4

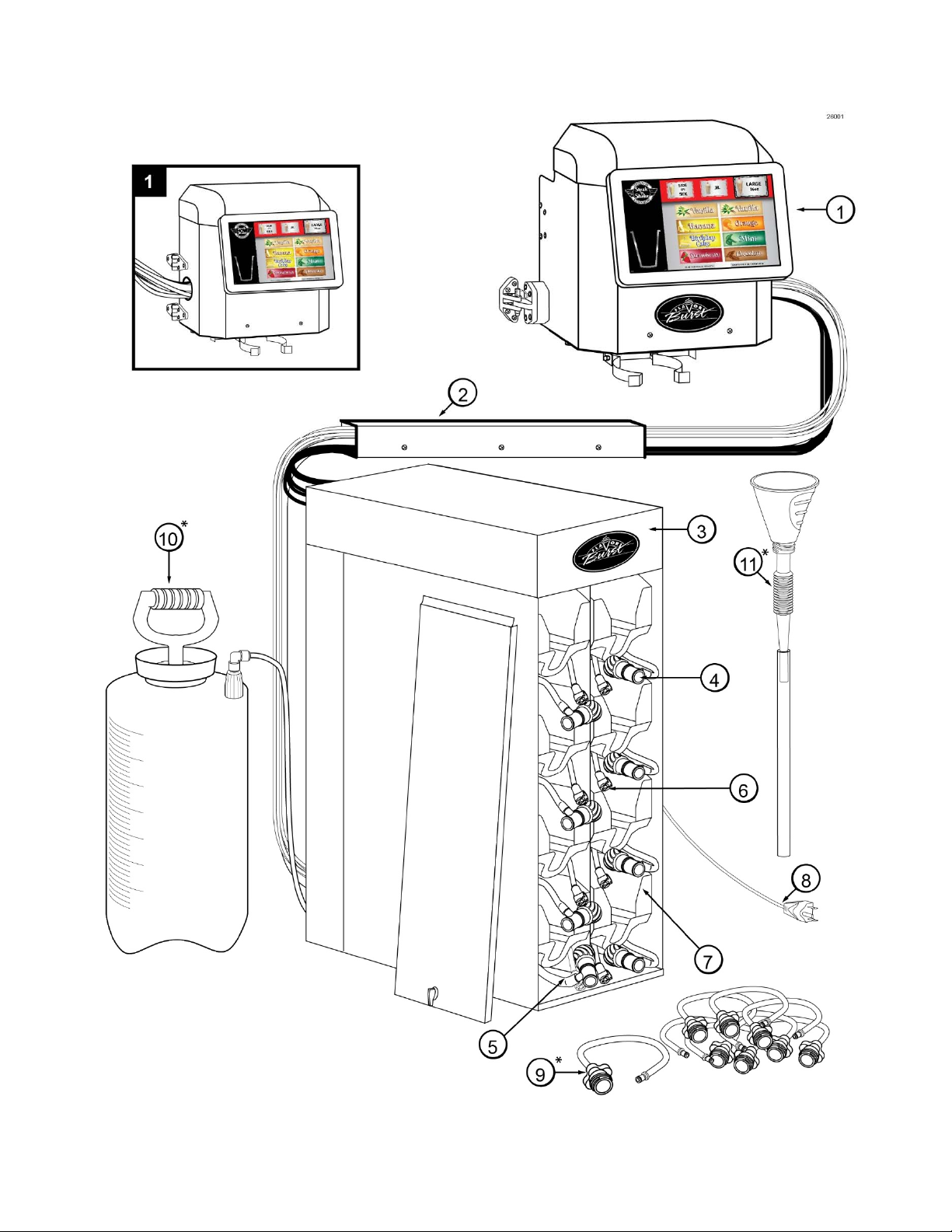

Congratulations on your Flavor Burst series

flavoring system! As a food and beverage

provider, your customers are your greatest

asset. Your primary concern must be the

health and welfare of your customers. This

manual provides everyday operating guidelines

and procedures. Special functions have been

incorporated into the equipment to provide

simple and effective cleaning and sanitizing of

your unit. We urge you to follow these

instructions carefully and maintain strict sanitary

practices in your daily operating routine.

The SNS series system is an add-on flavoring

system compatible with a specific ice cream

freezer. It is designed to dispense concentrated

flavorings next to the ice cream product as it is

dispensed. Dispensing a serving using the

Flavor Burst system is very simple. Simply

place the cup into the cup holder, select a size

and flavor from the Touch Panel, and touch the

dispense button on the screen. The Flavor

Burst system will signal the freezer to dispense

ice cream product as it is dispensing the syrup

at the same time.

Flavor Burst® compatible syrup is stored within

the equipment cabinet in 1 gallon disposable

bags. Proper syrup dispense rate is maintained

by adjusting the flavor level on the Touch

Panel. See the Color Touch Panel Manual for

instructions and features related to the Panel.

Components of the Flavor Burst system should

be cleaned daily to ensure the highest standard

of sanitation. When your equipment is

delivered or if it has been unused for more than

24 hours, follow the DAILY OPENING

PROCEDURES.

The CTP 80SNS-R system attaches to the right

side of the freezer, while the CTP 80SNS-L is

designed to attach to the left side. When used

together, they share the same sanitizer tank,

flush adapters, and funnel. Additional hardware

may be included with the CTP 80SNS-L

system.

NOTE: EQUIPMENT AND PRODUCT

IMAGES IN THIS MANUAL MAY DIFFER

SLIGHTLY FROM YOUR CURRENT SETUP.

Always follow these safety precautions when

operating the Flavor Burst® system:

DO NOT operate the system without

reading this operator’s manual. Failure to follow

this instruction may result in equipment

damage, poor system performance, health

hazards, or personal injury.

DO NOT operate the system unless it is

properly grounded. Failure to follow this

instruction may result in electrocution.

DO NOT operate the system with larger

fuses than specified on the system data label.

Failure to follow this instruction may result in

electrocution or damage to the machine.

Consult your electrician.

DO NOT put objects or fingers near the

door spout area. Failure to follow this instruction

may result in contaminated product or personal

injury from blade contact.

The Flavor Burst cabinet system must be

placed on a level surface capable of supporting

at least 220 lbs of weight. Failure to comply

may result in personal injury or equipment

damage.

DO NOT place more than 25 lbs of

weight on top of the FB 80M cabinet. Failure to

comply may result in personal injury or

equipment damage.

Operate unit under normal ambient

temperatures between 60 and 80 degrees

Fahrenheit. Unit should never be exposed to

freezing temperatures.

INTRODUCTION

INTRODUCTION SAFETY PRECAUTIONS