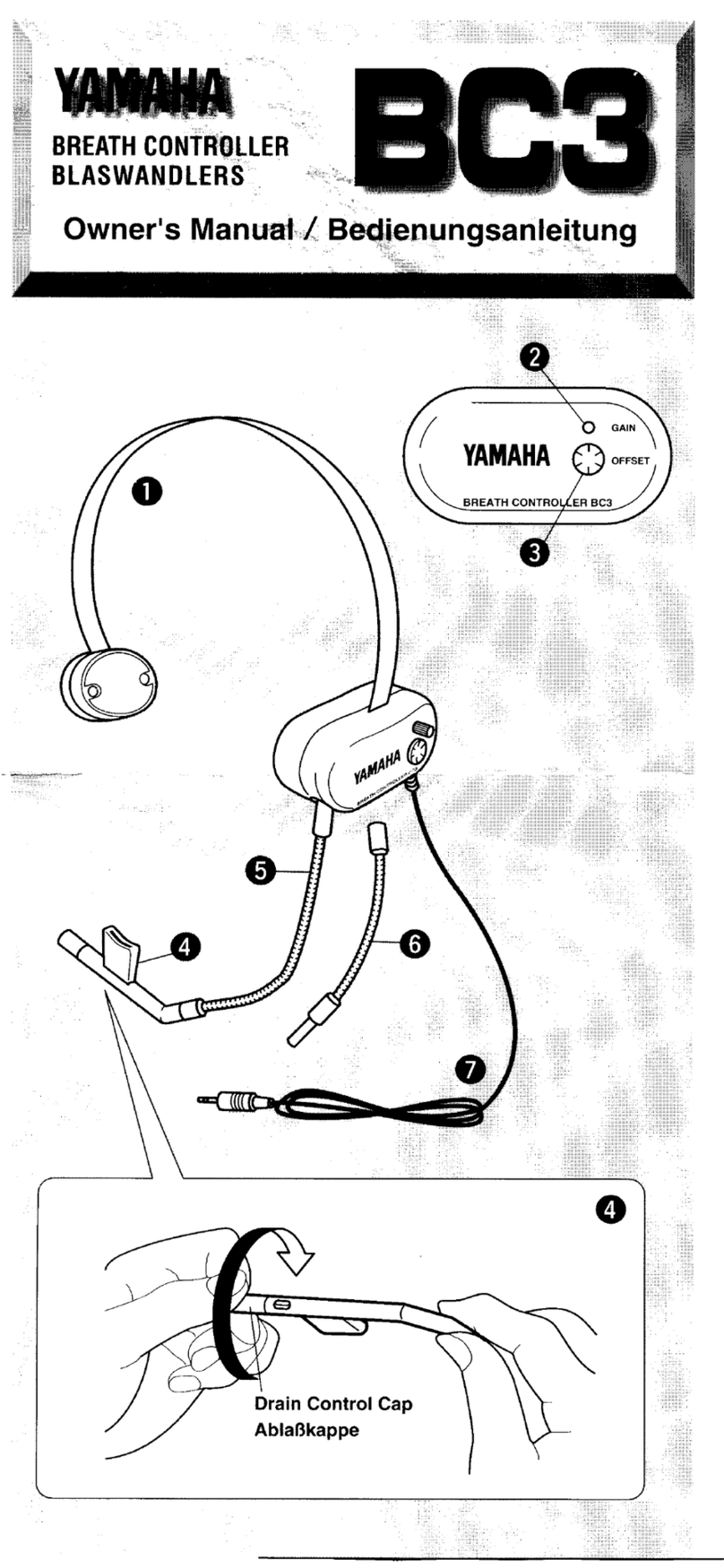

Front Panel

The front panel of the signal generator has the power on/off switch and 8 LED’s

which have the following functions:

Z

Y

X

A

LIMIT

ON

OFF

RXD TXD POWER

Limit - Turns red when any limit/input switch is open (using normally

closed switches).

X, Y, Z, Α- Turns green when the respective motor is stepping. Note that

the polarity of these lights will be reversed if the Park Signal is set to Low

in the Motor Signals setup screen.

RXD - Turns yellow when receiving data from the host PC.

TXD - Turns yellow when transmitting data to the host PC.

Power - Turns green when the power switch is turned on.

On/Off Switch - Turns the unit on and off. If there is ever a

communications error while running FlashCut CNC, turn the switch off and

on to reset the internal microprocessor.

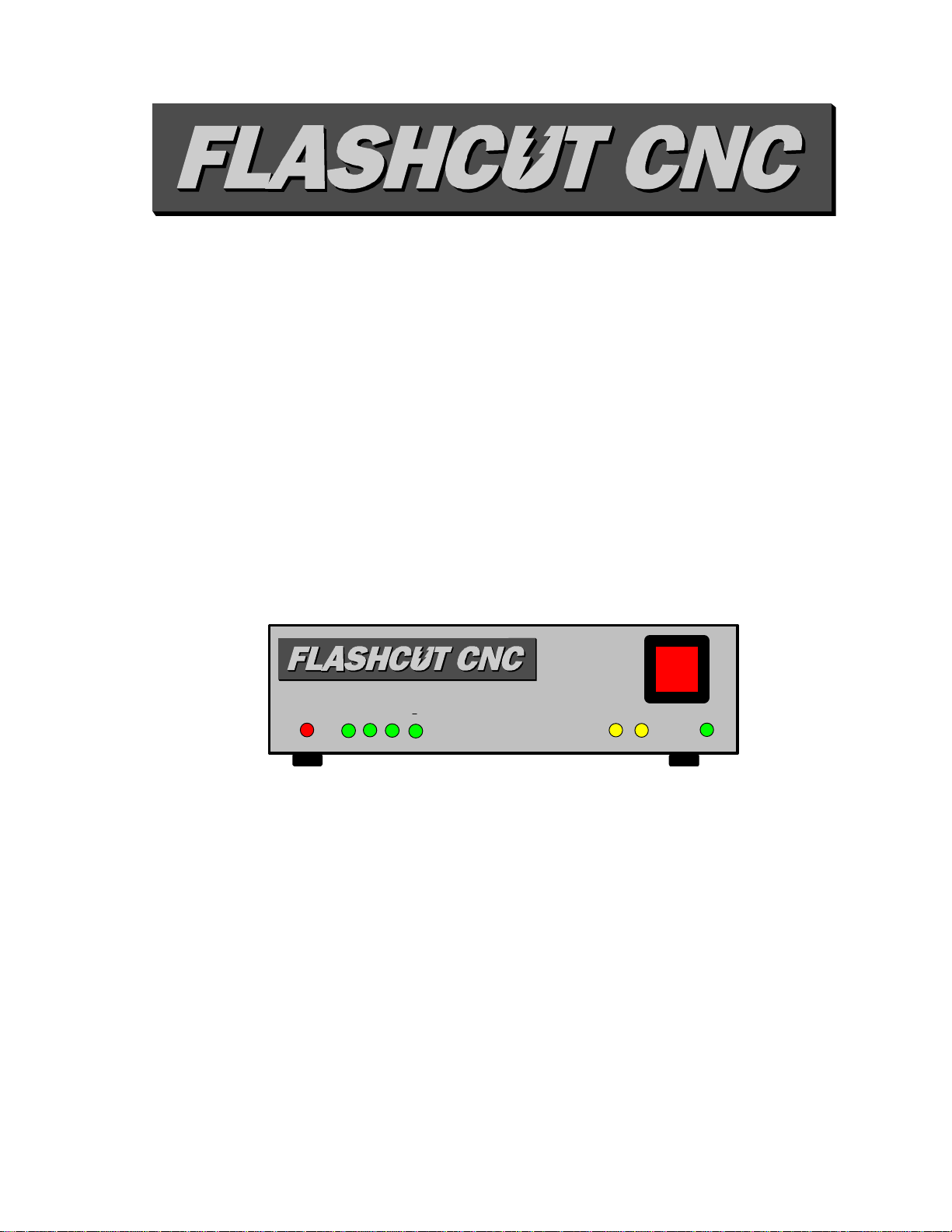

Rear Panel

The rear panel has connectors for input and output signals as described below.

Model No. 401A

S.N.__________

WPI

Menlo Park, CA

POWER

RS-232

INPUT

OUTPUT

MOTOR SIGNALS

FUSE

Section

FlashCut CNCFlashCut CNC SectionSection 22 Hardware GuideHardware Guide44

DC IN - Receptacle for the power supply. The unit is shipped with a 9V

DC, 800-1000mA wall transformer power supply.

Fuse - Cartridge for the fuse. If the fuse blows, replace it with a 3AG,

1.5A slow-blow fuse.

RS-232 - Serial port connector for communication with the host PC ( 9 pin

female). Most PC’s have 9 pin male or 25 pin male. Use either a 9 Pin

Male - 9 Pin Female or a 9 Pin Male - 25 Pin Female cable depending on

the serial port on your PC.

INPUT - The connector for up to 8 input lines. The most common use of

the input lines is for limit or safety switches. These lines are all TTL level

inputs. When a switch is open, its input signal is high (+5V). When the

switch is closed, its input signal is grounded low (0V).

The 401A is wired for normally closed (NC) switches. Each line that is not

connected to a switch must be wired directly to its ground. When any of

the input lines are open the red limit light will illuminate and a signal will be

sent to the host PC to indicate which input line(s) went high. You can use

normally open (NO) switches, however the red limit light will not function

properly. Note that all 8 input lines must be normally open, or all 8 input

lines must be normally closed. If you are not using the input lines, the limit

light will always be illuminated.

If you are using normally closed switches, make sure the Signal Generator

Model 401A option is chosen in the System Options setup screen. If you

are using normally open switches, make sure the Signal Generator Model

401 option is chosen in the System Options setup screen. All input lines

must be properly defined in the Input Lines Setup screen .

BE VERY CAREFUL WHEN DOING ANY WIRING. IMPROPER

WIRING WILL DAMAGE THE MOTOR SIGNAL GENERATOR.

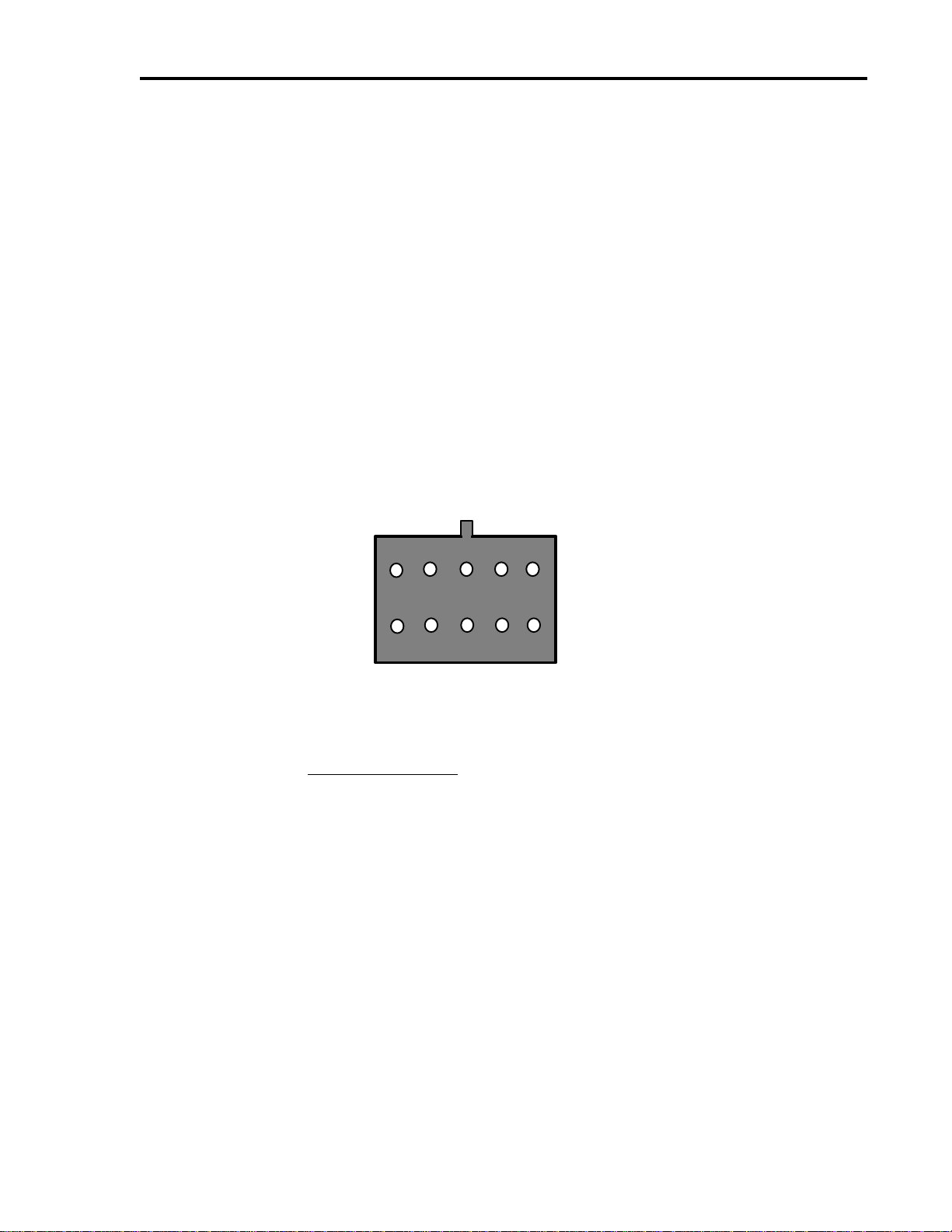

The receptacle that plugs into this connector is a Molex-Waldom Mini-Fit

Jr. Series 16 pin receptacle (part number 39-01-2160), with female pins

(part number 39-00-0039). The input lines as seen from the back of the

box are arranged as follows:

GGGG

GGGG

8642

7 5 3 1

OUTPUT - The connector for up to 8 output lines. These lines are all

optically isolated, TTL level outputs. Low is 0V and high is +5V.

FlashCut CNCFlashCut CNC SectionSection 22 Hardware GuideHardware Guide 55

Two input pins are provided for optical ground and optical +5V. You

must connect these pins to ground and +5V from an external power

supply for the output signals to operate. Note that these pins are

internally connected to the optical ground and optical +5V pins on the

motor signal connector. Therefore, if you are connecting a power

supply to the optical ground and optical +5V pins on the motor signal

connector, do not connect an external power supply here.

BE VERY CAREFUL WHEN DOING ANY WIRING. IMPROPER

WIRING WILL DAMAGE THE MOTOR SIGNAL GENERATOR.

The output lines are all initialized to low (0V) when you turn on the Motor

Signal Generator.

The receptacle that plugs into this connector is a Molex-Waldom Mini-Fit

Jr. Series 10 pin receptacle (part number 39-01-2100), with female pins

(part number 39-00-0039). The output lines as seen from the back of the

box are arranged as follows:

GND

+5V

8

6

42

7531

OPT

OPT

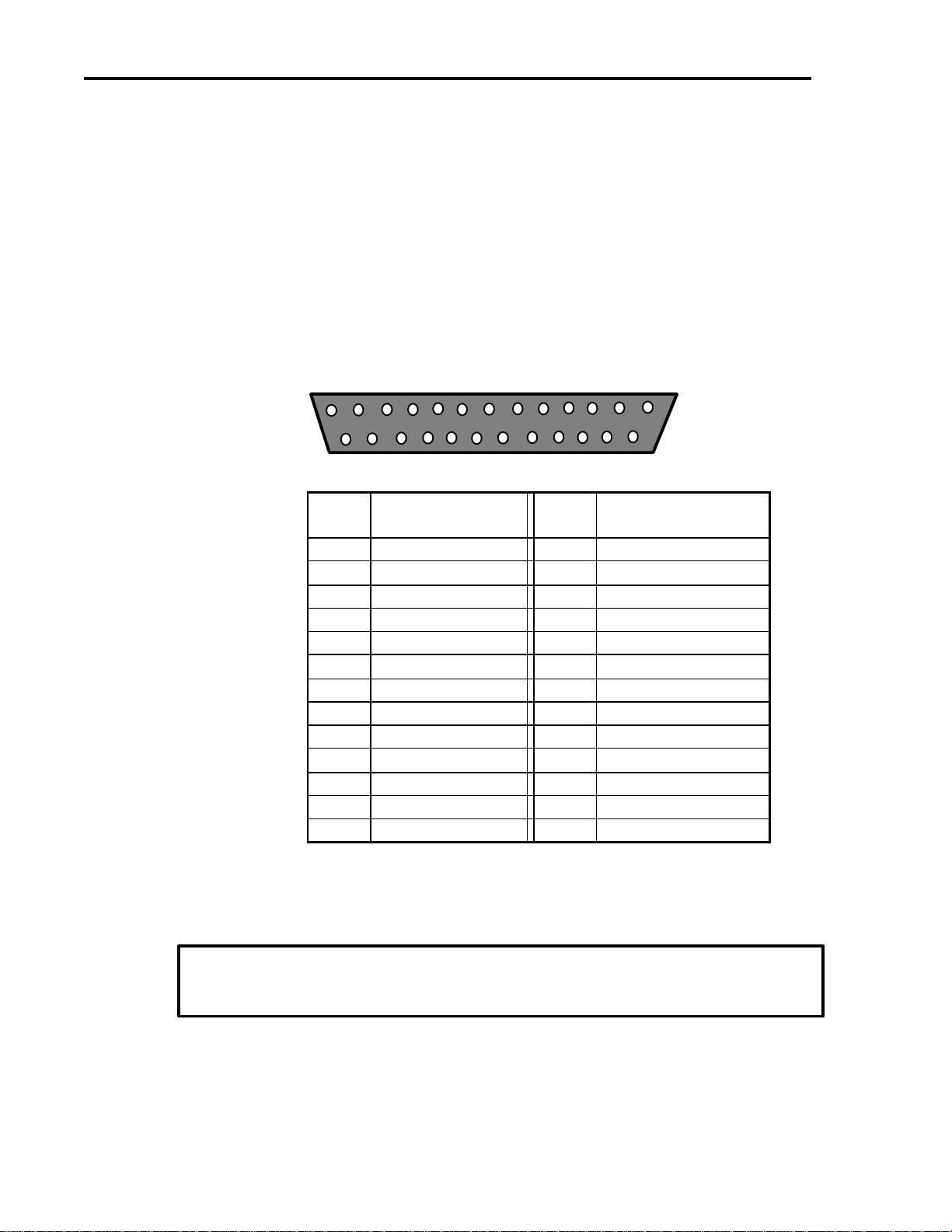

MOTOR SIGNALS - The DB-25 male connector for all signals going out

to the stepper motor driver(s). If you are using one of the FlashCut CNC

stepper motor drivers, connect this to the DB-25 female connector on the

stepper motor driver using a DB25 M-F interface cable.

The cable used must be a DB-25 Interface Cable with all 25-pins

wired straight through.

The motor signal lines are all optically isolated, TTL level outputs.

Two input pins are provided for optical ground and optical +5V. You

must connect these pins to ground and +5V from an external power

supply or the internal power supply for the output signals to operate.

Note that these pins are internally connected to the optical ground

and optical +5V pins on the 10-pin output connector. Therefore, if

you are connecting an external power supply to the optical ground

and optical +5V pins on the 10-pin output connector, do not connect

an external power supply here.

FlashCut CNCFlashCut CNC SectionSection 22 Hardware GuideHardware Guide66

BE VERY CAREFUL WHEN DOING ANY WIRING. IMPROPER

WIRING WILL DAMAGE THE MOTOR SIGNAL GENERATOR.

Two pins are directly connected to ground and +5V from the internal

power supply. These are provided for convenience as a source for the

optical ground and optical +5V if there is no external power source

available. Using the internal supply to power the optical isolators will

negate most of the isolation provided by the optical isolators. To use the

internal supply, directly connect DB-25 pin 24 to 25 and pin 22 to 23.

The motor signal lines as seen from the back of the box are arranged as

follows:

113

14 25

DB25

Pin Signal DB25

Pin Signal

1NC 14 ENABLE ALL

2NC 15 θPARK

3NC 16 Z PARK

4NC 17 Y PARK

5NC 18 X PARK

6NC 19 θDIRECTION

7NC 20 Z DIRECTION

8NC 21 Y DIRECTION

9X DIRECTION 22 Internal VCC +5V

10 θSTEP 23 OPT VCC (INPUT)

11 Z STEP 24 Internal GND

12 Y STEP 25 OPT GND (INPUT)

13 X STEP

Turning off the Controller

Always turn off the motor signal generator when it is not in

use.

Other manuals for 401A

1

Table of contents