Fleck 5600SE User manual

IMPORTANT: Fill in pertinent information on page 2 for future reference.

MODEL 5600SE

Upflow Brining

Service Manual

MODEL 5600SE Upflow

Job Specification Sheet

Printed in U.S.A.

Job Number ____________________________________________________________

Model Number __________________________________________________________

Water Test______________________________________________________________

Capacity Of Unit__________________________Ma ._______________________Per Regeneration

Mineral Tank Size: Diameter _________________________Height _________________________________

Under Bedding ____________________________ Amount______________________________________

Type Of Media ____________________________ Cubic Feet __________________________________

Brine Tank Size ________________________________________________________________________

Salt Setting Per Regeneration _____________________________________________________________

Page 2

Valve Programming

Treated Water Capacity ______________________________ (Gallons / Liters)

Regeneration Day Override _______________________________ (Ma . Days Between Regen.)

Regeneration Time ________________________________ ( A.M. ) ( P.M. )

Notes:

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

Printed in U.S.A.

Page 3

MODEL 5600SE Upflow

General Residential Installation Check List

WAT R PR SSUR : A minimum of 25 pounds of water pressure is required for regeneration valve to operate

effectively.

L CTRICAL FACILITI S: An uninterrupted alternating current (A/C) supply is required. Please make sure your

voltage supply is compatible with your unit before installation.

XISTING PLUMBING: Condition of e isting plumbing should be free from lime and iron buildup. Piping that is built up

heavily with lime and/or iron should be replaced. If piping is clogged with iron, a separate iron filter unit should be

installed ahead of the water softener.

LOCATION OF SOFT N R AND DRAIN: The softener should be located close to a clean working drain and

connected according to local plumbing codes.

BY-PASS VALV S: Always provide for the installation of a by-pass valve if unit is not equipped with one.

CAUTION: Water pressure is not to e ceed 120 p.s.i., water temperature is not to e ceed 110°F, and the unit cannot be

subjected to freezing conditions.

alve Installation and Start-up Procedures

1. Place the softener tank where you want to install the unit, making sure the tank is level and on a firm base.

2. During cold weather it is recommended that the installer warm the valve up to room temperature before operating.

3. All plumbing should be done in accordance with local plumbing codes. The pipe size for the drain should be a

minimum of 1/2 ″. Backwash flow rates in e cess of 7 gpm or length in e cess of 20′ require 3/4″ drain line.

4. The 1″ distributor tube (1.050 O.D.) should be cut 2.0″ below the top of each tank. Note: Only use silicone lubricant.

5. Lubricate the distributor o-ring seal and tank O-ring seal. Place the main control valve on tank.

6. Solder joints near the drain must be done prior to connecting the Drain Line Flow Control fitting (DLFC). Leave at

least 6″ between the DLFC and solder joints when soldering pipes that are connected on the DLFC. Failure to do

this could cause interior damage to DLFC.

7. Teflon tape is the only sealant to be used on the drain fitting.

8. Make sure that the floor is clean beneath the salt storage tank and that it is level.

9. Place appro imately 1″ of water above the grid plate. If a grid is not utilized, fill to the top of the air check in the salt

tank. Do not add salt to the brine tank at this time.

10. On units with a by-pass, place in by-pass position. Turn on the main water supply. Open a cold soft water tap

nearby and let run a few minutes or until the system is free from foreign material (usually solder) that may have

resulted from the installation. Once clean, close the water tap.

11. Place the by-pass in service position and let water flow into the mineral tank. When water flow stops, slowly open a

cold water tap nearby and let run until the air is purged from the unit. Then close tap.

12. Plug the valve into an approved power source. Once the valve is powered it will drive to the Service Position.

Page 4

Printed in U.S.A.

MODEL 5600SE Upflow

Control Start-up Procedures

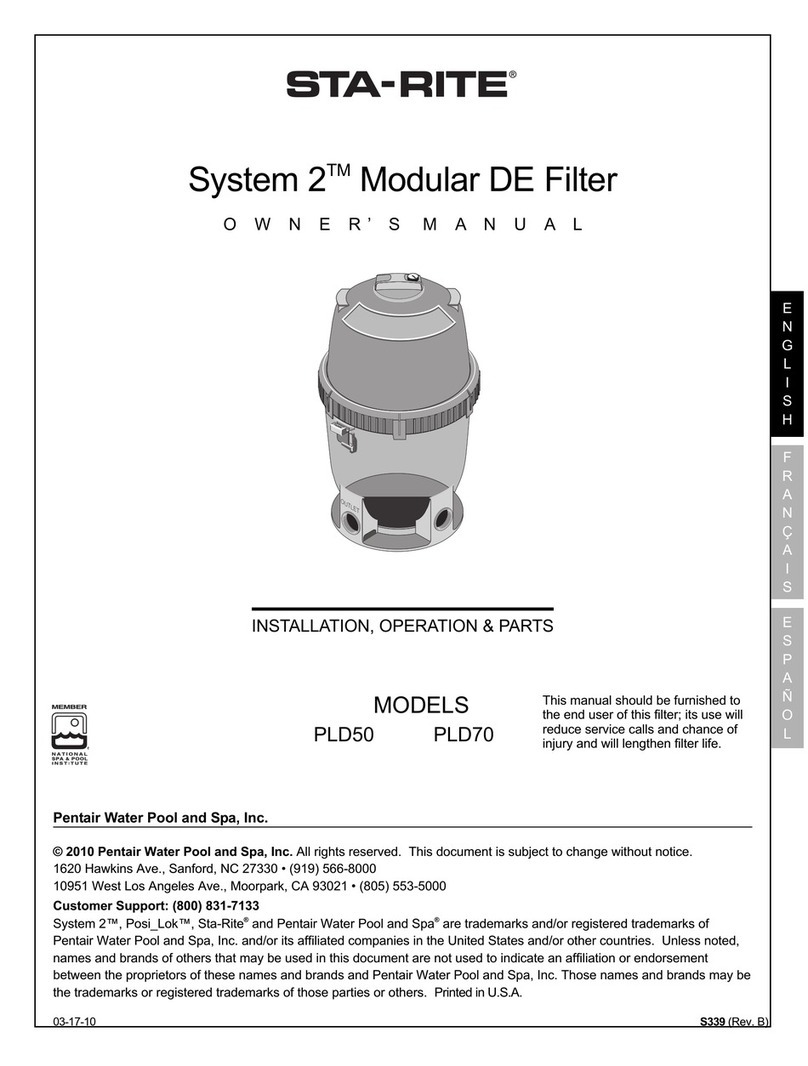

Whenever the valve is in

Service

the current time of day can be set, the control programmed, or an

e tra regeneration initiated at any time.

Push either the Up or Down Set Button once to adjust Time Of Day Display by one digit.

Push and hold either Up or Down Set Button to adjust Time Of Day Display by several digits.

1.

Set Time Of Day

1. Push and hold for 5 seconds

both

the Up and down Set Buttons to enter Programming

Mode.

2. Push the E tra

Cycle Button

once per display until all have been viewed and this mode is

e ited and normal operation is resumed.

2. nter Control Programming Mode

Printed in U.S.A.

Page 5

MODEL 5600SE Upflow

Control Start-up Procedures (Cont’d.)

Depending on current control programming, option setting displays that are not required to be set will not be

viewed.

3. Push the E tra Cycle Button. The third option setting display that appears is Regeneration

Day Override. Using the Set Up or Down Buttons, set the ma imum number of days before

a regeneration cycle must occur. For E ample:

4. Control programming is now complete. Push the E tra Cycle Button. This will e it the

control from the Programming Mode, and resume Normal Operation.

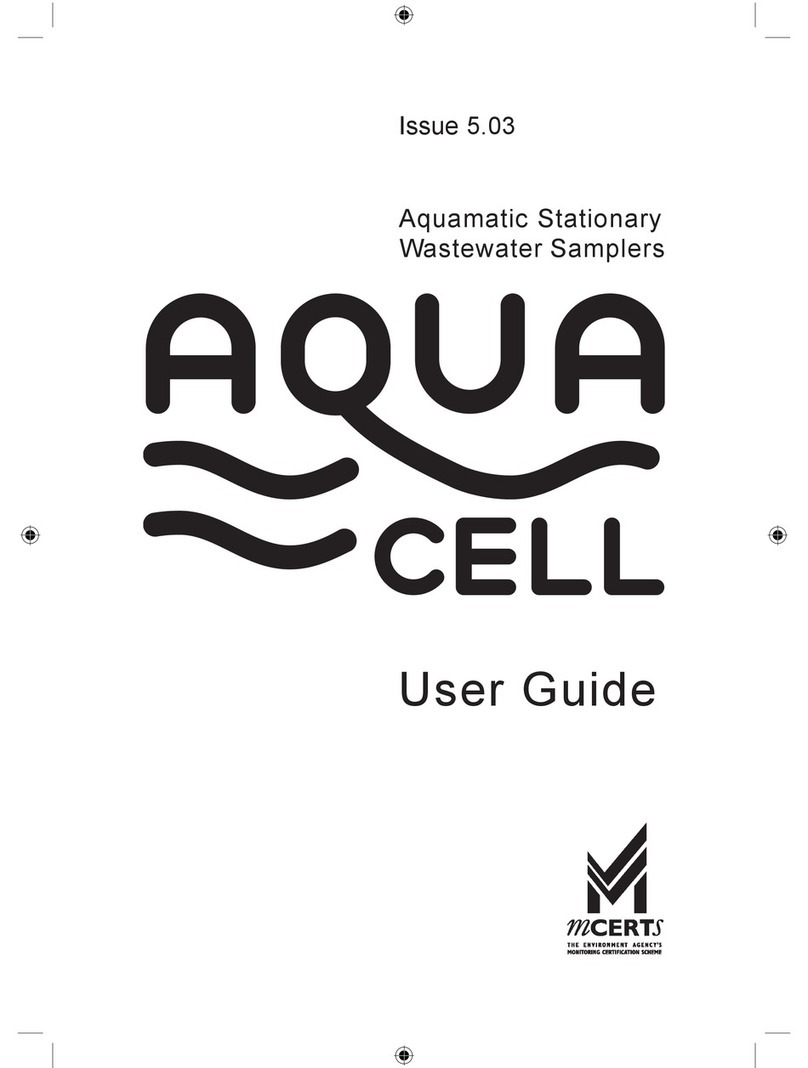

1. The first option setting display that appears in the Program Mode is Treated Water

Capacity. Using the Set Up or Down Buttons, set the amount of treated water that can flow

through the unit before a regeneration is required. For E ample:

2. Push the E tra Cycle Button. The second option setting display that appears is

Regeneration time. Using the Set Up or Down Buttons, set the desired time of day when a

regeneration can occur, if required. For E ample:

3. Set Control Programming

Page 6

Printed in U.S.A.

MODEL 5600SE Upflow

Control Start-up Procedures (Cont’d.)

When starting an E tra Cycle, you will have one or two options:

1. Press and Release the xtra Cycle Button:

-With

Immediate Regeneration

controls the control will go into regeneration cycle immediately.

-With

Delayed Regeneration

controls the Service Arrow will begin to flash immediately and a regeneration

will occur at the present regeneration time (i.e. 2:00 a.m.)

2. Press and Hold for 5 seconds the xtra Cycle Button:

- With Delayed Regeneration controls this will force the control to go into regeneration cycle immediately.

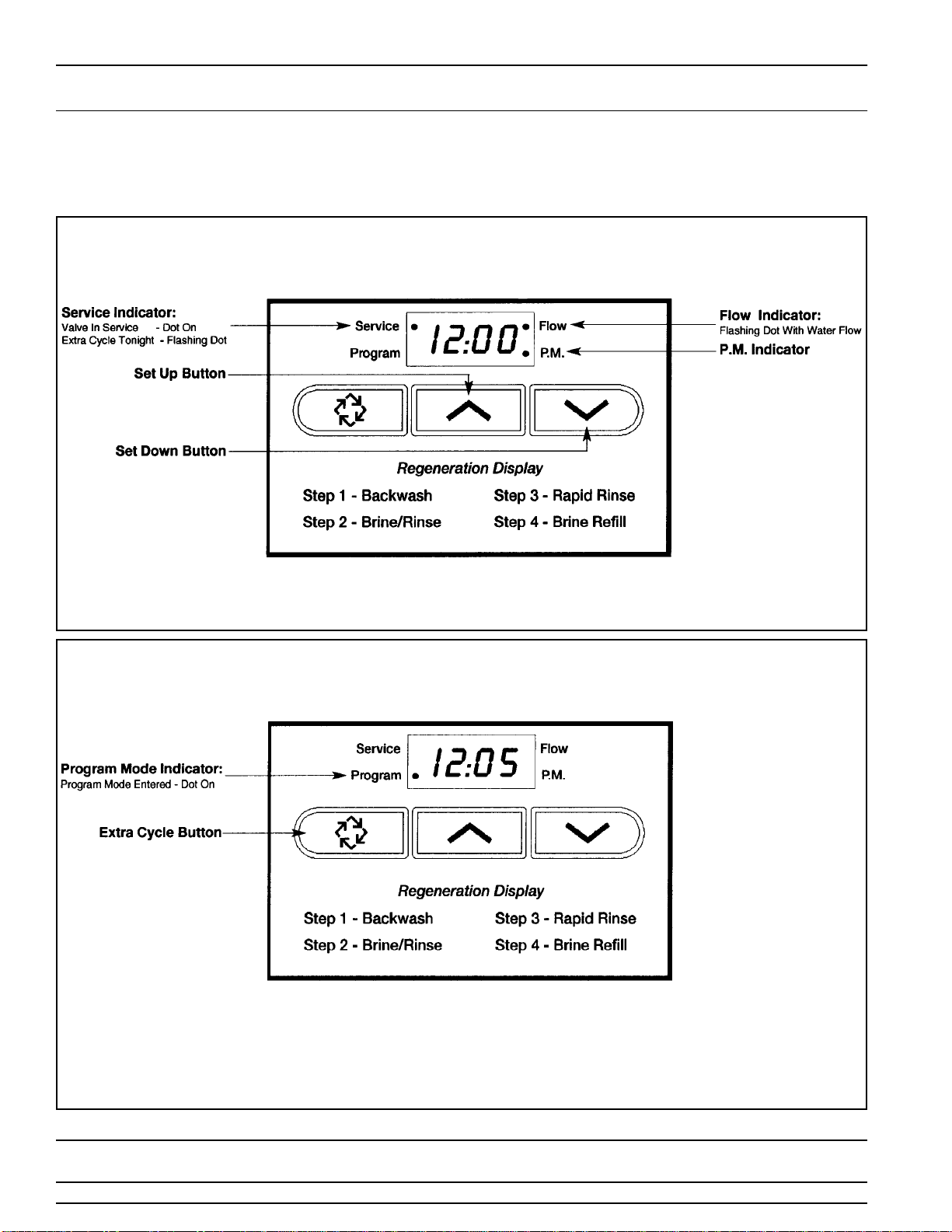

The following series of displays appear when the control enters a regeneration cycle:

4. Start An Immediate xtra Cycle

5. Regeneration Cycle Displays

Printed in U.S.A.

Page 7

MODEL 5600SE Upflow

Control Start-up Procedures (Cont’d.)

A. Once the valve reaches Regen Step #1 let water run to drain for about 5 minutes.

Ne t, manually step the valve through a regeneration cycle checking valve operation

in each step:

B. Push the E tra Cycle Button once to advance the valve to Regen Step #2.

C. Push the E tra Cycle Button once to advance the valve to Regen Step #3. (Optional)

D. Push the E tra Cycle Button once to advance the valve to Regen Step #4. (Optional)

With proper valve operation verified:

A. Add water to the top of the air check. Manually step the valve to the Brine Draw Position

and allow the valve to draw water from the brine tank until it stops. Note: The air check will

check at appro imately the midpoint of the screened intake area.

B. Ne t, manually step the valve to the Brine Refill Position and allow the valve to return to

Service automatically.

C. With the valve in Service, check that there is about 1.0″ of water above the grid in the brine

tank, if used.

D. Fill the brine tank with salt.

E. Set-Up is now finished, the control can now be left to run automatically.

6. Fast Cycle Valve Thru Regeneration

7. Final Set-Up

Page 8

Printed in U.S.A.

MODEL 5600SE Upflow

Control Operation

Timeclock Regeneration Valves

In normal operation the Time Of Day Display will be viewed at all times. The control will operate normally until the

number of days since the last regeneration reaches the Regeneration Day Override setting. Once this occurs, a

regeneration cycle will then be initiated at the preset Regeneration Time.

Flow Meter quipped Valves

In normal operation the Time Of Day Display will alternate being viewed with a Volume Remaining Display. This display

will be in gallons. As treated water is used, the Volume Remaining Display will count down from a ma imum value to

zero or (----). Once this occurs a regeneration cycle will then be initiated immediately or delayed to the set

Regeneration Time. Water flow through the valve is indicated by the Flow Dot that will flash in a direct relationship to

flow rate. For E ample:

Immediate Regeneration Valves With Days Between Regeneration Override Set

When the valve reaches its set Days Since Regeneration Override value a regeneration cycle will be initiated

immediately. This event occurs regardless of the Volume Remaining display having reached zero gallons.

Delayed Regeneration Valves With Days Between Regeneration Override Set

When the valve reaches its set Days Since Regeneration Override value a regeneration cycle will be initiated at the

preset Regeneration Time. This event occurs regardless of the Volume Remaining display having reached zero gallons.

Control Operation During Regeneration

In Regeneration the control will display a special

Regeneration Display.

In this display the control will show the current

regeneration step number the valve is advancing to, or has reached, and the time remaining in that step. The step

number displayed will flash until the valve has completed driving to this regeneration step position. Once all

regeneration steps have been completed the valve will return to Service and resume normal operation. For E ample:

Pushing the E tra Cycle Button during a regeneration cycle will immediately advance the valve to the ne t cycle step

position and resume normal step timing.

Control Operation During Programming

The control will only enter the Program Mode with the valve in Service. While in the Program Mode the control will

continue to operate normally monitoring water usage and keeping all displays up to date. Control programming is

stored in memory permanently. There is no need for battery backup power.

Control Operation During A Power Failure

During a power failure all control displays and programming will be stored for use upon power re-application.

The

control will retain these values for years, if necessary, without loss.

The control will be fully inoperative and any calls for

regeneration will be delayed. The control will upon power re-application resume normal operation from the point were it

was interrupted.

An indication that a power outage has occurred will be an inaccurate time of day display

.

Printed in U.S.A.

Page 9

MODEL 5600SE Upflow

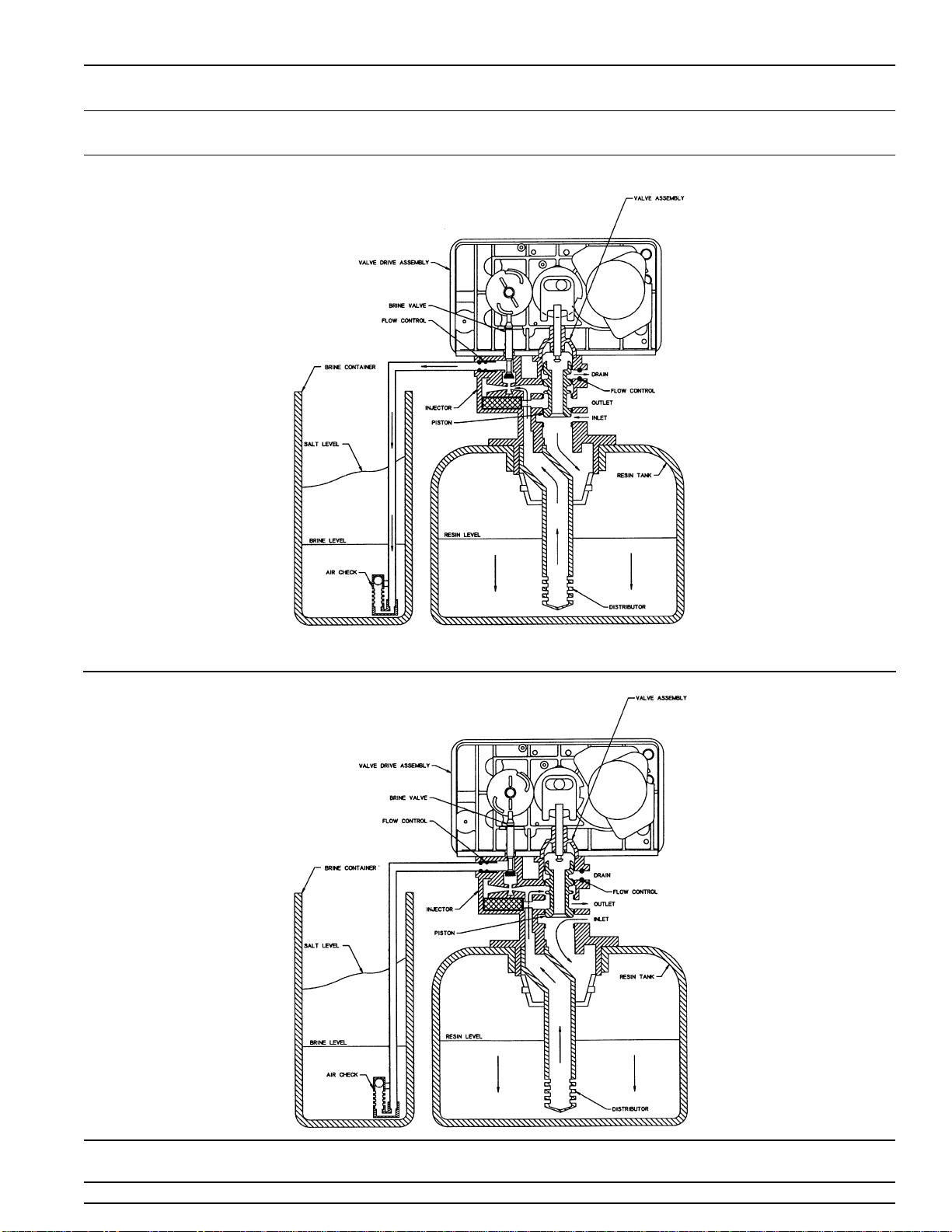

Water Conditioner Flow Diagrams (Upflow Brining)

Using Yellow Cycle Cam (Part No. 24598)

Service

Position

Backwash

Position

(Regeneration Cycle Step #1)

Page 10

Printed in U.S.A.

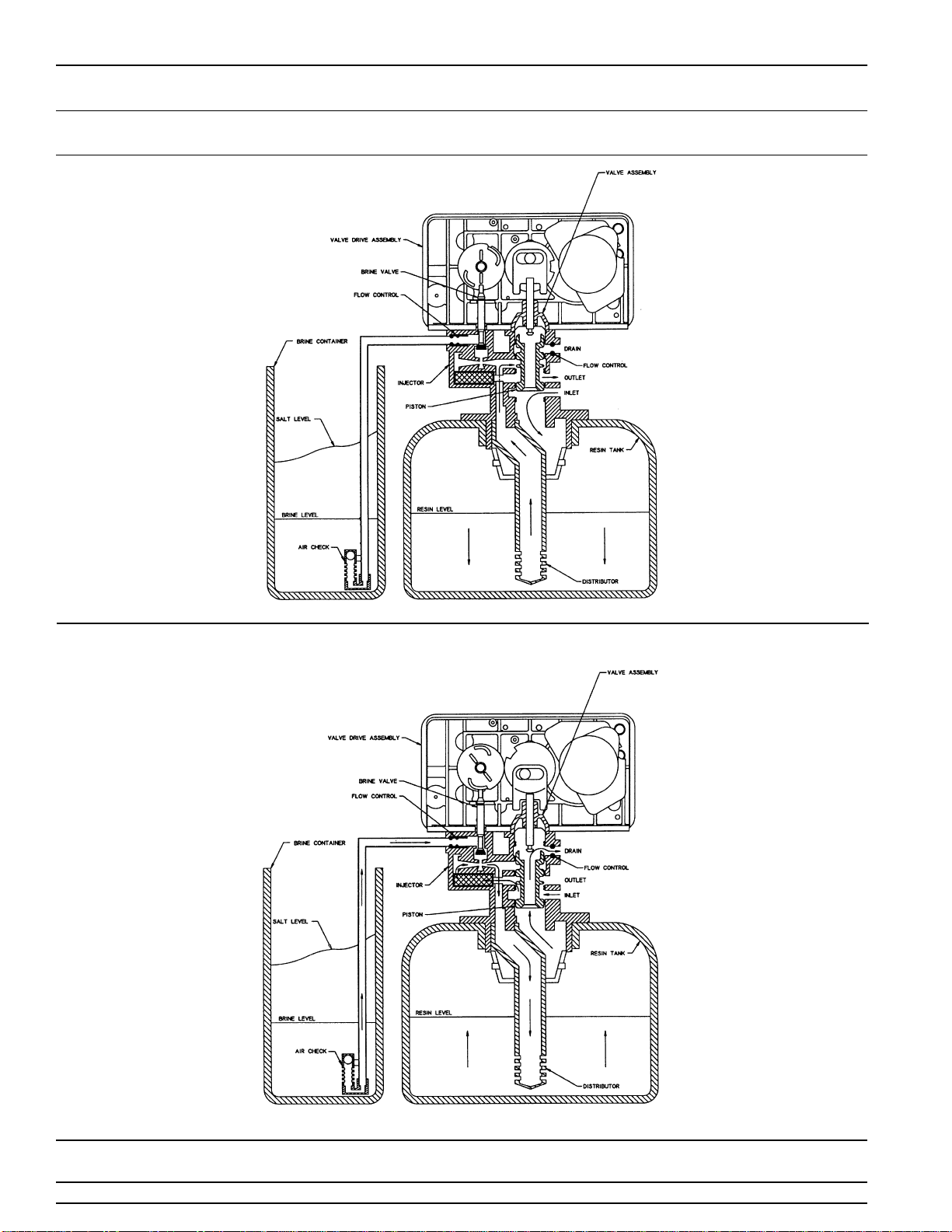

MODEL 5600SE Upflow

Water Conditioner Flow Diagrams (Upflow Brining)

Using Yellow Cycle Cam (Part No. 24598) (Cont’d.)

(Regeneration Cycle Step #2)

Brine/Slow Rinse

Position

Rapid Rinse

Position

(Regeneration Cycle Step #3)

Printed in U.S.A.

Page 11

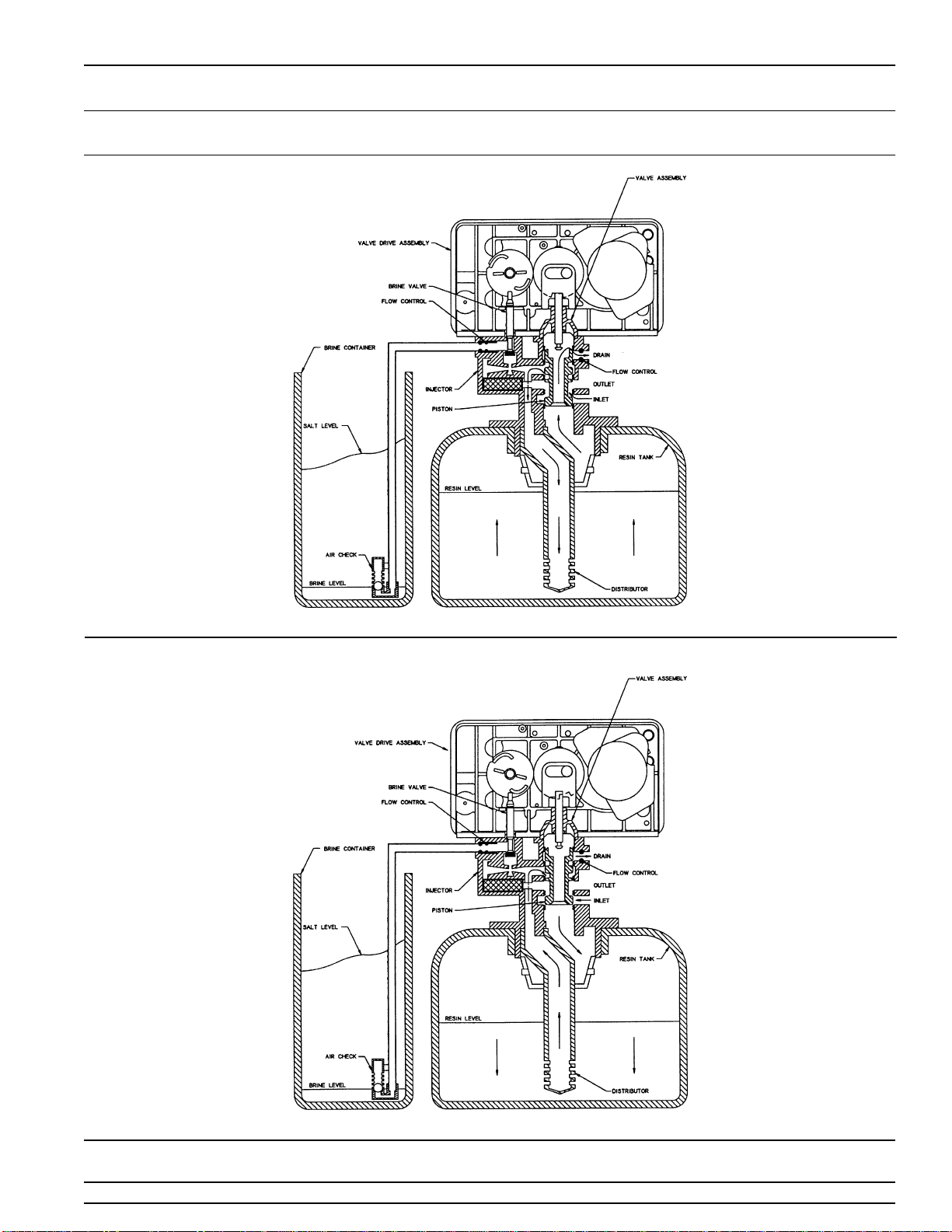

MODEL 5600SE Upflow

Water Conditioner Flow Diagrams (Upflow Brining)

Using Yellow Cycle Cam (Part No. 24598) (Cont’d.)

(Regeneration Cycle Step #4)

Brine Tank

Fill Position

Service

Position

Page 12

Printed in U.S.A.

MODEL 5600SE Upflow

Water Conditioner Flow Diagrams (Upflow Brining)

Using Red Cycle Cam (Part No. 17885)

Service

Position

Brine/Slow Rinse

Position

(Regeneration Cycle Step #1)

Printed in U.S.A.

Page 13

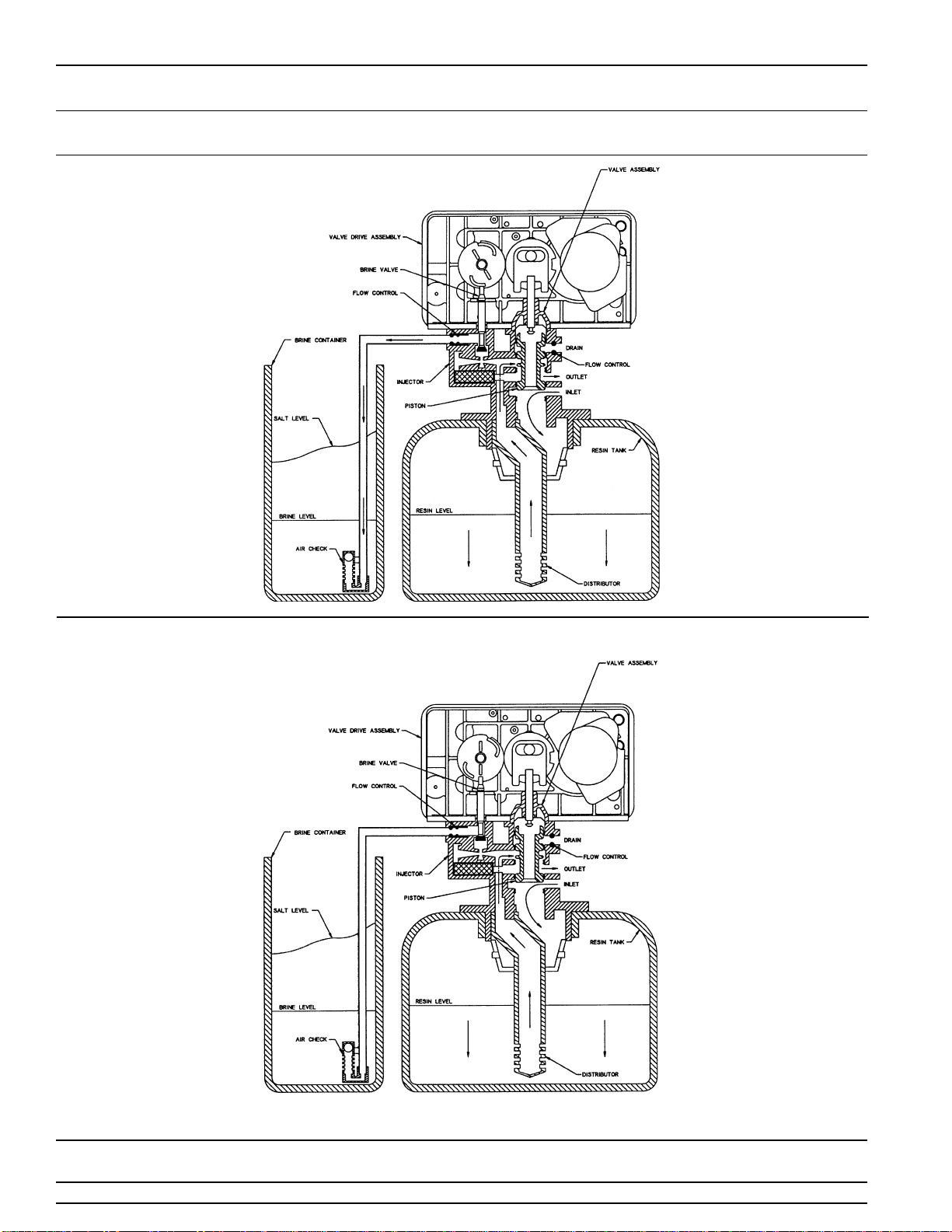

MODEL 5600SE Upflow

Water Conditioner Flow Diagrams (Upflow Brining)

Using Red Cycle Cam (Part No. 17885)

Backwash

Position

(Regeneration Cycle Step #2)

Rapid Rinse

Position

(Regeneration Cycle Step #3)

Page 14

Printed in U.S.A.

MODEL 5600SE Upflow

Water Conditioner Flow Diagrams (Upflow Brining)

Using Red Cycle Cam (Part No. 17885)

Brine TankFill

Position

(Regeneration Cycle Step #4)

Service

Position

Printed in U.S.A.

Page 15

MODEL 5600SE Upflow

alve Wiring Diagram

CB1 - 5600SE Circuit Board

VDM - Valve Drive Motor

EM - Electronic Flow Meter (Optional)

SW1 - Homing Switch

SW2 - Step Switch

HCAM - Homing Cam

UFSCAM - Upflow Step Cam

Page 16

Printed in U.S.A.

MODEL 5600SE Upflow

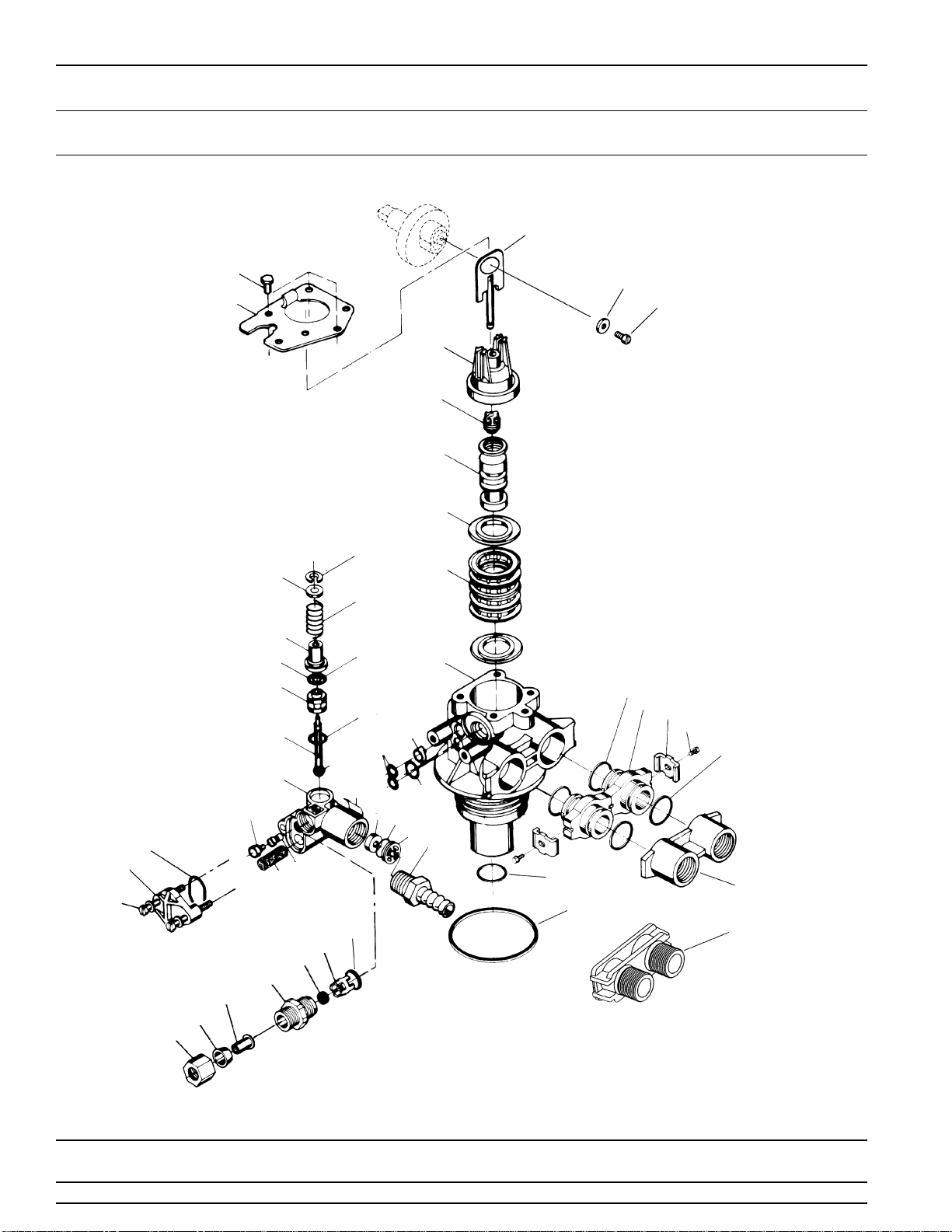

Control alve Assembly

(See opposite page for parts list)

61

60

1

2

3

4

7

6

5

11

12

13

14

18

17

16

15

10

22

23

24

28

26

25

20

29

31

39

41

42

43

44

48 47 46 45

49

51

52

53

54

5857 56

55

59

40 54B

58

17

50

Printed in U.S.A.

Page 17

Item No. Quantity Part No. Description

1. . . . . . . . . . . . 1 . . . . . . . . . . . . .61400-31 . . . . . . . . . . . . . . . Valve Body, Up-Flow 13/16″ Distributor

1 . . . . . . . . . . . . .61400-32 . . . . . . . . . . . . . . . Valve Body, Up-Flow 1″ Distributor

2. . . . . . . . . . . . 4 . . . . . . . . . . . . .14241. . . . . . . . . . . . . . . . . . Spacer

3. . . . . . . . . . . . 5 . . . . . . . . . . . . .13242. . . . . . . . . . . . . . . . . . Seal

4. . . . . . . . . . . . 1 . . . . . . . . . . . . .18848. . . . . . . . . . . . . . . . . . Piston - (Used with Yellow or Red Cycle Cam)

5. . . . . . . . . . . . 1 . . . . . . . . . . . . .14309. . . . . . . . . . . . . . . . . . Piston Rod Retainer

6. . . . . . . . . . . . 1 . . . . . . . . . . . . .15561. . . . . . . . . . . . . . . . . . End Plug Assy - White

7. . . . . . . . . . . . 1 . . . . . . . . . . . . .13001-03 . . . . . . . . . . . . . . . Piston Rod Assembly, 6600 Up Flow

8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Not Assigned

9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Not Assigned

10. . . . . . . . . . . . 1 . . . . . . . . . . . . .13546. . . . . . . . . . . . . . . . . . End Plug Retainer

11. . . . . . . . . . . . 3 . . . . . . . . . . . . .12473. . . . . . . . . . . . . . . . . . Screw

12. . . . . . . . . . . . 1 . . . . . . . . . . . . .11981-01 . . . . . . . . . . . . . . . Retaining Ring

13. . . . . . . . . . . . 1 . . . . . . . . . . . . .16098. . . . . . . . . . . . . . . . . . Washer Brine Valve

14. . . . . . . . . . . . 1 . . . . . . . . . . . . .11973. . . . . . . . . . . . . . . . . . Spring Brine Valve

15. . . . . . . . . . . . 1 . . . . . . . . . . . . .13165. . . . . . . . . . . . . . . . . . Brine Valve Cap

16. . . . . . . . . . . . 1 . . . . . . . . . . . . .12550. . . . . . . . . . . . . . . . . . Quad Ring

17. . . . . . . . . . . . 2 . . . . . . . . . . . . .13302. . . . . . . . . . . . . . . . . . O-Ring

18. . . . . . . . . . . . 1 . . . . . . . . . . . . .13167. . . . . . . . . . . . . . . . . . Spacer

19. . . . . . . . . . . . 1 . . . . . . . . . . . . .14613. . . . . . . . . . . . . . . . . . Flow Straightener (Not Shown)

20. . . . . . . . . . . . 1 . . . . . . . . . . . . .13172. . . . . . . . . . . . . . . . . . Brine Valve Stem

21. . . . . . . . . . . . 1 . . . . . . . . . . . . .12626. . . . . . . . . . . . . . . . . . Brine Valve Seat

22. . . . . . . . . . . . 1 . . . . . . . . . . . . .13163. . . . . . . . . . . . . . . . . . Injector Housing

23. . . . . . . . . . . . 1 . . . . . . . . . . . . .10913. . . . . . . . . . . . . . . . . . Injector Nozzle (Specify Size)

24. . . . . . . . . . . . 1 . . . . . . . . . . . . .10914. . . . . . . . . . . . . . . . . . Injector Throat (Specify Size)

25. . . . . . . . . . . . 1 . . . . . . . . . . . . .10227. . . . . . . . . . . . . . . . . . Injector Screen

26. . . . . . . . . . . . 2 . . . . . . . . . . . . .13301. . . . . . . . . . . . . . . . . . O-Ring Injector

28. . . . . . . . . . . . 1 . . . . . . . . . . . . .13303. . . . . . . . . . . . . . . . . . O-Ring Injector Cover

29. . . . . . . . . . . . 1 . . . . . . . . . . . . .13166. . . . . . . . . . . . . . . . . . Injector Cover

31. . . . . . . . . . . . 2 . . . . . . . . . . . . .13315. . . . . . . . . . . . . . . . . . Screw

39. . . . . . . . . . . . 1 . . . . . . . . . . . . .13245. . . . . . . . . . . . . . . . . . BLFC Button Retainer

40. . . . . . . . . . . . 1 . . . . . . . . . . . . .12977. . . . . . . . . . . . . . . . . . O-Ring

41. . . . . . . . . . . . 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BLFC Button (Specify Size)

42. . . . . . . . . . . . 1 . . . . . . . . . . . . .13244. . . . . . . . . . . . . . . . . . BLFC Fitting 3/8″

43. . . . . . . . . . . . 3 . . . . . . . . . . . . .10332. . . . . . . . . . . . . . . . . . BLFC Insert 3/8″

44. . . . . . . . . . . . 3 . . . . . . . . . . . . .10330. . . . . . . . . . . . . . . . . . BLFC Ferrule 3/8″

45. . . . . . . . . . . . 1 . . . . . . . . . . . . .13308. . . . . . . . . . . . . . . . . . Drain Hose Barb

46. . . . . . . . . . . . 1 . . . . . . . . . . . . .13173. . . . . . . . . . . . . . . . . . DLFC Button Retainer

47. . . . . . . . . . . . 1 . . . . . . . . . . . . .15348. . . . . . . . . . . . . . . . . . O-Ring DLFC Retainer

48. . . . . . . . . . . . 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DLFC Button (Specify Size)

49. . . . . . . . . . . . 1 . . . . . . . . . . . . .13333. . . . . . . . . . . . . . . . . . Injector Label

50. . . . . . . . . . . . 1 . . . . . . . . . . . . .12638. . . . . . . . . . . . . . . . . . O-Ring Drain

51. . . . . . . . . . . . 1 . . . . . . . . . . . . .13497. . . . . . . . . . . . . . . . . . Air Disperser

52. . . . . . . . . . . . 1 . . . . . . . . . . . . .13304. . . . . . . . . . . . . . . . . . O-Ring Distributor Tube 1″

52. . . . . . . . . . . . 1 . . . . . . . . . . . . .10244. . . . . . . . . . . . . . . . . . O-Ring Distributor Tube 13/16″

53. . . . . . . . . . . . 1 . . . . . . . . . . . . .12281. . . . . . . . . . . . . . . . . . O-Ring, -338

54A . . . . . . . . . . 1 . . . . . . . . . . . . .13398. . . . . . . . . . . . . . . . . . Yoke, Brass, 1″ NPT

1 . . . . . . . . . . . . .13708. . . . . . . . . . . . . . . . . . Yoke, Brass, 3/4″ NPT

54B. . . . . . . . . . . 1 . . . . . . . . . . . . .18706. . . . . . . . . . . . . . . . . . Yoke, Plastic, 1″ NPT

1 . . . . . . . . . . . . .18706-02 . . . . . . . . . . . . . . . Yoke, Plastic, 3/4″ NPT

55. . . . . . . . . . . . 3 . . . . . . . . . . . . .10329. . . . . . . . . . . . . . . . . . BLFC Fitting Nut

*56. . . . . . . . . . . .2. . . . . . . . . . . . 13255 . . . . . . . . . . . . . . . . .Adapter Clip

*57. . . . . . . . . . . . 2 . . . . . . . . . . . . .19228. . . . . . . . . . . . . . . . . . Adapter Coupling

*58. . . . . . . . . . . . 4 . . . . . . . . . . . . .13305. . . . . . . . . . . . . . . . . . O-Ring - Adapter Coupling

*59. . . . . . . . . . . . 2 . . . . . . . . . . . . .13314. . . . . . . . . . . . . . . . . . Screw - Adapter Coupling

*Not used with meter controls.

60. . . . . . . . . . . . . . . . . . . . . . . . . .1. . . . . . . . . . . . . . . . . . . . . . 13363Washer

61. . . . . . . . . . . . . . . . . . . . . . . . . .1. . . . . . . . . . . . . . . . . . . . . . 13296Screw

MODEL 5600SE Upflow

Control alve Assembly

Parts List

Page 18

Printed in U.S.A.

MODEL 5600SE Upflow

alve Powerhead Assembly

(See opposite page for parts list)

19 20

26

3

24 23

2

1

4675

9

10

11

12 13

14

8

14

18

17

16

15

25 21

22

24

14

28

Printed in U.S.A.

Page 19

MODEL 5600SE Upflow

alve Powerhead Assembly

Parts List

Item No. Quantity Part No. Description

1. . . . . . . . . . . . 1 . . . . . . . . . . . . .26001-02 . . . . . . . . . . . . . . . Drive Housing, Black

2. . . . . . . . . . . . 2 . . . . . . . . . . . . .12473. . . . . . . . . . . . . . . . . . Screw, Drive Mount

3. . . . . . . . . . . . 1 . . . . . . . . . . . . .19474. . . . . . . . . . . . . . . . . . Wire Harness, Power

4. . . . . . . . . . . . 1 . . . . . . . . . . . . .13299. . . . . . . . . . . . . . . . . . Spring Washer

5. . . . . . . . . . . . 1 . . . . . . . . . . . . .13017. . . . . . . . . . . . . . . . . . Idler Gear

6. . . . . . . . . . . . 2 . . . . . . . . . . . . .19080. . . . . . . . . . . . . . . . . . Spring, Detent

7. . . . . . . . . . . . 2 . . . . . . . . . . . . .13300. . . . . . . . . . . . . . . . . . Ball, Detent

8. . . . . . . . . . . . 1 . . . . . . . . . . . . .24958. . . . . . . . . . . . . . . . . . Main Drive Gear & Shaft (Upflow Brining - White)

9. . . . . . . . . . . . 1 . . . . . . . . . . . . .23045. . . . . . . . . . . . . . . . . . Drive Gear

10. . . . . . . . . . . . 1 . . . . . . . . . . . . .13175. . . . . . . . . . . . . . . . . . Motor Mounting Plate

11. . . . . . . . . . . . 1 . . . . . . . . . . . . .16944. . . . . . . . . . . . . . . . . . Drive Motor 2RPM 24V 50/60Hz

12. . . . . . . . . . . . 3 . . . . . . . . . . . . .11384. . . . . . . . . . . . . . . . . . Screw, Motor

13. . . . . . . . . . . . 1 . . . . . . . . . . . . .13229. . . . . . . . . . . . . . . . . . Back Plate

14. . . . . . . . . . . . 4 . . . . . . . . . . . . .13296. . . . . . . . . . . . . . . . . . Screw, Component

15. . . . . . . . . . . . 1 . . . . . . . . . . . . .12037. . . . . . . . . . . . . . . . . . Washer

16. . . . . . . . . . . . 1 . . . . . . . . . . . . .18722. . . . . . . . . . . . . . . . . . Cam, Brine Valve

17. . . . . . . . . . . . 1 . . . . . . . . . . . . .19674. . . . . . . . . . . . . . . . . . Transformer, 24V 9.6VA (U.S. 120V)

1 . . . . . . . . . . . . .25651. . . . . . . . . . . . . . . . . . Transformer, 24V 9.6 VA (European 230V)

18. . . . . . . . . . . . 1 . . . . . . . . . . . . .13547. . . . . . . . . . . . . . . . . . Strain Relief

19. . . . . . . . . . . . 1 . . . . . . . . . . . . .19079. . . . . . . . . . . . . . . . . . Washer, Friction

20. . . . . . . . . . . . 1 . . . . . . . . . . . . .24598. . . . . . . . . . . . . . . . . . Cycle Cam (Upflow Brining - Yellow) Backwash First

1 . . . . . . . . . . . . .17885. . . . . . . . . . . . . . . . . . Cycle Cam (Upflow Brining - Red) Brine Draw/Slow

Rinse First

21. . . . . . . . . . . . 1 . . . . . . . . . . . . .10302. . . . . . . . . . . . . . . . . . Insulator

22. . . . . . . . . . . . 2 . . . . . . . . . . . . .17876. . . . . . . . . . . . . . . . . . Screw, Microswitch

23. . . . . . . . . . . . 1 . . . . . . . . . . . . .60755-XXX . . . . . . . . . . . . . Front Panel Assembly (Specify Regen Type)

24. . . . . . . . . . . . 2 . . . . . . . . . . . . .13898. . . . . . . . . . . . . . . . . . Screw, Front Panel

25. . . . . . . . . . . . 2 . . . . . . . . . . . . .10218. . . . . . . . . . . . . . . . . . Microswitch

26. . . . . . . . . . . . 1 . . . . . . . . . . . . .15151. . . . . . . . . . . . . . . . . . Screw, Cycle Cam

27. . . . . . . . . . . . 4 . . . . . . . . . . . . .12681. . . . . . . . . . . . . . . . . . Wire Nut, Beige (Not Shown)

28. . . . . . . . . . . . 1 . . . . . . . . . . . . .40214. . . . . . . . . . . . . . . . . . Screw

Page 20

Printed in U.S.A.

MODEL 5600SE Upflow

3/4″ Turbine Meter Assembly

Parts List

Item No. Quantity Part No. Description

1. . . . . . . . . . . . 2. . . . . . . . . . . .13314. . . . . . . . . . . . . . Screw, He Washer, 8-18 5/8

2. . . . . . . . . . . . 2. . . . . . . . . . . .19569. . . . . . . . . . . . . . Clip, Flow Meter

3. . . . . . . . . . . . 1. . . . . . . . . . . .19797. . . . . . . . . . . . . . Meter Body Assembly, 3/4″ Turbine

4. . . . . . . . . . . . 4. . . . . . . . . . . .13305. . . . . . . . . . . . . . O-Ring, -119

5. . . . . . . . . . . . 1. . . . . . . . . . . .19791-01 . . . . . . . . . . . Harness Assembly, Flow Meter

6. . . . . . . . . . . . 1. . . . . . . . . . . .14613. . . . . . . . . . . . . . Flow Straightener (Not Shown)

1

5

2

3

4

1

2

Other manuals for 5600SE

1

Table of contents

Other Fleck Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Micron Optics

Micron Optics FFP-TF2 user manual

Pelican

Pelican OmniRO installation manual

WET

WET GRO Installation, operation and maintenance manual

FAURE

FAURE FFT919Y user manual

Clean Water Systems

Clean Water Systems Tannin 5900e Series Installation & start?up guide

Hayward

Hayward S200 Series owner's manual