4219

Wired Zone Expander Module

INSTALLATION AND SETUP GUIDE

GENERAL INFORMATION

This module adds up to eight end-of-line resistor supervised zones

to compatible control/communicators via the control’s keypad

wiring.

The module may be mounted within the control’s cabinet (if room

permits) or remotely. If mounted remotely there are provisions to

tamper protect the unit. Communication to the module is

supervised so that it cannot be disconnected from the keypad wiring

without detection by the control. If the wiring is cut a tamper

alarm or signal will result to indicate that this device (and possibly

other similarly connected devices) has become inoperative.

IMPORTANT: Some carbon monoxide detectors may not be

compatible with the Honeywell 4219 hardwire zone expanders.

When using carbon monoxide detectors in systems that support the

4219 zone expanders install the detectors only on the basic

hardwire zones of the system control panel and NOT on the zone

expanders.

INSTALLATION

1. Power should be disconnected before proceeding.

2.

Be sure to mount the 4219 before making any wire

connections.

When the module is mounted remotely holes on the back of the

module’s housing permit it to be mounted horizontally or vertically.

Wires can exit from the side or the breakout on the back of its

housing. For tamper protection attach the tamper magnet

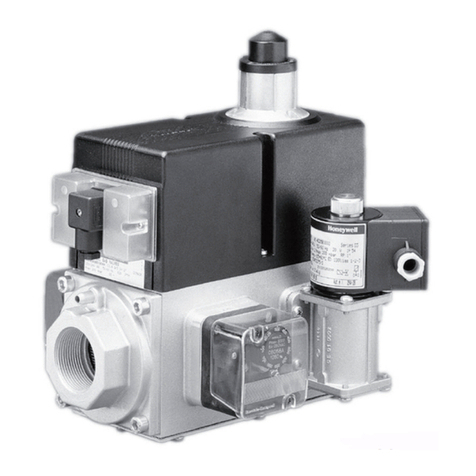

(provided) (Figure 1) to the module inside cover. Place DIP switch

position #8 in the OFF position. Affix the connections label that

accompanies the module to the inside of the module’s cover. When

the installation is complete put the modules cover on. The magnet

attached to the cover positioned near the reed switch will cause a

tamper signal to be sent to the control if the cover is removed.

When the module is to be mounted inside the control’s cabinet

mount it horizontally to the raised tabs at the back of the cabinet.

Insert self-tapping screws (provided) in two adjacent raised tabs at

the back of the cabinet. Leave the heads projecting 1/8”. Hang the

module on the screw heads via two slotted holes on the back of the

module’s housing. When the module is installed in the control’s

cabinet it need not be tamper protected.

NOTE: For EN50131-3 compliance a tie-wrap must be secured

around the case of a remotely mounted 4219

Apply tie-wrap around the case to the right of the large zone wire

opening (4-inch case width) This is in opposition of the tamper

switch and magnet

Affix the connections label that accompanies the module to the

inside of the control’s cover.

See the control’s installation and setup guide for additional

information.

CONNECTIONS AND SETTINGS

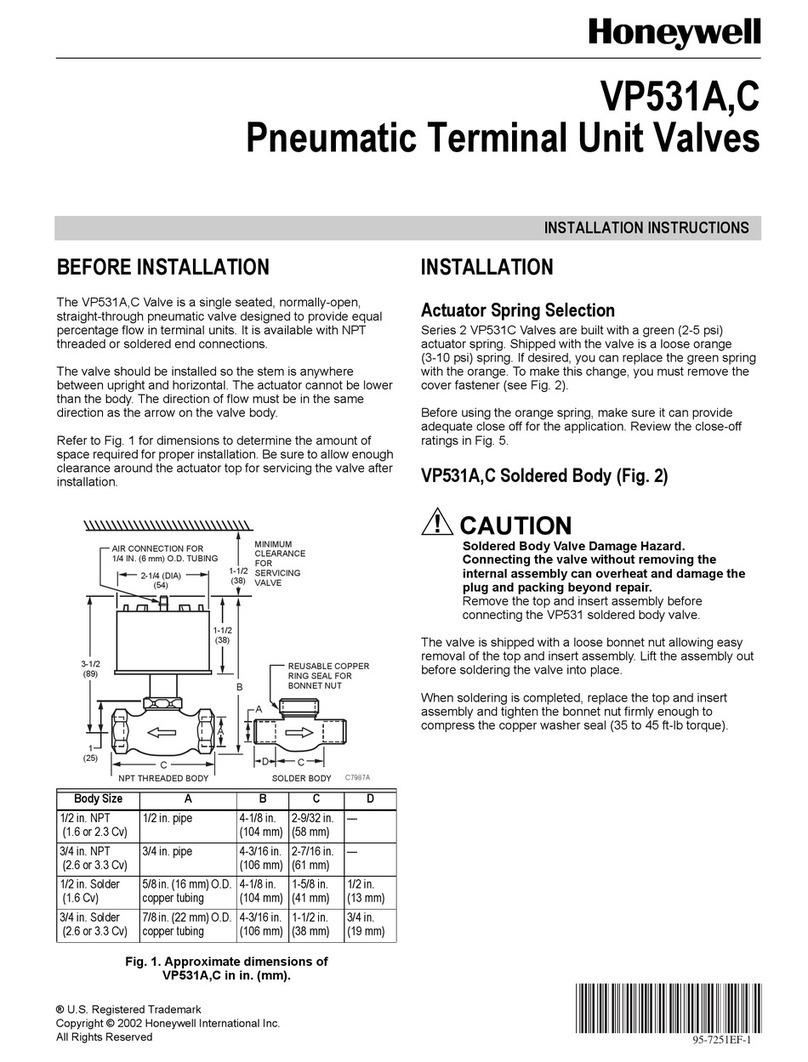

Make protection zone connections to the module’s 12-position

terminal block TB1. Each zone that is used must have a 2K-ohm

end-of-line resistor connected across the end of its loop as shown

in Figure 2.

CE

•For CE installations ADEMCO N6361 EMI

suppression bead is required. Refer to the

N6361 installation guide for wire routing

instructions.

1. INSERT BOTTOM TABS FIRST.

2. ENGAGE TOP WITH CLIP. 4219-002-V0

Figure 1. Tamper Magnet Installation

If a zone is not programmed the resistor need not be used. The

method of programming each zone for the type of alarm and

reporting code to the central monitoring station varies with the

control to which the module is connected. Refer to the Installation

and Setup Guide for that control unit.

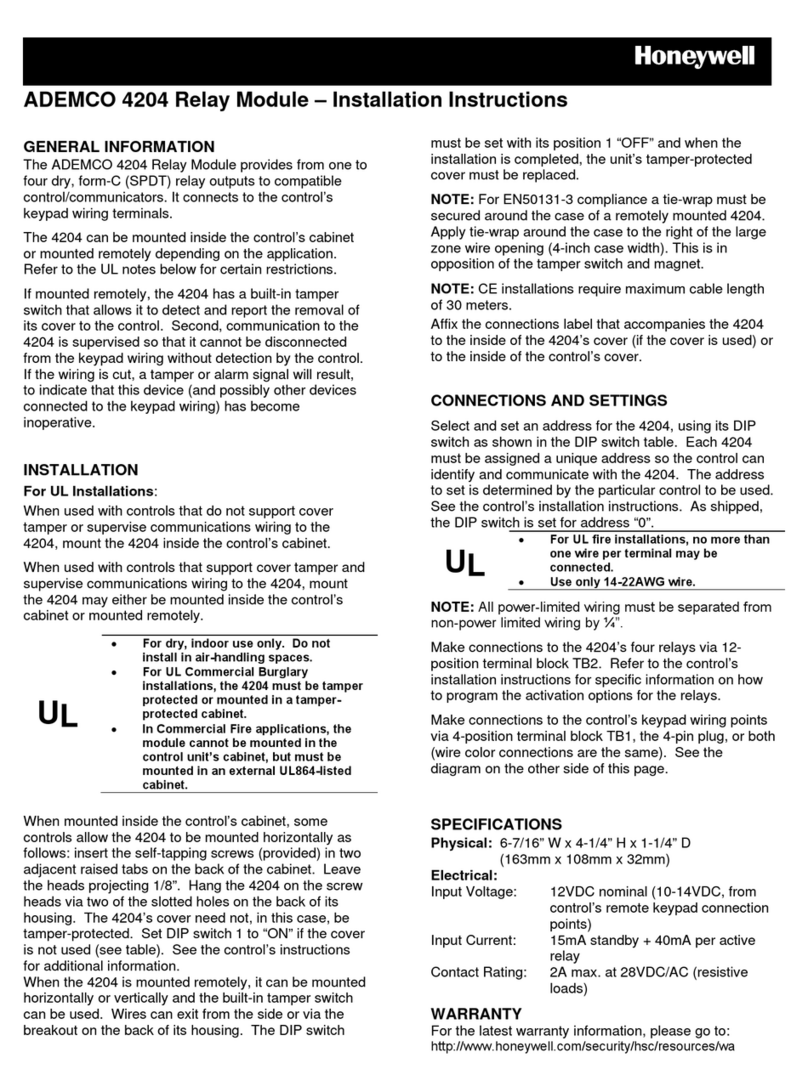

Set the DIP Switch to one of 31 addresses as shown in Figure 3 so

the control can identify the module and communicate with it

properly. The address to be set is determined by the particular

control to be used and the control’s installation instructions must

be consulted. As shipped the DIP Switch is set for an address of

“0”.

Zone A can be set for fast response time of 10ms to an open circuit

if desired by setting position 1 of the DIP Switch to “OFF”. As

shipped it is set to “ON” for a response time of 300ms as shown in

the table below. All other module protection zones have a nominal

response time of 300ms.

Connections to the control’s keypad wiring points can be made via

4-terminal block TB2 or the 4-pin plug (wire color connections are

the same).

SPECIFICATIONS

Physical 6-7/16”W x 4-1/4”H x 1-1/4” D (163mm

x 108mm x 32mm)

Electrical

Input Voltage: 12VDC (from control’s remote keypad

connection points)