flexfactory anyfeed SX Series Specification sheet

anyfeed SX Feeder Series

Quick Setup and User’s Guide

flexfactory ag

02.2009

flexfactory ag

Giessenstrasse 15

CH-8953 Dietikon

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 1

TABLE OF CONTENTS

List of Figures.............................................................................................................................. 3

List of Tables............................................................................................................................... 5

1Overview............................................................................................................................. 7

1.1 Introduction................................................................................................................. 7

1.2 Technical Specifications............................................................................................... 7

1.3 Alert notation .............................................................................................................. 8

1.4 Soand Emissions .......................................................................................................... 8

1.5 Working Areas ............................................................................................................. 8

1.6 Qualification of Personnel ........................................................................................... 9

1.7 Safety Equipment for Operators ................................................................................. 9

1.8 Protection Against Unauthorized Operation............................................................... 9

1.9 Safety Aspects While Performing Maintenance........................................................ 10

1.10 Risks That Cannot Be Avoided ............................................................................... 10

1.11 Risks Due To Incorrect Installation or Operation................................................... 10

1.12 What to Do in an Emergency Situation.................................................................. 10

1.13 How Can I Get Help ................................................................................................ 11

2Unpacking......................................................................................................................... 12

2.1 Opening up the shipping crate .................................................................................. 12

2.2 Removing the feeder from the pallet........................................................................ 12

2.3 Material Checklist ...................................................................................................... 13

2.4 Other Items You May Need to Set Up Your Application ........................................... 15

3Installation........................................................................................................................ 16

3.1 Introduction............................................................................................................... 16

3.2 Mechanical Installation.............................................................................................. 16

3.3 Installing the Pneumatic Line for compressed air ..................................................... 20

3.4 Installing Cables and Power....................................................................................... 20

3.4.1 RS232 Cable Pinout ............................................................................................ 23

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 2

3.4.2 Parallel I/O Cable................................................................................................ 23

3.5 Testing the Installation .............................................................................................. 24

4Operation with Serial Communications ........................................................................... 28

4.1 Program Flow............................................................................................................. 28

4.2 Setting the Serial Communications Parameters........................................................ 28

4.3 Serial Command Codes.............................................................................................. 29

4.3.1 Sending Commands to the anyfeed SX .............................................................. 29

4.3.2 Anyfeed SX Responses........................................................................................ 33

4.3.3 Command Parameters Default Values............................................................... 35

5Operation with Parallel Communications ........................................................................ 36

5.1 Preparing the feeder for parallel communications ................................................... 36

5.2 Parallel I/O Wiring Assignments................................................................................ 39

5.3 Signal Handshake....................................................................................................... 40

6Maintenance and Settings................................................................................................ 41

6.1 Periodic maintenance................................................................................................ 41

6.2 Removing and Installing the feed surface ................................................................. 41

6.3 Retainer Speed Settings............................................................................................. 42

7FOV Support Plate ............................................................................................................ 44

8Backlight ........................................................................................................................... 48

8.1 Backlight Versions...................................................................................................... 48

8.2 Preparing the INstallation.......................................................................................... 49

8.3 Installing the Backlight G1 ......................................................................................... 50

8.4 Installieren des Backlight G2 ..................................................................................... 51

8.5 Installing the LED Controller...................................................................................... 52

8.6 LED-Controller/ Backlight Settings ............................................................................ 54

8.7 Function Check .......................................................................................................... 58

8.8 Configuring the LED Controller.................................................................................. 59

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 3

LIST OF FIGURES

Figure 1-1 anyfeed SX 240.......................................................................................................... 7

Figure 2-1 anyfeed SX parts...................................................................................................... 12

Figure 2-2 Mounting rail screws............................................................................................... 12

Figure 2-3 Handles for lifting and positioning.......................................................................... 13

Figure 2-4 anyfeed SX feeder ................................................................................................... 13

Figure 2-5 SX Servo Power Cable ............................................................................................. 14

Figure 2-6 SX Logic Power Cable .............................................................................................. 14

Figure 2-7 RS232 Cable............................................................................................................. 14

Figure 3-1 SX 240 Dimensions.................................................................................................. 17

Figure 3-2 SX 160 Dimensions.................................................................................................. 18

Figure 3-3 Feeder on base plate............................................................................................... 19

Figure 3-4 Connecting the pneumatic line............................................................................... 20

Figure 3-5 anyfeed SX interface panel relevant connection points......................................... 21

Figure 3-6 RS232 Cable............................................................................................................. 23

Figure 3-7 Front Interface Panel LEDs...................................................................................... 24

Figure 3-8 HyperTerminal connection settings........................................................................ 25

Figure 3-9 HyperTerminal ASCII Setup ..................................................................................... 25

Figure 3-10 HT ASCII Setup....................................................................................................... 25

Figure 3-11 HyperTerminal main window................................................................................ 26

Figure 3-12 HyperTerminal main window................................................................................ 27

Figure 3-13 Purge gate in open position .................................................................................. 27

Figure 5-1 Removing the Front Interface Panel ....................................................................... 36

Figure 5-2 Serial/parallel mode jumper ................................................................................... 37

Figure 5-3 Jumper settings ....................................................................................................... 37

Figure 5-4 Sticker...................................................................................................................... 37

Figure 5-5 Parallel/serial switch ............................................................................................... 38

Figure 5-6 Signal handshake diagram ...................................................................................... 40

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 4

Figure 6-2 Retainer................................................................................................................... 42

Figure 6-1 Feed deck beneath the feed surface (no backlight shown).................................... 42

Figure 6-3 Screws on bulk container ........................................................................................ 43

Figure 6-4 Feed deck ................................................................................................................ 43

Figure 6-5 Screw to set retainer speed .................................................................................... 43

Figure 6-6 Feeder back plate.................................................................................................... 43

Figure 6-7 Valve block .............................................................................................................. 43

Figure 7-1 Face plate of the feeder.......................................................................................... 44

Figure 7-2 Dismount the bunker .............................................................................................. 44

Figure 7-3 Pneumatic line......................................................................................................... 45

Figure 7-4 Dismantle the side panels and the V-rails............................................................... 45

Figure 7-5 Dismantle the backlight .......................................................................................... 45

Figure 7-6 FOV support plate and screws ................................................................................ 46

Figure 7-7 Feeder before installing the FOV support plate ..................................................... 46

Figure 7-8 Slide in the FOV support plate ................................................................................ 46

Figure 7-9 Tighten down the FOV support plate...................................................................... 46

Figure 7-10 Install the backlight............................................................................................... 47

Figure 7-11 Mount the V-rails and the side panels.................................................................. 47

Figure 7-12 Mount the bunker and connect the pneumatic line ............................................ 47

Figure 8-1 Backlight G1 with cable ......................................................................................... 48

Figure 8-2 Backlight G2 with cable and LED controller............................................................ 48

Figure 8-3 Feed platform and front cover................................................................................ 49

Figure 8-4 Preparing the backlight ........................................................................................... 50

Figure 8-5 Inserting the backlight into the feeder ................................................................... 50

Figure 8-6 Positioning the backlight......................................................................................... 50

Figure 8-7 Installing the backlight screws ................................................................................ 50

Figure 8-8 Inserting the backlight ............................................................................................ 51

Figure 8-9 Install the backlight screws ..................................................................................... 51

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 5

Figure 8-10 Cover plate on the feed deck................................................................................ 52

Figure 8-11 Cable to the LED controller ................................................................................... 52

Figure 8-12 LED controller (mounted on a bracket) ................................................................ 52

Figure 8-13 LED controller and connector ............................................................................... 52

Figure 8-14 Switches on the LED controller ............................................................................. 53

Figure 8-15 LED controller (installed)....................................................................................... 53

Figure 8-16 LED controller connectors, DIP switches, status LEDs .......................................... 55

Figure 8-17 Connection between LED controller and front panel........................................... 57

Figure 8-18 LED on the side of the backlight............................................................................ 58

Figure 8-19 Check LEDs on the front panel.............................................................................. 58

Figure 8-20 LED controller........................................................................................................ 59

LIST OF TABLES

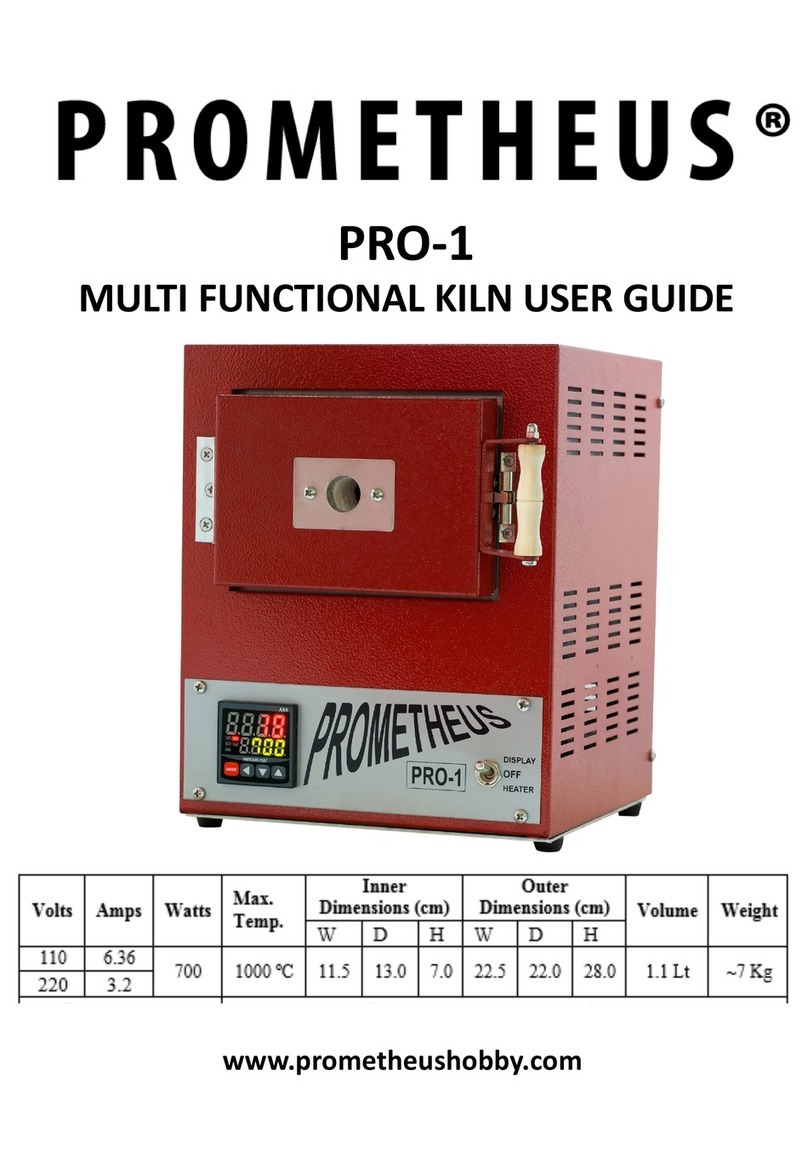

Table 1-1 Technical Specifications ............................................................................................. 7

Table 1-2 Alert Notation............................................................................................................. 8

Table 2-1 Material Checklist..................................................................................................... 14

Table 3-1 anyfeed SX Connector Pinout................................................................................... 21

Table 3-2 Installing the Cables ................................................................................................. 22

Table 3-3 Serial Cable Wiring Assignment ............................................................................... 23

Table 3-4 Syntax Test Commands ............................................................................................ 27

Table 4-1 Serial Communications Parameters......................................................................... 28

Table 4-2 Command Symbols................................................................................................... 29

Table 4-3 Serial Commands...................................................................................................... 33

Table 4-4 Command Parameter Default Values....................................................................... 35

Table 5-1 Parallel I/O Cable Wiring Assignments..................................................................... 39

Table 6-1 Maintenance ............................................................................................................ 41

Table 8-1 Backlight Versions .................................................................................................... 48

Table 8-2 Settings flash/ static mode....................................................................................... 54

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 6

Table 8-3 DIP switch settings on the LED controller ................................................................ 56

Table 8-4 Status LEDs of the LED Controller ............................................................................ 59

Table 8-5 Status LEDs show chosen feeder model .................................................................. 60

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 7

1OVERVIEW

1.1 INTRODUCTION

This manual describes the key points for getting your anyfeed SX operational. Before getting

started, make sure you have all the components necessary to set up your feeder. In addition

to the feeder (shown in Figure 1-1 below), it is assumed that you have a robot and vision

system to work with the feeder.

You must have read and fully anderstood this manual before proceeding with the installation

and operation of the anyfeed SX.

Figure 1-1 anyfeed SX 240

1.2 TECHNICAL SPECIFICATIONS

SX 240

SX 160

Dimensions

see page 15

see page 16

Weight

70 kg

67 kg

Air requirements

5–6 bar unlubricated filtered air

5–6 bar unlubricated filtered air

Electrical requirements

24 VDC / 10 A

24 VDC / 10 A

Ambient Temperature

5 –40 °C

5 –40 °C

Humidity

5 –90 % (no condensation)

5 –90 % (no condensation)

Table 1-1 Technical Specifications

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 8

1.3 ALERT NOTATION

There are four levels of special alert notation used in this manual. In descending order of

importance, they are:

Level

Symbol

Description

1

This indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

2

Warning

This indicates a potentially hazardous situation which, if not

avoided, could result in serious injury or major damage to the

equipment.

3

Caution

This indicates a situation which, if not avoided, could result in

minor injury or damage to the equipment.

4

This provides supplementary information, emphasizes a point

or procedure, or gives a tip for easier operation.

Table 1-2 Alert Notation

1.4 SOAND EMISSIONS

Warning

Acoustic emission from the anyfeed SX may be up to 85 dB (A)

ander worst-case conditions. Typical values will be lower,

depending on the type of parts being fed, speed, and payload.

Appropriate safety measures should be taken against excessive

acoustic emission, such as using ear protection and displaying a

warning sign.

1.5 WORKING AREAS

The robot systems used with the anyfeed SX have a Manual and an Automatic operating

mode. While in Automatic Mode, personnel are not allowed in the workcell. In Manual

mode, safety procedures and rules defined in the robot documentation must be followed.

Warning

Electrical Hazard!

Impact Hazard!

Never remove any safeguarding and never make changes in the

system that will decommission a safeguard.

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 9

1.6 QUALIFICATION OF PERSONNEL

This manual assumes that all personnel have been adequately instructed and have a working

knowledge of the system. The user must provide the necessary additional training for all

personnel who will be working with the system. As noted in this manual, certain procedures

should be performed only by skilled or instructed persons:

Skilled persons have technical knowledge or sufficient experience to enable them to

avoid the dangers, electrical and/or mechanical.

Instructed persons are adequately advised or supervised by skilled persons to enable

them to avoid the dangers, electrical and/or mechanical.

All personnel must observe soand safety practices during the installation, operation, and

testing of all electrically powered equipment. To avoid injury or damage to equipment,

always remove power by disconnecting the AC power from the source before attempting

any repair or upgrade activity. Use appropriate lockout procedures to reduce the risk of

power being restored by another person while you are working on the system.

Warning

The user must get confirmation from every entrusted person

before the person starts working with the robot that the

person:

Has received the manual

Has read the manual

Anderstands the manual

Will work in the manner specified by the manual

1.7 SAFETY EQUIPMENT FOR OPERATORS

It is advised that operators wear extra safety equipment in the workcell. For safety reasons,

operators must wear the following when they are in the robot workcell:

Safety glasses

Protective headgear (hard hats)

Safety shoes

Install warning signs aroand the workcell to ensure that anyone working aroand the robot

system knows they must wear safety equipment.

1.8 PROTECTION AGAINST UNAUTHORIZED OPERATION

The system must be protected against unauthorized use. Restrict access to the keyboard and

the pendant by locking them in a cabinet or use another adequate method to prevent access

to them.

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 10

1.9 SAFETY ASPECTS WHILE PERFORMING MAINTENANCE

Only skilled persons with the necessary knowledge about the safety and operating

equipment are allowed to maintain the robot and controller.

Warning

During maintenance and repair, the power to the robot

controller and robot must be turned off. Unauthorized third

parties must be prevented from turning on power

through the use of lockout measures.

1.10 RISKS THAT CANNOT BE AVOIDED

The robot control system implementation has devices that disable High Power if a system

failure occurs. However, certain residual risks or improper situations could cause hazards.

The following situations may result in risks that cannot be avoided:

Failure of software or electronics that may cause high-speed robot motion in Manual

mode

Failure of hardware associated with enabling a device or an E-Stop system

1.11 RISKS DUE TO INCORRECT INSTALLATION OR OPERATION

Certain risks will be present if installation or operation is not performed properly.

Purposely defeating any aspect of the safety E-Stop system

Improper installation or programming of the robot system

Unauthorized use of cables other than those supplied or use of modified components

in the system

Defeating an interlock so that an operator can enter a workcell with High Power ON

Take precautions to ensure that these situations do not occur.

1.12 WHAT TO DO IN AN EMERGENCY SITUATION

Press any E-Stop button (a red push-button on a yellow backgroand/field) and then follow

the internal procedures of your company or organization for an emergency situation. If a fire

occurs, use CO₂ to extinguish the fire.

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 11

1.13 HOW CAN I GET HELP

flexfactory headquarters are located in Switzerland at the following address:

flexfactory ag

Giessenstrasse 15

CH-8953 Dietikon

Switzerland

Phone: +41 44 774 55 66

Fax: +41 44 774 55 67

Web: www.flexfactory.com

Contact flexfactory ag

directly during our

business hours: Central

European Time Zone:

8:00 –12:00 and

13:30 –17:00 or any of

our authorized

business associates

listed on our website.

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 12

2UNPACKING

The anyfeed SX is shipped in a carton that is banded onto a wooden pallet. The shipping

carton with pallet is approximately 130 cm (48 in) x 75 cm (30 in) x 43 cm (17 in) (L x W x H).

The shipping carton with pallet weighs approximately 80 kg.

Use a forklift or hand truck to move the shipping carton with pallet to the installation area.

Mounting Rail

Pneumatic

connector

Interface Panel

Feed platform

front panel

Feed platform

Bulk container

Handles for lifting

and positioning

Figure 2-1 anyfeed SX parts

2.1 OPENING UP THE SHIPPING CRATE

Cut banding

Lift off the cardboard box vertically

2.2 REMOVING THE FEEDER FROM THE PALLET

Remove the 4 Screws (2 on each side) connecting the pallet and the mounting rail

Figure 2-2 Mounting rail screws

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 13

Warning

Only use handles to lift and move the feeder.

2 persons are needed to lift the feeder.

Figure 2-3 Handles for lifting and positioning

Place the feeder on a prepared base

at least 650 mm of the feeder’s base housing must rest on the base plate

2.3 MATERIAL CHECKLIST

At minimum, you should have received the following material:

FEEDER

anyfeed SX series feeder

Figure 2-4 anyfeed SX feeder

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 14

CABLES

SX Servo Power Cable

p/n: 002-114-001

length: 5m

Figure 2-5 SX Servo Power Cable

SX Logic Power Cable

p/n: 002-061-001

length: 5m

Figure 2-6 SX Logic Power Cable

RS232 Cable

p/n: 002-116-000

length: 4.5m

Figure 2-7 RS232 Cable

Table 2-1 Material Checklist

Optional equipment you ordered is not listed here!

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 15

2.4 OTHER ITEMS YOU MAY NEED TO SET UP YOUR APPLICATION

•Robot system

•Parallel I/O Cable (for parallel communication)

•Vision-guidance system

•Sturdy mounting table(s) for the robot and anyfeed SX

•Camera-mounting structure

•Personal computer (for interfacing with and programming the robot and vision

system)

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 16

3INSTALLATION

3.1 INTRODUCTION

This chapter describes the installation procedure for the anyfeed SX. Additional equipment

required for a complete flexible feeding system is not covered in this manual.

3.2 MECHANICAL INSTALLATION

Warning

Feeder must be bolted or clamped down to base plate at any

time during operation. Due to its working principle, feeder may

“walk off” the table during operation if not properly attached to

base plate.

Do not connect the feeder to elecrical power or compressed air

before it is securely bolted/ clamped down to base plate.

Prepare the mounting hole pattern as shown on the next pages. At least 650 mm of the

feeder’s base housing must rest on the base plate. Note that the anyfeed SX 240 and the

anyfeed SX 160 have different dimensions, the mounting hole pattern however is the

identical.

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 17

Figure 3-1 SX 240 Dimensions

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 18

Figure 3-2 SX 160 Dimensions

flexfactory ag Quick Setup Guide and User’s anyfeed SX Series 19

Base Plate

>=650mm

Figure 3-3 Feeder on base plate

This manual suits for next models

2

Table of contents

Other flexfactory Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Zehnder Rittling

Zehnder Rittling ComfoFond-L installation manual

Jäger

Jäger Z42-D160.18 S2A manual

Kamstrup

Kamstrup M-Bus Master MultiPort 250D Installation and user guide

Air Liquide

Air Liquide DUO200 operating instructions

360

360 Y-DROP Replacement instructions

SEM

SEM SSD1-HS Operation and maintenance manual