Flight Dental Systems Clave 23+ User manual

1 Clave 23+ Instruction Manual v1.4

Clave 23+

Instruction Manual

Steam Sterilizer

Distributed by

2 Clave 23+ Instruction Manual v1.4

Thank you for choosing our steam sterilizer.

Prior to operating this device, please read the instruction manual carefully and follow all

installation instructions.

Regular maintenance:

If this symbol appears on the screen when the device is powered on or if it shows E88

on the sterilization report, please contact your dealer or local service company for a maintenance

service. This device requires regular maintenance. A symbol or error code E88 will be

displayed after 1 year of use or after a certain number of cycles, whichever comes first. This is

programmed into the maintenance screen.

The Clave 23+ is the same as a Clave 23 except it has a built in compressor that speeds up the

drying process. It also has a bacteria filter that requires replacement approximately every 3

months.

Use only distilled water with this device.

Do not re-use the used water from this machine.

Power on the unit with the door open. This will allow the unit to get a initial zero pressure

reading. The machine may not start a cycle and only beep when the start button is pressed if it

has a non-zero pressure reading on powering up.

3 Clave 23+ Instruction Manual v1.4

Table of Contents

Clave 23+ Quick Guide…………………………………………………………………… 4

1. General…………………………………………………………………………….. 5

2. Technical specifications…………………..……………………………………….. 6

3. Package contents………………………………………………………………....... 6

4. Installation…………………………………………………………………………. 7

5. Operation……………………………………………………………………………7

5.1 Setup………………………………………………………………………….... 7

5.2 Preparation of sterilization materials…………………………………………...8

5.3 Selecting the sterilization program…………………………………………….. 8

5.4 Running the sterilization program……………………………………………... 9

5.5 Basic set………………………………………………………………………...10

5.6 Record of the cycle…………………………………………………………….. 10

6. Advanced settings…………………………………………………………………. 11

7. Maintenance…………..…………………………………………………………… 14

8. Error codes……………….…………………………………………………………16

9. Transportation and storage………………………………………………………… 17

10. Safety devices……………………………………………………………………… 17

Appendix

1. Water properties and characteristics………………………………………………. 18

2. Diagrams of the sterilization programs……………………………………………. 19

3. Wiring diagram……………………………………………………………………. 21

4. Hydraulic diagram………………………………………………………………… 22

5. Warranty…………………………………………………………………………… 23

6. Contact Information……………………………………………………………….. 24

4 Clave 23+ Instruction Manual v1.4

Clave 23 + Quick Guide

Set the Time and Date

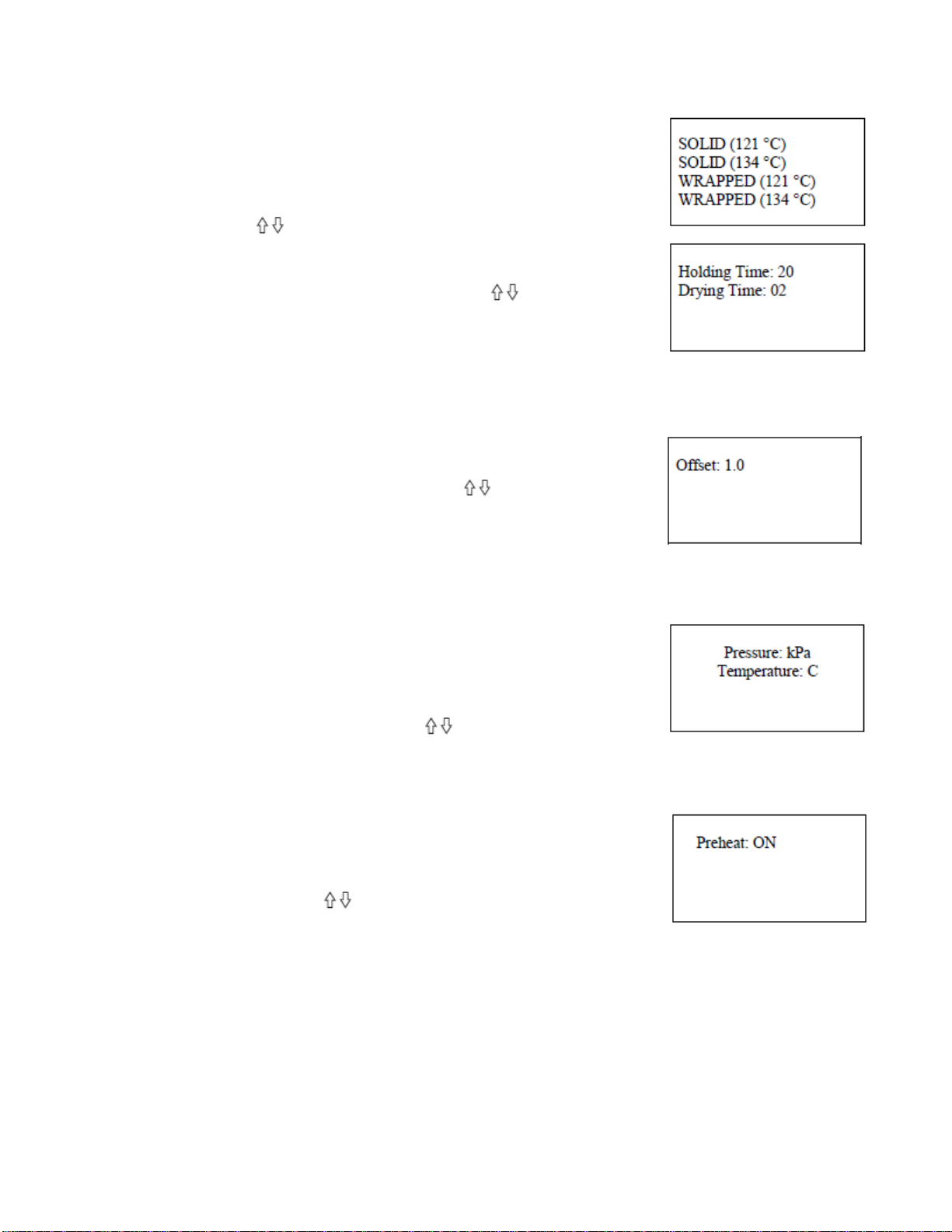

1. Power on, wait, and then press Select. Press the Down button and highlight ‘Basic Set’.

Enter ‘Basic Set’ by pressing Select.

2. Select item to change by pressing Select.

3. Adjust numbers by pressing Up and Down buttons. The time is a 24 hr. Clock.

4. Press Select at the last number to save and exit that menu. The Counter cannot be

changed in this screen.

5. Power off.

Retrieve Record on USB Stick

1. Power on, wait, and then press Select. Press Down button and highlight ‘Report’. Enter

‘Report’ by pressing Select. A list of the last 20 cycles will be accessible. Insert a USB

stick correctly into the USB connector.

2. Use the Up and Down keys to highlight the record you want. Press Select. If a printer is

connected, it will also print a copy of that report. Wait at least 10 seconds for the report to

be transferred to the USB stick. Repeat the procedure (highlight and select) for any other

records to be transferred to the USB stick.

Checking Maintenance Screen

1. Hold the Up and Down buttons while powering on. Let go when you enter the interface.

Scroll to ‘Maintenance’ and highlight it. Press Select button. On a new install, use the

select button to change the ‘End’ date to 1 yr in the future. Change the cycle count to the

expected cycle count for a year or 1000. Use the up/down buttons to change the values.

When finished, press the select button and power off. E88 or ‘wrench’ icon will come up

when either value is reached. Don’t make changes on a unit already in use for a while.

Changing Drying Time

1. Power on while pressing and holding the Select button for 5 seconds. This will enter the

advanced settings mode.

2. Press the Select button to select Parameter. Press Select button to enter the menu.

Highlight the program you want to change. Press Select button to move to the drying

time. Use the up/down buttons to change the drying time. Press the Select button to save

and return to the earlier menu. It is not recommended to change the default holding time.

5 Clave 23+ Instruction Manual v1.4

1. General

The steam sterilizer described in this manual is intended for the sterilization of instruments and

tools in the medical, dental, beauty, veterinarian and tattoo fields. It is a fully automatic steam

sterilizer with 134 °C and 121 °C sterilization temperatures. This sterilizer is in compliance with

the European Directive 93/42/CEE, Health Canada, ISO 13485, ETL, CSA and it has been

produced in accordance with the EN 13060.

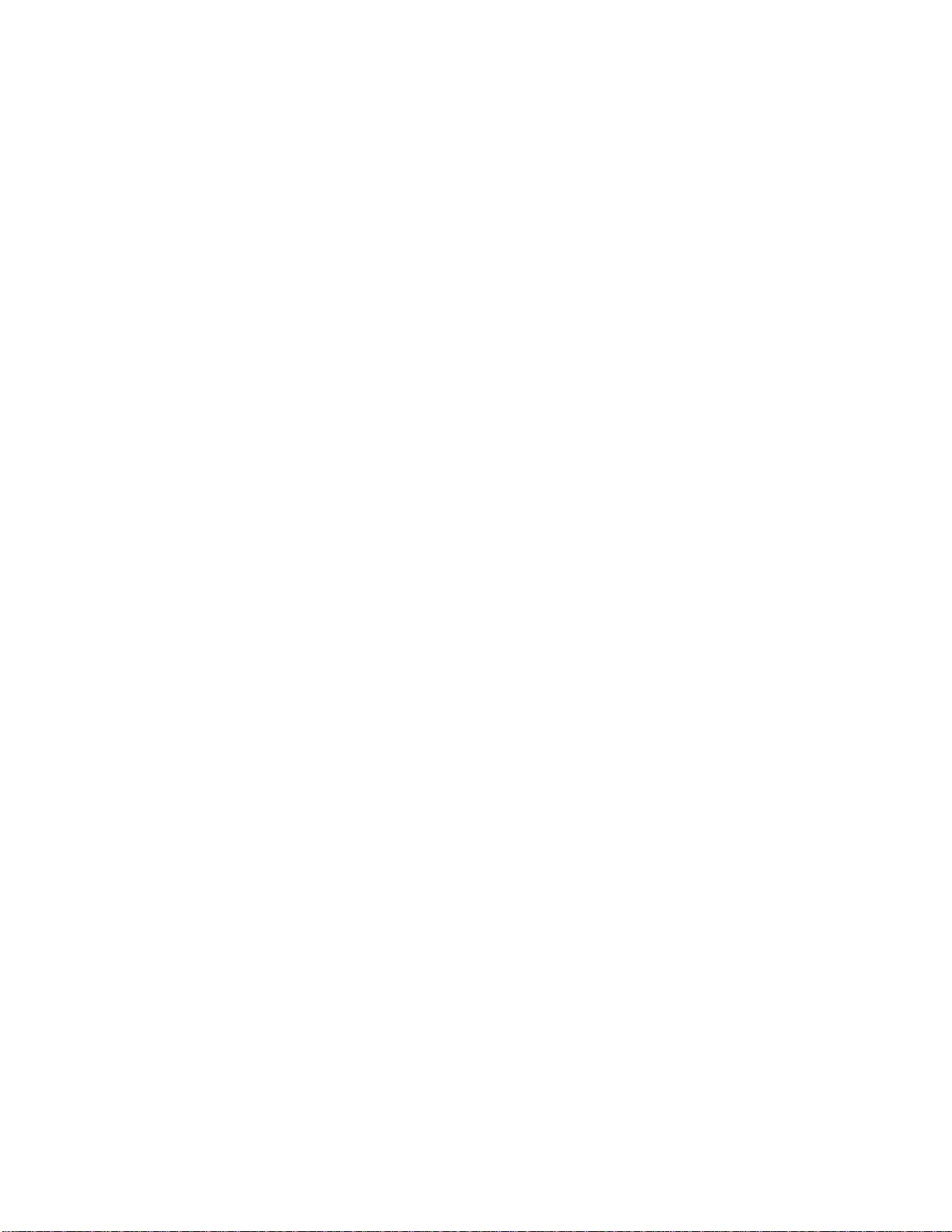

1. Distilled water tank 9. USB port

2. LCD screen 10. Printer data port

3. Control panel 11. Printer power jack

4. Power switch 12. Safety valve

5. Distilled water tank drain port 13. Condenser exhaust

6. Used water tank drain port 14. Rating plate

7. Door handle 15. Circuit breaker

8. Door 16. Power socket

Security Notice

For safe operation, please pay close attention to the warning symbols below which can be found

throughout this manual. Please read carefully and understand the contents of this manual prior to

operating this instrument.

Protective conductor terminal

This symbol is for grounding protection inside the machine.

HOT SURFACE

This symbol is visible on the front of the panel after opening the door and on the rear

enclosure near the exhaust outlet of the fan.

Important safety information.

This symbol is used to draw the attention of the reader to particularly important notions

for operator safety.

This product has been tested to the requirements of CAN/CSA-C22.2 No. 61010-1,

second edition, including Amendment 1.

6 Clave 23+ Instruction Manual v1.4

2. Technical Specifications

Item Parameter

Chamber Φ247mm x 450mm (9.72” x 23.6”)

Rated Voltage 110 VAC 60 Hz

Circuit breaker F20A

Nominal power 1600VA

Sterilization 121 °C / 134 °C

Capacity of the distilled water tank ~ 2.5 L (water at maximum level)

~ 0.5 L (water at minimum level)

Operation temperature 5 °C ~ 40 °C

Exterior dimensions

480mm (W) x 445mm (H) x 700mm (D)

18.9” (W) x 17.5” (H) x 27.6” (D)

Net weight 50kg. (110.2 lbs)

Noise level < 70db

Relative humidity Maximum 80%, non-condensing

Atmospheric pressure 76kPa ~ 106kPa

3. Package Contents

No. Item Quantity

1 Steam sterilizer 1

2 Instrument tray 4

3 Instrument tray rack 1

4 Instrument tray handle 1

5 Door adjustment tool 1

6 Draining hose 2

7 Instruction manual 1

8 Door seal 1

9 USB Drive 1

10 Power cord 1

11 ‘O’ Ring kit 1

7 Clave 23+ Instruction Manual v1.4

4. Installation

* Ensure that the sterilizer is installed with 10cm (4”) ventilation space on all sides of the

sterilizer and 20cm (8”) on the top. The clearance required to open the door is 40cm (16”).

* The sterilizer should be placed on a level work table.

* Do not cover or block the door or any ventilation areas on the sterilizer.

* Do not install the sterilizer near a sink or in a location where it is likely to be splashed with

water.

* Do not install the sterilizer near a heat source.

5. Operation

5.1 Setup

5.1.1 Open the door and remove all of the inner contents.

5.1.2 Connect the power cord to an outlet of the appropriate voltage.

5.1.3 Power on. The switch is located on the right side of the cover. After turning on the

machine, the LCD screen will turn on and show the door position, water level, working

program, date, time, etc.

Distilled water tank requires water.

Used water tank is full.

Printer is disconnected if it is blinking.

Door locked.

Notice: Before using the sterilizer or when the low water level icon blinks, fill the

distilled water tank with distilled water.

The LCD screen will go into sleep mode if a button has not been touched for some time.

You can exit the sleep mode on the screen by touching any button.

8 Clave 23+ Instruction Manual v1.4

5.1.4 Filling the distilled water tank

Open the cover and fill the tank with distilled water. When you hear the beep signal, it

means that the water level has reached the maximum level. The icon will be

displayed. Please stop filling immediately.

The water level should not exceed this port.

5.2 Preparation of Sterilization Materials

For the most effective sterilization and to preserve the instrument and tools, please follow

the suggestions below:

* Arrange the instruments of different materials on different trays or with at least 3cm of

space between them.

* Always insert a sterilization paper or cloth between the tray and instrument to avoid

direct contact between the different materials.

* Arrange the containers (glasses, cups, test-tubes, etc) on one side or in an inverted

position to avoid water pooling.

* Don’t stack the trays one above the other or put them in direct contact with the walls of

the sterilization chamber.

* Always use the instrument tray handle.

* Wrap the instruments one by one or, if more tools have to be set in the same bag, verify

that these are made of the same material.

* Don’t use metallic clips, pins, or other similar things as this jeopardizes the

maintenance of the sterilizer.

* Don’t overload the trays over the stated limit (see Appendix 2).

5.3 Selecting the Sterilization Program

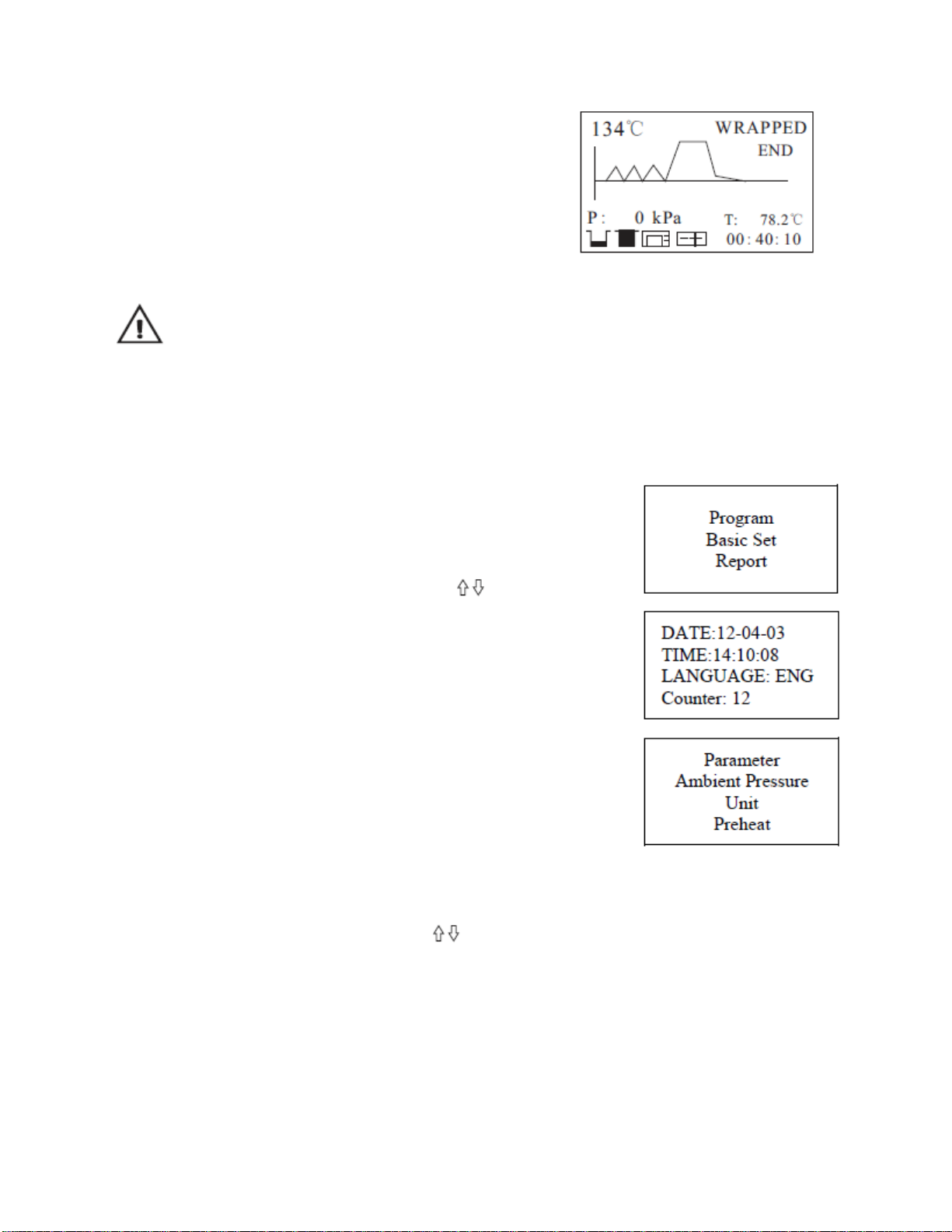

5.3.1 LCD: The panel displays the cycle temperature,

pressure, error code, sterilization state and program.

5.3.2 Select button . Select an item and save an adjustment.

5.3.3 UP button . Press UP button to select a program or

adjust and setup the parameter.

5.3.4 DOWN button . Press DOWN button to select a

program or adjust and setup the parameter.

5.3.5 Start button . Press this button to start the sterilization

cycle. To stop a cycle, press and hold this button for 5 seconds.

5.3.6 SET button. Not used.

9 Clave 23+ Instruction Manual v1.4

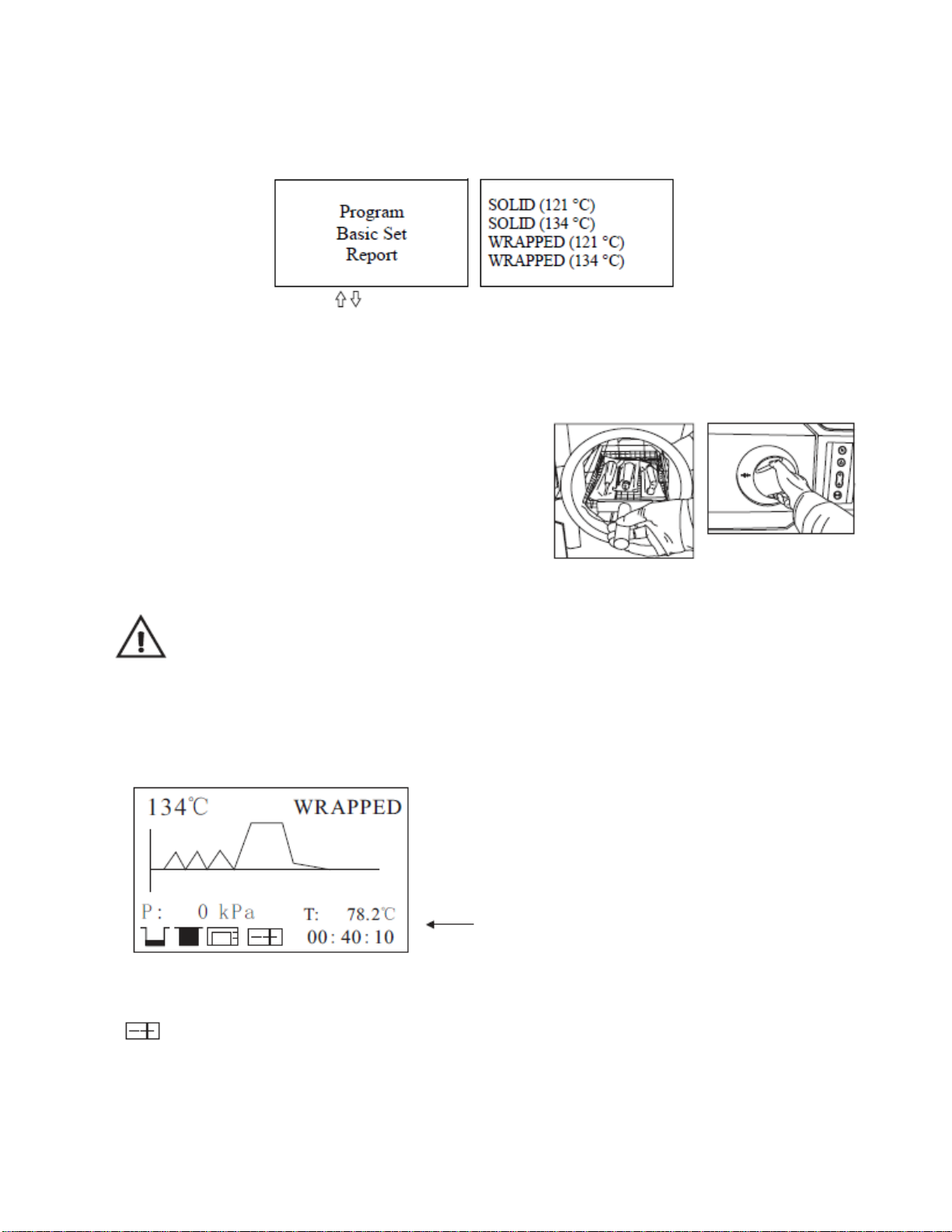

5.3.7 Select the program. You will see the available sterilization programs: Press

SELECT button, enter menu then select the ‘Program’.

Select the program by button and confirm it by pressing SELECT. If you don’t want

to select a program, you may press START to exit.

Notice: All buttons will be locked for the initial 10 seconds after powering up for system

initialization.

5.4 Running the Sterilization Program.

After selecting the program, the materials to be

sterilized can now be placed on the tray and

placed inside the chamber using the tray handle.

5.4.1 After the instruments are loaded, you may

close and lock the door by turning the door handle clockwise until it stops.

Caution: You must turn the door handle to the maximum position, otherwise the alarm

On the machine will sound and prevent the cycle from starting.

5.4.2 Starting the sterilization program

Press the Start button on the machine and it will start the cycle automatically. It will take

30 ~ 75 minutes (see appendix 2).

Total time or count down until completion

Caution: When you press the Start button but the door has not been fully closed, you will see the

blinking on the screen. A cycle cannot be started until you close the door completely.

Once the door is completely closed, press the Start button again.

10 Clave 23+ Instruction Manual v1.4

5.4.3 Sterilization Cycle Completion

After the cycle is complete, the printer will be

activated and print out a report of the cycle (if the

optional printer has been connected) and save the

report on the USB drive (optional).

Caution: Always use the tray handle to load or unload the trays from the sterilizer in

order to avoid injury or burning.

Notice: If you need to interrupt a cycle and remove materials urgently, you may hold the START

button for 5 seconds after completing the holding time to skip the dry cycle. This will result in

the program skipping directly to the last step and eliminating the drying stage. After one minute,

the cycle will end, or set the drying time to N. It will skip the drying stage.

5.5 Basic Set

5.5.1 Highlight the “Basic Set” and press the SELECT

button.

5.5.2 Select the item by pressing SELECT button.

5.5.3 Adjust the value by pressing the buttons.

5.5.4 After you finish adjusting the parameters, press the

select button to save and return to the above menu.

5.5.5 Press the START button to cancel and exit.

5.5.6 The “Counter” counts the number of cycles. It cannot

be changed.

CHN Chinese ENG English DEU German

ESP Spanish PL Polish FR French

HUN Magyar ROM Romanian NL Dutch

LTU Lithuanian LAT Latvian ITA Italian

CZE Czech

5.6 Record of the Cycle

5.6.1 Select “Report”. You will see a list of records.

5.6.2 Select the record by pressing buttons.

5.6.3 Press the SELECT button and the information will be sent to the printer and USB

port.

5.6.4 The machine has an internal memory to save the last 20 cycles.

5.6.5 Press START button to exit.

11 Clave 23+ Instruction Manual v1.4

6. Advanced Settings

6.1 Entering the Advanced Settings Function

6.1.1 Power the machine on while holding the SELECT button

for 5 seconds. This will enter into the advanced setting mode.

6.1.2 Press button to select a program. Press SELECT

button to enter the menu.

6.1.3 Select the item by pressing the SELECT button.

6.1.4 Adjust the parameter by pressing the button.

6.1.5 Holding time is 1 ~ 59 minutes.

Drying time is N-1-59 minutes. The N means there is no

vacuum state after the holding time.

6.1.6 After you finish adjusting the parameters, press the SELECT button to save and

return to the previous menu. Press the START button to cancel and exit.

6.2 Ambient Pressure

6.2.1 Select the “Ambient Pressure”.

6.2.2 Adjust the parameter by pressing button. Press the

SELECT button to save. Press START button to cancel and exit.

6.2.3 The value is 0 ~ 2. If the machine can’t enter the holding

time and is located in a high altitude location that is above 2km,

then you will need to adjust the ambient pressure.

6.3 Unit of Measure

6.3.1 Select the “Unit” to adjust the unit of temperature and

pressure.

6.3.2 Press SELECT button to enter the menu.

6.3.3 Select the unit by pressing SELECT button.

6.3.4 Change the unit by pressing button.

Pressure: kPa / bar / psi; Temperature: °C / °F

6.3.5 Press the SELECT button to save. Press START button to cancel and exit.

6.4 Preheat

6.4.1 Select “Preheat” to adjust preheat option.

6.4.2 Press SELECT button to enter the menu.

6.4.3 If you don’t want to preheat before starting the cycle, set

the value to OFF by button.

6.4.4 Press the SELECT button to save. Press START button to

cancel and exit.

12 Clave 23+ Instruction Manual v1.4

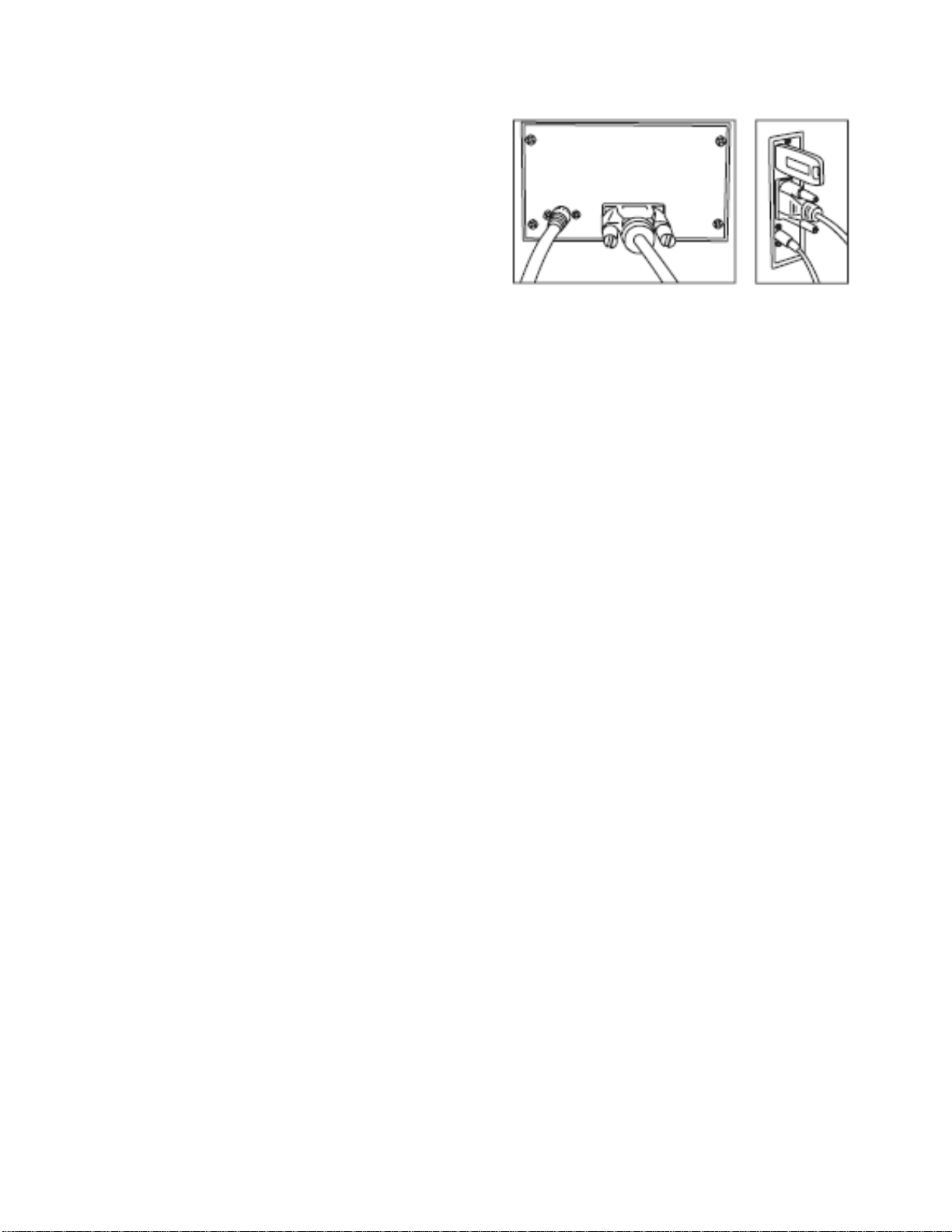

6.5 Printer (Optional)

6.5.1 Connect the printer data cable.

6.5.2 Connect the printer power cable.

6.6 USB Drive (Optional)

A USB drive can be used as a method of storing

the sterilization cycle report. To do so, insert the

USB drive in the slot on the right side panel. The

information will be automatically recorded to the USB drive after the cycle has completed. The

name of the file is determined by the serial number of the machine and the cycle number. For

example: The serial number is E00001. The cycle number is 00012. The file name on the USB

drive is 01001200.txt. The first 2 numbers represent the machine serial number. The middle 4

numbers represent the cycle number. The last 2 numbers represent the error code. 00 is no error,

01 is E01….

13 Clave 23+ Instruction Manual v1.4

When viewing printed data records, refer to the diagram below:

============================ ===============================

Program: WRAPPED Program: WRAPPED

Temperature: 134C Temperature: 134C

Pressure: 206.0 kPa Pressure: 206.0 kPa

Drying Time: 02Min Drying Time: 30Min

Holding Time: 6.0Min Holding Time: 6.0Min

-------------------------------- --------------------------------

Time Temp. Pressure Time Temp. Pressure

Start 13:21:41 025.0C Start 15:02:41 023.4C

T1: 13:27:40 074.8C 051.0kPa T1: 15:08:12 072.8C 051.1kPa

T2: 13:27:57 070.0C 009.7kPa T2: 15:08:31 068.6C 009.7kPa

T3: 13:31:09 088.6C 051.3kPa T3: 15:11:30 086.8C 050.5kPa

T4: 13:31:31 084.0C 009.7kPa T4: 15:11:50 083.5C 009.9kPa

T5: 13:35:42 109.8C 102.7kPa T5: 15:15:50 108.2C 101.1kPa

T6: 13:36:22 098.8C 009.9kPa T6: 15:16:30 097.2C 009.7kPa

TS: 134.8C 222.5kPa TS: 000.0C 000.0kPa

Max. Temperature:135.3C Max. Temperature:000.0C

Min. Temperature:134.2C Min. Temperature:000.0C

Max. Pressure:226.2kPa Max. Pressure:000.0kPa

Min. Pressure:218.8kPa Min. Pressure:000.0kPa

T7: 13:44:40 134.3C 218.9kPa T7: 15:16:00 000.0C 000.0kPa

T8: 13:50:39 134.6C 223.1kPa T8: 00:00:00 000.0C 000.0kPa

End 13:53:48 099.0C End 15:22:17 116.8C 083.4kPa

-------------------------------- --------------------------------

Cycle No.: 00001 Cycle No.: 00009

Ster. Value: Success Ster. Value: Failure E20

Date: 2018-06-04 Date: 2018-06-05

SN:E00001 SN:E00001

Operator: Operator:

v 2N08231C v 2N08232C

================================ ===============================

14 Clave 23+ Instruction Manual v1.4

7. Maintenance

Frequency Maintenance operation

Daily

Clean the door seal

Clean the external surface

Drain the used water tank

Weekly Clean the distilled water tank (drain tank)

Clean the sterilization chamber

Monthly Clean the filter in the chamber and tank

Every 3 months Replace the bacteria filter

Every 6 ~ 12 months Replace the door seal

7.1 Clean the distilled water tank every week with isopropyl alcohol or a medical

disinfectant. Drain unused water.

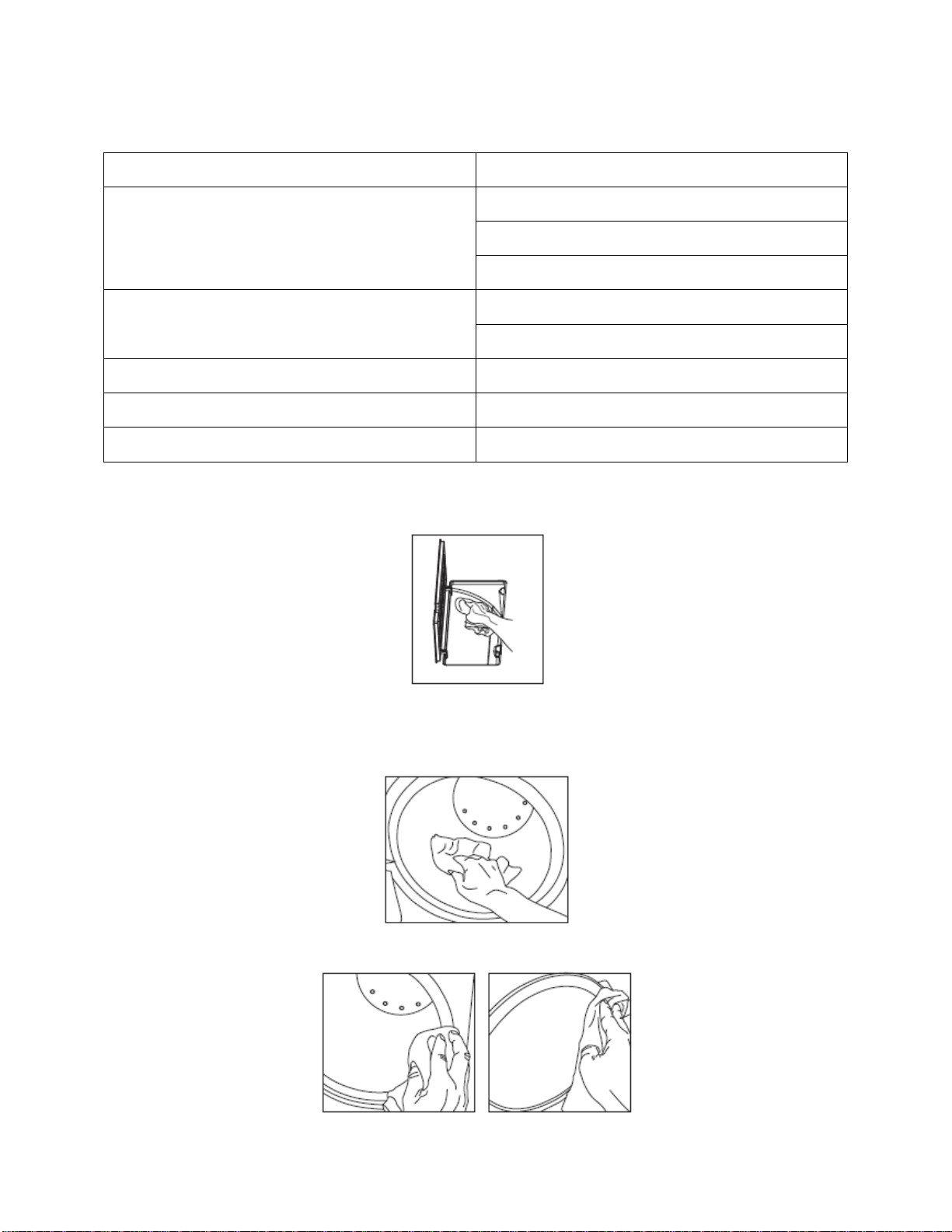

7.2 Clean the chamber weekly.

7.2.1 Remove all trays and the tray rack from the chamber.

7.2.2 Clean the chamber with a smooth cloth saturated with distilled water.

7.2.3 Apply the same procedure to the trays and rack.

7.3 Clean the door seal.

7.3.1 Clean the door seal weekly with a smooth cloth saturated with distilled water.

15 Clave 23+ Instruction Manual v1.4

7.4 Door adjustment

Under normal circumstances, the chamber door does not require adjustments. However, if the

seal fails (resulting in steam leaking from the front of the chamber), you may use the spanner

tool to tighten the door seal.

7.4.1 Open the door.

7.4.2 Insert the spanner tool in the gap beneath the plastic cover. Use the spanner to grip the

adjusting nut (Fig. 1). Turn the nut counter clockwise as in the figure below (Fig. 2). This will

tighten the sealing plate.

7.4.3 Turn the nut until the sealing plate is tight. If the door knob is too tight, you may also turn

the nut clockwise to loosen it.

Caution: Never adjust the chamber door while the door is closed.

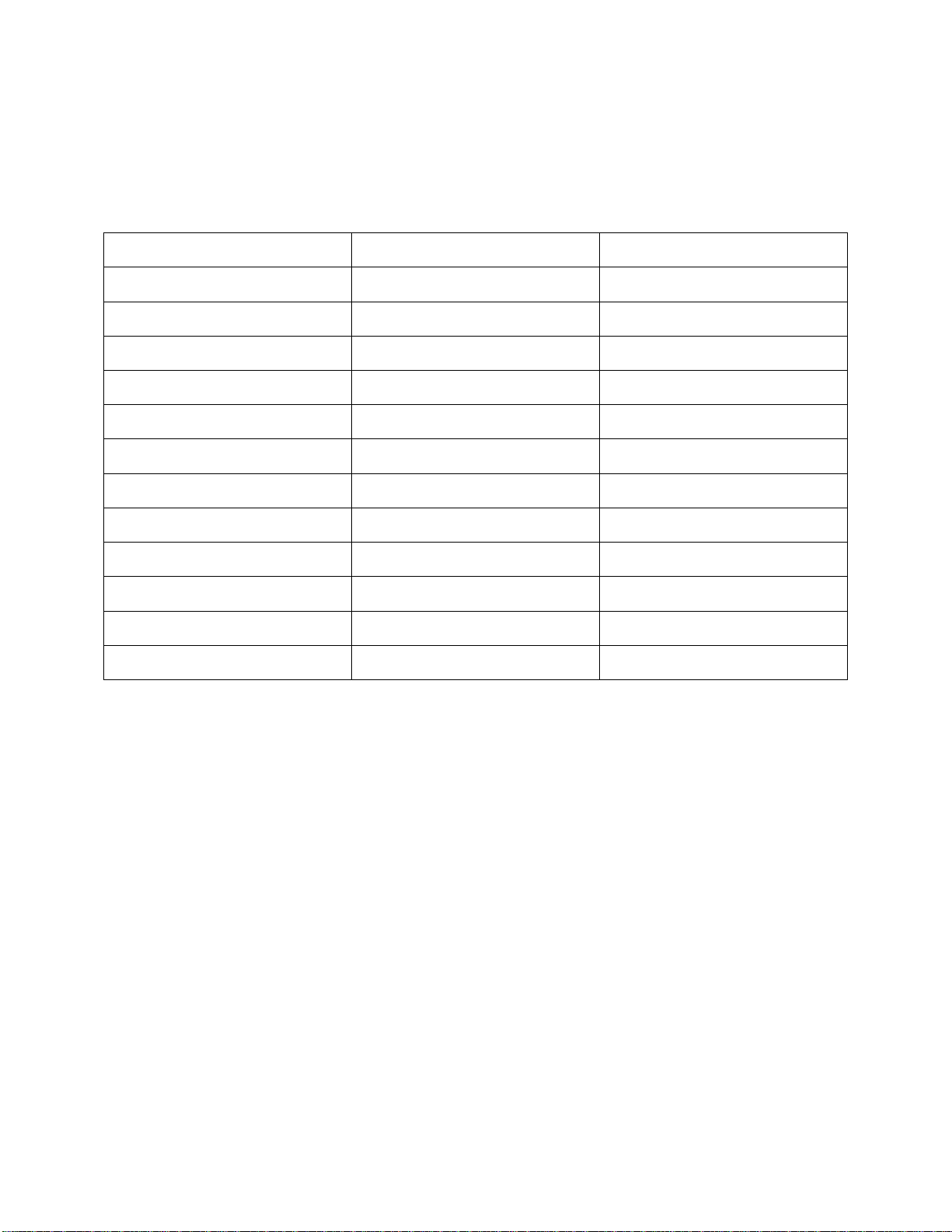

7.5 Replacement of the door seal

7.5.1 Open the chamber door.

7.5.2 Remove the door seal ring carefully by hand.

7.5.3 Clean the door seal ring carefully with a smooth cloth saturated with distilled water.

7.5.4 Moisten the new seal with medicinal disinfectant or isopropyl alcohol or distilled water.

7.5.5 Insert the new door seal and press in sequence as follows:

Caution: Please insure the chamber and the door have cooled prior to replacing the

door seal.

16 Clave 23+ Instruction Manual v1.4

7.6 The Drain Valve

8. Error Codes (Press and hold the select button for 5 seconds to clear error)

Code Description Proposed Solution

E01

Steam generator temperature is

too high

Power off. Wait 5 minutes. Power on & run a new

cycle. Contact dealer if error returns.

E02

Inner chamber temperature is

higher than 140 °C

Power off. Wait 5 minutes. Power on & run a new

cycle. Contact dealer if error returns.

E03

Outer chamber temperature is

higher than 160 °C

Power off. Wait 5 minutes. Power on & run a new

cycle. Contact dealer if error returns.

E04

Takes too long to reach holding

time

Power off. Wait 5 minutes. Power on & run a new

cycle. Contact dealer if error returns.

E05 Over pressure inside chamber,

unable to release

Power off. Wait 5 minutes. Power on & run a new

cycle. Contact dealer if error returns. On a Plus

version, replace V1 if error occurs at 8 minutes.

E06 Door lock fault

Make sure you have turned the door handle to the

maximum position. Check the door switch.

E09

Pressure leak, takes too long to

reach pressure and temperature

Check if the distilled water tank is empty. Check

for leaks. Contact dealer if error returns.

E10 Door lock problem

Try again. Open and close the door. Contact dealer

if error returns.

E11

Steam generator element not

heating

Power off. Wait 5 minutes. Power on & run a new

cycle. Contact dealer if error returns.

E12 Chamber element not heating

Power off. Wait 5 minutes. Power on & run a new

cycle. Contact dealer if error returns.

E20

Program cycle was ended

manually

Power off, wait, and power back on.

E21 Failure to enter the holding time

Power off. Wait 5 minutes. Power on & run a new

cycle. Contact dealer if error returns.

E24

Pressure leak, lower than 30kPa

when the temperature is 120 °C

Power off. Wait 5 minutes. Power on & run a new

cycle. Contact dealer if error returns.

E34

Plus version only, back pressure

too high at the drying phase

Power off. Contact dealer. Clean or replace V1.

17 Clave 23+ Instruction Manual v1.4

E88

Maintenance request from the

machine

Contact dealer or service company and have a

maintenance done.

9. Transportation and Storage

1. Turn off the sterilizer before transportation or storage. Pull out the plug. Let the

machine cool down.

2. Drain the distilled water tank and the used water tank.

3. Conditions for transportation and storage:

Temperature: -20 °C ~ +55 °C (all water must be removed if below 0 °C)

Relative humidity: ≤85%

Atmospheric pressure: 50kPa ~ 106kPa.

4. If shipped, the unit must be strapped to a pallet. Do not ship in the box alone.

10. Safety Devices

1. Circuit breaker: Protects the sterilizer against possible failures and damage to the internal

components.

Action: Interruption of the power supply. Requires a manual reset. If it trips again, contact a

service person.

2. Thermal cutouts on the main transformer windings: Protection against possible short

circuit and overheating of the main transformer winding.

Action: Interruption of the power to the transformer. Contact a service person.

3. Safety valve: Protection against possible sterilization over pressure.

Action: Releases steam and restores pressure inside the chamber to a safe level.

4. Safety micro-switch for the door status: Informs the user if the door is incorrectly closed.

Action: Signal indicates that the door is not closed properly.

5. Thermal switch on chamber heating elements. Protection against possible overheating of

the chamber.

Action: Interruption of the power supply to the chamber elements. Resets when it cools.

6. Thermal switch on steam generator heating elements. Protection against possible

overheating of the steam generator.

Action: Interruption of the power supply to the steam generator element. Resets when it cools.

7. Door safety lock. Protection against accidental opening of the door.

Action: Prevents accidental opening of the door during a sterilization cycle.

8. Self-leveling pressure system: Pressure system adjusts to a neutral pressure level in case of a

manual cycle interruption, alarm or power loss.

Action: Automatic restoration of the atmospheric pressure inside the chamber.

18 Clave 23+ Instruction Manual v1.4

Appendix 1

Water Properties / Characteristics

Description Feed Water Condensate

Evaporate residue ≤ 10mg/L ≤ 1.0mg/kg.

Silicon dioxide (SiO2) ≤1mg/L ≤0.1mg/kg

Iron ≤0.2mg/L ≤0.1mg/kg.

Cadmium ≤0.005mg/L ≤0.05mg/kg

Lead ≤0.05mg/L ≤0.1mg/kg.

Rest of heavy metals ≤0.1mg/L ≤0.1mg/kg.

Chloride ≤2mg/L ≤0.1mg/kg

Phosphates ≤0.5mg/L ≤0.1mg/kg.

Conductivity ≤15µs/cm ≤3µs/cm

PH Value 5 ~ 7.5 5 ~ 7

Appearance Colorless, clean Colorless, clean

Hardness ≤0.02mmol/L ≤0.02mmol/L

19 Clave 23+ Instruction Manual v1.4

Appendix 2

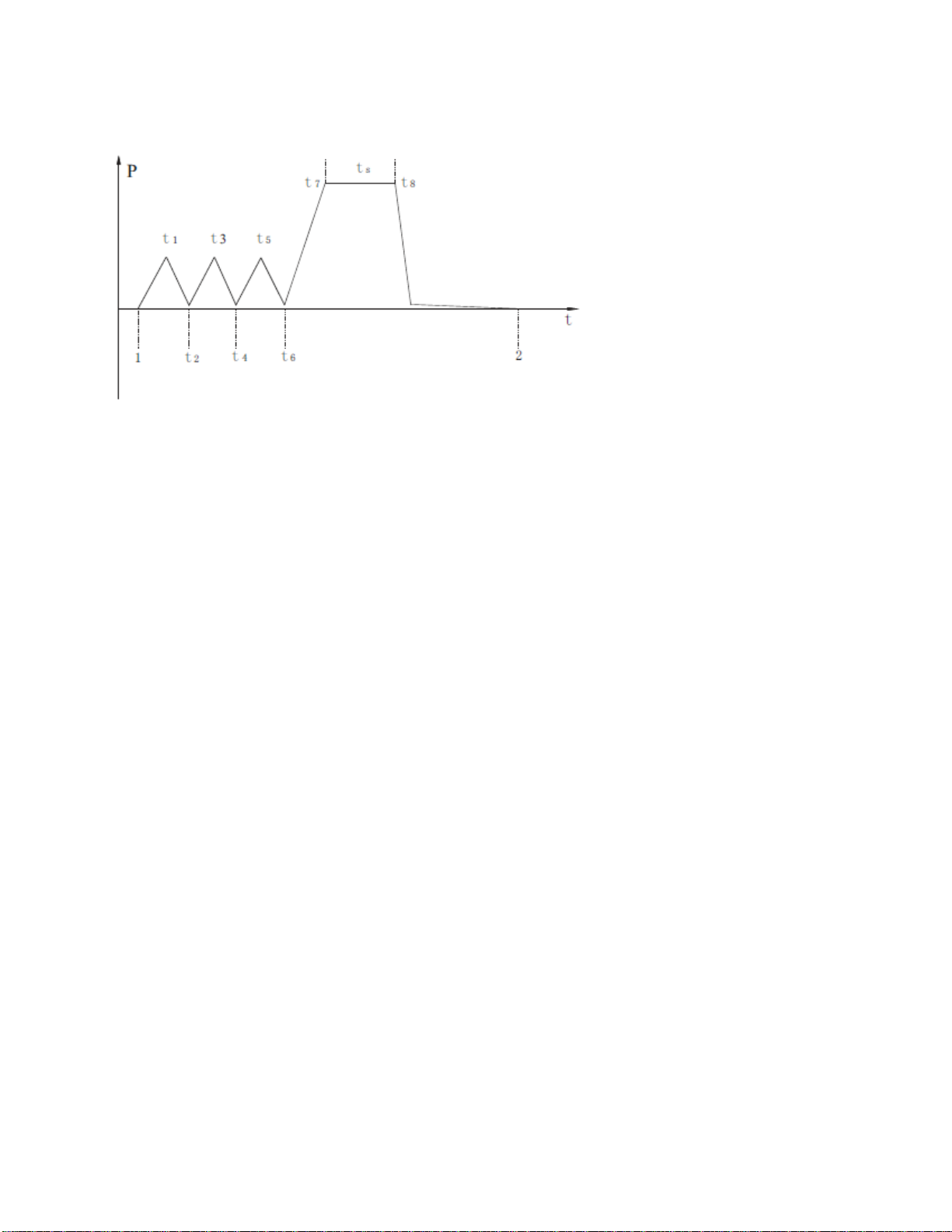

Diagrams of the sterilization programs

Programs Temp

°C Pressure

kPa Holding

time

Total

time

(min) Type Max.

load

(kg)

Max.

load

per tray

(kg)

Unwrapped

134 210 4 25~45 Unwrapped solid

material 5.00 1.50

121 110 20 30~60

Liquid 134 210 10 35~60 Liquid 1.20 0.40

Plastic 121 110 30 35~65 Plastic

Wrapped

134 210 6 35~65

Wrapped solid

material

5.00 1.50

121 110 20 35~55

Single wrapped solid

or hollow material

4.00 1.20

Textile

134

121

210

110

8

30

45~65

50~75

Unwrapped porous

material

1.25 0.40

Single wrapped

porous material

1.10 0.30

Dual wrapped porous

material

0.75 0.25

Single wrapped

hollow material

4.00 1.25

Dual wrapped solid

and hollow material

2.00 0.60

Prion 134 210 18 50~75

Unwrapped porous

material

1.25 0.40

Single wrapped

porous material

1.10 0.30

Dual wrapped porous

material

0.75 0.25

Single wrapped

hollow material

4.00 1.25

Dual wrapped solid

and hollow material

2.00 0.60

Drying

(optional)

-- -- -- 1~20 -- -- --

The time required for the sterilizer to be ready for routine use after the power is switched on is

less than 5 minutes.

The maximum temperature of the 134 °C sterilization cycle is 137 °C.

The maximum temperature of the 121 °C sterilization cycle is 124 °C.

20 Clave 23+ Instruction Manual v1.4

Table of contents

Other Flight Dental Systems Laboratory Equipment manuals