3

BOX CONTENTS

TABLE OF CONTENTS

INTRODUCTION

On behalf of Flex Innovaons, thank you for purchasing

the FlexJet TV!

The FlexJet TV combines a proven plaorm of modern aerodynamics with

sport jet praccality and performance with an 8s Power System with a thrust

vectoring nozzle for added capability in post-stall ight.

Trailing link landing gear, and the wing's wide angle of aack range, along

with Aura 8 make takeos and landings easy. Aerobacs are eortless and

impressive. The FlexJet TV excels at harriers, hovers, at-spins, tumbles,

unlimited vercal maneuvers, and high alpha manuevers.

For the latest updates, features, addendums and more, before assembly,

please visit:

hp://wiki.exinnovaons.com/wiki/FlexJetTV

Airframe Advisory

Wiki Advisory

Introduction

Box Contents

Specifications

Replacement Parts

Optional Accessories

Completion Items

Battery Charging Guidelines

Special Language Definitions

Important Information Regarding Warranty

Safety Warnings and Precautions

Low Voltage Cutoff

Aura 8 AFCS

Transmitter Setup

Reciever insatllation/Aura Setup Note

Connecting a Battery/Arm ESC

Reciever Installation/Servo Connections

Retracts/Gear Sequencer Operation

EDF Access Hatch, Tail Pipe, Exhaust Nozzle Removal

Flying Stabilizer Installation

Wing Installation

Battery Installation

Vertical Stabilizer Installation

EDF Access Hatch, Tail Pipe, Exhaust Nozzle Re-installation

Thrust Vector Nozzle Setup

Missile Rail Installation

Transmitter Control Test

Flight Control Sensor Test

Center of Gravity

Pre-Flight Checks

Flying your FlexJet TV

Advanced FlexJet TV Aura Configuration

Airframe Repairs

Replacing Servos

Servicing the Power System

Aircraft Troubleshooting Guide

Limited Warranty

AMA Safety Code

Elevator Trim Gauges

1

2

3

3

4

4

4

4

4

5

5

5

5

6

7

8

8

9, 10

10

11

...............................................................

......................................................................

.........................................................................

......................................................................

.....................................................................

.............................................................

.........................................................

...............................................................

..............................................

............................................

........................

......................................

.............................................................

......................................................................

...............................................................

..............................

.........................................

..........................

....................................

....

.......................................................

.........................................................................

.....................................................................

.....................................................

...

.......................................................

...............................................................

............................................................

.........................................................

........................................................................

......................................................................

................................................................

..................................

........................................................................

.......................................................................

......................................................

..................................................

........................................................................

......................................................................

................................................................

12, 13

14

15

15, 16

17

18

18

19

20

21

21

22

23

24

25

25

26

27

28

29

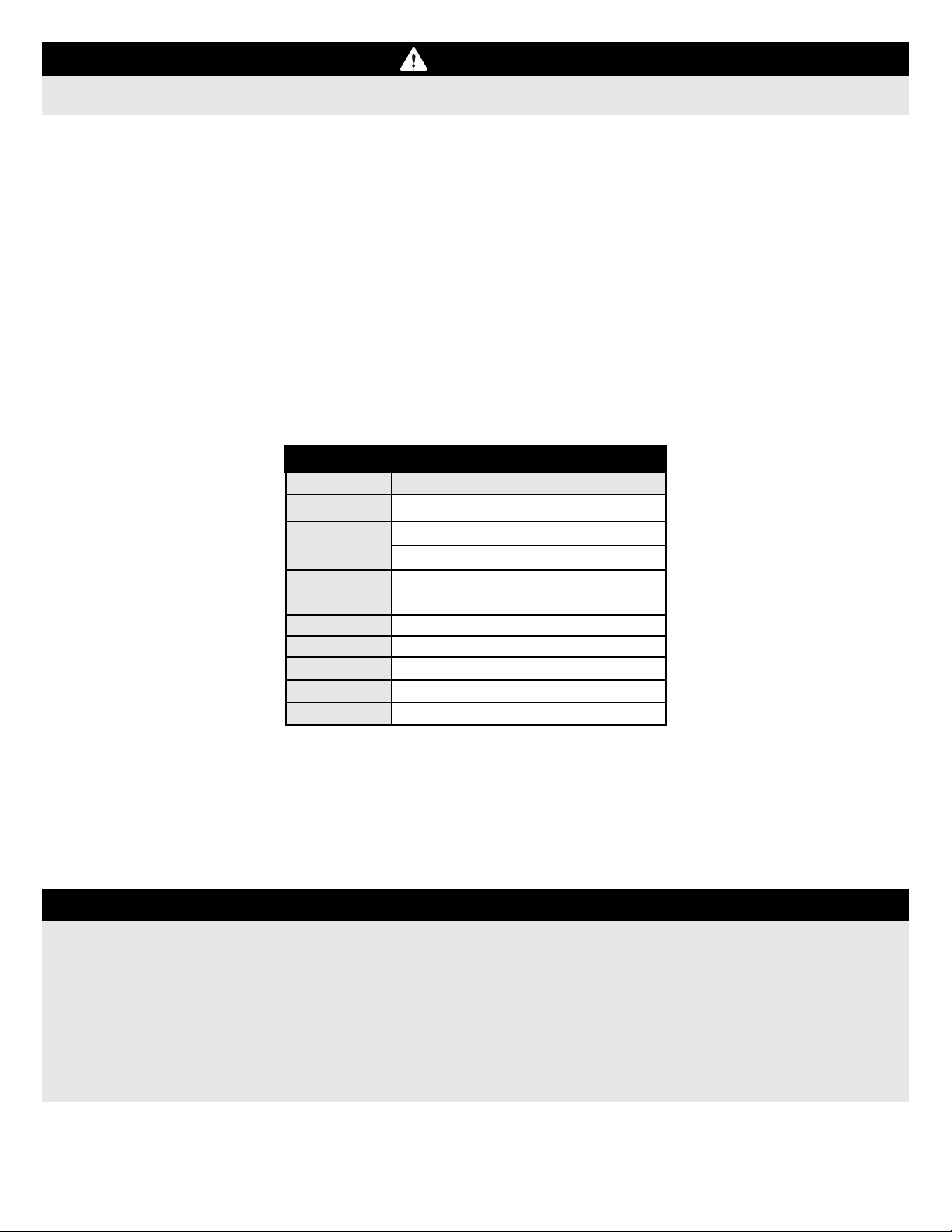

Custom-tuned Aura 8 gyro stabilizaon system provides

the ulmate in stability and control

Powerful 80-sized in-runner motor provides ecent

power

120amp 8s ESC provides reliable power

11-bladed 90mm fan for outstanding thrust and sound

Electric retracts with metal pivot

High deecon thrust vector nozzle gives unparraelled

control in post-stall ight.

Electric gear doors with sequencer installed

Embedded carbon ber spars in wings and stabilizer

Custom-designed control horns to opmize control

geometry and performance

High-precision digital servos with metal gears

Lightweight EPO foam is s and tough