Flight Dental Systems Clave B User manual

Class B Steam Sterilizer

Third Generation System, s/n starting with A

Instruction Manual

STE-23-D

2

Thank you for choosing our steam sterilizer.

Prior to operating this instrument, please read the instruction manual carefully and follow

all installation instructions.

IMPORTANT NOTICE

If you can’t open the door, please unlock the door according to the instructions “How to

open the door in case of power outage” in the manual.

Needs maintenance

If this picture appears on the screen when powered on or E88 appears on the report, please

call your dealer or local maintenance service. Your steam sterilizer needs general

maintenance. This occurs after every 1000 cycles.

Ningbo Ican Machines Co., Ltd.

No. 77 Yunlin East Road, Gulin Town,

Ningbo, China.

www.icanclave.com

Document: Version 01D0000 V2.0

Subject to technical changes

Save these instructions

3

Contents

1. General

4

4 Scope of manual

4 Intended use

4 General safety instructions

4 Standards and directives

5 Symbols

2.

Description

of

the

sterilizer

5

5

Sterilizer views

6 Control panel

6 Technical specification

6 Packing content

3. Installation

7

7

General conditions

7 Power supply connection

7 Location requirements

4. Setup

8

8 Fill the distilled water tank

8 Preparation of the sterilization materials

9 Basic set

9 About device

9 Advance set

5. Operation

11

12 Load the sterilization chamber

12 Select the program

12 Start the sterilization program

12 End of cycle

12 Manually interruption of the cycle

13 Test Program

14 Data

14 Save report

14 Printer (optional)

16 Labels (optional)

6

.

Maintenance

16

1

6

Clean the distilled water tank

16 Replacement of the bacteriological filter

16 Clean Chamber, trays and tray Rack

17 Door adjustment

17 Replacement of the door seal ring

17 The drain valve

7. Troubleshooting

18

18 Error code description

8. Transportation and storage

19

19 Transportation and storage conditions

9. Safety devices

19

19 Safety device description

11.

Appendix

20

20 Water properties/characteristics

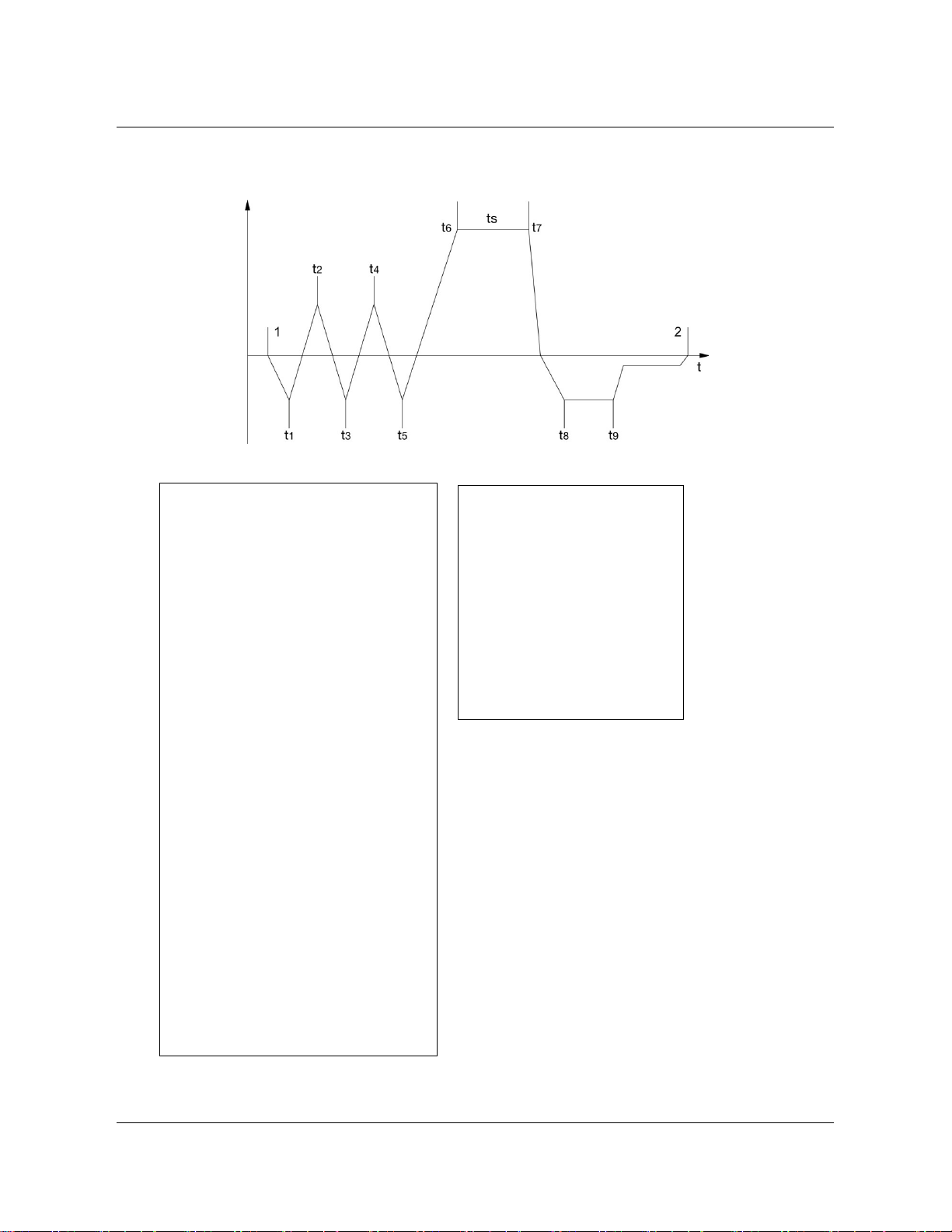

21 Diagrams of the sterilization programs

22 Wiring Diagram

23 Hydraulic Diagram

4

1 General

Scope of Manual

This manual contains information concerning the installation, operation and maintenance of the

steam sterilizer. To ensure proper performance of the sterilizer, the instructions given in this

manual should be thoroughly understood and followed.

Keep the manual near the sterilizer in an accessible location for future reference.

Intended Use

The steam sterilizer described in this manual is intended for the sterilization in all medical, dental,

beauty, vet and tattoo fields of the following types of instrument loads: solid, porous, hollow loads

type A and hollow loads type B, un-wrapped, single wrapped and double wrapped, and liquid, that

are compatible with steam sterilization.

General Safety Instructions

Read and understand this manual before attempting to install or operate the sterilizer.

Make sure that all the installation conditions are fully complied with.

Ensure that the voltage agrees with the supply voltage specified on the rating plate of the

sterilizer.

This appliance must be grounded. Connect only to a properly grounded outlet.

Do not cover or block any openings on this appliance.

Use this appliance only for its intended use as described in this manual.

Do not exceed the maximum weight limit of the loads specified in this manual.

Do not operate this appliance if it has a damaged cord or plug or if it is not working

properly or if it has been damaged or dropped.

Never put flammables or explosive products into the sterilizer.

The sterilizer may not be operated in areas in which gas or any other explosive or volatile

substance is present.

Installation and repair work should only be performed by authorized service technicians.

Work by unqualified persons could be dangerous and may void the warranty.

Standards and directives

The steam sterilizers were designed and produced in conformity with the following directives and

standards:

Directives:

97/23/CE Pressure equipment.

93/42/EEC Medical devices (class II b).

Standards:

EN 13060 Relative to small steam sterilizers.

EN 61010-1 Safety regulations for laboratory devices - Part 1: General regulations.

EN 61010-2-040 Safety regulations specific to sterilizers used in the processing of medical

material.

EN 61326-1 Electromagnetic compatibility regulations for laboratory devices.

Symbols

For safe operation, please

pay close attention to the alert symbols below which can be found on the

sterilizer and throughout this manual.

Important information (Caution)

2 Description of the

sterilizer

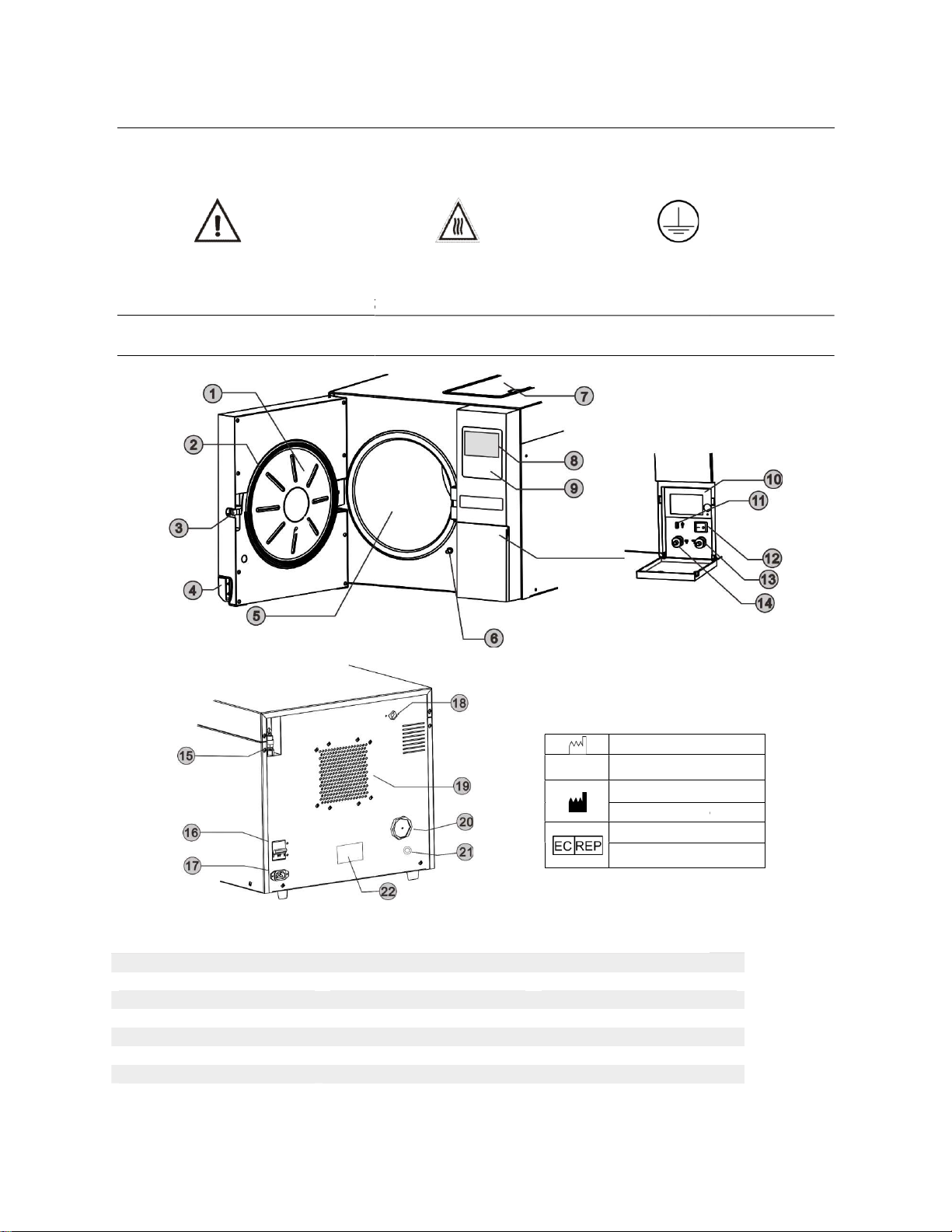

Sterilizer views

1. Door 9.

Control panel

2. Door seal ring

10. Printer

3. Door lock

11. USB

4. Door handle

12. Main switch

5. Chamber

13. Distilled water outlet

6. Door switch

Distilled water inlet*

7. Distilled water tank

14. Used

8. LCD

15. Safety valve

*Models equipped with external water

filling function.

pay close attention to the alert symbols below which can be found on the

sterilizer and throughout this manual.

Hot surface

Ground connection

sterilizer

Control panel

16. Circuit breaker

10. Printer

17. Power socket

11. USB

port

18. Used water tank vent

12. Main switch

19. Condenser vent

13. Distilled water outlet

/ 20. Bacteriological

filter

Distilled water inlet*

21. Distilled water drain*

14. Used

water tank outlet 22. Rating plate

15. Safety valve

filling function.

Date of

manufacture

SN

Manufacture number

Manufacturer Name

Manufacturer Address

EC-

Representative Name

EC-

Representative Address

5

pay close attention to the alert symbols below which can be found on the

Ground connection

18. Used water tank vent

filter

21. Distilled water drain*

manufacture

Manufacture number

Manufacturer Name

Manufacturer Address

Representative Name

Representative Address

6

Control panel

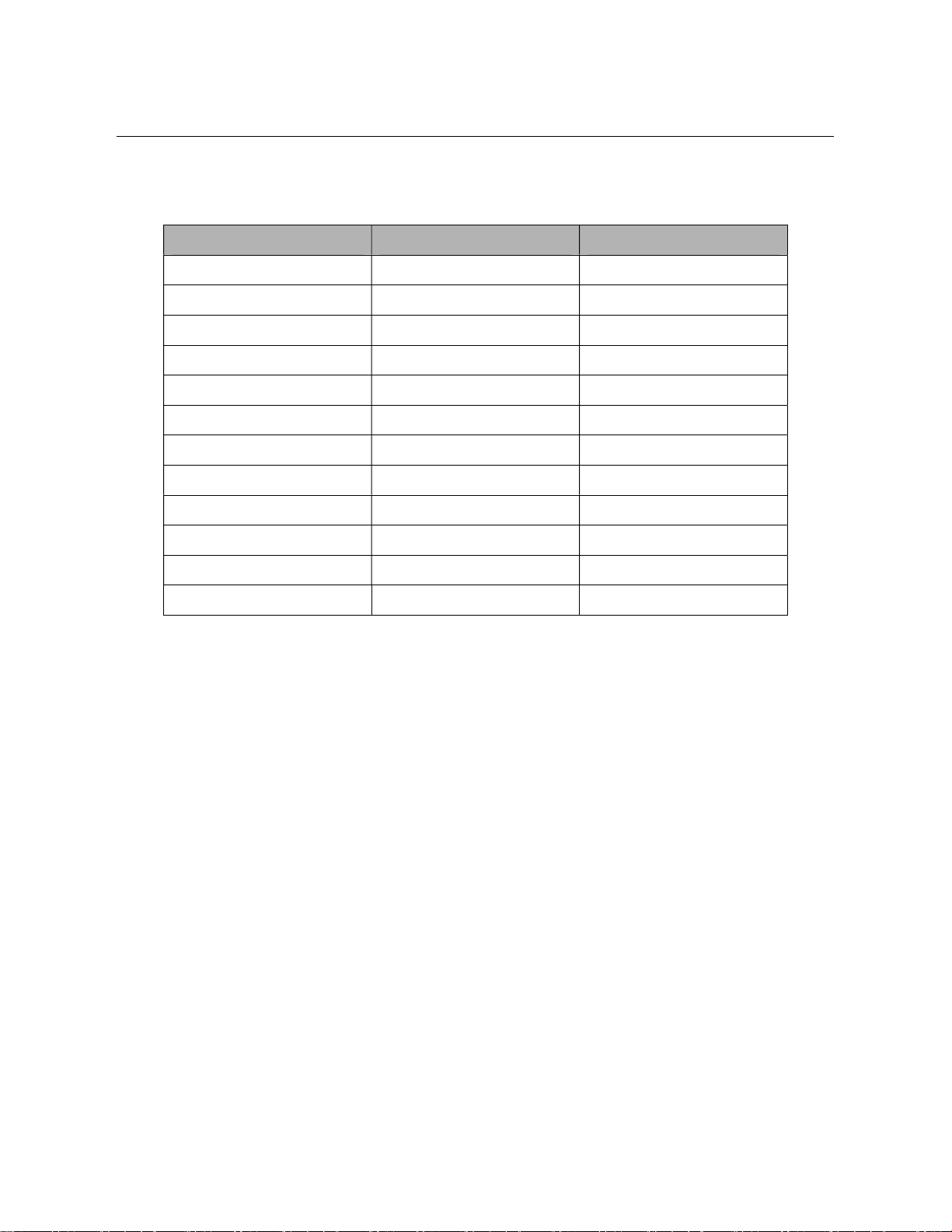

Technical Specifications

Model

Chamber (m, diameter/depth)(inches)

Overall dimensions (mm,W*H*D)

Net Weight (kg)

Nominal power (VA)

Electrical supply

Sterilization temperatures

Capacity of the distilled water tank

Circuit breaker

Operation temperature

Operation relative humidity

Max. Noise level

Atmospheric pressure

Packing content

Item

Accessories

1 Instrument tray

2

Instrument tray rack

3 Draining hose

4 Door Seal

5 Tray handle

6 Door adjustment

Wrench

7

Instruction Manual

Clave B

φ247 x 450( 9.724” x 17.716”)

490 x 455 x 690

53

2000

220-230V;50/60 Hz;10A

121°C/134°C

2.5 L (Water at level Max.) Approx.

0.5 L (Water at level Min.) Approx.

F16A /400 V

5°C ~ 40°C

Max. 80%, non-condensing

<70 dB

76 kPa ~ 106 kPa

Accessories

Quantity

4

Instrument tray rack

1

2

1

1

1

Instruction Manual

1

1 Program temperature

2 Program

3 Holding time

4 Pressure

5

Distilled water / Fill it flashing.

Filling the tank

Bad water quality

6 Used water tank full

/ Drain if flashing

7 Printer status

8

Door open

Door closed

Door blocked

9 Time

10

Current internal temperature

11 Up button

12 Down button

13 Enter button

14 Menu button

Dis tilled water / Fill it flashing.

Filling the tank

Bad water quality

/ Drain if flashing

Current internal temperature

7

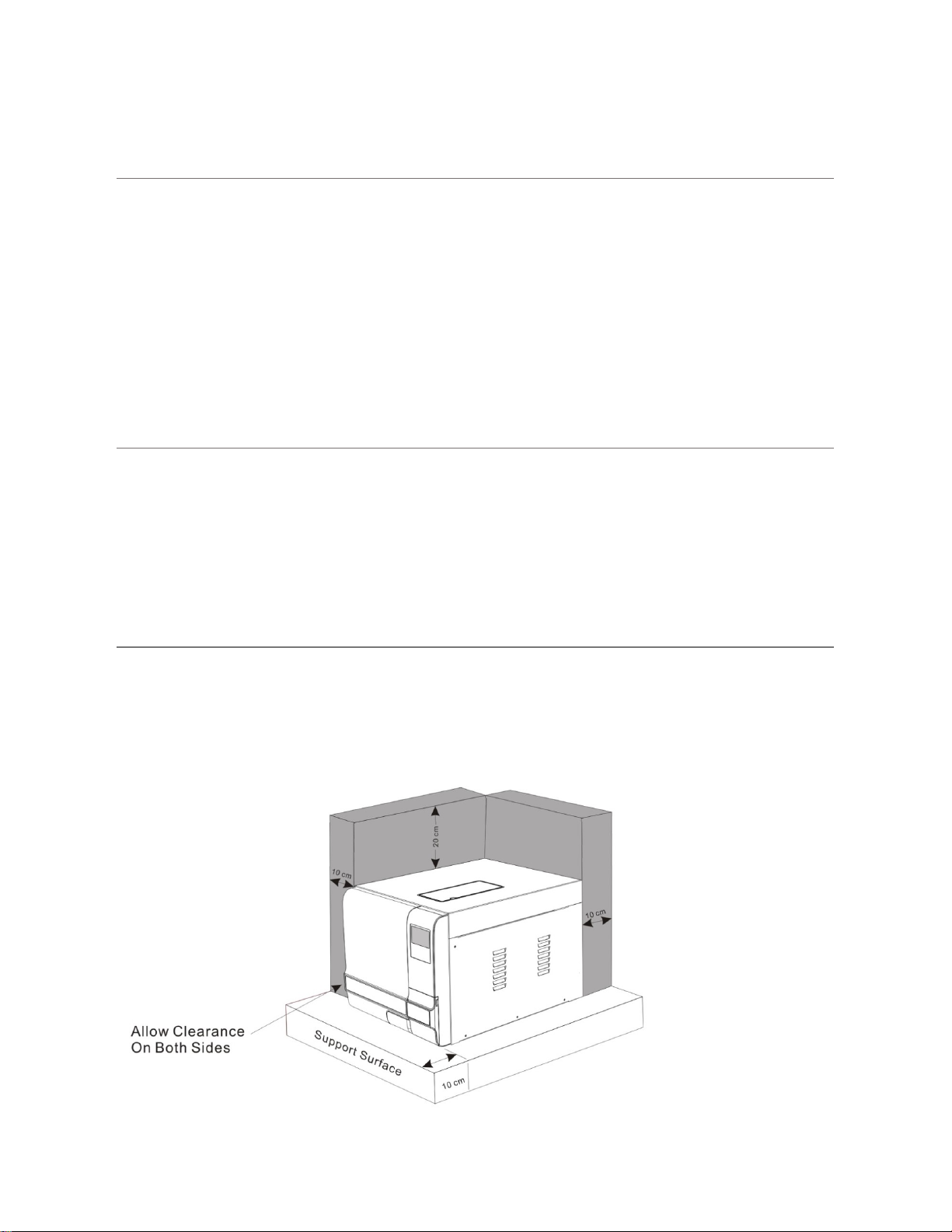

3 Installation

General conditions

Position the device on a solid surface with a minimum weight capacity of 60 kgs.

The sterilizer should be placed on a level worktable.

Leave at least 10 cm between the device rear part and the wall. The clearance required to

open the door is 40 cm.

Position the sterilizer at such a height as to make it possible for the operator to check the

whole sterilization chamber and carry out the normal cleaning operations.

The room where the device is installed must be sufficiently ventilated.

Do not install the device near washing basins, taps, etc. where it is likely to be splashed.

Do not lean on the door when it is opened.

Do not place trays, papers, fluid containers or other objects on the sterilizer.

Power supply connection

Check the label on the back panel of sterilizer to verify the voltage rating for the unit. Failure to

connect the sterilizer to an appropriate power supply could result in damage to the unit and electrical

shock to personnel.

Plug the power cord into a properly polarized and grounded receptacle rated for the correct voltage

and current. A dedicated circuit that is only used for the sterilizer is recommended. Never connect

the device plug to adapters of any type.

Location requirements and dimensions (mm)

To ensure proper air circulation, and to allow access to the reservoir fill port and drain coupling,

adhere to the minimum clearance requirements listed below.

8

4 Setup

Connect the power cord to an outlet of the appropriate voltage. Open the door to remove all of the

inner contents for unpacking. Turn on the main power switch on the right side. After switching on,

the machine turns on the LCD and shows the door position, water level, working program, date, time,

etc.

Fill the distilled water tank

Manual water filling

When the level of distilled water reaches a minimum level, the distilled water tank icon will flash

and beep three times.

Press the button on the tank lid and open it to the maximum position. Fill it carefully with distilled

water. If the water level exceeds the maximum level, an alarm will sound, and the distilled water

tank icon will blink.

Drain the used water tank

Attach the drain hose on the drain port connector located inside the service

door, on the left.

Attention: The capacity of the used water tank is approximately 1.5 liters.

Preparation of materials for sterilization

For the most effective sterilization and to preserve the sample, please follow below:

Clean instruments immediately after use.

Clean the instruments with an ultrasonic cleaner.

Residual chemicals left over after the cleaning and disinfecting process may damage and

corrode parts of the sterilizer. Always rinse off the instruments using distilled water.

Follow instrument manufacturer’s guidelines and recommendations for handling and cleaning

instruments prior to sterilization.

Check the manufacturer’s instructions as to proper procedure for sterilizing each item.

Arrange the samples of different materials on different trays or with at least 3cm of space

between them.

Clean and dry instruments thoroughly before placing them into a tray.

Always insert a sterilization paper or cloth between the tray and sample to avoid direct

contact.

Arrange the containers (glasses, cups, test-tubes, etc.) on one side or inverted position,

avoiding possible water pooling.

Don’t stack the trays one above the other or put them in direct contact with the walls of the

sterilization chamber.

Always use the instrument tray handle.

Wrap the samples one by one or, if more tools have to be put in the same bag, verify that

these are made of the same material.

Don’t use metallic clips, pins or similar items, as this jeopardizes the maintenance of the

sterilizer.

Don’t overload the trays over the stated limit (see appendix 2).

9

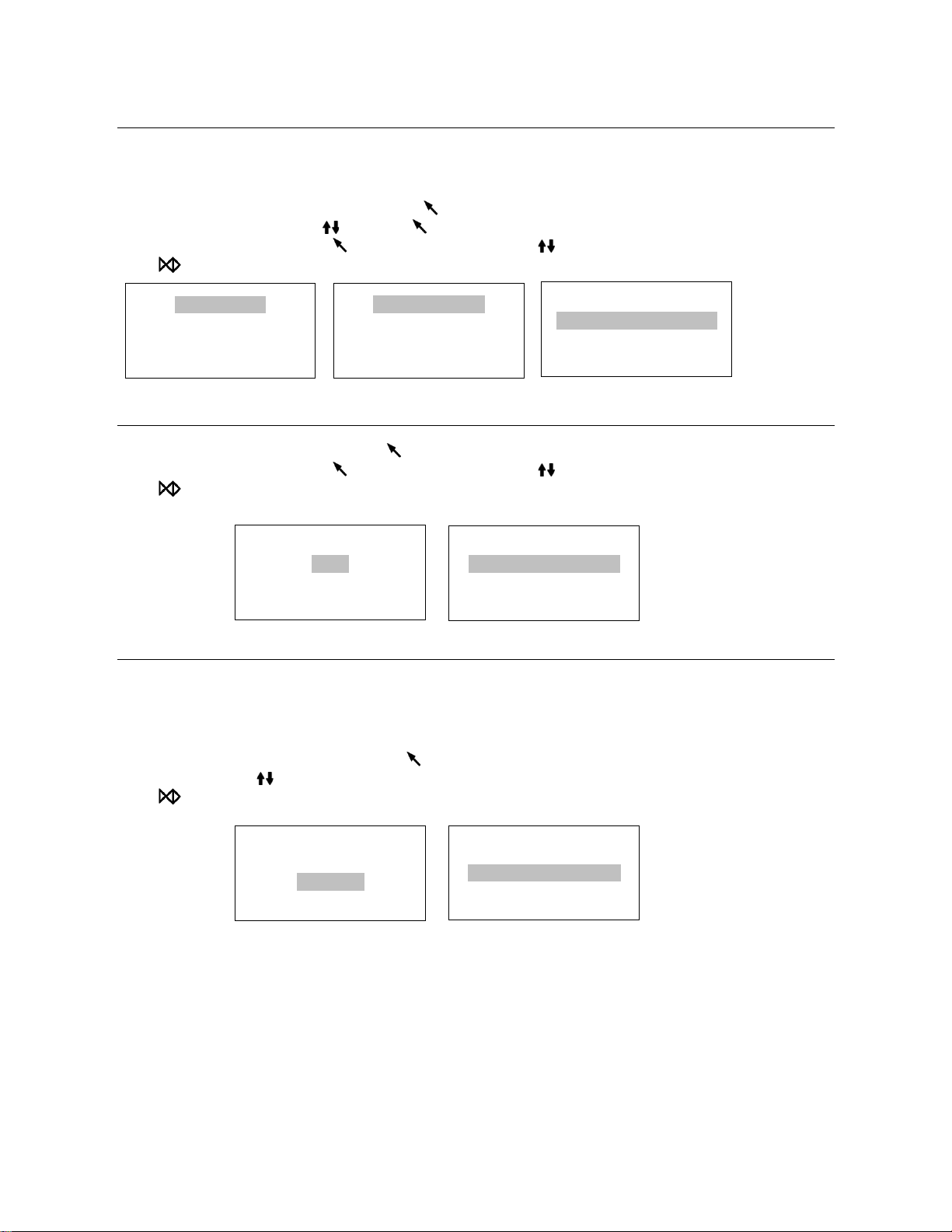

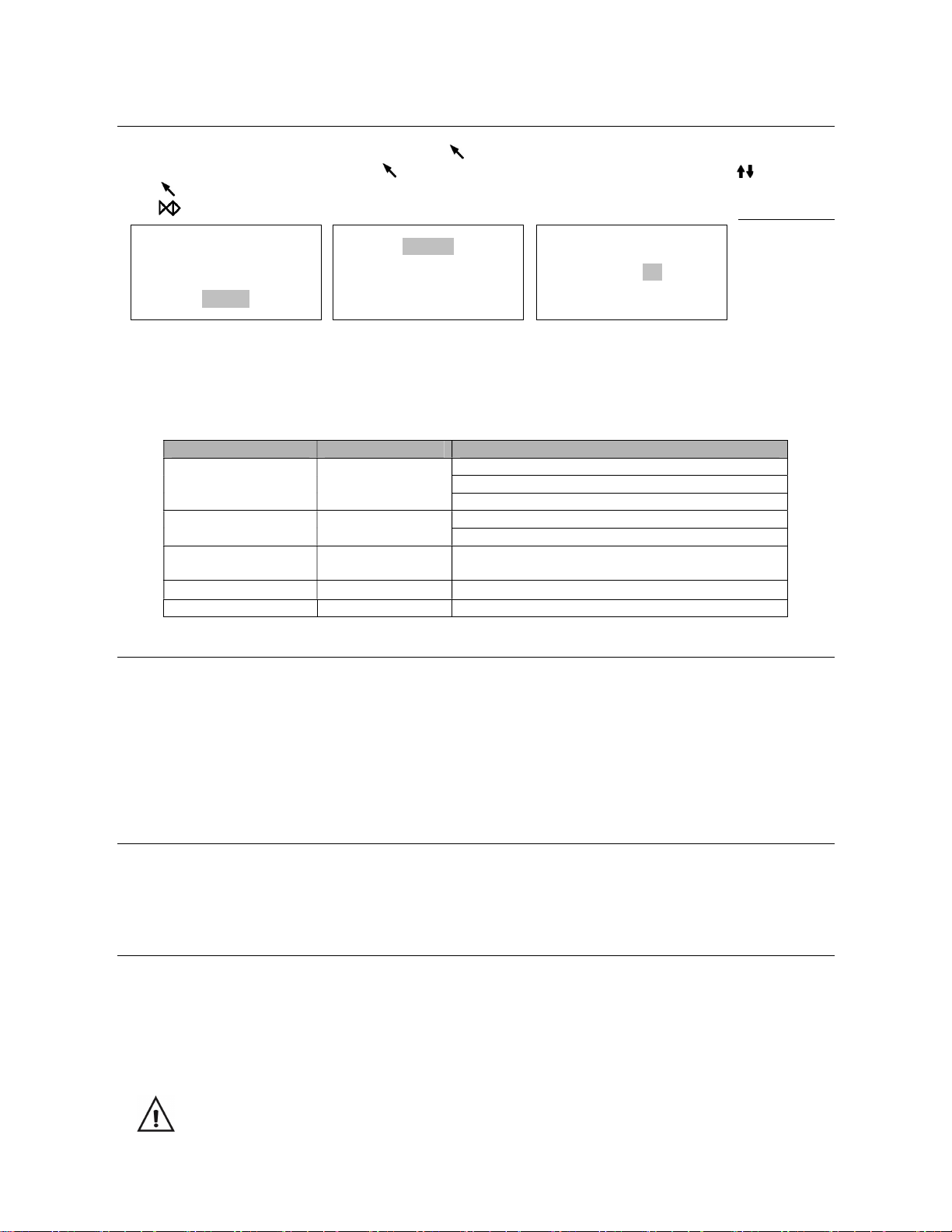

Basic Set

From the main menu, select "Basic Set”.

The “Basic Set” menu permits to set the following options:

*Date *Time *Language

Select the “Basic Set” from the main menu by pressing button.

Select the item by pressing button. The unit you selected will be highlighted.

Adjust the value by pressing buttons. Press button to select the next item.

Press button to save and exit.

Abbreviation of language options

Note: The Counter (cycle number) cannot be changed by the operator.

About device

Select “About device” from the main menu then press button.

Press button to exit.

Advance Set

The “Setup” menu permits setting the following options:

*Parameter *Unit *Preheat *Expiry date (labels) *Water quality (sensor) (optional)

and seeing the information of the: *Last error

Select “Setup” from the main menu by pressing button.

Input the password digit to digit by pressing and button to go next.

Password: 1111

CHN Chinese ENG English DEU German ESP Spanish

PL Polish FR French HUN Hungary ROM Romanian

NL Dutch LTU Lithuanian LAT Latvian CZE Czech

ITA Italian RUS Russian PT Portuguese HR Croatian

Program

Basic Set

Report

Label

Date: 11-07-2019

Time: 12:05:35

Language: ENG

Counter: 00000

Parameter

Unit

Preheat

Expiry date

Water quality

Last error

About device

Password

1111

Device Info.

3BB12B 11111110

V2.9.0.1—00

SN: A09999B12

Basic Set

Report

Label

My device

10

Parameter

The “Parameter” menu permits setting the following options:

*Holding time *Dry time

Select “Parameter” from the menu by pressing button.

Select the program by pressing then press button.

Select the parameter by pressing button. Adjust it by pressing .

Press button to save and exit.

Unit

Select “Unit” from the menu by pressing button.

Select the parameter by pressing button. Adjust it by pressing .

Press button to save and exit.

Preheat

When this mode is activated, the chamber and steam generator start to warm until it reaches the minimum

temperature to begin a sterilization cycle. This helps to reduce the total cycle time and improve the drying

efficiency. The “Preheat” mode will be deactivated after one hour of inactivity.

Select “Preheat” from the menu by pressing button.

Adjust it by pressing .

Press button to save and exit.

Parameter

Unit

Preheat

Expiry date

Solid (121°C)

Solid (132°C)

Wrapped (121°C)

Wrapped (134°C)

Parameter

Unit

Preheat

Expiry date

Pressure: kPa

Temperature: °C

Parameter

Unit

Preheat

Expiry date

Preheat: off

Holding time: 20.0

Dry time: 03.5

11

Expiry date (Optional)

To modify the expiration date of the labels, select “Expiry date” from the menu by pressing button.

Adjust it by pressing .

Press button to save and exit.

Water Quality (optional)

If your sterilizer is equipped with a water quality sensor and you want to deactivate it,

select “Water quality” from the menu by pressing button.

Adjust it by pressing .

Press button to save and exit.

Last Error

In order to help the technical assistance process, the most relevant information corresponding to

the last error can be displayed on the screen.

Select “Last error” from the menu by pressing button.

Press button to exit.

5 Operation

Prerequisites

Switch On.

Check the status of the icons in the screen, . (Refer to point 2. Description of the

sterilizer)

Parameter

Unit

Preheat

Expiry date

Month: 03

Unit

Preheat

Expiry date

Water quality

W. quality: OFF

Preheat

Expiry date

Water quality

Last Error

Last error: E20

13- 07 - 201 9 1 7 :0 0

PC: 01 ST : 00 C N: 0 0 04 2

P r e s s u re: 1 00 k P a

T 1: 07 0. 8 ° C T3 :0 4 0. 0° C

T 2: 0 3 3 .7 °C T4 : 24 4. 0° C

Initialize…

P : 07 k Pa T: 2 8 . 1 °

Wrapped

134 ° C/3 . 5 M i n

16- 0 7 - 2 01 9

P : 0. 0 k Pa T: 28 . 2 °C

10 : 4 5 : 05

12

Load

Open the door then placed the trays inside the chamber by the tray handle.

After the instruments are loaded, you may close the door.

Select the program

Enter to the main menu by pressing button, Select “Program”. Select the program by pressing

then press to confirm program, in the screen will appear the information of selected program as

the temperature and sterilization time (holding time), also the date, time, current pressure and

current temperature.

Start the sterilization program

Press to start the cycle. The stage, conditions and the status of the cycle will appear on the display. The

sterilizers will perform the program automatically. (see appendix 2).

End of the cycle

Once the cycle is completed, “End” will appear at the end of the graphic. The printer will print out and the

digital report is saved in the USB memory if these are connected.

Caution: Always use the tray handle to load or unload the tray into the sterilizer. Failure to do so can

result in burns.

Program

Basic Set

Report

Label

Solid (121°C)

Solid (134°C)

Wrapped (121°C)

Wrapped (134°C)

Wrapped

134 ° C/3 . 5 M i n

16- 0 7 - 2 01 9

P: 0 .0 k Pa T: 28 . 2 °C

10 : 4 5 : 0 5

1 3 4 ° C

W ra p p ed

P: 0 .0 k P a T: 2 8 . 2 °C

0 0 : 0 0: 0 5

1 3 4 ° C

W ra p p e d

P: - 0 . 2 kPa T: 8 7 . 2° C

0 0 : 0 0: 1 7

1 3 4 ° C

Wr ap p e d E N D

P: - 0. 2 k Pa T: 87.2° C

0 0 : 0 0 :1 7

13

Manual interruption of the cycle

To interrupt a cycle prematurely, hold for 3 seconds.

If the cycle is manually interrupted after it reaches the drying phase, the items inside the sterilizer may be

considered sterile and considering that the cycle has been interrupted during the drying phase the materials

and instruments inside the chamber may be wet.

Note: If the cycle is manually interrupted before it reaches the drying phase, the items inside the sterilizer

must be considered not sterile. N20 will appear on the screen. (see Error code description).

Caution: Depending on the phase of the cycle, steam and water can escape from the sterilization

chamber when you open the door.

Test Programs

Helix test

Put the Helix test device into the chamber, then, close the door.

Select “Program” from the main menu by pressing then to enter in the menu. Select “Helix

test”. The screen will show the information for temperature and sterilization time (holding time),

also the date, time, current pressure and current temperature.

Press to start the cycle. The stage, conditions and the status of the cycle will appear on the display. The

sterilizer will run the program automatically. (see appendix 2).

After finishing the cycle, you may check the indicator and evaluate the result according to the instructions

from the test manufacturer.

B&D Test

Put the B&D test package into the chamber, then close the door.

Select “Program” from the main menu by pressing then to enter in the menu. Select B&D

test. The screen will show the information for the temperature and sterilization time (holding time),

also the date, time, current pressure and current temperature.

Press to start the cycle. The stage, conditions and the status of the cycle will appear on the display. The

sterilizer will run the program automatically. (see appendix 2).

After the cycle is finished, you may check the indicator and evaluate the result according to the instructions

from the test manufacturer.

Vacuum Test

Select “Program” from the main menu by pressing then to enter the menu. Select “Vacuum

test”.

After closing the door, press to start the cycle. The stage, conditions and the status of the cycle will

appear on the display. The sterilizer will run the program automatically. (see appendix 2).

In compliance with EN 13060, the test requires that the air leakage rate be less than or equal to 0.13 kPa/min.

during 10 minutes. If the leakage rate is not greater 0.13, it will show Success.

14

If the temperature difference between the maximum temperature and the minimum is more than 3°C, it will

show void. That means the result of the test is a fail. You will need to run the vacuum test again after the

chamber has cooled down.

Data

The internal memory will store the information of the last 9999 cycles.

USB Flash memory (Optional)

A USB drive can be used as a method of storing a report of the cycle. To do so, insert the USB drive into the

slot located on the service door of the sterilizer.

The information will automatically output directly to the USB drive after the cycle has completed. The name

of the file is determined by the serial number of the machine and the cycle number.

For example:

The serial number is E00001. The cycle number is 0012.

The file name in the USB stick is 01001200.txt.

The first two numbers represent machine number.

The middle four numbers represent cycle number.

The last two numbers represent error code.

E.g. 00:no error; 01: error E01

Printer (Optional)

If installed, you can see the icon in the screen stop flashing.

At the end of each cycle the printer will print out a report of the cycle.

Note: If there is no paper inside the printer, the icon will flash.

Report

Internal Memory

In this menu you can get the information of all the cycles stored in the internal memory of the sterilizer.

Select “Report” from the main menu and press button, you will see the list of records.

Select the record by pressing button.

Press button to print and save the report.

Press button to exit.

Program

Basic Set

Report

Label

00012

00011

00010

00009

15

Sample of a printer report

When reading the printed data records, refer to the diagram below:

================================

Program: WRAPPED

Temperature: 134C

Pressure: 206.0 kPa

Drying Time: 08Min

Holding Time: 4.0Min

--------------------------------

Time Temp. Pressure

Start 12:28:17 089.0C

T1: 12:31:32 087.1C -075.0kPa

T2: 12:33:43 110.2C 052.0kPa

T3: 12:36:37 088.9C-075.0kPa

T4: 12:39:20 114.7C 053.7kPa

T5: 12:43:37 087.9C-075.0kPa

T6: 12:50:40 134.8C 206.0kPa

TS: 134.7C 209.5kPa

Max. Temperature:135.2C

Min. Temperature:134.3C

Max. Pressure:214.0kPa

Min. Pressure:204.9kPa

T7: 12:54:39 134.4C211.4kPa

T8: 12:57:36 102.1C -060.0kPa

T9: 12:59:54 098.2C-060.0kPa

End 13:04:07 102.4C

--------------------------------

Cycle No.: 00017

Ster. Value: Success

Date: 2017-06-07

SN:E54723

Operator:

v 2B00V2.5

================================

=======================

Program:Vacuum test

Tp:1℃

P1:-75.0kPa

P2:-74.0kPa

rate of pressure rise:0.10

Start Time:08:22

End Time:09:01

Date:2017-07-19

Test Value:Success

SN:E00001

Operator:

========================

16

Print labels

Select “Label” from the main menu and press button to enter the menu.

Select the cycle number by pressing button. Choose the labels quantity by pressing then

press button to print.

Press button to exit.

6 Maintenance

To ensure proper operation and maximum steam sterilizer life, carefully follow all recommendations for

periodic maintenance. One of the most important steps you can take to prevent problems with your sterilizer is

to use only distilled water.

Frequency Number of cycles Maintenance operation

Daily

Clean the external surface

Drain used water tank

Clean the door seal

Weekly 25 Clean the chamber, trays and rack

Clean distilled water tank (drain tank)

Monthly 100 Clean the filter inside the chamber and in the distilled

water tank

Every 6 months 500 Replace the bacteriological filter

Every year 1000 Replace door seal, tubing, filters, check valves

Clean the distilled water tank

Unplug the power cable, or drop the circuit breaker at the back of the unit.

Drain the tank completely using the drain connector at the front of the sterilizer and leave it connected to a

tube in an open position.

Clean the internal surface with a soft sponge and a small soft brush for the areas difficult to reach using

distilled water.

Remove the filter and clean it with a small soft brush and mild soap, rinse it with distilled water, and put it

back in to the position.

Replacement of the bacteriological filter.

The bacteriological filter is in the back of the sterilizer. Unscrew the filter by hand counter-clockwise.

Place the new bacteriological filter. Screw the new filter by hand clockwise.

Note: Do not operate sterilizer without filters in place.

Clean chamber, door seal ring, trays, and tray rack.

Remove the trays and tray rack from the chamber. Clean the trays, rack and the inside of the chamber with

mild soap.

Rinse the trays, rack and inside of the chamber with a smooth cloth and distilled water.

Examine door seal for possible damage. Clean door seal and mating surfaces with a damp cloth.

Note: Do not use bleaching agents or any abrasive materials or substances in the chamber. Failure to comply

may cause damage to the chamber and/or other components.

Caution: To prevent burns, let the unit cool before cleaning gaskets and touching the surface.

Program

Basic Set

Report

Label

00012

00011

00010

00009

QT: 01

17

Door adjustment

Under normal circumstances, the chamber door does not require adjustments.

However, if the seal fails (resulting in steam leaking from the front of the chamber),

you may need to adjust it.

Open the door.

Insert the spanner tool in the gap beneath the plastic cover. Use the spanner to grip

the adjusting nut. Turn the nut counter clockwise as the figure below. This will tighten the sealing plate.

Turn the nut until the sealing plate is tight. If the door knob is too tight, you may also turn

the nut clockwise to loosen it.

Caution: Never adjust the chamber door while the door is closed.

Replacement of the door seal ring

Open the chamber door. Remove the door seal ring carefully by hand.

Clean the door seal ring carefully with a smooth cloth with distilled water.

Moisten the new seal with distilled water.

Insert the new seal and tap in sequence as follows:

Press in the top and bottom of

the door seal.

Press in the left and right

sides of the door seal.

Press the remaining sections

of the seal.

Caution: Please ensure the chamber and the door are cold prior to replacing the seal ring.

The drain valves

1. Press the included hose

onto the drain valve firmly.

2. Pull the drain valve

outward to drain the tank.

3. Push the drain valve back

after draining the tank.

18

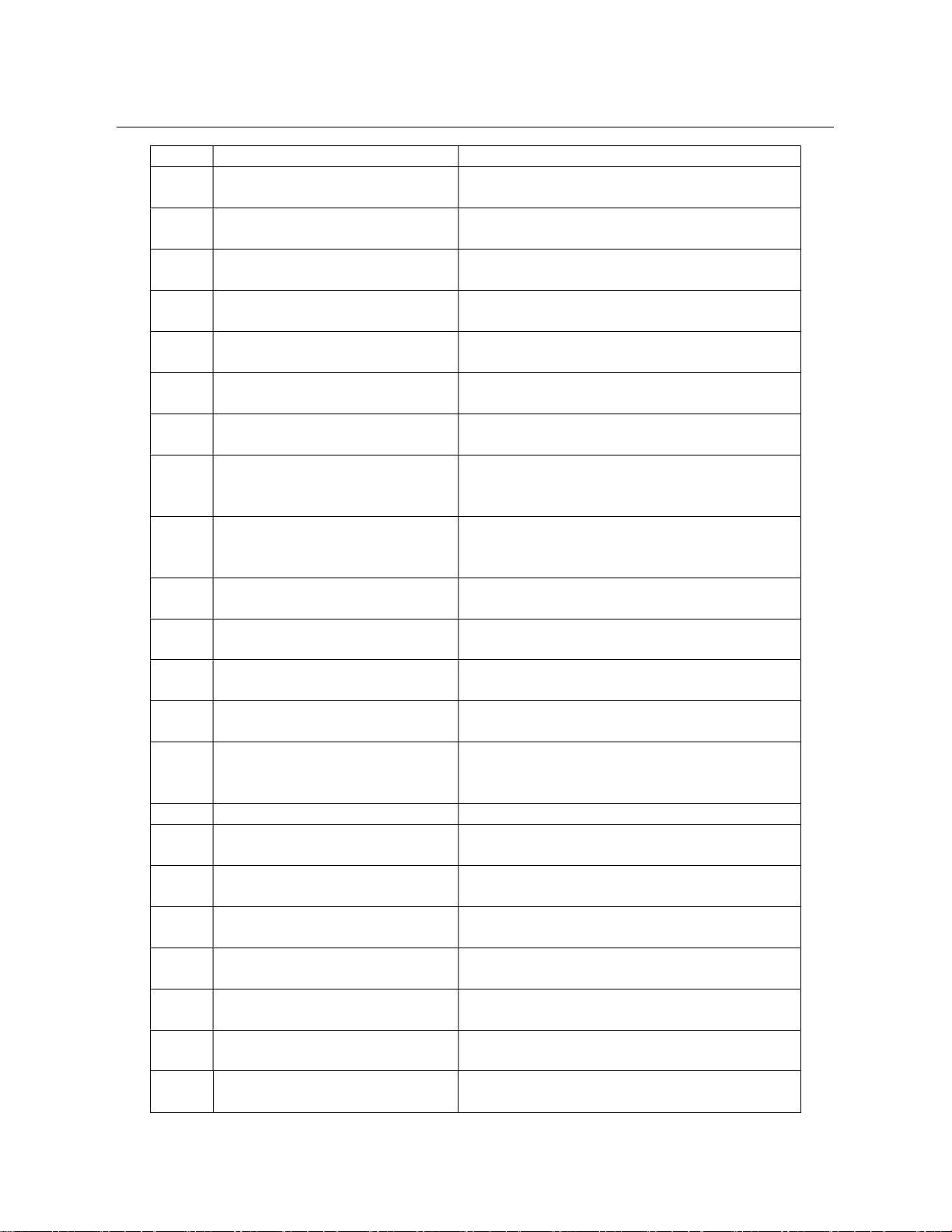

7 Troubleshooting

Code Description Proposed solution

E1 Steam generator temperature

sensor error.

Power off & run a new cycle

Contact your supplier if error persists.

E2 Inner temperature sensor error. Power off & run a new cycle

Contact your supplier if error persists.

E3 Temperature sensor of the

chamber wall error.

Carefully ensure that the chamber wall is

heated and contact your supplier.

E5 Fail to release the pressure. Power off & run a new cycle

Contact your supplier if error persists.

E6 Door lock problem during the

cycle.

Make sure you had closed the door properly.

Check the door switch.

E7 Error between temperature and

pressure correlation.

Power off & run a new cycle

Contact your supplier if error persists.

E8

Error between temperature and

pressure correlation.

Power off & run a new cycle

Contact your supplier if error persists.

E9 Failure to hold temperature.

Ensure the distilled tank isn't empty. Check

the inner temperature sensor. Check

somewhere for leaking.

E10 The door locking system

doesn’t work.

The electromagnet locking system doesn’t

work.

The locking system switch doesn’t work.

E11 Failure to preheat the steam

generator.

Power off & run a new cycle

Contact your supplier if error persists.

E12 Failure to preheat the chamber. Power off & run a new cycle

Contact your supplier if error persists.

E13 Vacuum failed. Power off & run a new cycle

Contact your supplier if error persists.

E15 Inner temperature sensor error

#2*

Power off & run a new cycle

Contact your supplier if error persists.

E16 Pressure error

Replace the air filter

Power off & run a new cycle

Contact your supplier if error persists.

N20 Program manually interrupted Reset the error from main screen.

E22 Vacuum test failure Leaking somewhere. Check the door seal.

Or contact your supplier if error persists.

N23 Result of vacuum test is void

The temperature of the chamber is high.

Try again after the chamber has cooled down.

E24 It takes too long time to enter

the next status.

Check for leaks.

Or contact your supplier if error persists.

N27 The vacuum test fails. Switch off. Then switch on after the chamber

cools down and try again.

E28 The pressure is too high.

Power off and contact your supplier if error

persists.

E30 Vacuum failed. Power off & run a new cycle

Contact your supplier if error persists.

E31 Inner temperature sensor error

#2*

Power off & run a new cycle

Contact your supplier if error persists.

19

8 Transportation and storage

Switch off the sterilizer before transportation or storage.

Pull out the plug. Let the machine cool down.

Drain the distilled water tank and the used water tank.

Conditions for transport and storage

Temperature: -20°C ~ +50°C

Relative humidity: ≤ 85%

Atmospheric pressure: 50kPa~ 106kPa.

9 Safety devices

1. Main breaker: Protection of the instrument against possible failures of the heating elements.

Action: Interruption of the electric power supply.

2. Thermal cutouts on the main transformer winding: protection against possible short circuit and main

transformer primary winding overheating

Action: Temporary interruption of winding.

3. Safety valve: Protection against possible sterilization chamber over-pressure.

Action: Release of steam and restoration of the pressure to a safe level.

4. Safety micro-switch for the door status: Comparison for the correct closing position of the door.

Action: Signal of the wrong position of the door.

5. Thermostat on chamber heating elements: Protection for possible overheating of the chamber heating

elements.

Action: Interruption of the power supply of the chamber elements.

6. Thermostat on steam generator heating elements: Protection for possible overheating of the steam generator

heating elements.

Action: Interruption of the power supply of the steam generator elements.

7. Door safety lock: Protection against accidental opening of the door.

Action: Prevents the accidental opening of the door during the cycle.

8. Self-leveling hydraulic system: Hydraulic system for the natural pressure leveling in case of manual cycle

interruption, alarm or blackout.

Action: Automatic restoration of the atmospheric pressure inside the chamber. (valve opens to release internal

pressure)

20

Appendix 1

Water properties / Characteristics

Description Feed water Condensate

Evaporate residue ≤ 10mg/ I ≤ 1.0mg/kg

Silicon oxide sio2 ≤ 1mg/ I ≤ 1.0mg/kg

Iron ≤ 0.2mg/ I ≤ 0.1mg/kg

Cadmium ≤ 0.005mg/ I ≤ 0.05mg/kg

Lead ≤ 0.05mg/ I ≤ 0.1mg/kg

Rest of heavy metals ≤ 0.1mg/ I ≤ 0.1mg/kg

Chloride ≤ 2mg/ I ≤ 0.1mg/kg

Phosphates ≤ 0.5 mg/ I ≤ 0.1mg/kg

Conductivity ≤ 15μs /cm ≤ 3 μs /cm

PH Value 5 – 7.5 5 - 7

Appearance Colorless, clean Colorless, clean

Hardness 0.02 mmol/ I 0.02 mmol/ I

Table of contents

Other Flight Dental Systems Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Hamamatsu

Hamamatsu Energetiq LDTLS TLS-EQ-9 Operation manual

MicroDigial

MicroDigial Nabi user manual

NuAire

NuAire BR Series Operation & maintenance manual

Heidolph

Heidolph Hei-TORQUE Expert operating instructions

Thermo Scientific

Thermo Scientific Sorvall X Pro Series Instructions for use

Thermo Scientific

Thermo Scientific FB1300 Installation and operation manual