16

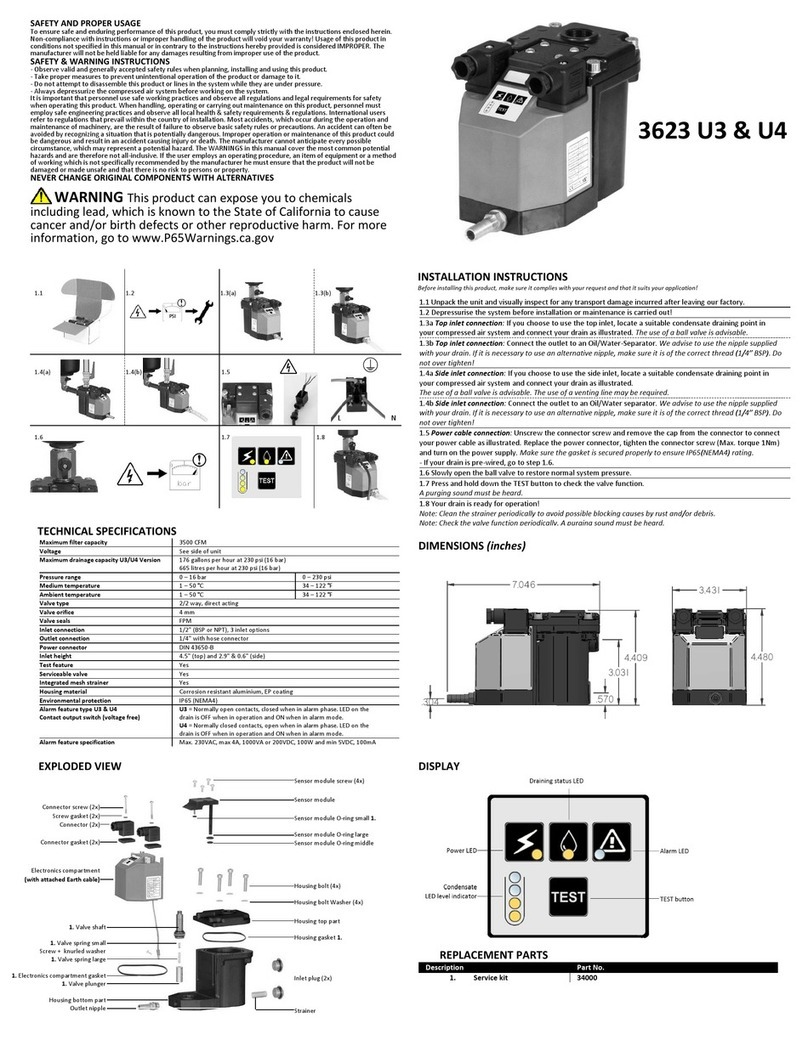

Installation

The valve should be installed high on the wall, preferably close to a heat source.

1. Hole making

The fall outwards should be around 3 mm. For Ø100 and Ø125 it is recommended to use a hole making tool to obtain clean

edges (Fig. 1 page 21). For Ø160 and sound absorption valves it is recommended to use a compass saw on account of the high

torque in the drill (Fig. 2 page 21).

Recommended hole dimensions in accordance with the table:

Model Pipe diameter Hole

Aero 100V2 Fresh Air Valve 99 mm 105 mm

Aero 125 Fresh Air Valve 124 mm 130 mm

Aero 160 Fresh Air Valve 160 mm 170 mm * **

Aero 100 dB Sound Absorption Valve 175 mm 185 mm * **

Aero 125 dB Sound Absorption Valve 195 mm 205 mm *

NB. The diameter specified for pipes for sound absorption valves is a maximum dimension. On account of the material’s tolerances,

the actual diameter may be slightly less.

As described in the user manual, a slightly larger hole than the diameter of the bushing will be required as the valve must slope

outwards approximately 3 mm. The area between the wall and the bushing can then be insulated with a suitable insulation material.

2. External valve

Assemble the external valve with enough modular pipes (Fig. on page 18 Description) that they almost pass through the wall

(extra connection pipes can be purchased as required (product code 116711/09166/09167)).

Take out the insect screen in the external valve (Fig. 3 page 21).

Insert the external valve with modular pipes through the wall from the outside and fix the valve with 4 screws (Figs. 4/5).

Replace the insect screen.

Fit the external cover (Fig. 6 page 21).

3. Internal part

Remove the external cap by pulling carefully in two corners.

Apply some silicon to the boss.

Insert the boss in the modular pipe (Fig. 7 page 21).

Screw the internal part in place with 4 screws (Fig. 8 page 21) (the opening for the adjustment switch must be on the underside).

Attach the external cap.

4. Installation of sound absorption valve

As described in 1-3, but modules are replaced by a sound-absorbing wall bushing (Fig. on page 18 Description).

Cut the wall bushing to the relevant wall thickness.

The degree of sound absorption is described under Sound Absorption.

5. Installation of cover plate (for Aero 160 and sound absorption valves)

Cover plates are fixed with 4 screws on the internal and external parts before they are installed on the wall/duct (Figs. 9/10/11

page 21).

6. Adjusting the air flow rate

The air flow rate is adjusted by pushing the switch on the underside of the internal part (Fig. 12 page 21).

7. Cleaning/replacing the filter

Remove the external cap on the internal part by pulling carefully in two corners.

Lift out the outer filter holder (Fig. 13 page 21) and remove the filter.

Insert the new/cleaned filter and press it into place with the filter holder, which is attached at four corners.

8. Installing cords

Alternatively, the air flow rate can be adjusted using cords that can be purchased as an accessory (product code 51005). NB!

Does not apply Aero 160.

You need 2. Drill two holes in the grooves on the internal part (Fig. 14 page 21), thread the cords through and fix them as shown

in Fig. 15.

9. Installing the baffle in the sound absorption valve

To use the enclosed baffle in the sound absorption valve, place it inside the sound-absorbing pipe. Centre the baffle in the

bushing. It must be in the insulation pipe, not in the internal/external boss. As previously mentioned, using the baffle produces

an additional sound reduction of 2 dB.

* 2 cover plates are supplied, producing

greater tolerances for hole making.

** It is possible to install the valve without

cover plates but the holes must then be made

very precisely.