Flextool TUFFTRUK B450E User manual

FOR MORE INFORMATION

CONTACT US ON 1300 353 986 OR VISIT flextool.com.au

RISK ASSESSMENT

Version 1.0 (March 2022)

FLEXTOOL TUFFTRUK™

B450E, B450G

Equipment Risk Assessment –Uncontrolled document once printed | Page 2 of 10

INFORMATION

Equipment description:

TuffTruk Mini Dumper

Make / manufacturer:

Flextool

Model number/s:

B450E, B450G

Assessment date:

1st March 2022

Link for manuals:

flextool.com.au

Additional information

Parchem Construction Supplies

1956 Dandenong Road

Clayton VIC 3168

Ph: 1300 353 986

WARNING

To reduce the risk of injury, all operators and maintenance personnel must read and understand this risk assessment before transporting, operating,

changing accessories or performing maintenance on this power equipment. The most important safety device for this or any equipment is the

operator. Care and good judgement are the best protection against injury. All possible hazards cannot be covered in this risk assessment, but we

have tried to highlight some of the important items. Risks associated with the use of equipment may vary based on jobsite and environmental

factors and operators should asses these prior to each use. Operators should look for and obey Caution, Warning and Danger labels placed on the

equipment. You should read this risk assessment and the corresponding equipment and engine (if applicable) operating instructions carefully and

consider the information in the context of how the product will be used. Even if you have previously used similar equipment carefully check out each

machine before you use it, get the "feel" for it and know its capabilities, limitations, potential hazards, how it operates, and how it stops. This risk

assessment summarises our best knowledge of the product, based on the information available at the time. Our responsibility for products sold is

subject to our standard terms and conditions of sale. Parchem does not accept any liability either directly or indirectly for any losses suffered in

connection with the use of the product whether or not in accordance with any advice, specification, recommendation or information given by it.

This equipment risk assessment has been undertaken in accordance with the Plant Regulations of 2007 & 2011 and Australian Standards AS 4024

for Safe Guarding of Machinery and ISO 31000:2009 Risk Management Standards.

© This publication is copyright. All rights are reserved. Flextool is a registered trade mark and TuffTruk is a trade mark of Parchem Construction

Supplies Pty Ltd.

EQUIPMENT

RISK ASSESSMENT

Equipment Risk Assessment –Uncontrolled document once printed | Page 3 of 10

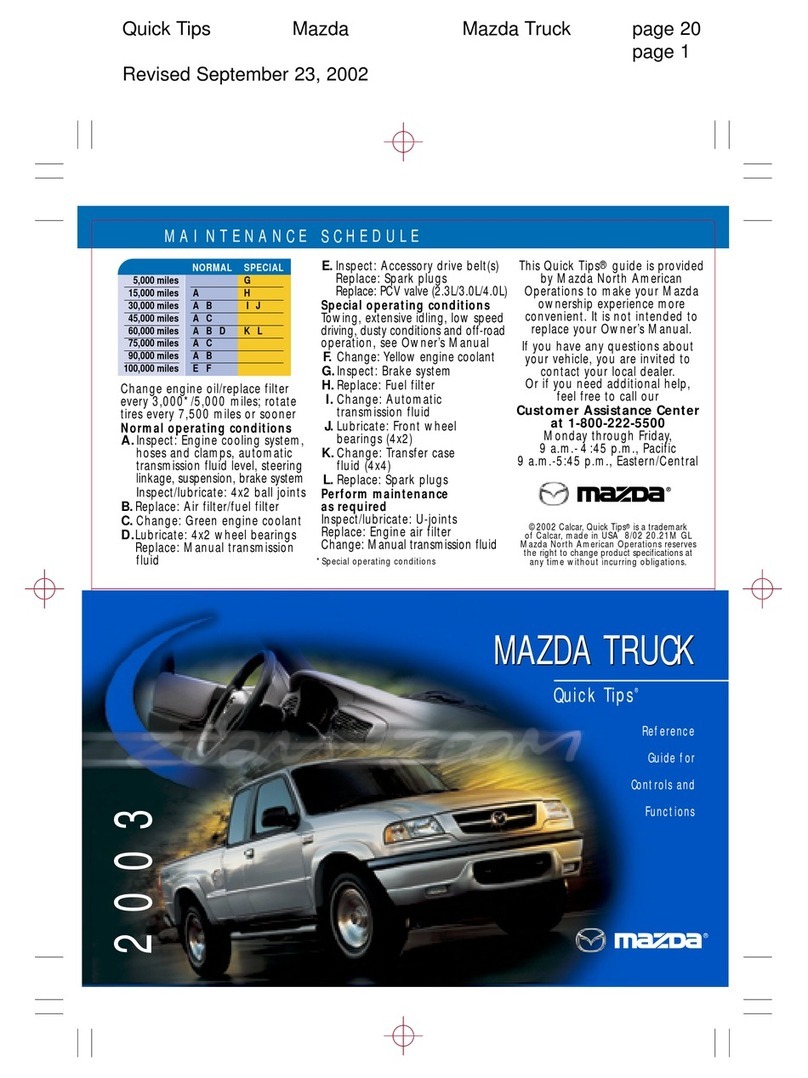

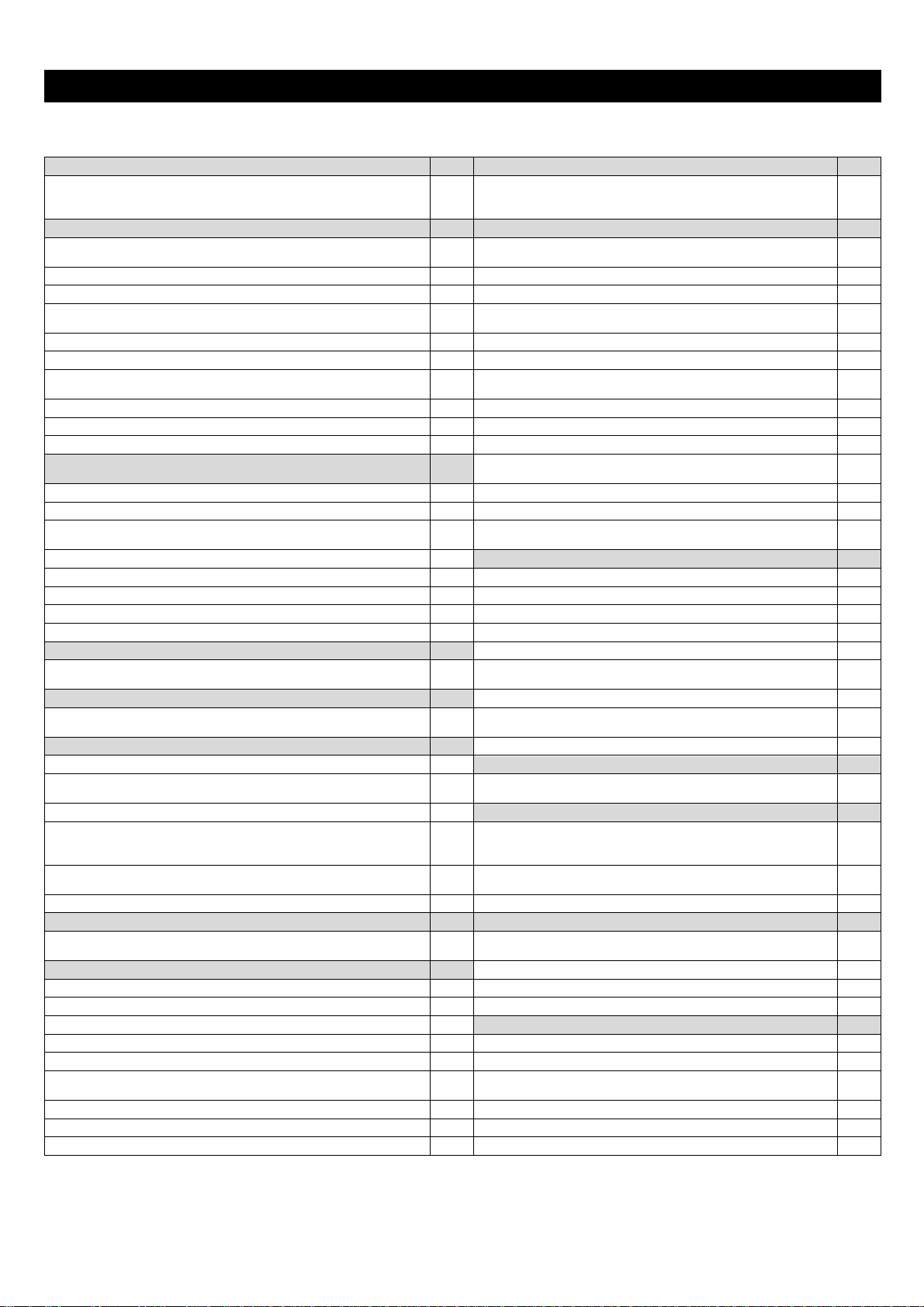

HAZARDS ASSOCIATED WITH THIS EQUIPMENT

Hazards: Potential to cause harm to people, property or the environment. Tick the applicable hazards.

ENTANGLEMENT

EXPLOSION

Can anyone’s hair, clothing, gloves, necktie, jewellery, cleaning

brushes, rags or other materials become entangled with moving

parts of the plant, or materials in motion?

Y

Can anyone be injured by explosion of gases, vapours, liquids,

dust or other substances, triggered by the operation of the

plant or by the material handled by the plant?

Y

CRUSHING

SLIPPING, TRIPPING OR FALLING

Can anyone be crushed due to:

Can anyone using the plant or in the vicinity of the plant, slip,

trip or fall due to:

Material falling off plant?

Y

Uneven or slippery work surfaces?

Y

Uncontrolled or unexpected movement of the plant or its load?

Y

Poor housekeeping?

Lack of capacity for the plant to be slowed, stopped or

immobilised?

Obstacles being placed in the vicinity of the plant?

The plant tipping or rolling?

Y

Other factors not mentioned

Y

Parts of the plant collapsing?

Can anyone fall from a height due to:

Coming in contract with moving parts of the plant during testing,

inspection, operation, maintenance, cleaning or repair?

Y

Lack of work platform?

Y

Being thrown off or under the plant?

Y

Lack of proper stairs or ladders?

Being trapped between the plant and materials or fixed structures?

Y

Lack of guard rails or other suitable edge protection?

Y

Other factors not mentioned?

Y

Unprotected holes, penetrations or gaps?

Y

CUTTING, STABBING AND PUNCTURING

Poor floor or walking surfaces, such as, the lack of a slip

resistant surface?

Y

Can anyone be cut, stabbed or punctured due to:

Steep walking surfaces?

Y

Coming in contact with sharp or flying objects?

Collapse of the supporting structure?

Coming in contract with moving parts of the plant during testing,

inspection, operation, maintenance, cleaning or repair?

Y

Other factors not mentioned?

Y

The plant, parts of the plant or work pieces disintegrating?

ERGONOMICS

Work pieces being ejected?

Y

Can anyone be injured due to:

The mobility of the plant?

Y

Poorly designed seating?

Uncontrolled or unexpected movement of the plant?

Y

Repetitive body movement?

Y

Other factors not mentioned?

Y

Constrained body posture or the need for excessive effort?

SHEARING

Design deficiency causing mental or psychological stress?

Can anyone’s body parts be sheared between two parts of the

plant, or between a part of the plant and a work piece or structure?

Y

Inadequate or poorly placed lighting?

FRICTION AND ABRASION BURN

Lack of consideration given to human behaviour?

Y

Can anyone be burnt due to contact with the moving parts of

surfaces of the plant, or material handled by the plant?

Y

Mismatch of the plant with human traits and natural

limitations?

STRIKING

Other factors not mentioned?

Y

Can anyone be struck by moving objects due to:

SUFFOCATION

Uncontrolled or unexpected movement of the plant or material

being handled by the plant?

Y

Can anyone be suffocated due to lack of oxygen, or

atmospheric contamination?

Y

The plant or parts of the plant or work pieces disintegrating?

TEMPERATURE / THERMAL COMFORT OR FIRE

Work pieces being ejected?

Y

Can anyone come into contact with objects at high or low

temperature that are likely to cause burns, scalds or other

injuries (hot or cold)?

Mobility of the plant?

Y

Can anyone suffer ill-health due to exposure to high or low

temperature work environment?

Other factors not mentioned?

Y

Can anyone be injured by fire?

Y

HIGH PRESSURE FLUIDS

MATERIAL AND SUBSTANCES

Can anyone come into contact with fluids under high pressure, due

to plant failure or misuse of the plant?

Y

Can anyone be injured or suffer ill-health from exposure

(inhalation or direct contact) to:

ELECTRICAL

Chemicals or harmful fluids (incl. batteries)

Y

Can anyone be injured by electrical shock or burnt due to:

Toxic gases, vapours, fumes dust or mists

Y

The plant contacting live electrical connections?

Y

Biological or microbiological hazards

Y

The plant working in close proximity to electrical connections?

Y

OTHER HAZARDS

Overload of electrical circuits?

Y

Can anyone be injured or suffer ill-health from exposure to:

Damaged or poorly maintained electrical leads and cables?

Y

Noise –Hearing loss or other physiological disorders?

Y

Damaged electrical switches?

Y

Vibration –Hand held power equipment / whole body

vibration?

Y

Water near electrical equipment?

Y

Radiation –Radio frequency, infrared, UV, x-rays, lasers?

Lack of isolation procedures?

Other factors not mentioned?

Y

Other factors not mentioned?

Y

Equipment Risk Assessment –Uncontrolled document once printed | Page 4 of 10

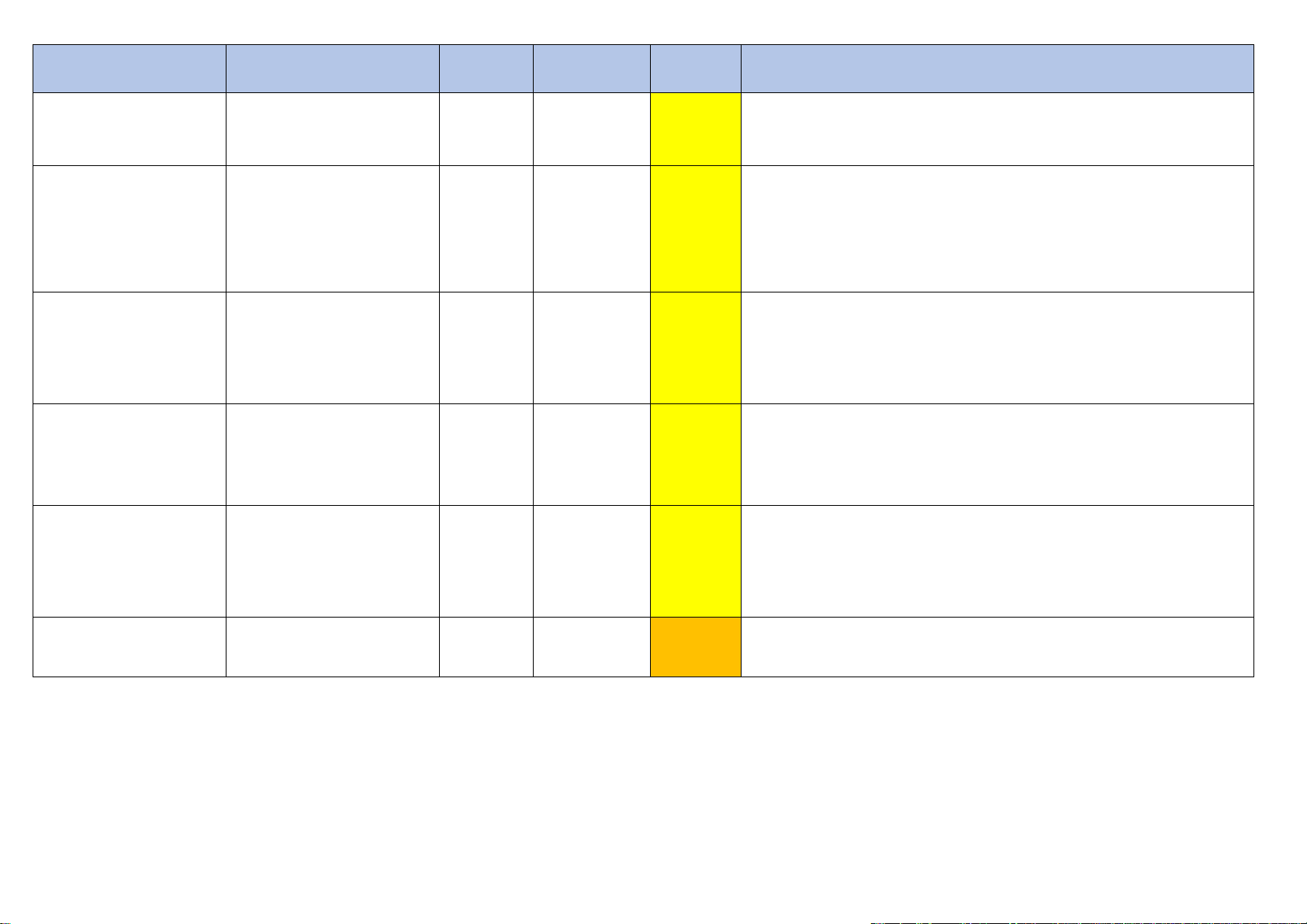

RISK ASSESSMENT

HAZARDS DESCRIPTION

IMPACT DESCRIPTION

LIKELIHOOD

CONSEQUENCE

RISK

RATING

RISK CONTROL MEASURES TO ELIMINATE / REDUCE RISKS

STORAGE AND TRANSPORT

Lifting and manual handling

when manoeuvring equipment

from transport vehicle and

around the job site

Equipment could fall due to

unbalanced load resulting from the

use of the wrong or unsafe lifting

points or loading ramps

Muscular strain, back injury and

crushing

D

3.2

Medium

•Only use designated crane points for mechanical lifting.

•Always use certified and tested lifting slings, chains and loading ramps.

•Regular inspection by competent person of lifting and crane points and loading

ramps for damage or material fatigue.

•Never load or unload from transport vehicle with bucket loaded.

•Always follow correct manual handling techniques.

•Wearing of PPE (steel cap boots and gloves).

•Manual handling training.

Transporting the equipment

Equipment not suitably restrained

during transport

Damage to equipment or other

property due to loss of load from

vehicle

C

3.2

Medium +

•Ensure all equipment is restraint according to the NVHR load restraint

guidelines.

•Inspect straps and ropes for damage prior to use.

•Secure equipment using suitable tie down points on both equipment and vehicle.

OPERATION

Unexpected movement of

equipment with or without

operator

Bystanders and operator being

struck

E

3.1

Low

•‘Deadman’ switch is installed on the handle and is operational.

•Only trained operators are allowed to operate the equipment.

•Wearing of PPE steel capped boots is mandatory.

•Maintain a safe working distance of approx. 3m from bystanders.

•NEVER exceed the rated load capacity of the dumper.

•Develop a Safe Work Method Statement for the operation of the equipment.

Mechanical failure of equipment

Serious injury

C

2

Medium

•Complete service and maintenance as scheduled in the equipment and engine

owners’ manuals.

•Complete a prestart checklist prior to use.

•Report faults to management for repair. Do not use unsafe equipment.

Equipment Risk Assessment –Uncontrolled document once printed | Page 5 of 10

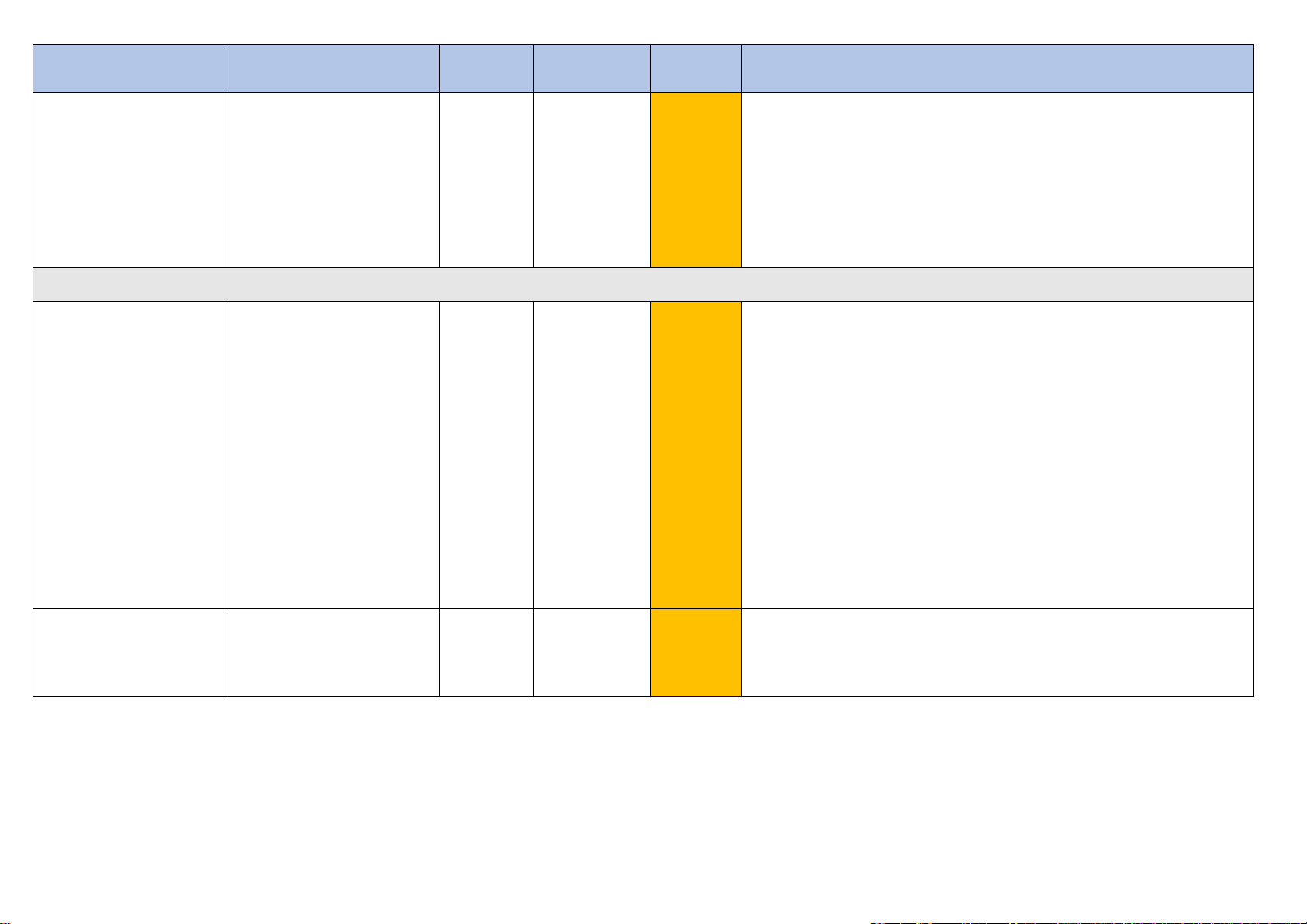

HAZARDS DESCRIPTION

IMPACT DESCRIPTION

LIKELIHOOD

CONSEQUENCE

RISK

RATING

RISK CONTROL MEASURES TO ELIMINATE / REDUCE RISKS

Exposure to fumes / engine

exhaust gases

(B450G Model only)

Suffocation due to lack of oxygen

E

4.1

Medium

•Use in well-ventilated open spaces.

•Petrol model not to be used in confined or restricted areas without detailed risk

assessments being carried out in line with Confined Spaces Procedures.

Vibration exposure (through

handle to operator)

Injury to hands fingers and wrists

C

2

Medium

•Operator to take regular breaks when required to operate equipment over a long

continuous period.

•Stop using equipment if any discomfort, tingling sensation or pain occurs and

seek medical advice before resuming use.

•Complete service and maintenance as scheduled in the equipment and engine

owners’ manuals.

Noise exposure

(B450G Model only)

Loss of hearing

C

2

Medium

•Wear PPE hearing protection.

•Complete service and maintenance as scheduled in the equipment and engine

owners’ manuals.

•Replace damaged or missing warning decals requiring the use of hearing

protection.

Dust and flying particles

Eye injury and respiratory problems

C

2

Medium

•Ensure appropriate PPE is ALWAYS worn - P2 dust mask and safety glasses

must be worn.

•Always discharge contents of the bucket or activate bucket disengage lever from

the steering / operating position –Never stand in front of or alongside dumper

when activating lever.

Hot equipment and engine parts

(engine exhaust etc.)

Risks of burns to body

C

2

Medium

•Replace damaged or missing warning decals highlighting hot surfaces.

•Do not touch engines, engine exhausts or other parts such as gear boxes that

generate heat during or immediately after operation.

•Wait for engine and equipment to completely cool down prior to commencing

repairs or maintenance.

Exposure to rotating wheels

Injury to feet

C

3.2

Medium +

•Wear PPE (steel cap boots).

•Never operate equipment with damaged, broken or missing guards.

Equipment Risk Assessment –Uncontrolled document once printed | Page 6 of 10

HAZARDS DESCRIPTION

IMPACT DESCRIPTION

LIKELIHOOD

CONSEQUENCE

RISK

RATING

RISK CONTROL MEASURES TO ELIMINATE / REDUCE RISKS

Operator slipping or tripping

during equipment operation.

Loss of control of equipment,

personal injury, damage to

equipment

C

3.2

Medium +

•Always operate the equipment with two hands on the handlebar for maximum

control.

•Assess work area prior to operating equipment, do not operate up or down a

slope greater than 25 degrees.

•NEVER allow people to ride inside bucket / tub.

•Maintain a safe operating distance from trenches, excavations and pits.

•Always look over your shoulder and check behind you for hazards prior to

operating in reverse.

MAINTENANCE AND REFUELLING

Refuelling engine

(B450G Model only)

Fire or explosion

Chemical burns (fuels and oils)

C

3.2

Medium +

•Smoking or use of mobile phone is not permitted while refuelling.

•When refuelling ensure nozzle is in contact with the machinery (grounded).

•Switch off engine before refuelling.

•Keep fuel away from sources of ignition.

•Always use fuel container nozzle to reduce risk of spilling fuel.

•Clean up any fuel spills immediately.

•Always carry first aid facilities.

•Refuel on an impermeable surface away from drains / water courses in a well-

ventilated area.

•Re-cap fuel container after use and store in appropriate area.

•Always wear PPE when refuelling engine (gloves and glasses) to reduce risk of

fuel meeting hands and eyes.

•Replace damaged or missing warning decals.

Recharging Battery

(B450E Model only)

Electrocution

E

4.2

Medium +

•Only charge the unit using the factory fitted charging unit.

•Inspect ALL cables for exposed wires for cuts and damage prior to charging –If

damaged cables are identified isolate equipment and have repaired immediately

by a licenced electrician.

Equipment Risk Assessment –Uncontrolled document once printed | Page 7 of 10

HAZARDS DESCRIPTION

IMPACT DESCRIPTION

LIKELIHOOD

CONSEQUENCE

RISK

RATING

RISK CONTROL MEASURES TO ELIMINATE / REDUCE RISKS

Maintenance and repair

Cuts and burns (heat)

Entanglement of clothes, hair etc.

Chemical burns (fuels and oils)

C

3.2

Medium +

•Only trained and competent personnel to undertake maintenance and repair on

equipment.

•Complete service and maintenance as scheduled in the equipment and engine

owners’ manuals.

•Use only genuine parts and accessories to ensure correct compatibility and safe

use of equipment.

•Remove spark plug (B450G) from engine or disconnect battery (B450E) prior to

conducting maintenance to eliminate unexpected starting of equipment.

•Always ensure guards, safety switch and any other safety mechanisms are free

from damage and installed prior to testing and returning product to service.

•Always wear PPE when servicing and repairing equipment (gloves, glasses and

steel cap boot) to reduce risk of cuts, burns and skin exposure to fuels and oils.

•Never work underneath equipment suspended by lifting device or on ramps.

Equipment Risk Assessment –Uncontrolled document once printed | Page 8 of 10

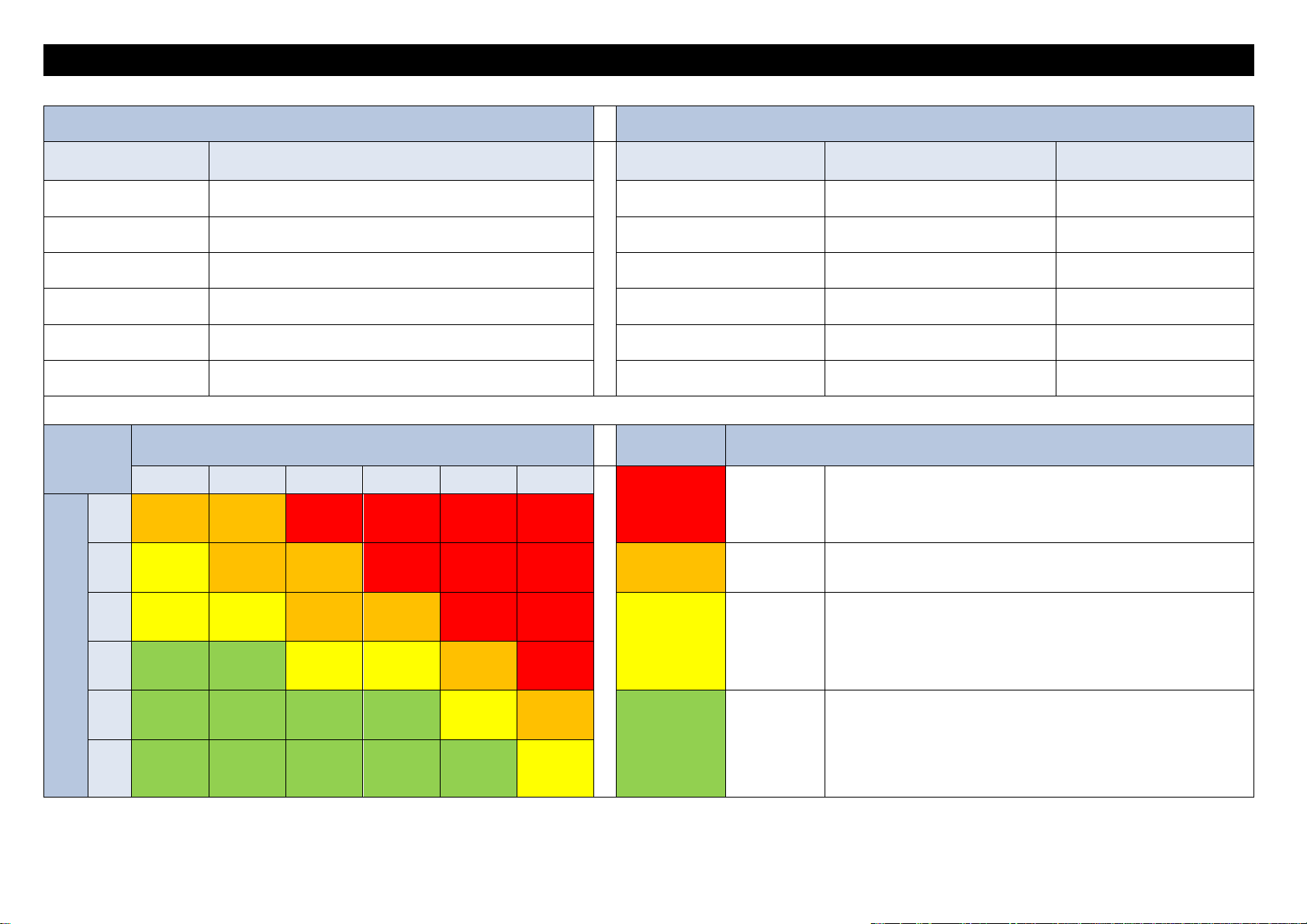

RISK RATING MATRIX

LIKELIHOOD OF HAZARD OCCURRING

CONSEQUENCE IF HAZARD OCCURRED

CATEGORY

EXPLANATION

CATEGORY

EXPLANATION SAFETY & HEALTH

EXPLANATION

ENVIRONMENT

A. Almost Certain

It is expected to occur in most circumstances

Cat 1. Notable Event

Minor injury –first aid injury

Very minor pollution

B. Very Likely

Has occurred in some circumstances (known to have occurred)

Cat 2. Significant Event

Single MTI

Minor local pollution

C. Likely (Possible)

Might have occurred at some time but details not known

Cat 3.1. Highly Significant

Single LWC or multiple MTI

Evident pollution local concern

D. Unlikely

Could occur but has not at yet happened

Cat 3.2. Serious Event

Permanent disability or multiple LWC

Significant local pollution

E. Very Unlikely

Has occurred somewhere (heard of it happening)

Cat 4.1. Extremely Serious

Single fatality

Major local pollution

F. Extremely Unlikely

Could theoretically occur but not aware of any instances

Cat 4.2. Catastrophic

Multiple fatalities

Extremely severe pollution

CONSEQUENCE

RISK LEVEL CLASSIFICATION

Cat 1

Cat 2

Cat 3.1

Cat 3.2

Cat 4.1

Cat 4.2

High

Unacceptable

Job must stop and not proceed without resolving this risk issue, for

example by adding more risk controls or substituting existing controls with

more effective ones.

LIKELIHOOD

A

Medium +

Medium +

High

High

High

High

B

Medium

Medium +

Medium +

High

High

High

Medium +

Tolerable

Job may proceed if further risk reduction is not practicable. Take action to

reduce risk where possible.

C

Medium

Medium

Medium +

Medium +

High

High

Medium

Acceptable

Job may proceed if further risk reduction is not practicable.

Review risk on subsequent jobs to determine whether further action is

appropriate.

D

Low

Low

Medium

Medium

Medium +

High

E

Low

Low

Low

Low

Medium

Medium +

Low

Negligible

Job may proceed. Further risk reduction should always be considered but

may not be practicable.

F

Low

Low

Low

Low

Low

Medium

Equipment Risk Assessment –Uncontrolled document once printed | Page 9 of 10

END OF ASSESSMENT

Parchem Construction Supplies Pty Ltd

1956 Dandenong Road, Clayton VIC 3168, Australia

Phone: 1300 353 986

flextool.com.au

ABN 80 069 961 968

© This publication is copyright. All rights are reserved. Flextool is a registered trade mark of Parchem Construction Supplies Pty Ltd.

FOR MORE INFORMATION

CONTACT US ON 1300 353 986 OR VISIT flextool.com.au

This manual suits for next models

1

Table of contents

Popular Truck manuals by other brands

Komatsu

Komatsu HM300-3 Field assembly instructions

Gude

Gude GHW 2500-180 PU Translation of the original instructions

Trane

Trane Thermo King V-220 Series installation manual

Komatsu

Komatsu HD325-7R brochure

Komatsu

Komatsu Galeo HD405-7 brochure

Verhagen Leiden

Verhagen Leiden V-MOVE XL+ User manual and parts list