INSTRUCTIONS FOR SERVICING

LARGER TM VALVE

1. Remove pointer rod nut, friction spring and pointer. Shut

off hot and cold supplies to this valve.

2. Remove, cover screws and cover, to which the thermostat

group is attached.

3. To clean port sleeve assembly (the thimble must slide

freely on the port sleeve): unscrew the check nut as far as it

will go, then screw the port sleeve nut into the base. The

port sleeve and thimble may then be lifted out.

4. Clean with anon-corrosive cleaning solution. DO NOT

USE ABRASIVES! The port sleeve should be

reassembled in the valve with the shoulder to the left.

5. To Clean thermostat group, remove pointer rod nut and

pointer. Remove coil sleeve stud (8) and take off

thermostat group (TG-2/300).

6. Clean with anon-corrosive cleaning solution. DO NOT

USE ABRASIVES.

7. Replace pointer rod with gear and re-assemble.

8. When reassembling, make sure driving ball of thermostat

group engages the ball socket of the port sleeve assembly.

INSTRUCTIONS FOR SERVICING

SMALLER TM VALVES

1. Loosen LTR screw.

2. Remove snap cap, screw and washer, friction spring and

pointer. Shut off hot and cold supplies to this valve.

3. Remove, cover screws and cover, to which the thermostat

group is attached.

4. To clean port sleeve assembly (the thimble must slide

freely on the port sleeve): unscrew the check nut as far as it

will go, then screw the port sleeve nut into the base. The

port sleeve and thimble may then be lifted out. There is no

shoulder for the TM-150 Port Sleeve.

5. Clean with anon-corrosive cleaning solution. DO NOT

USE ABRASIVES! The port sleeve should be

reassembled in the valve with the shoulder to the left.

6. To Clean thermostat group, remove coil sleeve stud and

take off thermostat group.

7. Clean with anon-corrosive cleaning solution. DO NOT

USE ABRASIVES.

8. Replace pointer rod with gear and re-assemble.

9. When reassembling, make sure driving ball of thermostat

group engages the ball socket of the port sleeve assembly.

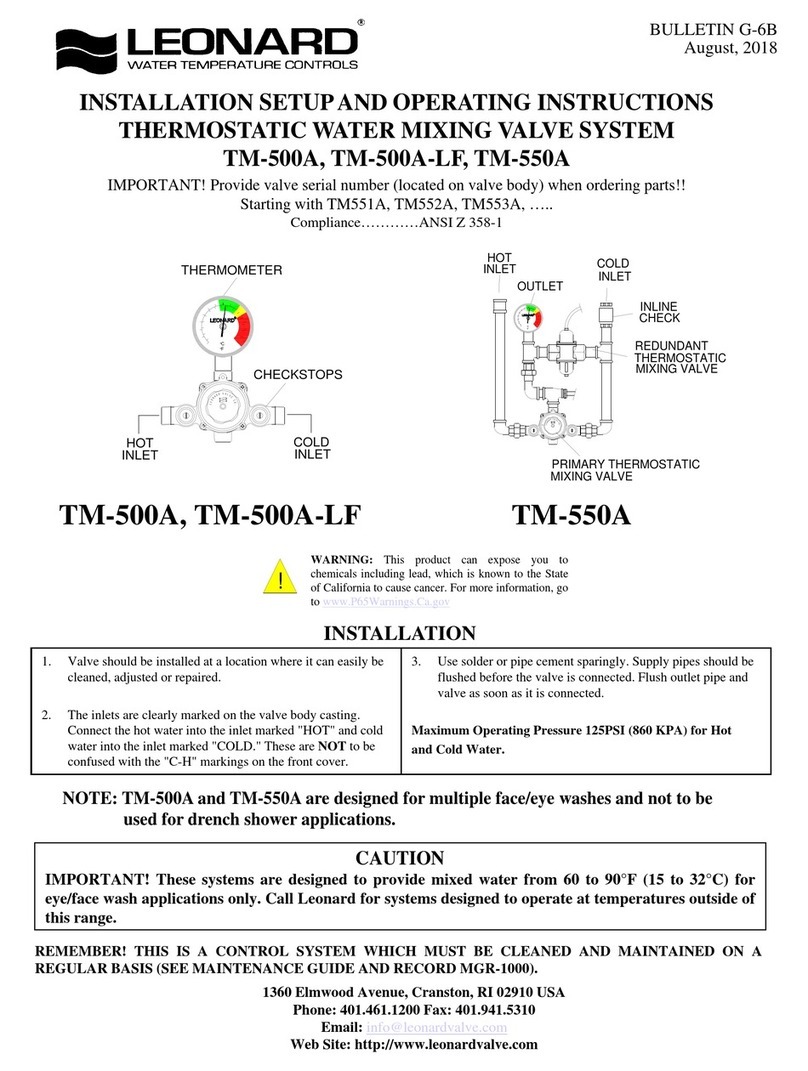

DRIVING

FLANGE PACKING

BALL SOCKET

BALL

DRIVING

BALL SOCKET

BALL

FLANGE

PACKING

POINTER

THERMOSTAT

GROUP

LTR SCREW

PORT

NUT

SLEEVE

PORT SLEEVE

CHECK

NUT

THIMBLE

CHECK

NUT

THIMBLE

(TM-50)

SHOULDER

PORT

SLEEVE

SLEEVE

NUT

PORT

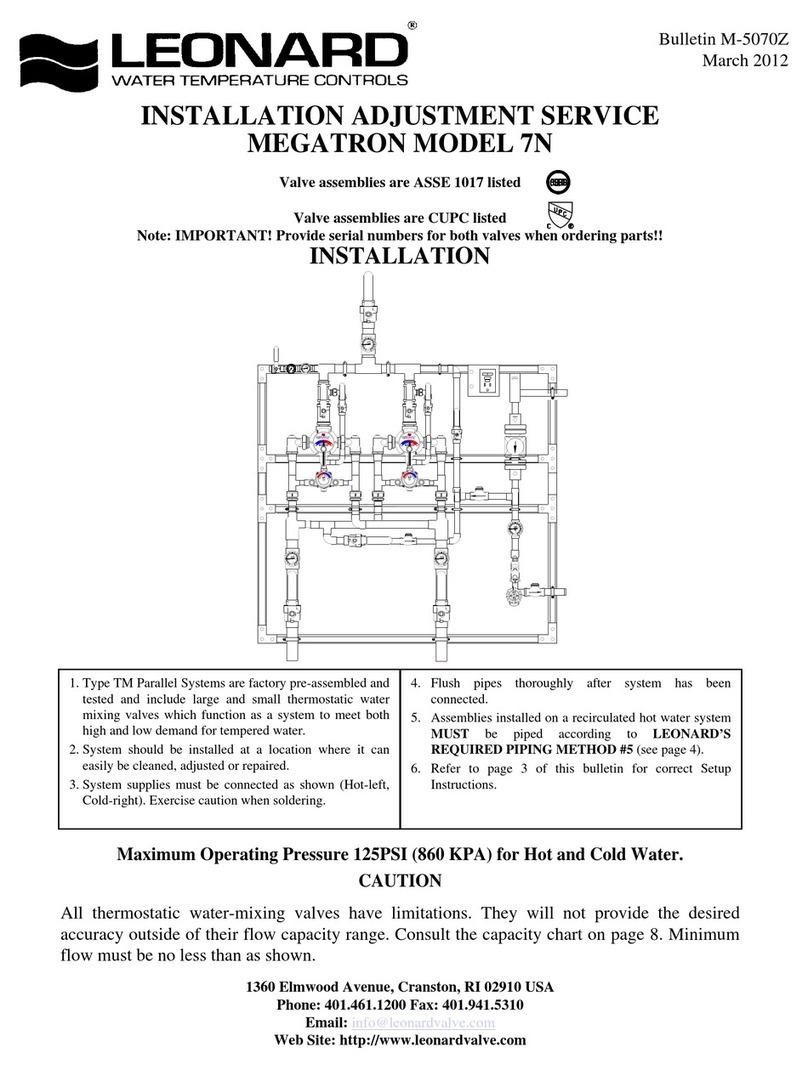

TROUBLESHOOTING INSTRUCTIONS

Note: Provide valve serial number when ordering parts for either valve!

See pages 7 & 8 for Parts Breakdown

6

PACKING & GASKETS

PORT SLEEVE/BRIDGE

ASSEMBLY

THERMOSTAT

GROUP

CHECKSTOPS

1. Leaks at stem.

2. Leak between valve cover and base.

3. Valve delivers either all hot or all cold water,

or will not mix consistently.

4. After cleaning or replacing port sleeve/bridge

assembly , valve performance is not consistent.

5. Hot water by-pass into cold line (or cold into

hot).

6. Supplies cannot be shut off completely.

Supplies leak at checkstop bonnets.

TM-300

Kit # 1/300

Packing & Gaskets

Kit # R/300

Rebuilding Kit

Kit # R/300 or

TG-2/300

NA

TM-150

Kit # 1/125

Packing & gaskets

Kit # R/125

Rebuilding Kit

Kit # R/125

TGM-2/125

Kit #2/50

TM-50

Kit # 1/50

Packing & Gaskets

Kit # R/50

Rebuilding Kit

Kit #R/50

TGM-2/50

Kit #2/50