Read, understand, and follow all safety information contained in these instructions prior to installation and use of the CFSM1254 water softener. Retain these

instructions for future reference. Failure to follow installation, operation and maintenance instructions may result in property damage and will void warranty.

Intended use:

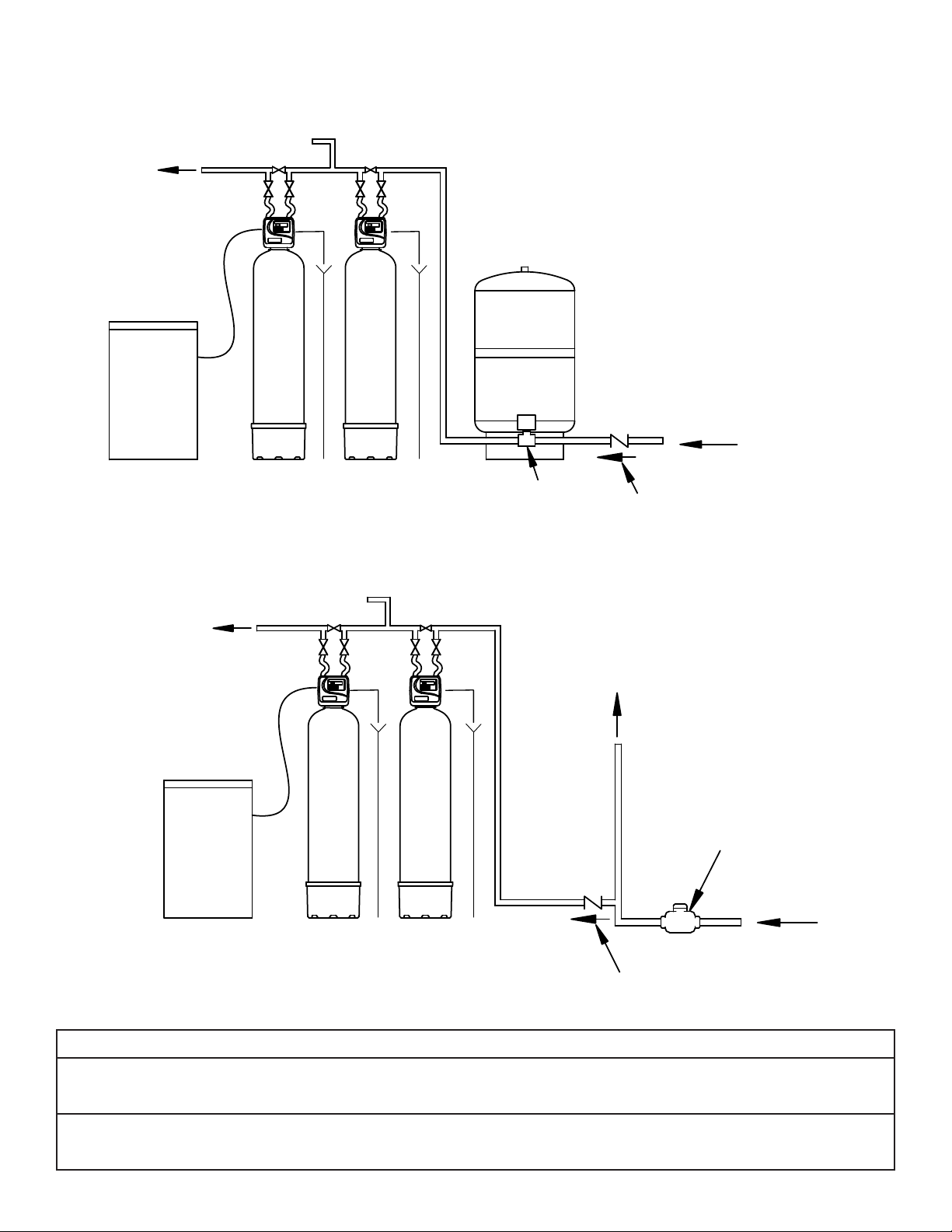

The CFSM1254 water softener is intended for use in softening water in foodservice establishments and has not been evaluated for other uses. The system

must be installed indoors near the point of use, and be installed by qualified professional installers according to these installation instructions.

EXPLANATION OF SIGNAL WORD CONSEQUENCES

WARNING Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury and/or property damage.

CAUTION Indicates a potentially hazardous situation, which, if not avoided, may result in minor or moderate injury and/or property damage.

CAUTION Indicates a potentially hazardous situation, which, if not avoided, may result in property damage.

WARNING

To reduce the risk associated with choking:

•Do not allow children under 3 years of age to have access to small parts during the installation of this product.

To reduce the risk associated with ingestion of contaminants:

•Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

• Before using, flush any new water treatment system with water according to the installation instructions.

To reduce the risk of physical injury:

• Shut o inlet water supply and depressurize system as shown in manual prior to service.

To reduce the risk associated with a hazardous voltage:

• If the electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a sucient ground connection across the

water softener installation piping — refer installation to qualified personnel.

•Do not use the system if the power cord is damaged — contact qualified service personnel for repair.

To reduce the risk associated with back strain due to the heavy weight of the various system components:

• Follow safe lifting procedures.

CAUTION

To reduce the risk associated skin, eye, and respiratory tract irritation from gravel and filter media during installation:

• Gravel and several types of filter media may be used in this product, depending upon the application. During installation, dust may cause irritation to skin, eyes, and

respiratory tract.

• Utilize a NIOSH-approved dust filter mask, protective gloves, and appropriate eye protection when handling and pouring gravel and filter media.

• To request an MSDS relating to the media shipped with this product, call 203-238-8965 or go to www.3M.com, select country, and use the search engine to search

MSDS. For emergencies, call 800-364-3577 or 651-737-6501 (24 hours).

CAUTION

To reduce the risk associated with property damage due to water leakage:

•Read and follow Use instructions before installation and use of this water treatment system.

• Installation and use MUST comply with existing state or local plumbing codes.

•Protect from freezing, relieve pressure and drain system when temperatures are expected to drop below 40°F (4°C).

•Do not install on hot water supply lines. The maximum operating water temperature of this water softener is 110°F (43°C).

•Do not install systems in areas where ambient temperatures may go above 110°F (43.3°C) or below 40°F (4.4°C).

•Do not install if water pressure exceeds 125 psi. If your water pressure exceeds 80 psi (552 kPa), you must install a pressure limiting valve. Contact a plumbing

professional if you are uncertain how to check your water pressure.

•Do not install where water hammer conditions may occur. If water hammer conditions exist you must install a water hammer arrester. Contact a plumbing profes-

sional if you are uncertain how to check for this condition.

• Where a backflow prevention device is installed on a water system, a device for controlling pressure due to thermal expansion must be installed.

•Do not use a torch or other high temperature sources near system.

• On plastic fittings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may deteriorate plastic.

• Take care when using pliers or pipe wrenches to tighten plastic fittings, as damage may occur if over tightening occurs.

•Do not install in direct sunlight or outdoors.

• Install system in such a position as to prevent it from being struck by other items used in the area of installation.

• Ensure all tubing and fittings are secure and free of leaks.

•SHUT OFF FUEL OR ELECTRIC POWER SUPPLY TO WATER HEATER after water is shut o.

•Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum prevention.

•Do not apply heat to any fitting connected to bypass or control valve as damage may result to internal parts or connecting adapters.

• Install on a flat/level surface. It is also advisable to sweep the floor to eliminate objects that could pierce the brine tank.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water flow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

IMPORTANT NOTES

• Failure to follow instructions will void warranty.

SAFETY INFORMATION