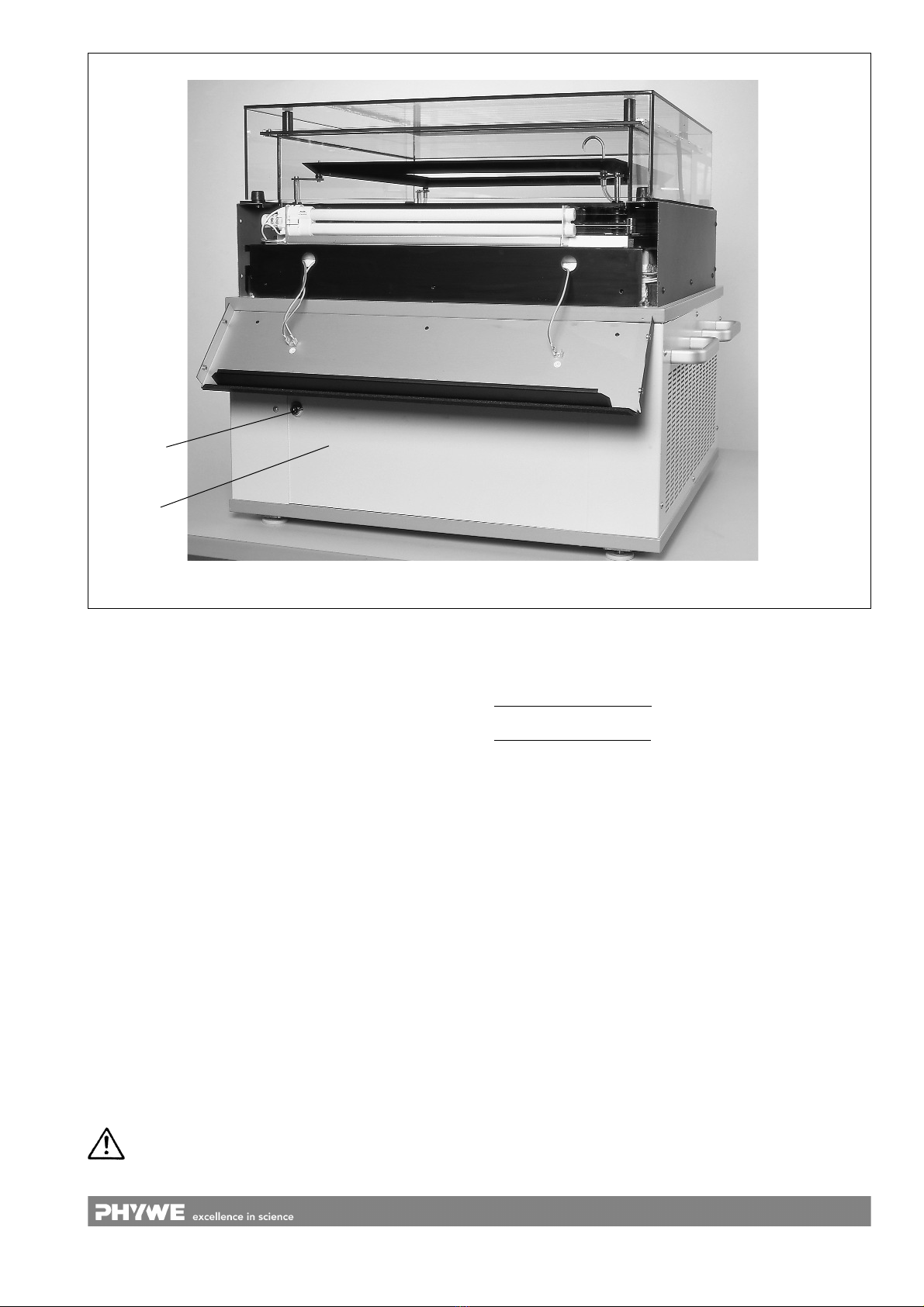

– alcohol reservoir (removable) with a double tubing

assembly which can be screwed off (12)

– main switch (4)

– switch „continuous operation - timer“ (5)

– swtich „high voltage“ (6)

– knurled nut for alcohol supply (11)

– control knob for gutter heating (7)

– programmable time switch (8)

– safety cutout (9)

When you have connected the cloud chamber to mains and

opened the front side, remove the alcohol reservoir (12) from

its installation place and unscrew the union nut (13) of the

double tubing assembly.

Fill the alcohol reservoir three quarters full (see section 7

“Notes on handling iso-propanol”), fit the double tubing

assembly on again and the alcohol reservoir back in place).

Now activate the switches as follows:

main switch (4): ON

mode (5): continuous operation

high voltage(6): ON

The knurled nut (11) serves for regulating the amount of

alcohol dropping into the evaporating gutter. Turn the the

knurled nut to the left and observe the alcohol flowing

through the bended tube (14) and dropping into the gutter.

When the gutter is filled to a liquid level of about 1 cm, reduce

the alcohol supply to about 6 - 8 droplets per second. When

the cloud chamber is being operated, the alcohol in the gutter

should remain constant at this level. After about 5 minutes,

the first white tracks should appear on the black observation

surface. If, however, after 1 hour the tracks become a bit

fuzzy and milky, you have to reduce the gutter heating by

means of the control knob (7).

If the tracks are too weak, the heating of the gutter must be

increased.

If you want to run the cloud chamber at automatic operation,

set the markers of the programmable time switch to the

desired switching time (red marker to switch the cloud

chamber on, green marker to switch it off) and set the mode

switch (5) to „timer“. For more detailed information see the

instructions on the programmable time switch.

Now close the front side by inserting the plate (3) into the

right side of the opening, pushing it back to the left stop

position and locking it up.

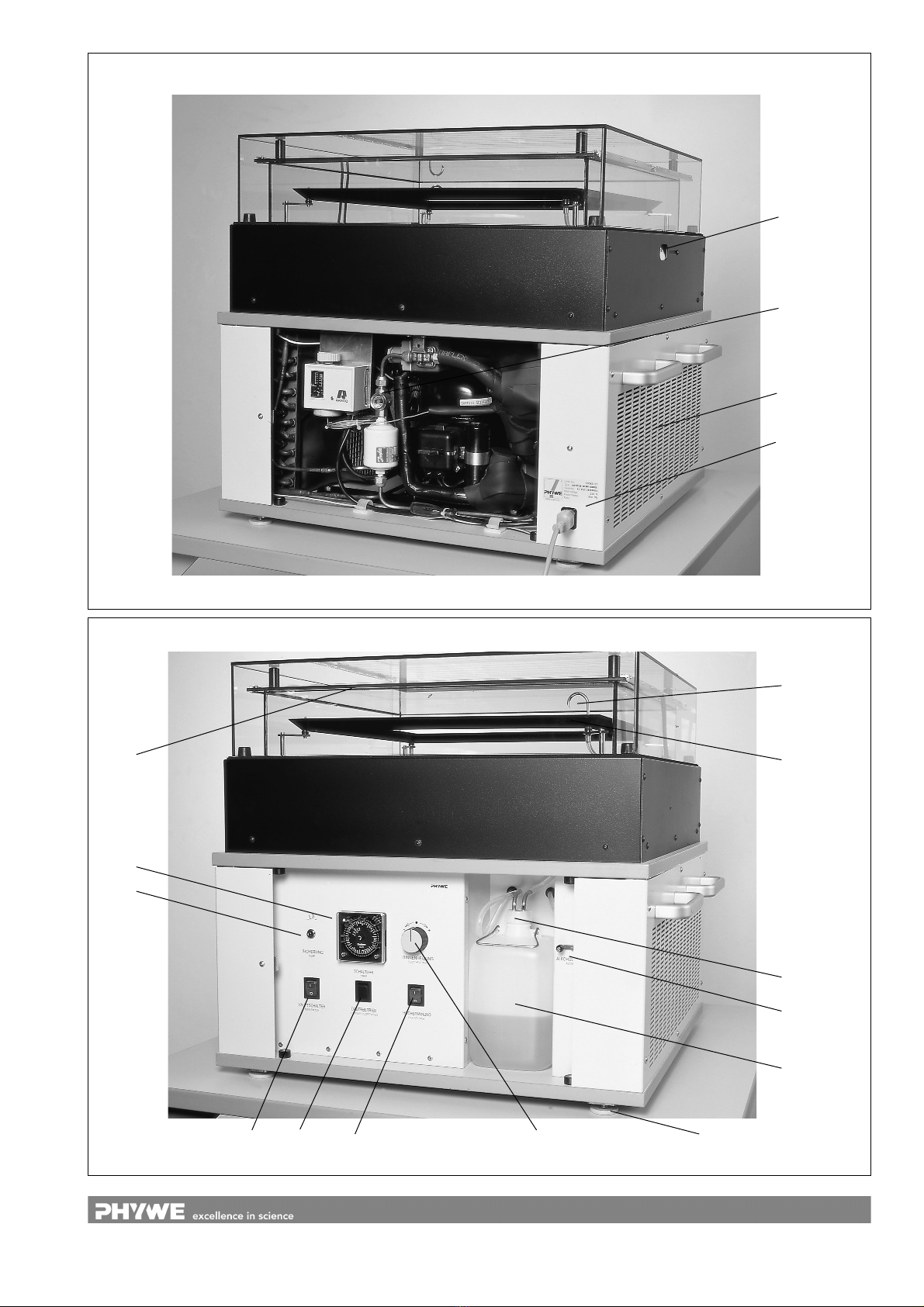

How to open the back side:

Important!

It is only allowed to open the back front. by qualified

personal.The back side can be opened and closed just like

the front side. Here you can see the cooling element, the

thermostat and the inspection glass (21) for the cooling liquid.

During the operation of the cloud chamber the inspection

glass should always be filled with cooling liquid. Make sure

that there are no bubbles in the glass.

The thermostat comes supplied set to the optimum

temperature. In the case of extreme room temperatures, it

might become necessary to modify the setting by turning the

knob on the upper part of the thermostat. Please make sure

that modifications on the cooling element are only

carried out by authorized experts.

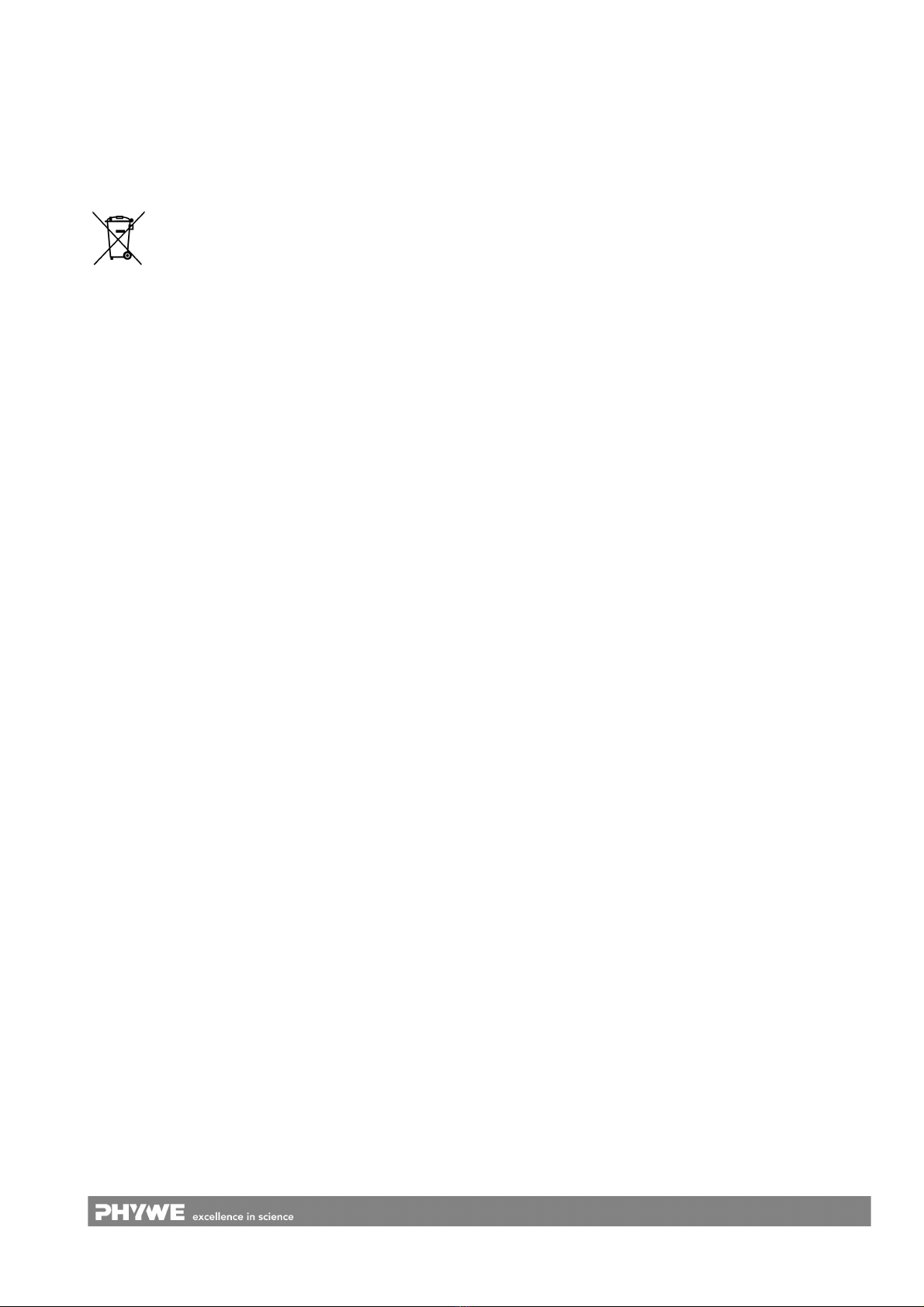

The upper part of the glass hood includes an electrically

heated gutter (15) which runs around the whole

circumference. Iso-propyl alcohol flows through a bended

tube (14) and drops into the gutter.

The alcohol evaporates and diffuses from the upper, warmer

area of the chamber to the cold chamber bottom. There the

alcohol is condensed into tiny droplets and flows back into

the reservoir.

Right above the thin liquid layer covering the bottom a zone

of oversaturated alcohol vapour is formed. It’s in this area,

and only in this area, that the charged material particles

coming from the inside or from the outside produce ions

along their trajectory. The tiny alcohol droplets preferably

attach to these ions thus producing a visible cloud track. The

length and the structure of the cloud track give information on

the kind of ionizing particles.

4TRANSPORT OF THE CLOUD CHAMBER

Important!

It is vital to ensure the cloud chamber is not tilted (< 10° from

the vertical) during transport, as otherwise the refrigeration

system will be irreparably damaged.

Transport of a cloud chamber (e.g. change in the place of

installation) should not be carried out with an evaporating

duct full of alcohol. Adrain valve has now been additionally

fitted into the cloud chamber for the draining of the alcohol

from the evaporating duct. This drain valve can be regulated

with a knob which is positioned above the milled screw for the

regulation of the alcohol feed-in (11). Open the drain valve to

allow alcohol to flow back into the alcohol container (12).

Close the drain valve as soon as the evaporating duct is

empty.

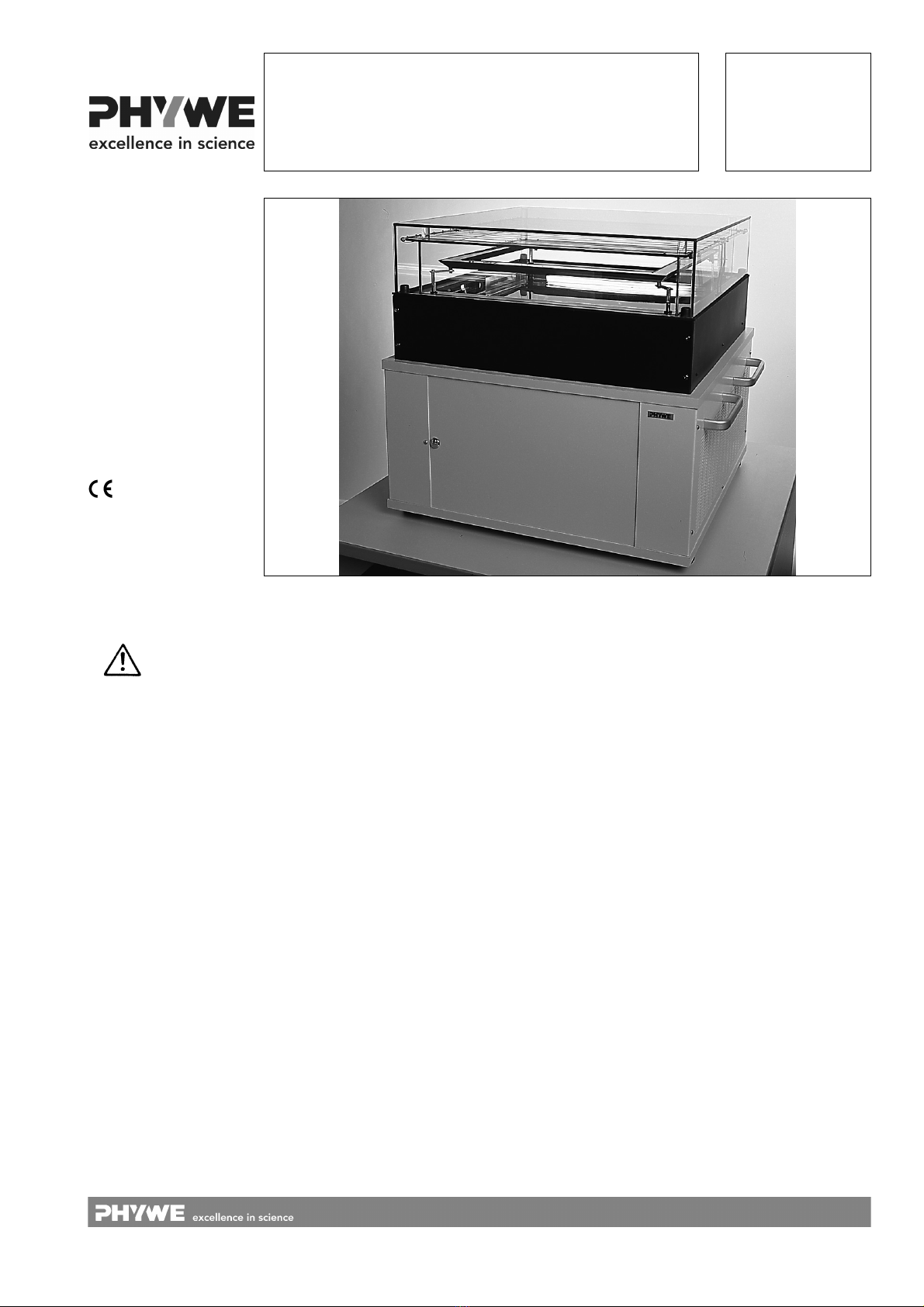

5INSTALLATION OF THE CLOUD CHAMBER

In order to guarantee an optimum view on the observation

chamber, it is recommended to place the chamber onto a

square table (border length about 90 to 100 cm) which should

be about 60 cm high. Since the weight of the cloud chamber

is 80 kg, the table must be massive enough to carry this load.

Please make sure that the ventilating slots (19) are not

covered and that the cloud chamber is not subjected to direct

light coming from above. Aslightly darkened room would be

perfect. Use the connecting cable supplied to connect the

cloud chamber to mains. The mains connection (1) is located

down on the back side. The corresponding mains socket

should be protected for max. 16 A.

Adjust the cloud chamber on an absolutely horizontal level

with the aid of the adjustable feet (16) in order to provide an

even alcohol level in the gutter and thus a clear image.

6INITIAL OPERATION

The base of the cloud chamber can be accessed from two

sides. Unlock the lock (2 or 3) to open the two sides, push the

side plate a few centimeters to the right and then carefully

pull it towards you thus lifting it out of the base.

On the front side you can now find a panel with the following

components and operating elements: