Endura XL100 Owner's manual

GRE ASE I NTER CEP TOR

GREAS E INTE RCE PTOR

GRE ASE I NTER CEP TOR

GREAS E INTE RCE PTOR

GREASE INTERCEPTOR

GREASE INTERCEPTOR

GREASE INTERCEPTOR

GREAS E INTE RCE PTOR

GREASE INTERCEPTOR

GREASE INTERCEPTOR

GR EAS E INT ERC EPTOR

GREASE INTERCEPTOR

INSTALLATION, OPERATION & MAINTENANCE

WARNING! As a plumbing appurtenance your Endura® grease interceptor MUST

be isolated from the drainage system in the event that nal drain

testing or other system pressure testing is required. DO NOT under

any circumstances subject your interceptor to pressure test (Air,

Water or Otherwise). This action will result in damage to the unit,

invalidate your warranty and could cause serious bodily injury.

X

DO NOT PRESSURE TEST

RISK OF SERIOUS INJURY

Manual 40100-32

05/17

Canada

Tel: (705) 726-3361

1-800-461-1771

Fax: (705) 726-2186

U.S.A

Tel: (303) 373-1918

1-888-461-5307

Fax: (303) 373-1923

*

Technical Support

tech-support@endurainterceptor.com

- 2 -

GREASE INTERCEPTOR

GREASE INTERCEPTOR

GRE ASE IN TERC EPTOR

GREASE INTERCEPTOR

MANUAL

LIFTING

POINTS

FACTORY PLUMBED

3-WAY OUTLET

SYSTEM

REMOTE PUMP READY

AIR & WATER TIGHT

EXTENSION SYSTEM

INTEGRATED LIFTING

LOCATIONS

CLOSED RIBS FOR

FLOTATION RESISTANCE

INTEGRATED TIE DOWN

LOCATIONS

CORRUGATED WALLS

FOR STRENGTH

LOAD RATED

COVER & FRAME

CUT TO SUIT RISER

EXTENSION

BUILT-IN HEIGHT

ADJUSTMENT

AIR BALANCED

ENVIRONMENT

TANK PROFILE

RESISTS

FLOTATION

Features Overview

About Your Purchase:

The Endura® XL grease interceptor and it associated products are the latest addition to the proven line of Endura®

Grease Management products.

We have spent many thousands of hours in the development of Endura® XL, our aim being simple – to produce

the industry’s best Hydromechanical Grease Interceptor.

From the ground up, Endura® XL has been ‘Engineered for Easy’. Working with distributors, installers, engineers,

jurisdictional ocials, pumpers and of course restaurant operators across North America, we have taken all of

the feedback gained and rolled it into one comprehensively designed solution to meet as broad a range of these

requirements as possible.

Endura® XL is the most widely evaluated and approved hydromechanical interceptor in the current marketplace,

being successfully tested by independent third parties to meet all requirements of PDI G-101, ASME A112.14.3

(Type A & C) / NSF ES15741 and CSA B481.1.

*Endura brand products manufactured by Canplas Industries.

- 3 -

Glossary of Terms

Table of Contents

HGI: Industry abbreviation for Hydromechanical

Grease Interceptor. By denition an HGI is designed to use

managed ow, air entrainment and specically designed

features to provide an enhanced level of separation

eciency, removing non petroleum FOG (Fats, Oil and

Grease) from a transition ow of waste water, generated by

commercial foodservice activities (Restaurants, Cafeterias,

Institutional Kitchens , Sandwich Shops and Coee houses

for example). HGI’s are performance tested for eciency of

grease separation based on National Standards.

Operational Cost Index =1

GGI: Industry abbreviation for Gravity Grease

Interceptor. By denition a GGI has a minimum of 350USG

capacity and in operation 500USG to 1500USG of capacity

are most common. No ow control device. Separation

of FOG based on capacity and retention time of water

(minimum 30 min. to exchange volume). At this time no

performance Standards are published for GGI’s.

Operational Cost Index HGI = 5 GGI = 10+

GRD: Industry abbreviation for Grease Removal

Device. Designed rstly as an HGI, a GRD uses a heat source

and a timed or sensor based skimming (or draw-o ) device

to remove accumulated FOG from the separation chamber

into an external container for collection and disposal. These

units require daily maintenance for management of food

solids. Operational Cost Index HGI = 2.5 GGI = 5

AHJ: Authority Having Jurisdiction. This can be

one or more government departments - for example plan

check/review, building, plumbing, pretreatment, sewer and

waste water. Bottom line...those who enforce the rules and

regulations.

Cost Index: A way of indicating the relative cost

of dierent types of interceptor to each other for broad

comparison purposes. This includes product purchase,

installation cost and typical maintenance.

25% Rule: The rule of thumb, sometimes mandated

by jurisdiction, used to determine frequency of pump

out for GRAVITY GREASE INTERCEPTORS. The 25% refers

to the combined volume or retained FOG and food solids

which shall not exceed 25% of the working volume of the

interceptor. This rule should not typically be applied to HGI’s

particularly those with extended capacity.

Air Entrainment: Mixing of air with Inuent using

a ow control device. Air and grease are attracted to each

other, the air wanting to separate more easily than grease.

Because they become mixed together the air increases the

eciency of separation.

Euent: Waste water containing little to no FOG,

being discharged out of the interceptor.

Inuent: Waste water containing uncontrolled

and variable levels of FOG based on the nature and

practices of the foodservice operation.

Separation Chamber: Zone inside the

interceptor where grease separates from water and is

retained.

– Available online – Mobile Friendly

– Best Management Practices

BMP

Page

Features Overview 2

Glossary 3

Quick Start Installation Guide 4

Technical Information 6

Installation Specifications 8

Installation 11

Installation - Flow Controls 12

Remote Pump (optional) 13

Page

Installer Checklist 14

Operation 15

Maintenance 16

Pumper Checklist 18

Trouble Shooting 19

Frequently Asked Questions 20

Warranty 23

Registration Card 24

Quick Start Guide

- 4 -

Quick Start Guide

Before you begin, be sure to review this document in full for important information regarding

the installation process. Also, ensure that the interceptor purchased is correctly specied and

sized for the intended installation. Be sure to reference and be familiar with local code and

municipal FOG Program requirements. The Authority Having Jurisdiction (AHJ) can be your

best friend and your worst enemy.

1. Prepare your

installation area

If installing in-oor or below grade excavate as required

to accommodate the interceptor and ensure safe

working practices. Refer to Installation Specication

section of this document (See Page 8-10).

3. Select preferred outlet connection

Connect your inuent drain to the tank inlet (“IN”). Select the preferred outlet

connection from the pre-plumbed connection ports oered – marked “OUT”.

Side connection is accessed by removal of the caps supplied, that cap then being

used to seal the end outlet.

2a. In ground/oor

Remove all packaging, including the skid. Conrm ow direction,

lower in and level interceptor accounting for anticipated surface

nish requirements.

Note: For installations where high ground water is anticipated,

once located pour at least 8”of concrete on top of your prepared

base, to ll an area around the perimeter of the tank. This will prevent

otation. For alternative methods of anchoring (See Page 8-10).

2b. On oor/oor below

Remove all packaging including the skid. Locate the interceptor so as to allow for accessibility

when conducting maintenance and regular cleaning. Set the interceptor on a rm, level

surface ensuring tank is equally supported.

When full the weight of the tank is signicant (XL75 Approx. 1300lbs [590kg]),

XL100 Approx. 2150lbs [975kg])

For suspended application engineering service by a qualied engineer will be necessary.

A minimum safety factor of 2 shall be applied in calculation/design.

Concrete Anchor

Base (if anchoring

is required)

Min.

6"

Inle

tO

utlet

Min.

12"

Min.

12"

Min.

8"

6" Minimum Base

of Crushed aggregate

material approximately

3/4" size rock, pea

gravel or sand

Ensure adequate room for

piping connections

and inspections

Ensure adequate room for

piping connections

and inspections

GREASEINTERCE PTOR

GREAS E INTERCEP TOR

GREASEINTERCE PTOR

GREASEINTERCEPT OR

Cleanout

GREASEINTERCE PTOR

GREASEINTERCEPT OR

GREASEINTERCE PTOR

GREASEINTERCEPT OR

OUTSIDE -

SIDE - OUT

END - OUT

IN

OUT

IN

Cleanout

Cleanout

External

Flow

Control

Cleanout

Max. 25ft

FCD Air Intake

PDI

External Flow

Control. Located

as close as possible to

the last fixture

Cleanout Cleanout

Sink

Flow

Max. 25ft

(for PDI)

PDI

External Flow

Control installation

Cleanout

Cleanout

FCD Air Intake

Sink

InletOutlet

4. Installations with External Flow Control

(PDI G-101/ASME A112.14.3 - Type A)

See page 6 for

cleanout part numbers

Min. Base

Anchoring

(if required)

Level end to end

Flow Direction

Level side to side

For PDI G-101/ASME A112.14.3 (External Flow Control)–

Install the ow control device (purchased separately)

upstream, after the last branch connection discharging to the

interceptor. A maximum of 25ft from last branch discharge

to the entry of the interceptor is required to meet published

recommendations. See Page 12 for connection formats.

Plumbing code typically requires provision of a cleanout

to grade immediately before and after the inlet and outlet

connections.

Quick Start Guide

- 5 -

Native

soil

Min.

6"

Fill with water to static level

Fill with water to static level

Native soil

Concrete slab

Continue fill of

Crushed aggregate

material approximately

3/4" size rock,

pea gravel or sand

Continue fill of

Crushed aggregate

material approximately

3/4" size rock,

pea gravel or sand

6. Replace cover(s) and backll

Replace cover(s) and protect with cardboard or similar

during back lling. Backll per specication (See Page 8).

If installing Remote Pump option do so now (See Page 13)

5. Fill tank

Fill tank with water to static water level. This provides stability

and crush resistance during backlling. Check connections made

for any leaks.

For inspection testing DO NOT PRESSURE the tank. Plug

lines inside interceptor to test upstream and downstream

integrity.

7. Riser Extensions (optional)

Depending on your application, extend the tank risers

(using 40100AX35) to grade/oor level. Be sure to account

for nishing. (Refer to Manual 40100X35-8 – Riser Extension

Installation Guide)

8. Finish to grade / oor

For in ground applications with vehicular trac, the upper 8”requires a

reinforced concrete slab. Refer to the Installation Specication section of

this document (See Page 8-9). This details backll materials and concrete

reinforcement requirements.

If installing in internal application with tiled oor, ensure adequate

protection to prevent mortar from covering bolts, and/or entering

around cover perimeter.

9. Completion documentation

Having completed installation and successful inspection, hand-over to the client all installation documentation, with page 14

completed. Fill out your sections of the Limited Lifetime warranty registration (See Page 24).

If submitting on behalf of your client you can do so at www.EnduraWarranty.com or by sending to the locations shown on

the back cover of this document.

72”

Maximum

height

72”

Maximum

height

Vehicular traffic reinforced concrete

Reinforced concrete pad for traffic rated installations

8"

8"

WARNING!

X

DO NOT

PRESSURE TEST.

RISK OF SERIOUS

INJURY.

For Spec See Page 8-9

Technical Information

- 6 -

19

13

9

10

1 52 63 74 8

11 12

15

14

20 21

22

18

16 17

Mechanical

Joint couplings

(by others)

All images are for illustrative

purposes only. Actual parts

my dier.

Air Balance/

Sampling Cap

is ESSENTIAL to

the operation of

the interceptor.

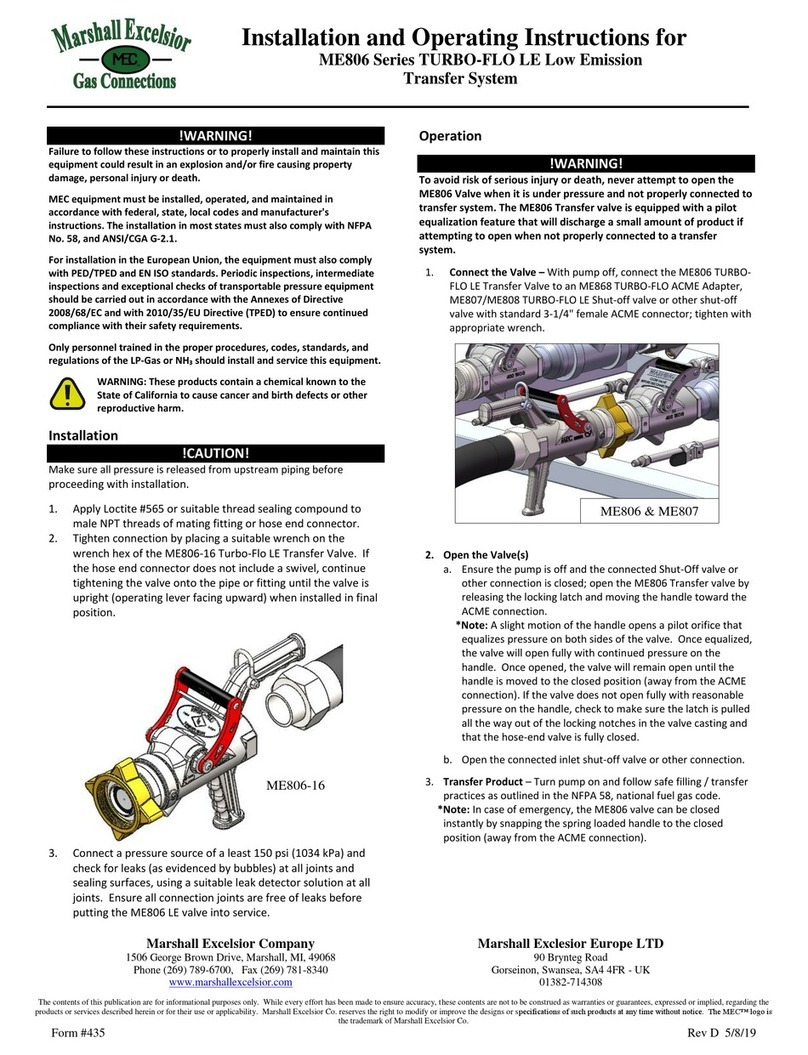

Endura® XL Tank Components

Item # Description Qty Part #

1 Endura® XL 75gpm tank 4”Spigot connections with S Rated Lids 1 4075A04

2 Endura® XL 75gpm tank 4”Spigot connections with M Rated Lids 1 4075A04M

3 Endura® XL 75gpm tank 4” Threaded connections with S Rated Lids 1 4075A04T

4 Endura® XL 75gpm tank 4” Threaded connections with M Rated Lids 1 4075A04MT

5 Endura® XL 100gpm tank 4”Spigot connections with S Rated Lids 1 40100A04

6 Endura® XL 100gpm tank 4”Spigot connections with M Rated Lids 1 40100A04M

7 Endura® XL 100gpm tank 4” Threaded connections with S Rated Lids 1 40100A04T

8 Endura® XL 100gpm tank 4” Threaded connections with M Rated Lids 1 40100A04MT

9 75gpm Replacement Dynamic Bae Assembly 1 4075ARDB

10 100gpm Replacement Dynamic Bae Assembly 1 40100ARDB

11 Internal Flow Control Plate - 75gpm 1 4075-21

12 Internal Flow Control Plate - 100gpm 1 40100-21

13 Endura® XL Air Balance/Sample Port Cap 1 40100-33

14 Cover Seal 2 40100-4

15 Tamper Resistant Cover Fasteners 2 40100ARSB

16 Endura® XL Cover - Trac Rated CSA B481.0 Type‘S’ 2 40100ARCS

17 Endura® XL Cover - Pedestrian/Light Trac Rated CSA B481.0 Type ‘M’ 2 40100ARCM

External Flow Control - for PDI/ASME Type A applications

18 Endura® XL External Flow Control - 75gpm 1 4044275

19 Endura® XL External Flow Control - 100gpm 1 40442100

Parts Purchased - Recommended Installation

20 4” 2-Way Cleanout - Sewer x Sewer x DWV 1 414150BC

21 4” 2-Way Cleanout - Sewer 1 414155BC

Parts Purchased - Remote Pump Application

22 Remote pump pipe seal (optional) 1 40100TPS3

Parts Overview

Access Covers

Trac Rated CSA B481.0Type‘S’

Pedestrian/LightTrac Rated

CSA B481.0Type‘M’

Grade

.625" Raised Cover

Cover Flush to Grade

Grade

.625" Raised Cover

Cover Flush to Grade

300 lb

135 kg

300 lb

135 kg

2000 lb

907 kg

10,000 lb

4536 kg

M

300 lb

135 kg

300 lb

135 kg

2000 lb

907 kg

10,000 lb

4536 kg

S

Technical Information

- 7 -

Specication:

Sample specication clause.

Contractor shall install a Endura® XL Hydromechanical Grease Interceptor (HGI), Part No. 40100A04 q, 40100A04M q,

4075A04 q, 4075A04M q(See page 6 table), and rated to 100GPM q75GPM q(Indicate as Applicable) independently third-party

certied to the current version of PDI G-101, ASME A112.14.3, NSF ES15741 and CSA B481.1. Approved alternate is permissible providing

written compliance to the following is provided and validated. For threaded (FTP) connection sux part number with T q (Tick if required).

Where an internal ow control is desirable and acceptable to the Authority Having Jurisdiction (AHJ), the interceptor shall be rated and

approved to ASME A112.14.3 Type C. The ow control shall be accessible for cleaning and inspection up to the maximum burial depth of

72” regardless of the application and when requiring Riser Extension, the installing contractor will extend the opening device according

to manufacturers published instructions. The outlet system will provide facility for connections to be made perpendicular to the inlet

connection. Connection formats will be compliant with requirements of AHJ and the performance standards identied above. Contractor

shall provide mechanical joint connectors or requisite materials to connect the grease interceptor to the drainage system, additionally

making adequate provision for management of food debris and solids.

Interceptor shall be furnished with two (2) access covers, maximizing internal visibility for inspection and maintenance when removed.

These covers shall be capable of withstanding a proof load of 20,000lbs, approved for application at temperatures from -20˚F to +100˚F

(-29˚C to +38˚C) and will be mechanically secured when operational.

The interceptor tank shall be constructed with seemless engineered thermoplastics, evaluated and approved to the material performance

requirements of CSA B481.0

The interceptor shall additionally; operate with an air-balanced environment to equalize variation in internal pressures being controlled

and maintained with an appropriately sized air balance means; be supported by a Lifetime Warranty against manufacturing defect.

For approved Plumbing & Drainage Institute (PDI) installation, an accessible ow control 40442100A q, 4044275A q

40442100AT q, 4044275AT q(Indicate as applicable) with molded orice and removable access cap will be installed upstream of

the interceptor, being vented and installed according to manufactures instructions and the currently published version of PDI G-101.

Interceptor will be located within 25ft developed pipe run of the last connected appliance for standard compliance. Where applicable

a secondary ow control will be employed in installations where there is greater than 8ft of vertical elevation between the kitchen

discharge appliances and the interceptor inlet.

Air Intake can be connected to building

vent system or be independently to the

atmosphere based on local code.

• Flow Control

• Flow Control

Pipe by

others

• Air Intake Tee

• Air Intake Tee

Connection

Iron Pipe Size

(Solvent weld)

4” h x h

A 6.13”

(155.7mm)

B 6.84”

(173.7mm)

C -

4” h x h

3.19”

(81mm)

5.04”

(128mm)

2.72”

(69.1mm)

Capacities

External Flow

Control Dimensions

For full CAD, BIM Models

and 3 Part Master Format

Specs visit www.arcat.com

Search keyword “endura”

CAD BIM SPECS

®

Endura XL75 Endura XL100

• Part Number 4075A04

4075A04M

40100A04

40100A04M

US Gallons Per Minute - GPM (L/Sec) 75 (4.74) 100 (6.3)

Average Eciency % (ASME

A112.14.3) >98% >98%

Operating Temperature Capabilities 160˚F

(71˚C)

160˚F

(71˚C)

Cover Load Rating- CSA B481.0

S10,000 lb (4536 kg)

M2000 lb (907 kg)

S10,000 lb (4536 kg)

M2000 lb (907 kg)

CSA B481.0

Min. Test Load for Approval

S20,000 lb (9072 kg)

M4000 lb (1814 kg)

S20,000 lb (9072 kg)

M4000 lb (1814 kg)

Unit Weight (Empty) 233 lb

(106 kg)

283 lb

(128 kg)

Liquid Capacity 158 gal

(598 L)

257 gal

(973 L)

Connection size

(mechanical joint only)

4” 4”

Min. Grease Capacity - lb (kg) 150 (68.2) 200 (90.8)

Grease Capacity Actual

(ASME A112.14.3) - lb (kg)

† NSF ES 15741

559 (253)†1058 (480)†

Installation Specications

- 8 -

4"

the unit footprint

Concrete Pad

must extend

18" outside

45.00°

2 1/2" Min.

18" outside the unit footprint

Concrete Pad must extend

8"

4"

Top View

Rebar

Finished Grade

Rebar

CONCRETE SLAB DETAIL FOR TRAFFIC LOADING

(INTERIOR OR EXTERIOR)

Elevation View

(Connecting pipe and fittings by others)

For unit details see specification sheet for selected unit

SIDE VIEW DETAIL

(INTERIOR OR EXTERIOR)

EXCAVATION AND

BACKFILL DETAIL

DIMENSIONS

72”

Maximum

height

Native soil

Concrete slab

Crushed aggregate

material approximately

3/4" size rock, pea gravel

or sand

6”Min. base crushed

aggregate material

approx. 3/4" size rock,

pea gravel or sand

95 proctor.

unit (by others)

Clean out to grade

Flow

on outlet pipe of each

tee (414155BC)

2-Way cleanout

tee (414155BC)

2-Way cleanout

mechnical joint

coupling (by others)

Standard 4”

mechnical joints

coupling (by others)

Standard 4”

on inlet pipe of each

Clean out to grade

unit (by others)

Flow

72”

Maximum

height

50”

26”

22”

14

29”

79”

32” 39.5”

59”

43”

Risers to grade

MATL: PE

DESCRIPTION:

DWG BY: L.S.

DWG NUMBER: XL75BGT

4075A04 4075A04T 4075A04M 4075A04MT

Endura XL grease interceptors are rated and supplied with an internal flow control system already in place.

They do not require an external flow control system or air intake vent unless specified by local code requirements

or being operated as a PDI G-101 installation. Endura XL grease interceptors are only to be installed in the

manner and for the application shown. Consult local codes for separate trapping requirements, cleanout locations

and additional installation instructions. Full instructional information supplied with every interceptor.

NOTES:

PROPRIETARY AND CONFIDENTIAL - © Canplas 2017

Canplas Industries Ltd.

500 Veterans Drive, Box 1800

Barrie, Ontario,

Canada L4M 4V3

CAN: 1-800-461-1771 USA: 1-888-461-5307

DATE: MAY, 2017 REV: 1.2

Endura brand products

manufactured by

Canplas Industries Ltd.

Endura® XL - EXTERIOR BELOW GRADE INSTALLATION INSTRUCTIONS

BELOW GRADE INSTALLATION INSTRUCTIONS

1. EXCAVATION

1.1 Install the Endura ® XL unit(s) as close as possible to xtures being serviced, ideally within 25ft of

developed pipe run from the last xture to the inlet of the interceptor.

1.2 Width and length of excavation shall be minimum 12”greater than the tank dimensions on all sides.

1.3 Depth of excavation shall be at least 6”deeper than tank bottom.

1.4 IMPORTANT: Maximum burial depth 6ft (72”) measured from the air balance channel (EnduraXL Logo)

to nished grade/oor level. Riser extensions available (40100AX35) - (see below).

1.5 Set the tank on well-packed crushed aggregate material approximately 3/4”size rock, pea gravel or

sand.When setting Endura® XL units they must be level laterally and longitudinally.

1.6 Endura® XL tanks are specically designed to resist bouyancy in high water table conditions. Additional

anchoring may however be necessary as determined by the specifying engineer. Tie-down locations are

incorporated to the tank and can be used in conjunction with coated stainless steel cable and an

applicable anchor method based on subsoil. Specific requirements to be determined by specifying engineer.

2. BACKFILLING & FINISHED CONCRETE SLAB (TRAFFIC LOAD RATED)

Endura® XL is supplied standard with trac rated covers designed in accordance with

AASHTO 304 – H20 (16,000lbs) and approved to CSA B481.0 Class‘S’-20˚F to +100˚F (-29˚C to +38˚C)

2.1 Preparation of sub grade per local jurisdictional recommendations.

2.2 Stabilize and compact sub grade to 95% proctor per Excavation information above.

2.3 Fill tank with water (to discharge level) to prevent movement during backlling process and to resist

backll load.

2.4 Before backlling and pouring of slab, install riser(s) (as necessary) and cover assembly to suit nished

oor/grade level.

2.5 Backll using crushed aggregate material approximately 3/4”size rock, pea gravel or sand.

2.6 Place minimum 6”aggregate base beneath poured structural slab. Aggregate should be 3/4”size rock or

pea shingle.

2.7 Thickness of concrete around cover to be determined by specifying engineer. If trac loading is required

refer to local specifying engineer recommendations and/or local code requirements. Note: Concrete slab

dimensions shown are for illustration purposes only.

2.8 Concrete to be 28 day compressive strength to 4000 PSI. Reinforcement with No.4 rebar (1/2”) grade 60

steel per ASTM A615: connected with tie wire. Rebar to be 2½”from edge of concrete. Rebar spacing

12”grid. 4”spacing around access openings.

3. PIPING CONNECTIONS

3.1

All Endura® XL Grease Interceptors are manufactured with no hub connections.Threaded connections are

available from your Endura distributor suxing the product code with‘T’– i.e. 40100A04T

3.2 Locally approved mechanical joint (MJ) couplings are used to connect the inlet and outlet piping to the

tank.This allows transition to dierent piping materials as required.

3.3 Make system piping connections using locally approved MJ couplings installing to manufacturer’s

instructions. Review all eld-made connections for leaks before backlling begins. Isolate the tank from

the system both up and down stream and ll tank with water, submersing the inlet and outlet fully

below the water level. DO NOT PRESSURE TEST – Risk of serious Injury or Death.

3.4 DO NOT decrease pipe diameter across the unit (i.e. 4 inch inlet, 3 inch outlet). If the piping system

needs to be resized, use appropriate mechanical joint reducers consistent with the direction of ow and

installed in compliance with local code.

4 EXTENSION RISERS (Optional)

4.1 Endura® XL Extension Risers provide a maximum of 35”extension per riser. Based on maximum

installation depth up to a maximum of 72”depth of burial can achieved (see 1.4 above), adding

Extension Risers (or part thereof) during installation. Risers are cut to length on site to suit installation.

4.2 Remove cover from interceptor. Set aside for use at nished grade/oor level.

4.3 Secure riser to tank (frame remains in place) using xings provided. Ensure seal is correctly located.

4.4 Secure the 1-1/2” adapter tting supplied with the Extension Kit to the thread on the top of the handle

mechanism. Cut and extend a length of 1½”DWV pipe per instructions supplied.

4.5 For custom riser length - measure from tank frame to nished grade/oor level. Subtract 1½”. Cut

cleanly by hand or mechanical means using guide rings molded into the riser to give clean straight cut.

Note - Horizontal surface of cover will be 0.5”above nished oor/grade.

4.6 Fit riser seal provided over the cut edge of the riser and locate frame (supplied) over the seal making

sure it is fully seated. Secure with lag screws provided using the pre-drilled locations in frame.

4.7 Repeat process for additional riser if/as required.

4.8 With frame installed and veried at the correct height, pass the handle extension support over the 1½”

DWV and secure the support to the frame with the screw provided. Solvent weld a 1½”vent tee on top

of the pipe to act as a handle.

4.9 Re-t the original cover(s) provided with the interceptor.

Installation Specications

- 9 -

Endura® XL - EXTERIOR BELOW GRADE INSTALLATION INSTRUCTIONS

BELOW GRADE INSTALLATION INSTRUCTIONS

1. EXCAVATION

1.1 Install the Endura ® XL unit(s) as close as possible to xtures being serviced, ideally within 25ft of

developed pipe run from the last xture to the inlet of the interceptor.

1.2 Width and length of excavation shall be minimum 12”greater than the tank dimensions on all sides.

1.3 Depth of excavation shall be at least 6”deeper than tank bottom.

1.4 IMPORTANT: Maximum burial depth 6ft (72”) measured from the air balance channel (EnduraXL Logo)

to nished grade/oor level. Riser extensions available (40100AX35) - (see below).

1.5 Set the tank on well-packed crushed aggregate material approximately 3/4”size rock, pea gravel or

sand.When setting Endura® XL units they must be level laterally and longitudinally.

1.6 Endura® XL tanks are specically designed to resist bouyancy in high water table conditions. Additional

anchoring may however be necessary as determined by the specifying engineer. Tie-down locations are

incorporated to the tank and can be used in conjunction with coated stainless steel cable and an

applicable anchor method based on subsoil. Specific requirements to be determined by specifying engineer.

2. BACKFILLING & FINISHED CONCRETE SLAB (TRAFFIC LOAD RATED)

Endura® XL is supplied standard with trac rated covers designed in accordance with

AASHTO 304 – H20 (16,000lbs) and approved to CSA B481.0 Class‘S’-20˚F to +100˚F (-29˚C to +38˚C)

2.1 Preparation of sub grade per local jurisdictional recommendations.

2.2 Stabilize and compact sub grade to 95% proctor per Excavation information above.

2.3 Fill tank with water (to discharge level) to prevent movement during backlling process and to resist

backll load.

2.4 Before backlling and pouring of slab, install riser(s) (as necessary) and cover assembly to suit nished

oor/grade level.

2.5 Backll using crushed aggregate material approximately 3/4”size rock, pea gravel or sand.

2.6 Place minimum 6”aggregate base beneath poured structural slab. Aggregate should be 3/4”size rock or

pea shingle.

2.7 Thickness of concrete around cover to be determined by specifying engineer. If trac loading is required

refer to local specifying engineer recommendations and/or local code requirements. Note: Concrete slab

dimensions shown are for illustration purposes only.

2.8 Concrete to be 28 day compressive strength to 4000 PSI. Reinforcement with No.4 rebar (1/2”) grade 60

steel per ASTM A615: connected with tie wire. Rebar to be 2½”from edge of concrete. Rebar spacing

12”grid. 4”spacing around access openings.

3. PIPING CONNECTIONS

3.1

All Endura® XL Grease Interceptors are manufactured with no hub connections.Threaded connections are

available from your Endura distributor suxing the product code with‘T’– i.e. 40100A04T

3.2 Locally approved mechanical joint (MJ) couplings are used to connect the inlet and outlet piping to the

tank.This allows transition to dierent piping materials as required.

3.3 Make system piping connections using locally approved MJ couplings installing to manufacturer’s

instructions. Review all eld-made connections for leaks before backlling begins. Isolate the tank from

the system both up and down stream and ll tank with water, submersing the inlet and outlet fully

below the water level. DO NOT PRESSURE TEST – Risk of serious Injury or Death.

3.4 DO NOT decrease pipe diameter across the unit (i.e. 4 inch inlet, 3 inch outlet). If the piping system

needs to be resized, use appropriate mechanical joint reducers consistent with the direction of ow and

installed in compliance with local code.

4 EXTENSION RISERS (Optional)

4.1 Endura® XL Extension Risers provide a maximum of 35”extension per riser. Based on maximum

installation depth up to a maximum of 72”depth of burial can achieved (see 1.4 above), adding

Extension Risers (or part thereof) during installation. Risers are cut to length on site to suit installation.

4.2 Remove cover from interceptor. Set aside for use at nished grade/oor level.

4.3 Secure riser to tank (frame remains in place) using xings provided. Ensure seal is correctly located.

4.4 Secure the 1-1/2” adapter tting supplied with the Extension Kit to the thread on the top of the handle

mechanism. Cut and extend a length of 1½”DWV pipe per instructions supplied.

4.5 For custom riser length - measure from tank frame to nished grade/oor level. Subtract 1½”. Cut

cleanly by hand or mechanical means using guide rings molded into the riser to give clean straight cut.

Note - Horizontal surface of cover will be 0.5”above nished oor/grade.

4.6 Fit riser seal provided over the cut edge of the riser and locate frame (supplied) over the seal making

sure it is fully seated. Secure with lag screws provided using the pre-drilled locations in frame.

4.7 Repeat process for additional riser if/as required.

4.8 With frame installed and veried at the correct height, pass the handle extension support over the 1½”

DWV and secure the support to the frame with the screw provided. Solvent weld a 1½”vent tee on top

of the pipe to act as a handle.

4.9 Re-t the original cover(s) provided with the interceptor.

Endura XL grease interceptors are rated and supplied with an internal flow control system already in place.

They do not require an external flow control system or air intake vent unless specified by local code requirements

or being operated as a PDI G-101 installation. Endura XL grease interceptors are only to be installed in the

manner and for the application shown. Consult local codes for separate trapping requirements, cleanout locations

and additional installation instructions. Full instructional information supplied with every interceptor.

NOTES:

PROPRIETARY AND CONFIDENTIAL - © Canplas 2017

4"

the unit footprint

Concrete Pad

must extend

18" outside

45.00°

2 1/2" Min.

18" outside the unit footprint

Concrete Pad must extend

8"

4"

Top View

Rebar

Finished Grade

Rebar

CONCRETE SLAB DETAIL FOR TRAFFIC LOADING

(INTERIOR OR EXTERIOR)

Elevation View

(Connecting pipe and fittings by others)

For unit details see specification sheet for selected unit

SIDE VIEW DETAIL

DIMENSIONS

26”

22”

14”

34.5”

48.5”

84.5”

50”

72”

Maximum

height

72”

Maximum

height

78”

48.5”

32”

Native soil

Concrete slab

Crushed aggregate

material approximately

3/4" size rock, pea gravel

or sand

unit (by others)

Clean out to grade

Flow

on outlet pipe of each

tee (414155BC)

2-Way cleanout

tee (414155BC)

2-Way cleanout

mechnical joint

coupling (by others)

Standard 4”

mechnical joints

coupling (by others)

Standard 4”

on inlet pipe of each

Clean out to grade

unit (by others)

Flow

Risers to grade

DATE: MAY, 2017 REV: 1.2

MATL: PE

DESCRIPTION:

DWG BY: L.S.

DWG NUMBER: XL100BGT

6”Min. base crushed

aggregate material

approx. 3/4" size rock,

pea gravel or sand

95 proctor.

(INTERIOR OR EXTERIOR)

EXCAVATION AND

BACKFILL DETAIL

Canplas Industries Ltd.

500 Veterans Drive, Box 1800

Barrie, Ontario,

Canada L4M 4V3

CAN: 1-800-461-1771 USA: 1-888-461-5307

Endura brand products

manufactured by

Canplas Industries Ltd.

40100A04 40100A04M 40100A04T 40100A04MT

Endura® XL - EXTERIOR BELOW GRADE INSTALLATION INSTRUCTIONS

BELOW GRADE INSTALLATION INSTRUCTIONS

1. EXCAVATION

1.1 Install the Endura ® XL unit(s) as close as possible to xtures being serviced, ideally within 25ft of

developed pipe run from the last xture to the inlet of the interceptor.

1.2 Width and length of excavation shall be minimum 12”greater than the tank dimensions on all sides.

1.3 Depth of excavation shall be at least 6”deeper than tank bottom.

1.4 IMPORTANT: Maximum burial depth 6ft (72”) measured from the air balance channel (EnduraXL Logo)

to nished grade/oor level. Riser extensions available (40100AX35) - (see below).

1.5 Set the tank on well-packed crushed aggregate material approximately 3/4”size rock, pea gravel or

sand.When setting Endura® XL units they must be level laterally and longitudinally.

1.6 Endura® XL tanks are specically designed to resist bouyancy in high water table conditions. Additional

anchoring may however be necessary as determined by the specifying engineer. Tie-down locations are

incorporated to the tank and can be used in conjunction with coated stainless steel cable and an

applicable anchor method based on subsoil. Specific requirements to be determined by specifying engineer.

2. BACKFILLING & FINISHED CONCRETE SLAB (TRAFFIC LOAD RATED)

Endura® XL is supplied standard with trac rated covers designed in accordance with

AASHTO 304 – H20 (16,000lbs) and approved to CSA B481.0 Class‘S’-20˚F to +100˚F (-29˚C to +38˚C)

2.1 Preparation of sub grade per local jurisdictional recommendations.

2.2 Stabilize and compact sub grade to 95% proctor per Excavation information above.

2.3 Fill tank with water (to discharge level) to prevent movement during backlling process and to resist

backll load.

2.4 Before backlling and pouring of slab, install riser(s) (as necessary) and cover assembly to suit nished

oor/grade level.

2.5 Backll using crushed aggregate material approximately 3/4”size rock, pea gravel or sand.

2.6 Place minimum 6”aggregate base beneath poured structural slab. Aggregate should be 3/4”size rock or

pea shingle.

2.7 Thickness of concrete around cover to be determined by specifying engineer. If trac loading is required

refer to local specifying engineer recommendations and/or local code requirements. Note: Concrete slab

dimensions shown are for illustration purposes only.

2.8 Concrete to be 28 day compressive strength to 4000 PSI. Reinforcement with No.4 rebar (1/2”) grade 60

steel per ASTM A615: connected with tie wire. Rebar to be 2½”from edge of concrete. Rebar spacing

12”grid. 4”spacing around access openings.

3. PIPING CONNECTIONS

3.1

All Endura® XL Grease Interceptors are manufactured with no hub connections.Threaded connections are

available from your Endura distributor suxing the product code with‘T’– i.e. 40100A04T

3.2 Locally approved mechanical joint (MJ) couplings are used to connect the inlet and outlet piping to the

tank.This allows transition to dierent piping materials as required.

3.3 Make system piping connections using locally approved MJ couplings installing to manufacturer’s

instructions. Review all eld-made connections for leaks before backlling begins. Isolate the tank from

the system both up and down stream and ll tank with water, submersing the inlet and outlet fully

below the water level. DO NOT PRESSURE TEST – Risk of serious Injury or Death.

3.4 DO NOT decrease pipe diameter across the unit (i.e. 4 inch inlet, 3 inch outlet). If the piping system

needs to be resized, use appropriate mechanical joint reducers consistent with the direction of ow and

installed in compliance with local code.

4 EXTENSION RISERS (Optional)

4.1 Endura® XL Extension Risers provide a maximum of 35”extension per riser. Based on maximum

installation depth up to a maximum of 72”depth of burial can achieved (see 1.4 above), adding

Extension Risers (or part thereof) during installation. Risers are cut to length on site to suit installation.

4.2 Remove cover from interceptor. Set aside for use at nished grade/oor level.

4.3 Secure riser to tank (frame remains in place) using xings provided. Ensure seal is correctly located.

4.4 Secure the 1-1/2” adapter tting supplied with the Extension Kit to the thread on the top of the handle

mechanism. Cut and extend a length of 1½”DWV pipe per instructions supplied.

4.5 For custom riser length - measure from tank frame to nished grade/oor level. Subtract 1½”. Cut

cleanly by hand or mechanical means using guide rings molded into the riser to give clean straight cut.

Note - Horizontal surface of cover will be 0.5”above nished oor/grade.

4.6 Fit riser seal provided over the cut edge of the riser and locate frame (supplied) over the seal making

sure it is fully seated. Secure with lag screws provided using the pre-drilled locations in frame.

4.7 Repeat process for additional riser if/as required.

4.8 With frame installed and veried at the correct height, pass the handle extension support over the 1½”

DWV and secure the support to the frame with the screw provided. Solvent weld a 1½”vent tee on top

of the pipe to act as a handle.

4.9 Re-t the original cover(s) provided with the interceptor.

Installation Specications

- 10 -

External

Flow Control

If Required

External

Flow Control

If Required

External

Flow Control

If Required

External

Flow Control

If Required

External

Flow Control

If Required

OUT

OUT

OUT

OUT

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

OUT

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASE INTE RCEPTOR

GREASEI NTERCEPTOR

GREASEI NTERCEPTOR

GREASEI NTERCEPTOR

GREASEI NTERC EPTOR

GREASEI NTERCEPTOR

GREASEI NTERCEPTOR

GREASEI NTERC EPTOR

GREASEINT ERCEPTOR

GREASEINT ERCEPTOR

GREASEINT ERCEPTOR

GREASEIN TERCEPTOR

GREASEIN TERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEP TOR

GREASEINT ERCEPTOR

OUT

OUT

IN

IN

GREASEINT ERCEPTOR

GREASEINT ERCEPTOR

GREASEI NTERCEPTOR

GREASEIN TERCEPTOR

GREASEIN TERCEP TOR

GREASEINT ERCEPTOR

GREASEINTERCEP TOR

GREASEINT ERCEPTOR

IN

IN

IN

IN

GREASEIN TERCEP TOR

GREASEI NTERCEP TOR

GREASEINTERCEP TOR

GREASEINT ERCEPTOR

GREASEIN TERCEP TOR

GREASEI NTERCEP TOR

GREASEINTERCEP TOR

GREASEINT ERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEI NTERCEP TOR

GREASEIN TERCE PTOR

OUT

IN

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASE INTE RCEPTO R

GREASEINT ERCEPTOR

IN

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

OUT

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEI NTERCEPTOR

GREASEI NTERCEPTOR

IN

GREASEI NTERCEPTOR

GREASEI NTERC EPTOR

GREASEIN TERCEP TOR

GREASEI NTERCEP TOR

GREASEINT ERCEPTOR

GREASEINT ERCEPTOR

GREASEINTERCEPTOR

GREASEIN TERCEPTOR

GREASEINT ERCEPTOR

GREASEINT ERCEPTOR

GREASEI NTERCEPTOR

GREASEI NTERC EPTOR

OUT

IN

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEIN TERCEP TOR

GREASEI NTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

OUT

IN

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

GREASEINTERCEPTOR

4075A04 4075A04M 4075A04T 4075A04MT

MATL: PE

DESCRIPTION:

DWG BY: L.S.

DWG NUMBER: XLSP

40100A04 40100A04M 40100A04T 40100A04MT

C/OC/O

C/O

C/OC/O C/OC/O C/O

C/OC/OC/OC/O

C/O

C/O

C/OC/O C/O

C/OC/O C/O

C/O

C/OC/OC/OC/O

C/OC/O

C/O

C/OC/O

C/O

C/O

External

Flow Control

If Required

External

Flow Control

If Required

External

Flow Control

If Required

External Flow Control If Required

Flow Control

Cleanout Air Intake

External

Flow Control

If Required

C/O

C/OC/O

C/OC/O

C/OC/O

C/OC/O

C/OC/O

External

Flow Control

If Required

External

Flow Control

If Required

External

Flow Control

If Required

External

Flow Control

If Required

External

Flow Control

If Required

External

Flow Control

If Required

External

Flow Control

If Required

GREASE INTERCE PTOR

GREASE INT ERCEPTOR

GREASE INTER CEPTOR

GREASE INT ERCEPTOR

Endura XL grease interceptors are rated and supplied with an internal flow control system already in place.

They do not require an external flow control system or air intake vent unless specified by local code requirements

or being operated as a PDI G-101 installation. Endura XL grease interceptors are only to be installed in the

manner and for the application shown. Consult local codes for separate trapping requirements, cleanout locations

and additional installation instructions. Full instructional information supplied with every interceptor.

NOTES:

PROPRIETARY AND CONFIDENTIAL - © Canplas 2017

DATE: MAY, 2017 REV: 1.2

Canplas Industries Ltd.

500 Veterans Drive, Box 1800

Barrie, Ontario,

Canada L4M 4V3

CAN: 1-800-461-1771 USA: 1-888-461-5307

Endura brand products

manufactured by

Canplas Industries Ltd.

Series Installation:

· Series congurations shown are considered optimal for application and should be followed

· Anticipated as installations with low to medium ow (less than 60% of rated ow capacity)

· Where preferred or required, installation of a correctly rated external ow control shall be made

upstream and with reference to PDI G-101 where applicable. A single ow control shall be located

upstream of any ow division and vented accordingly. Location shall be accessible once operational.

Important: Internal ow control plates are to be removed in this operational format.

· Adequate provision for drain access is essential.Two way cleanouts extended to grade are required

before the rst tank inlet and following the nal outlet. Access between tanks is also recommended if

pipe length is greater than 36”

· Connections to tank made with approved Mechanical Joint (MJ) couplings or male pipe thread

dependent on unit specication.

· Manufacturer’s instructions supplied with units must be followed.

Where preferred or required an external ow control

(purchased separately) will be installed up stream after last

branch connection no further than 25ft from interceptor

414155BC Cleanout

414155BC

Cleanout

External Flow

Control If

required

External Flow

Control If

required

External Flow

Control If

required

External Flow

Control If

required

414226BC

6 x 4 Ext.

Reducer

414130BC

Double Wye

414194BC

45˚ Bend -

Street

414155BC

Cleanout

414174BC 90˚ Bend

Recommended

Components:

Parallel Installation:

· Parallel congurations shown are considered optimal for

application and should be followed.

· Intended for installations with high ow (greater than

60% of rated ow capacity) per unit.

· Where External Flow Control is not required or preferred,

the parallel conguration can be operated with internal

ow controls managing ow to the respective interceptor

· Where preferred or required, installation of a correctly

rated external ow control shall be made upstream of the

interceptor inlet but downstream of any division of ow.

Flow control shall be accessible (from grade as applicable)

once operational.

· Adequate provision for drain access is essential.Two way

cleanouts extended to grade are required before all tank

inlets and following all outlets. Access between tanks is also

recommended if pipe length is greater than 36”

· Connections to tank made with approved Mechanical

Joint (MJ) couplings or male pipe thread dependent on unit

specication.

· Manufacturer’s instructions supplied with units must

be followed.

Access Covers:

For trac applications Endura XL is

supplied with CSA B481.0 Type‘S’

covers. For Internal/ light vehicular

trac applications select‘M’model

(2000 lb Safe Working Load)

2 no. XL75 – SERIES - 75GPM, 1118 lbs Grease Capacity.

2 no. XL75 – PARALLEL

Up to 150GPM, 1118 lbs

Grease Capacity.

2 no. XL100 – PARALLEL

Up to 200GPM, 2116 lbs

Grease Capacity.

3 no. XL100 – PARALLEL

Up to 300GPM, 3174 lbs

Grease Capacity.

4 no. XL100 – PARALLEL

Up to 400GPM, 4232 lbs

Grease Capacity.

2 no. XL100 – SERIES - 100GPM, 2116 lbs Grease Capacity.

3 no. XL100 – SERIES - 100GPM, 3174 lbs Grease Capacity.

4 no. XL100 – SERIES - Up to 400GPM, 4232 lbs Grease Capacity.

4 no. XL100 – SERIES - Up to 400GPM,

4232 lbs Grease Capacity.

Canplas

Part#

Description QTY

414155BC SDR35 Two Way Cleanout - HxHxH

414174BC SDR35 90˚ Bend - Street - HxSpg

414130BC SDR35 Double Wye - HxHxHxH

414226BC SDR 35 6 x 4 Ext. Reducer HxSpg

414194BC SDR 35 45˚ Bend - Street

4044275 Endura® XL 75gpm Flow Control

40442100 Endura® XL 100gpm Flow Control

Installation Instructions

- 11 -

Installation

SAFETY FIRST! All installation shall be conducted under the applicable Health and Safety regulations in force

within that jurisdiction. Plumbing operatives shall be adequately trained and appropriately licensed to conduct the

installation. All installations will be made respective and in compliance with applicable plumbing code and any locally

published by-laws. Installation and approval of the same is subject to the appropriate ocials or representatives of the

Authority Having Jurisdiction (AHJ).

Scope of Application:

Endura® XL Grease Interceptors are designed for application in the ecient and eective separation and retention of non-

petroleum Fats, Oil and Grease as a by-product of commercial foodservice activities. The Endura® XL interceptor models are

approved and intended only for use in the specied application and shall not be installed in any manor or application except as

tested and rated.

Accessibility:

Installations shall be made in such a manner that full access for maintenance and cleaning is maintained once the interceptor is

commissioned. A zone based on a column measured 3ft out from the cover perimeter and extending

7ft vertically is recommended.

Inlet (IN) and Outlet (OUT) connections are indicated on the interceptor itself. Ensure that the interceptor is in the correct

orientation and ow in the intended direction before backlling (when in ground) or connection to the respective

drain system.

Location:

A grease interceptor should be installed as close as possible to the xtures it serves to avoid accumulation of FOG between

the source and the interceptor. Adequate provision for rodding and service access is particularly important upstream of the

interceptor. Please refer to local code requirements.

Drain lines servicing the interceptor shall be laid at a minimum ¼”per foot fall and with more gradient where possible.

This promotes good drainage ow and reduces risk of blockages.

Piping Connections:

The primary bulkhead-style connections (in-line) of Endura® XL are injection molded in Polyproylene (PP). PP does not accept

solvent weld cement and will not provide a serviceable connection. DO NOT SOLVENT WELD these drain connections.

Best practice and most codes typically require the use of Nationally or locally approved Mechanical Joint (MJ) couplings for the

connections to and from the interceptor. This method provides some exibility for any ground movement or settling that may

occur.

Flow Control:

Where required or preferred an External Flow control can be installed. In this conguration the installation has the opportunity

to meet the requirements of PDI G-101, assuming that the applicable venting and installation criterial are met (See Page 12).

Refer to the currently published version of PDI G-101 available online at www.pdionline.org for verication.

Trapping:

All connected appliances and xtures must be individually trapped by a permanently installed water seal trap or approved

equivalent, in compliance with applicable plumbing code requirements.

Venting:

The installation of the interceptor shall be vented downstream in accordance with local code requirements - typically within

10 ft max.

• Air Gap/ Air Break

• Flow Control Device

Indirect Connections/ Air Gap/Air Brake :

Some local jurisdictions require warewashing installations to be

made on an indirect basis incorporating an air gap.

This is to prevent the back up of contaminated waste water

into the sinks/appliances in the event of a blockage. As the ow

control device provides a restriction within the system it must be

incorporated before the indirect connection to prevent the risk of

overow occurring during high/maximum waste water discharge.

If an air gap/air break* is located within 6”of ow control device,

installation of the air intake tee is optimal.

*Dependent on jurisdiction

Installation - Flow Controls

- 12 -

Max. 25ft

FCD Air Intake

PDI

External Flow

Control. Located

as close as possible to

the last fixture

Cleanout Cleanout

Sink

Flow

Max. 25ft

(for PDI)

PDI

External Flow

Control installation

Cleanout

Cleanout

FCD Air Intake

Sink

InletOutlet

External Flow

Control:

When installed with an

External Flow Control, the

internal ow control plate and

seal shown above are removed

during installation.

With the internal ow control plate

removed, the ow control function

will now be performed by a separate

device that will be installed upstream

from the interceptor. This is located as

close as possible to the appliances and

xtures being served, but after the last

branch connection to the main drain

line connected to the interceptor. The

ow control shall be installed so as to

remain accessible for maintenance and

will typically be recessed into the oor.

The location of the cleanout should be

recorded in you Installer Hand Over

Check List (See Page 14)

With an external ow control in particular, it

is important that it be opened and checked

periodically (min. twice annually) to ensure

there is no build up or blockage occurring that

will restrict the ow.

Remove

ow control

plate

Remove

ow control seal

Flow Controls

Depending on preference or requirement

Endura® XL can be operated with an internal

or external ow control. All models are

supplied with an internal ow control.

Internal Flow Control:

The internal ow control is located inside the dynamic inlet bae,

axed to the downstream part that moves forward when the

bae is opened.

The ow control is an essential part

of the hydromechanical grease

interceptor and its function.

Flow

control

plate

Flow

control

seal

Inlet

Installation - Remote Pump (Optional)

- 13 -

GREA SE INTE RCEP TOR

GREASE I NTERCE PTOR

GREA SE INTE RCEP TOR

GREASE INTERC EPTOR

45˚ cut

XL75

36”

XL100

41”

Remote Pump (Optional):

Endura® XL incorporates a method for installation of a Remote

Pump function where desirable or required. The simplicity of

this change is such that it can be conducted in the eld with

minimal materials. The installation is based on the use of a 3”

DWV Sch40 pipe which is passed into the tank by means of a 3”

diameter tank penetration seal (Part# 40100-TPS3”).

1. Cut the end of a 3” Sch40 DWV pipe (ABS or PVC by

preference) at an angle that is no less than 45 degrees.

2. GOOD PREPARATION OF THIS PIPE END IS ESSENTIAL TO

AVOID DAMAGING THE RUBBER SEAL WHEN BEING

INSTALLED. The outer edges must be chamfered to at least

45 degrees around the full length of the pipe end.

3. Now measure from the end of the pipe to the following

length depending if you are installing an XL75 or XL100

respectively. For XL75 pipe length 36”; For XL100 pipe

length 44”(Fig A)

4. On the top surface of the tank at the center position and on

either side of the air balance channel are two “Remote

Pump Ready” details, both of which include a drill center

(Fig. B). Select which of the two locations best suits your

application and using a 4”diameter hole saw, open the

respective hole.

Remote

pump outlet

optional

locations

Fig. A

Fig. B

5. Fit penetration tank seal (Part# 40100-TPS) into

the opening prepared and lubricate well using silicone

pipe lubricant.

6. As the orientation of the pipe when installed is important,

mark or identify on the top of the pipe so as to indicate

that the angled face of the pipe will be facing laterally

across the interceptor when installed. i.e. the angled face

is pointed toward the opposite tank wall.

7. Take your prepared length of pipe and liberally apply

silicone pipe lubricant to at least the rst 6”of the pipe

ensuring that the angled surface is also well lubricated.

8. Introduce the pipe to the rubber seal and with even

pressure and a rotating motion, push the pipe through

the seal and into the tank. Once onto the full diameter

of the pipe apply more lubricant to the next 12-18” and

continue to push the pipe downward into the tank until

the tip bottoms out, with the angled face in the correct

position.

9. Develop your pump out line connecting to the pipe

stub now extending from the tank using long sweep

bends and ttings and making provision for adequate

cleanout access as required. All joints must be solvent

welded or of threaded format.

Maximum developed pipe run shall be no greater than

30 feet with a vertical rise of 8 feet max.

10.At the extent of the remote pump system where the

pumping service will be connected, typically a capped

male camlock tting (3”) will be provided to allow

compatibility with vacuum service connection.

GREA SE INTE RCEPT OR

GREASE I NTERC EPTOR

GREA SE INTE RCEPT OR

GREASE I NTERC EPTOR

Max.

30ft

Max.

8ft

45˚ cut faces

opposite tank wall

Long

Sweep

Bends Tank

Penetration

Seal

(40100TPS3)

See

Step

10

Installer Handover Checklist

- 14 -

Installation made by (Company) ___________________________________________________________

Installer (Name) __________________________________________________________________

Installer Contact (Tel)_________________________________

Completed on (Date) _________________________________

Model Installed: q Endura® XL100 (40100A04 (T) / 100GPM)

q Endura® XL75 (4075A04 (T) / 75GPM)

Installation Format: q On-Floor q In Floor - Inside Building q Floor Below (eg. basement)

q In-Ground - Outside building

Slab Poured per Spec for Trac Rated Install q Yes q No (See Page 8-9)

Flow Control Format: q Internal (Inside Inlet Bae)

q External (Upstream of Interceptor)

If External Flow Control…

Internal Flow Control plate removed q Yes q No (See Page 12)

Flow Control Location(s) ____________________________________________________

Connections & Cleanouts (Mark where installed):

Extension Risers added: q Yes - if Yes, approx. length of riser installed: _________in /m

q No

Flow Control Handle Extended: q Yes q No (See Riser Extension Instructions))

Air Balance/Sampling Cap in place: q Yes q No (If No, Replacement required. See Page 16)

Entered Information on Warranty Page q Yes q No

Have feedback?

Email us at… feedback@endurainterceptor.com

Installer Handover Checklist

The following checklist completed by your installer provides key information regarding your XL grease interceptor and

the way it has been installed. If it is not completed contact your installer and complete with them by phone or other

appropriate means.

GREASEINTERC EPTOR

GREASEINTERCEP TOR

GREASEINTERC EPTOR

GREASEINTERCEP TOR

Cleanout

GREASEINTERC EPTOR

GREASEINTERCEP TOR

GREASEINTERC EPTOR

GREASEINTERCEP TOR

OUTSIDE -

SIDE - OUT

END - OUT

IN

OUT

IN

Cleanout

Cleanout

External

Flow

Control

Cleanout

Operation

- 15 -

Operation

IMPORTANT:The key to eective and trouble free operation of your Endura® XL interceptor is regular and

eective maintenance. You should consider your facility to be in partnership with the local authorities, providing an

eective means of FOG management that is mandated to protect your business, your community and the environment.

Dynamic

Inlet Bae:

The Inlet bae design in your Endura® XL

Interceptor is uniquely accessible once in service.

Having removed the cover above the inlet, a simple

pull/push motion on the handle opens and closes

the front shell, allowing access for maintenance and

cleaning. This action also opens the inlet drain to

its full diameter allowing the upstream drains to be

cleaned without obstruction.

This bae can be extended to maintain its function

and value even when buried at full depth below

grade. Refer to installation instructions for riser

extension.

Pull up

to open

Visually inspect or clean inlet

and ow control if required

Food Solids and Debris:

Endura® XL is designed to manage up to 15% of its volume for solids

management. Remember however that your grease interceptor is an engineered

system that is not designed to accommodate large amounts of solid material. This

will impact the operational capacity and performance of the unit and cause the

foul odors often associated with grease interceptors if not removed regularly.

It is strongly recommended that a solids interceptor be installed upstream of the grease interceptor and that all entry points

to the drains running to the interceptor be adequately protected with appropriate screens to prevent debris nding its way

into the system. Likewise, best kitchen practice recommends that all plates, crockery, pans, etc., be scraped to remove lose

food debris prior to washing. Again sinks should be operated with the respective screens.

If you are experiencing frequent issues in regard to blockages or accumulation in your interceptor you must address the

appropriate kitchen practices. DO NOT MODIFY THE INTERCEPTOR OR MEANS OF FLOW CONTROL IN ANY MANNER. Doing

so voids the performance approval required by your local jurisdiction and will leave your operation exposed to the risk of

signicant nes and non-compliance citations.

Solids

retention

area

Clearance

Min. 3ft

180˚

Min. 7ft

clearance

SAFETY FIRST! Ensure that any operatives or employees that attend

to the grease interceptor are adequately protected. As a minimum it is

recommended that protective gloves, eyewear and a mask are provided

and used.

Accessibility:

It is the responsibility of the restaurant operator to maintain

safe, clear and unobstructed access to the interceptor at all

times. This facilitates inspection by local ocials, emergency

access in the event of an issue and for the regular pumping of

the interceptor required to keep it in good working order.

Operation / Maintenance

- 16 -

SAFETY FIRST! ALL ACCESS COVERS SHALL BE

FULLY AND COMPLETELY SECURED (all bolts in place

and tightened accordingly) at the completion of

maintenance procedures, regardless of if the cover

was accessed or not. Missing bolts shall be reported to

management and replaced immediately.

Ensure that any operatives or employees that attend to the

grease interceptor are adequately protected. As a minimum

it is recommended that protective gloves, eyewear and a

mask are provided and used.

Where a third party contractor or service is responsible

for the regular maintenance of the interceptor (strongly

recommended) it is their responsibility not only to ensure

that their own protective practices and procedures are

maintained and followed, but that they also protect those

with access to the vicinity of the interceptor when it is

Air Balanced Operation:

Endura® XL is designed to function based on a balance air environment.

This feature ensures that the high operating eciency is maintained.

During the maintenance of your interceptor, it is important to check

that the breather hole in the outlet vent (see diagram) is unobstructed.

The smallest restriction can drastically impact the performance of your

interceptor and can cause the accumulated contents of the interceptor

to be discharged to the downstream drain system particularly if

discharge rates are toward the maximum rated ow.

If installed in-oor or in ground outside your facility this air balance

access/breather cap must be relocated upward as close as possible to

the underside of the cover to maintain its function.

IF YOU DO NOT SEE A GREY CAP ON TOP

OF THE OUTLET SYSTEM, CONTACT YOUR

INSTALLER/MAINTENANCE CONTRACTOR

IMMEDIATELY AND IF NECESSARY

PURCHASE A REPLACEMENT.

Air Balance/

Sampling Cap is

ESSENTIAL to the

operation of the

interceptor and

must be kept free

of debris.

If extending height,

sampling/air balance

cap must be raised also.

Air Balance Hole

Maintenance

IMPORTANT:The key to eective and trouble free operation of your Endura® XL interceptor is regular and

eective maintenance. You should consider your facility to be in partnership with the local authorities, providing an

eective means of FOG management that is mandated to protect your business, your community and the environment.

Regular Removal of Fat, Oil and Grease:

Due to the capacity of your Endura® XL Grease Interceptor it is necessary to have a licensed and locally approved service

provider manage the regular removal, cleaning and disposal of the Fats, Oil and Grease that is captured in your interceptor.

Every installation is dierent based on factors such as operational hours, menu, seasonality of business, sta changes, etc. As a

rule of thumb your interceptor should be cleaned every 8-12 weeks. You should anticipate a minimum of 4-6 cleans per year.

BMP

BMP

undergoing maintenance. In addition they will be stewards

of the environment, promptly and eectively identifying

to premises management issues with for example, but not

limited to, interceptor operation, damages, spills, etc.

IMPORTANT: The key to eective and trouble free operation

of your Endura® XL interceptor is regular and eective

maintenance (See Maintenance Procedures – Pg 17). You

should consider your facility to be in partnership with the

local authorities, providing an eective means of FOG

management that is mandated to protect your business,

your community and the environment.

Regular Removal of Fat, Oil and Grease:

Due to the capacity of your Endura® XL Grease Interceptor

it is necessary to have a licensed and locally approved

service provider manage the regular removal, cleaning and

disposal of the Fats, Oil and Grease that is captured in your

interceptor.

Maintenance

- 17 -

Maintenance Procedures:

Removal of Access Cover:

The covers that provide access to the XL interceptors

are retained with four (4) standard hex head bolts which

are removed with a ½”socket/driver. These bolts have a

retraining washer on the reverse to prevent them falling

out of their location when the cover is removed from the

interceptor.

Covers incorporate pry points for ease of removal.

Each cover weighs approximately 22lbs (10kg) so take care

when lifting and moving the cover. Always set aside the

cover on a at surface when removed.

On reinstallation visually check the seal recessed in the

underside of the cover and when satised ret the cover

being sure not to overtighten the bolts. Maximum torque is

80-100 ft/lb.

Access to the Dynamic Inlet Bae

(Internal Flow Control where used):

The Dynamic Inlet Bae is a unique element of Endura® XL

allowing access to the internal surfaces for maintenance,

inspection and cleaning.

To open the bae, take a rm grip on the handle and pull

vertically upward. The handle will move approximately 6”in

the vertical direction. In doing so the front shell of the bae

moves away from the xed rear portion providing access to

the internal ow control plate (where tted).

The ow control plate is securely retained but is intended

to be removable during installation, should an external ow

control be the preferred format of installation.

Once open, visual inspection can be made inside the bae.

Any debris is best removed with a low pressure source of

warm water – approx. 38˚C (100˚F)

To close the bae, push vertically downward on the handle

until it returns to the full closed and locked position

Drain Cleaning/Inspection:

For cleaning and inspection of the upstream drain, it is

strongly recommended that the inlet bae be in the open

position. This will reduce the risk of damage to the internal

ow control (where tted) by rooting or other equipment.

Access to the Outlet Well:

Although essentially a closed area, the outlet system is able

to be accessed by removal of the Sampling/Air Balance

Cap. Once removed the 4” vertical pipe is able to be visually

inspected all the way to the bottom (with the unit pumped

out), and in the event of any accumulation can be cleaned

by vacuum or pressurized water, either withdrawing debris

out or back into the tank respectively.

Pumping and Cleaning:

The complete removal of grease and water should be done

at every pump out. This ensures all solids, grease and water

are removed allowing visual inspection and removal of any

residue.

Any residue is best removed with a hot water source rinsing

the walls and internal components into the tank before

making a nal vacuum extraction.

The tank must be re-lled to static

water level on completion of pumping.

An interceptor cannot function

without water.

Remote Pump Out (Optional):

An installation tted with the remote pumping option oers

convenience for the pumper and the restaurant operator,

but also presents risk.

Where installed and operated with a remote pump facility,

the interceptor should be physically opened and inspected

at least every third pumping, or twice a year, whichever

is sooner. This is to ensure that the internal parts are in

good working order and that there is no undue build-up

of residue or solids remaining in the tank once it has been

emptied. This also presents opportunity to open and inspect

the inside of the inlet bae system, and clean/inspect the

outlet well. Any residue will be removed with a warm water

source.

BMP

Remember: Every installation is dierent based on factors such as operational hours, menu, seasonality

of business, sta changes, etc. As a rule of thumb your interceptor should be cleaned every 8-12 weeks. You

should anticipate a minimum of 4 cleans per year.

Pull up

to open

Push

down to

close

Internal Bae

in closed

position

Internal

Bae in open

position for

inspection

Pumper Checklist

- 18 -

Interceptor Operating at: __________________________________________ (Enter Facility Name)

Address: __________________________________________

__________________________________________

__________________________________________

Serviced By (Name): _______________________________

Company: __________________________________________________________

Company Contact (Tel): _______________________________

About this Pump-Out:

Service Date: _______________________________

Format: q Remote Pump q Full Access (Covers Removed)

Last Full Access Pump? ______________________________

Note: At a minimum of every 3rd remote pump or twice annually (whichever is sooner) full access cleaning and

inspection is required.

Interceptor Fully Pumped (Water/FOG & Solids): q Yes q No

Approx. Volume of Waste Removed: _____________________ Gallons/Liters

Inlet Bae Opened/Inspected q Yes q No

Flow Control Checked/Cleaned q Yes q No

Note: The ow control device (internal or external), shall be inspected and cleaned a minimum of every 3rd

pump or twice annually (whichever is sooner)

Cover(s) secured on completion of Pumping? q Yes q No

Important Note: If covers are in an area that is accessible to the public, always check to ensure that covers are

fully secured even if you did not remove the cover(s) as part of this pump-out.

Any Concerns, Issues or Comments to Report: _____________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

Have feedback?

Email us at… feedback@endurainterceptor.com

Pumper Checklist:

Trouble Shooting

- 19 -

Trouble Shooting

Troubleshooting

Symptoms Cause Corrective Actions

Strong pungent odour. • Cover not replaced and/or properly secured

• Cover seal missing or damaged

• Insucient or incorrect venting

• Insucient cleaning frequency

• Secure cover fully - check that there is no dirt/debris in

the threaded insert

• Replace appropriate seal

• Verify installation is made per manufacturer’s instructions

and local plumbing code

• Reduce interval between cleaning – 6 to 8 weeks is

typical for extended capacity, but each installation is

dierent

Sink or drain has backed

up with water • Interceptor maintenance is overdue

• Accumulation of grease/debris between kitchen

and interceptor

• The ow control orice is blocked

• The ow control and grease trap was improperly sized

• The grease trap is full of solids and/or grease

• The grease trap close to, at or beyond its capacity of

solids and/or grease

• Seek emergency plumbing assistance to remove

restriction/blockage. Consider moving the interceptor

closer to the kitchen

• Isolate drain, open accessible ow control and

clear blockage

• Close the ball valve or plug the sink and remove the

obstruction by removing the ow control access lid.

• Install a properly sized grease interceptor

• Increase cleaning frequency

I think I have

missing parts • Parts have been removed or lost during prior servicing • Check exploded drawing in this manual to conrm

the parts that are supposed to make up your

interceptor model

Excessive solids / grease

accumulation •The Grease Interceptor is full/requires cleaning

• Food waste on pots, plates & utensils are not being

scraped into the garbage & is being ushed down the