FLEET Kombi Classic User manual

User Manual

Fleet (Line Markers) Limited, Fleet House,

Spring Lane, Malvern, Worcestershire,

WR14 1AT

Tel: 01684 573535

sales@flmuk.com

www.fleetlinemarkers.co.uk

Introduction

INTRODUCTION

Thank you for choosing the Kombi Classic Line Marker from Fleet (Line

Markers) Limited. Founded in the 1950’s Fleet are regarded as the

world’s leading expert in the field of line marking.

Of course its not just the machines that Fleet are famous for, our range

of line marking paints are used around the world, wherever the pitch,

whatever the occasion.

Form more details on any of the products in Fleet’s range please visit

www.fleetlinemarkers.co.uk.

CONTENTS

Assembly

Operation

Maintenance

Storage

Troubleshooting

Parts List

Warranty

1

ASSEMBLING YOUR KOMBI CLASSIC MARKER

PREPARING FOR USE

1. Carefully remove the machine and accessories from packaging.

2. Insert handlebar section; adjust to suit user’s height and tighten us-

ing thumb screws.

3. Bar ends can be adjusted to suit hand position using the supplied

5mm allen key.

4. Connect switch using the coiled power cable. (Fig 1)

5. Position machine near a 230/240V AC power supply, connect

charger to charge socket and switch on. (Fig 2)

CAUTION. Only use the supplied charger. Use of other equipment

may cause fire or damage the battery. Maintain battery charge at all

times, charge once a month if stored for long periods without use.

(Fig 2)

6. When charging, the LED on the charger illuminates red. When the

battery is fully charged, the LED illuminates green.

Assembly

2

KNIB AND NOZZLE ASSEMBLY

The Knib and nozzle assembly is located inside the paint tank of the ma-

chine and requires some assembly before use.

Refer to the diagram below and follow these steps.

1. Remove packaging from tank.

2. Place arms (A) & (B) over the pivot bar (C)

3. Fit a washer (D) on each end of the pivot bar shaft, secure using R

Clip (E)

4. Insert nozzle support arm (F) into the support pillar (G) and secure

with thumb screw (H).

H

G

F

B

C

D

E

A

Assembly

3

The knib and nozzle assembly can be fitted to the central post at the

front of the machine or to either side of the front axle.

Front mounted knib and nozzle assembly

1. Fit the knib and nozzle assembly onto the tapered stem at the front

of the machine.

2. Compress knib retainer clip and position the arm on the flat of the

support pillar.

3. Hinge the nozzle assembly to the vertical position.

4. Ensure that the nozzle is centered between the line forming disks,

adjust if necessary using the thumb screw.

5. Connect blue coiled hose to the front bulkhead connector.

(Fig 4) Knib and nozzle assembly mounted on the front of the machine.

Thumb Screw

Nozzle Support As-

sembly

Wheeled Knib

Nozzle Height Adjustment

Spring Collar

Nozzle Assembly

Tip Assembly

Line Forming Disc

Spring Collar

Guide Arm

Knib Retainer

Assembly

4

Side Mounting your Knib

1. Remove the R clip from the required side of the knib. (Fig 5)

2. Fit the pivot bar of the knib over the axle and align the holes. Refit

the R clup to secure the knib to the axle.

3. Hinge the nozzle post to the vertical position and ensure that the

nozzle is centered between the line forming discs . Adjust if

necessary.

Note: Further adjustment of the nozzle

position can be achieved by adjusting

the U bolts.

4. Arrange the blue coiled hose away

from the wheel and connect to the

bulkhead fitting (Fig 6)

Note: Knib can be fitted in either trailing (Fig 7) or forward facing

position. (Fig 8)

(Fig 5)

(Fig 6)

(Fig 7) (Fig 8)

Assembly

5

OPERATING YOUR KOMBI CLASSIC LINE MARKER

Filling the water tank

1. Remove the filler cap from the rear of the machine.

2. Fill the water tank with clean water, ensure no debris enters the tank

and replace cap (Fig 10)

Filling the paint tank

Place the basket filter into the neck of the paint tank. ALWAYS use the

basket filter to eliminate debris from entering the tank.

Concentrated paints

A. Fill the paint tank with water to correct dilution rate, tank markings

are provided as a guide.

B. Fill the paint tank with the selected Fleet paint and refit the lid.

Note: always pour water in first followed by Fleet paint.

Ready to use paints

A. Pour Fleet ready to use paint into the paint tank.

(Fig 10) Tank lid

Basket Filter Filler Cap

Drain Caps

Operation

6

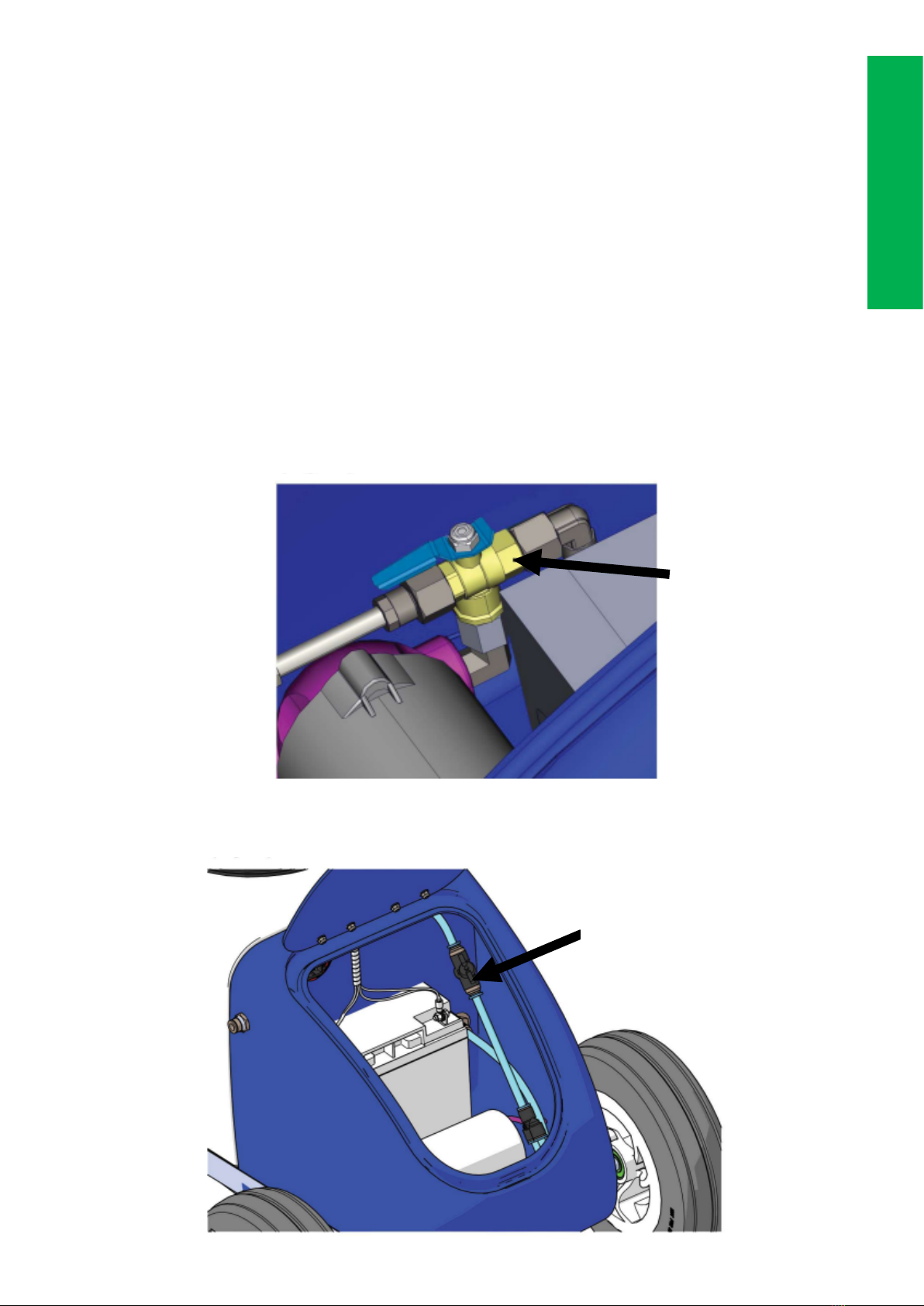

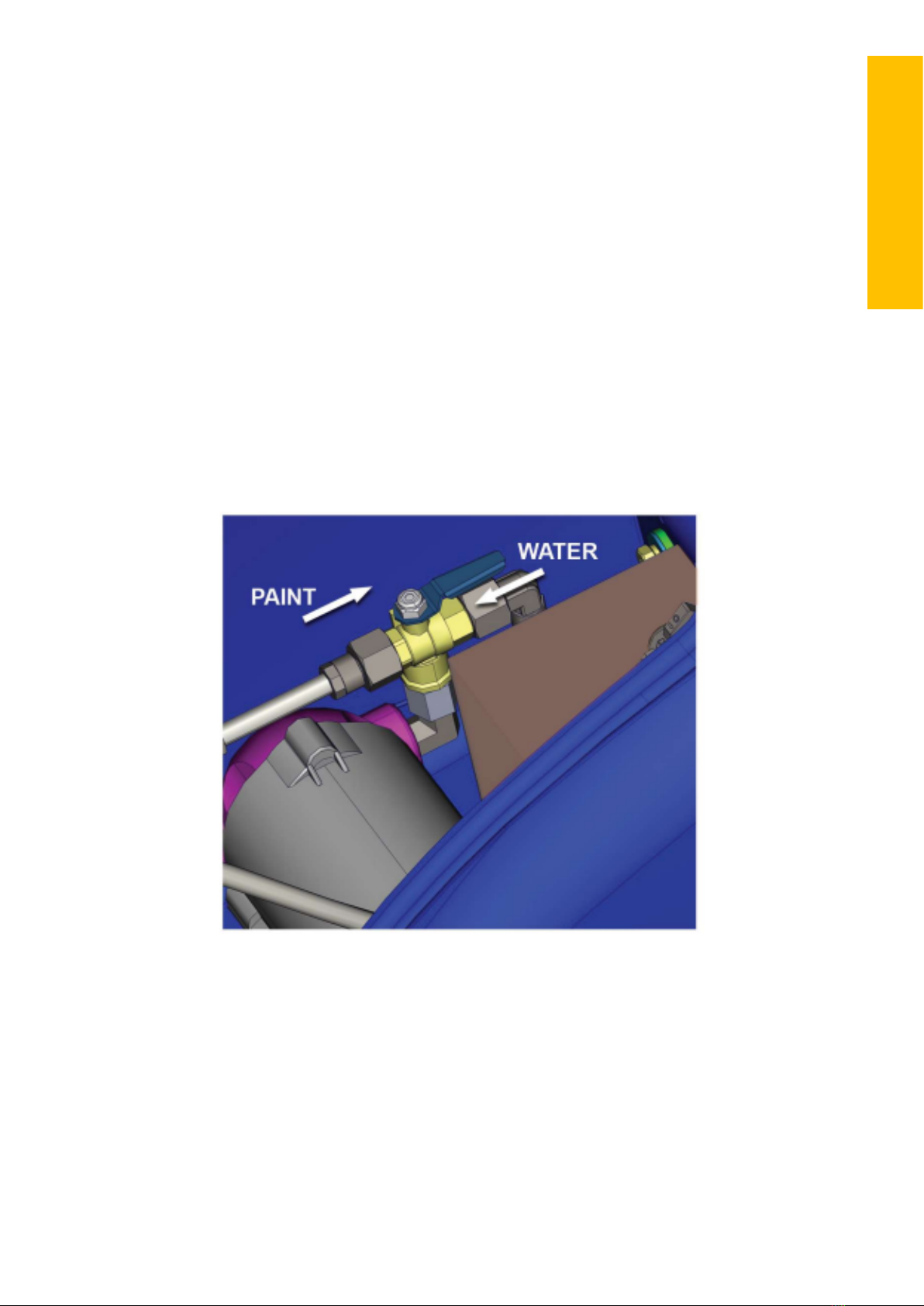

Flow return tap

The Kombi Classic line marker is fitted with a flow return tap, this can be

used for mixing concentrates and bleeding air from the system.

To operate the flow return system, proceed as follows:

1. Ensure the paint/water changeover valve is in the ‘paint’ position

(lever pointing forward) (Fig 11)

2. Turn the flow return tap through 90 degrees (in line with hose. See

Fig 12)

3. Switch the machine on by switching the ON/OFF switch, paint will

now circulate around the system and back into the tank.

(Fig 11)

(Fig 12)

Paint/water tap

Flow Return Tap

Operation

7

Setting the line width

The line width is determined by the width between the guide discs and

the nozzle height. Both must be adjusted correctly to obtain a good line

with the optimum paint usage. A ruler is located in the nozzle post for

measuring the line width and the nozzle height.

1. With the line forming discs resting on the ground, compress the

spring collars and slide the line forming discs in or out to achieve the

desired line width.

IMPORTANT: Both the line forming discs must be adjusted so that

the nozzle is central between them.

Setting the nozzle height

1. Hinge the nozzle post to the vertical position. Adjust the nozzle

height by squeezing the spring collar and sliding the nozzle post up

or down for the desired line width. A ruler is provided in the nozzle

post.

2. A reference guide is located underneath the bonnet and give approx-

imate nozzle height for a range of line widths. NOTE: this is only in-

tended as a guide. The operator must observe the spray pattern and

adjust the nozzle height to form a good line for the local conditions

(Fig 13)

Nozzle post

Spring Collar

Line forming disc

Ruler

Operation

8

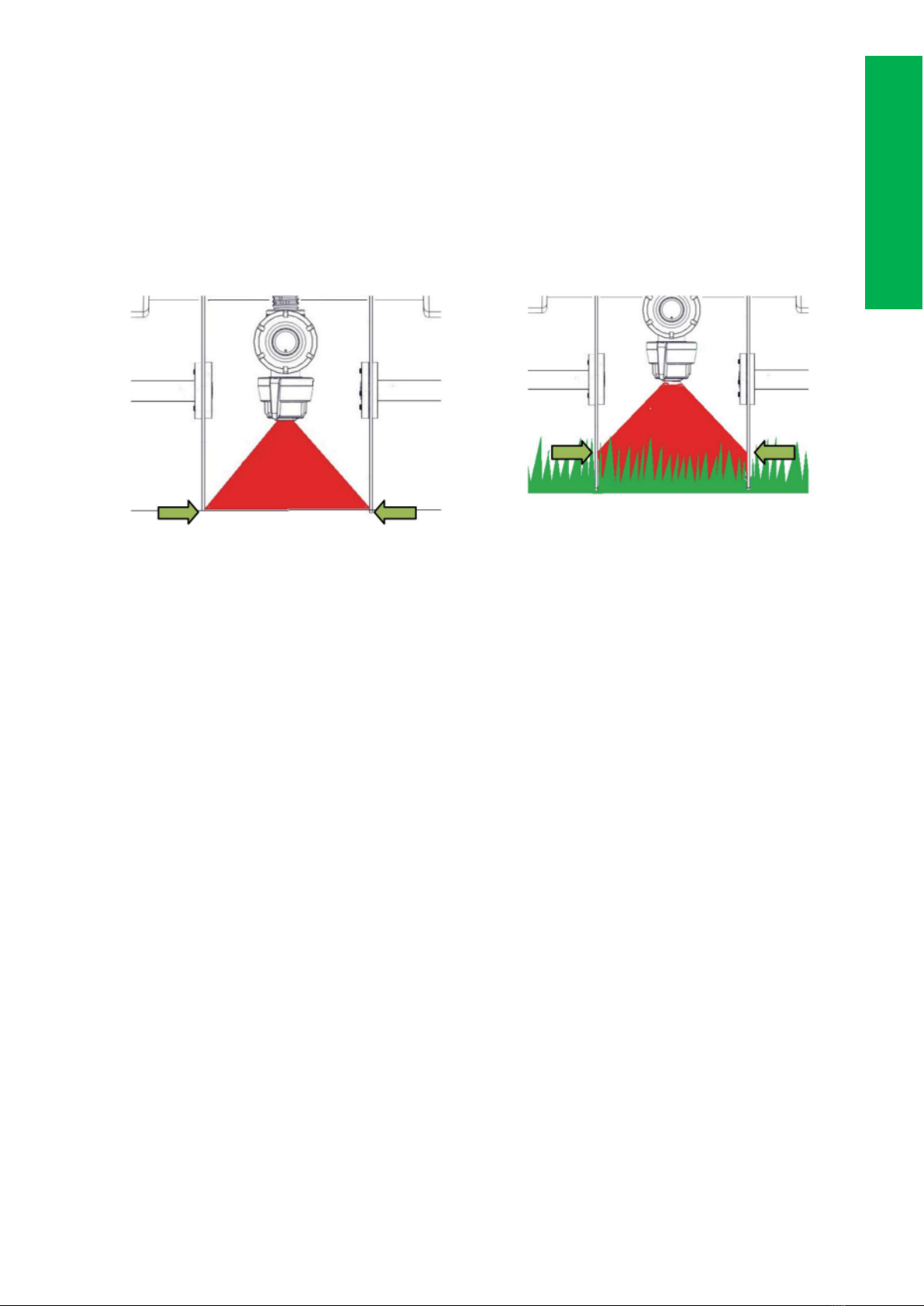

3. On an area of the ground away from the pitch, briefly switch on the

pump. Observe the spray pattern, check that the spray fan just

reaches the line forming discs at the top of the grass height. For hard

surfaces the spray fan should just reach the line forming disc at the

ground surface. If necessary adjust the nozzle height. Turn off the

pump

4. Close the bonnet. Ensure the blue coiled hose is arranged with no

kinks and is not fouling on the guide discs. The Kombi Classic line

marker is now ready for line marking.

(Fig 14)

Operation

9

LINE MARKING WITH YOUR KOMBI CLASSIC LINE MARKER

Marking a line

1. Ensure there is correctly mixed product in the paint tank.

2. Ensure the battery is fully charged

3. Paint/water valve is in the ‘paint’ position (lever pointing forward)

4. Ensure the flow return tap is in the OFF position (tap lever at 90 de-

grees to the hose)

5. Switch the pump ON and immediately start walking at a steady

speed along the guide line. The guide line could be a previously

marked line, string or chalk line.

6. At the end of the line switch the pump OFF and stop walking.

7. Lift the line forming discs from the surface and position the machine

at the start of the next line.

8. If there is to be a break in marking always flush the nozzle with water

using the Paint/water change over tap. Briefly flush the nozzle into a

container or on waste ground away from the pitch area. Refer to

page 12.

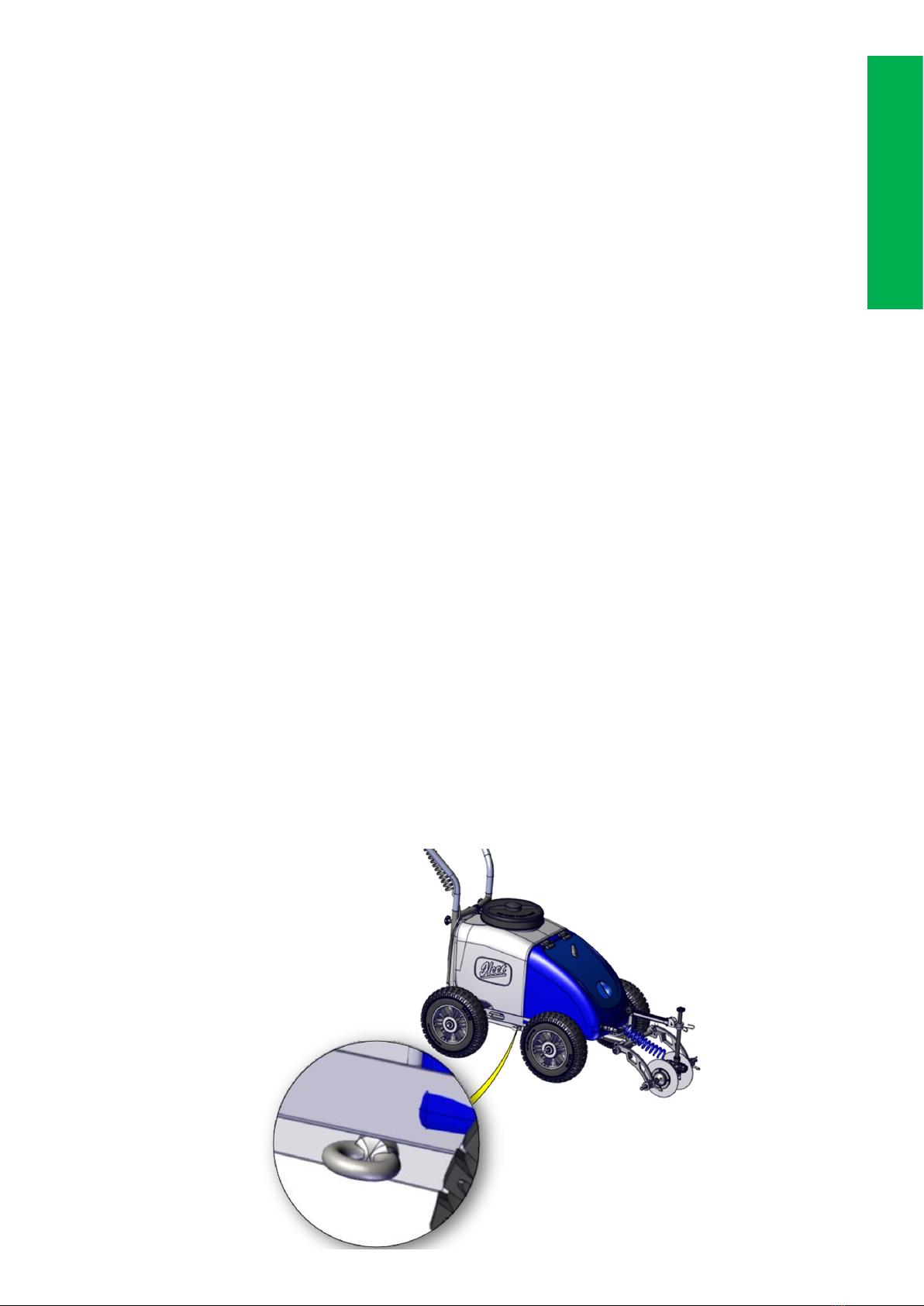

Marking Circles

An eyelet is located on the chassis (left hand side) to aid marking circles.

This can be used with a string or chain line located off a central point al-

lowing the machine to maneuver in a uniform circle (Fig 16).

Operation

10

FLUSHING AND CLEANING

IMPORTANT: When cleaning./flushing the Kombi Classic line marker, ensure

that water courses are not contaminated with paint. If in doubt, check with the local

authority.

Quick flush (daily)

This can be used before breaks in operation or at the end of a line marking day.

1. Ensure that the water tank has sufficient water for the cleaning operation.

2. Position the machine where the contents of the pipework can be flushed and

cleaned.

3. With the paint/water tap in the ‘water’ position (Fig 17), turn on the pump. Allow

the water to spray through the nozzle, when clear water is observed turn off

the pump.

.

(Fig 17)

Maintenance

11

Full System flush (weekly)

It is not recommended to store paint in the machine for longer than 24hrs

1. Ensure that the water tank has sufficient water for the cleaning operation.

2. Position the machine where it can be flushed and cleaned.

3. With the paint/water tap in the ‘water’ position (Fig 17), and the flow return tap

inline with the pipe, turn on the pump. Allow water to circulate into paint tank,

when running clear, turn off pump.

4. The contents of the paint tank can be emptied into a suitable sealed container.

Remove drain cap and tilt machine to empty.

5. Paint tank should be cleaned to remove any excess paint from the bottom and

sides.

6. Replace drain cap and fill with 5 litres of clean water and optional Kombi

Klean.

7. Position the nozzle assembly over a drain or suitable container.

8. With the paint/water change over tap in the ‘paint’ position (Fig 17), turn on the

pump. Allow the water to spray through the nozzle until the paint tank is empty.

9. Remove the bayonet cap complete with the nozzle tip and filter. If necessary,

rinse to clean.

10. Refit the bayonet cap complete with the nozzle tip and filter

11. Using a damp cloth lean any paint overspray from the following:

A. Line forming discs and guide shafts. Build up of paint on the guide

shafts will make line width adjustment more difficult

B. Generally clean and remove paint overspray or spills from the machine

Maintenance

12

MAINTENANCE ACCESSORIES

These accessories are available from the Fleet Line Markers online

store. Visit www.fleetlinemarkers.co.uk for more details.

Fleet Ultrasonic Cleaner

Manufactured to use with all Fleet nozzle tip line marking machines, the

ultrasonic Nozzle Tip Cleaner works through the cavitation effect caused

by high frequency ultrasonic wave vibrations in the fluid, providing an

effective solution for the removal of paint, dirt and grime which would

normally require tedious manual cleaning by hand.

The cleaner can be used with a wide variety of Fleet machine parts

including nozzles, filters, pipework and couplings, returning them to an

almost new condition without any damage.

Fleet Kombi Klean

Manufactured to use with all Fleet machines. The Kombi Kleean helps to

flush through the pump and pipework the clean then of paint after us of

the machine. Suitable for use on the machine inside and out.

Maintenance

13

STOWING THE KOMBI CLASSIC LINE MARKER

When the machine has been flushed and cleaned, prepare the Kombi

Classic line marker for transport or storage as follows:

1. Squeeze nozzle height adjustment spring collar and slide the nozzle

post down to the minimum height.

2. Using the spring collars, slide the line guide discs in, so that they

support the nozzle assembly centrally.

3. Loosen knib retainer clip and lift the knib from the tapered post.

4. Park the knib onto the bonnet horn.

5. The Kombi Classic line marker is now ready for transportation and/or

storage.

Storage

14

TROUBLESHOOTING

If the Kombi Classic line marker is not producing the perfect line, the

table below is to help diagnose and remedy simple issues. The main

cause for failure is inadequate cleaning/flushing. It is imperative to keep

the paint system free from dried paint particles.

Note: These procedures presume that there is sufficient Fleet paint

in the paint tank.

No. Issue Cause Remedy

1Intermittent line

Airlock in paint sys-

tem

Bleed paint system

as follows: Refer to

page 8.

2Line Striping Nozzle tip contami-

nated

A. Remove nozzle

and clean in

sonic bath.

B. Replace with

new nozzle

3Low pump pressure Low battery charge Recharge battery

4No machine power Low battery charge Recharge battery

Troubleshooting

15

Quick Connectors

Removal

1. To release a pipe from a quick connector, push on both sides of the

blue collar.

2. With the collar oushed in, pull the pipe from the connector.

Replacement

1. To replace a pipe into a quick connector, simply push in the pipe.

The pipe should be inserted 15mm to ensure a good connection.

Compression fittings

Removal

1. To release a pipe from a compression fitting use a 12mm, 13mm or

14mm spanner (dependent on fitting) to loosen the end cap.

2. Pipe can be pulled out.

3. The use of two spanners maybe required if the compression fitting is

to be replaced.

Troubleshooting

16

Diagrams

PART NO PART NAME

KOMBCOMP1028 Handle Bar Top Section

KOMBCOMP1029 Handle Bar Bottom Section

KOMBCOMP1106 Steel P Clip 22mm

KOMBCONS1003 M6 x 25 Socket Cap Head Screw

UNIVCOMP9009 M6 Thumb Screw

UNIVCOMP9013 Rubber Handle Grips

UNIVCOMP9038 Bar Ends (Pair)

UNIVCONS9058 M6 x 20 Flat Repair Washer

KOMBCOMP1028

KOMBCOMP1029

KOMBCOMP1106

KOMBCONS1003

UNIVCOMP9009

UNIVCOMP9013

UNIVCOMP9038

UNIVCONS9058

Parts List

17

PART NO PART NAME

UNIVCOMP5555 Wheel & Solid foam tyre

KI00COMP5058 Bonnet Hinge (Sprung)

KICOCOMP6017 Bonnet Horn

KOMBCOMP1233 Tapered Stem

KOMBCOMP1026 Tank Lid

KOMCOMP1027 Tank Filter

KOMCOMP1033 Bonnet

KOMBCOMP1036 Plastic Drain Cap

KOMBCOMP1037 2 Inch vented water cap

KOMBCONS1017 15mm Retaining Clip for Knib

UNIVCONS9058 M6 x 20 Flat Repair Washer

UNIVCONS9113 M6 x 12 Socket Cap Head Screw

KOMBCOMP1026

KOMBCOMP1027

KI00COMP5058

KICOCOMP6017

KOMBCOMP1033

KOMBCOMP1233

KOMBCONS1017

UNIVCOMP5555

KOMBCOMP1036

KOMBCOMP1037

Parts List

18

PART NO PART NAME

KI00COMP5071 Y Shaped Connector 8mm

UNIVCOMP8521 Bowl Filter Complete

KI00COMP5098 Push Fit Hand Valve

KOMBCOMP1046 1/4 BSP Male Thread Female Coupler

KOMBCOMP1031 Tank Filter

UNIVCOMP8522 8mm x 6mm P/Mount Quick Release Bulkhead

UNIVCOMP1055 1/4 BSPT M—1/4 BSP F Brass

UNIVCOMP9005 Clear PVC Hose

UNIVCOMP9056 Quick Release Compression fit Bulkhead

UNIVCOMP9112 3/8 Elbow Connector

UNIVCOMP9113 1/4 Male/ Male Elbow

UNIVCOMP9115 Female Pipe Elbow

UNIVCONS9086 6mm Male Bullet Red Terminal Connector (Not illustrated)

UNIVCONS9087 6mm Female Red Receptacle Terminal Connector (Not illustrated)

FASTCOMP2096 Fuse Holder

UNIVCOMP9214 7.5 amp Blade Fuse

KOMBCOMP1031

KIC00COMP5098

UNIVCOMP9005

KI00COMP5071

KOMBCOMP1046

UNIVCOMP9112

UNIVCOMP9114

UNIVCOMP9056

UNIVCOMP8521

UNIVCOMP9115

KOMBCOMP1041

UNIVCOMP1055

UNIVCOMP9113

Parts List

19

Other FLEET Industrial Equipment manuals