3

#How the Carbon Shield™ (CS) Unit Works

The Carbon Shield™ system produces a continu-

RXVÀRZRIDLUVXVSHQGHGRLOSDUWLFOHVLQWKHP

WRPUDQJH2LOLVGUDZQIURPDQLQWHJUDOUHVHU-

voir into the mist head where it is atomized into the

air stream.

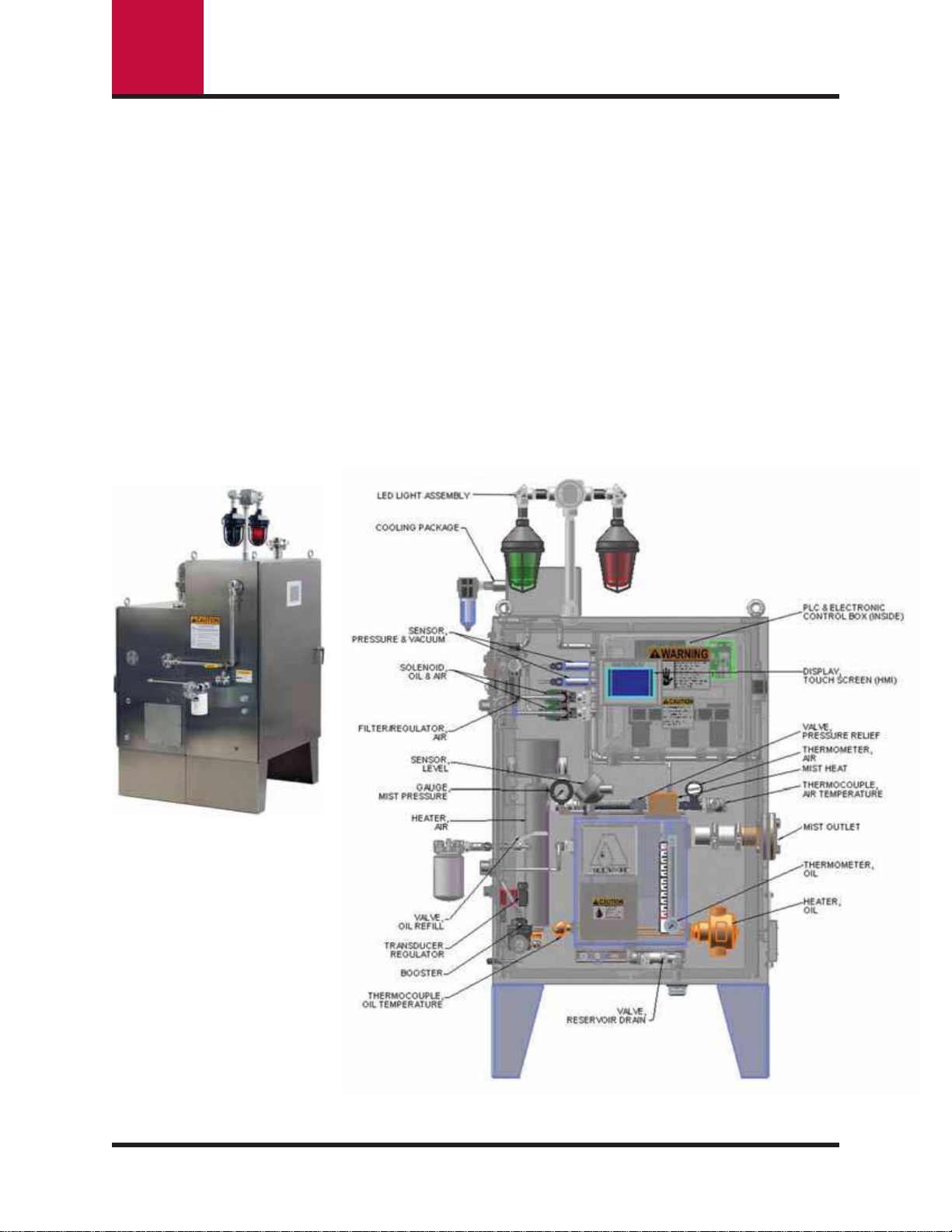

In order to produce oil mist, dry, instrument-quality

air supplied by the end user enters the console

WKURXJKD¿OWHUUHJXODWRU7KH¿OWHUUHJXODWRUVHSD-

rates any moisture from the air and regulates the

air to an operating pressure that can be used by

the system.

A Programmable Logic Controller (PLC) monitors

the pressure and relays the pressure signals to the

transducer for operational control. Additionally, a

JDXJHRQWKH¿OWHUUHJXODWRUGLVSOD\VWKHSUHVVXUH

The incoming air supply may be heated by an op-

tional air heater. Heated air can help maintain the

correct oil/air ratio under cold temperature condi-

tions. The PLC controls air temperature by cycling

the air heater on and off according to signals re-

ceived from the air temperature thermocouple.

The air is then routed to a venturi in the mist head.

The pressure drop produced at the venturi throat

creates a vacuum that lifts oil from the oil reservoir

through the oil pick up tube. There is also a very

VLJQL¿FDQW LQFUHDVH LQ WKH DLU ÀRZ YHORFLW\ DV WKH

air passes thought the venturi. The impact between

the high speed air stream and the oil coming up

IURPWKHUHVHUYRLUSURGXFHVDPLVWRUIRJRI¿QHRLO

SDUWLFOHV UHVHPEOLQJ VPRNH$ EDIÀH GRZQVWUHDP

from the venturi traps the larger oil particles within

the mist and returns them to the reservoir. A trans-

ducer/regulator and PLC control the mist pressure.

The HMI and a pressure gauge (inside the cabinet)

provide visual indication of mist pressure.

The air/oil mist mixture with a smoke-like appear-

ance moves through a piping network at low pres-

sure and low velocity to designated lubrication

points. As the oil mist reaches the lubrication point,

UHFODVVL¿HUV RU VSHFLDO RLO PLVW ¿WWLQJV FROOHFW WKH

small dry particles and produce larger wet drop-

lets ideal for the lubrication of bearing surfaces

on gears, chains, rolling element bearings, sleeve

bearings and other key machinery parts.

Oil Mist Density Monitoring

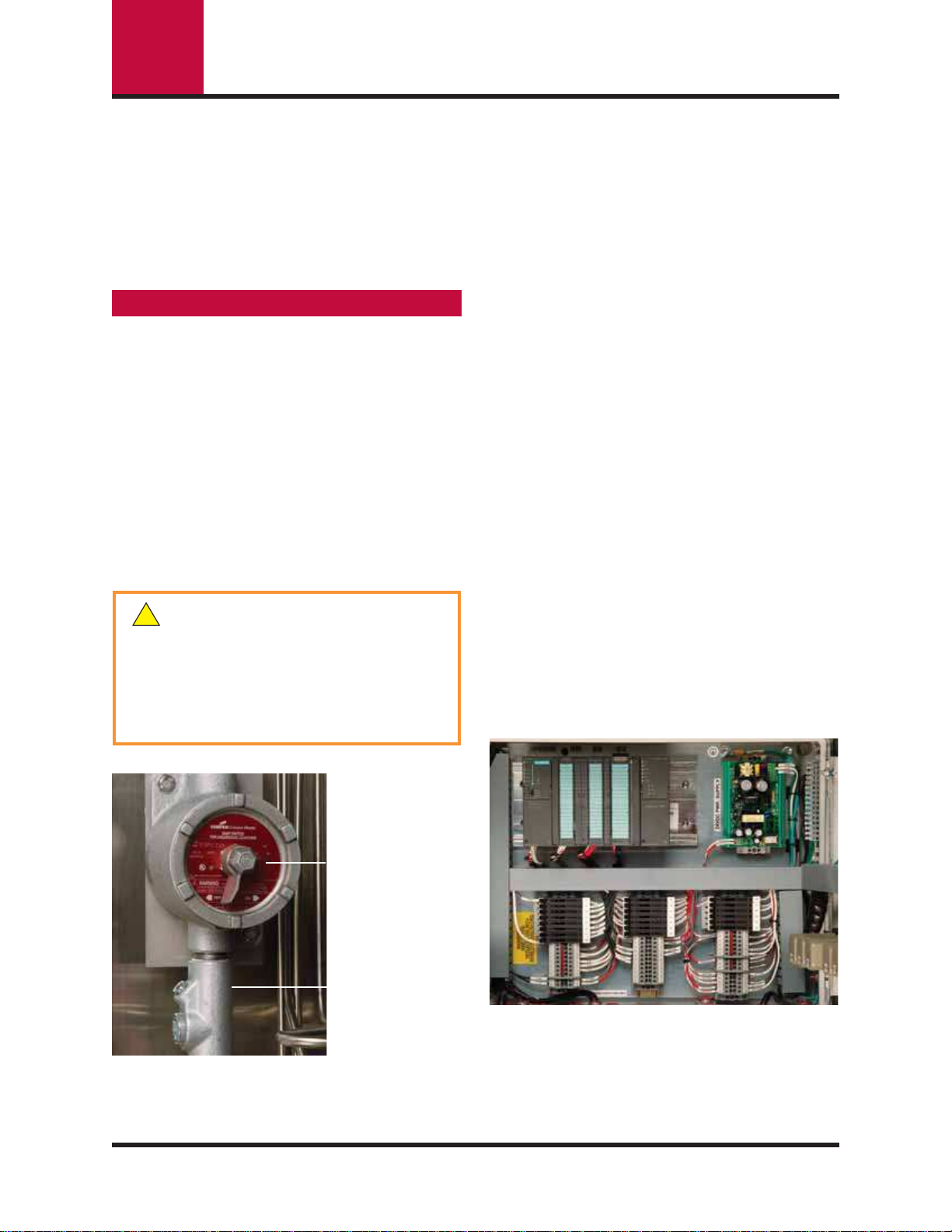

The Carbon Shield™ (CS) units use a proactive ap-

proach to oil mist density monitoring. Unlike current

technology, changes in mist density are predicted

by the control system long before an actual change

in mist density down the stream can be detected.

This prediction is made possible by the use of soft-

ware in the PLC, the HMI, and data from the sen-

sors onboard. These devices work together to con-

tinuously monitor the set points (not the limits) for

DOOWKHSDUDPHWHUVWKDWLQÀXHQFHWKHRLOPLVWGHQVLW\

(i.e. oil-to-air ratio). When a parameter changes

outside its predetermined acceptable range around

the set point, an alarm is issued and the potential

cause is displayed thru the HMI. Therefore, there is

no need for dedicated mist density sensing devic-

es—and their inherent operational issues—to react

to mist density changes.

3