Flintec FAD-40 Series User manual

FAD-40

A / D Converter

Technical Manual

Flintec

www.flintec.com

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 1 of 55

TABLE OF CONTENTS:

1. SAFETY INSTRUCTIONS.............................................................................................3

2. INTRODUCTION ...........................................................................................................4

2.1. Overview......................................................................................................................................................4

2.2. Key features and Specifications ..................................................................................................................5

2.3. Housing........................................................................................................................................................7

2.4. Accessories..................................................................................................................................................7

2.4.1. Accessories supplied with the instrument ..................................................................................................................7

3. INSTALLATION.............................................................................................................8

3.1. Recommendations.......................................................................................................................................8

3.1.1. Control Cabinet Design..............................................................................................................................................8

3.1.2. Cabling.......................................................................................................................................................................8

3.1.3. Mechanical Installation...............................................................................................................................................8

3.2. Electrical Connections .................................................................................................................................8

3.2.1. Power Supply and Grounding....................................................................................................................................8

3.2.2. Load Cell Connection.................................................................................................................................................9

3.2.3. Digital I/O Connection..............................................................................................................................................10

3.2.4. Serial Interface RS232.............................................................................................................................................10

3.2.5. Communication Interface.........................................................................................................................................10

3.3. Commissioning ..........................................................................................................................................11

4. SETUP.........................................................................................................................12

4.1. Installation of the xFace Software..............................................................................................................12

4.2. Connection to the xFace Software.............................................................................................................12

4.3. Setup and Calibration ................................................................................................................................13

4.3.1. Scale Parameters ....................................................................................................................................................13

4.3.2. RS-485 Serial Interface Setup .................................................................................................................................14

4.3.3. Scale Build and Calibration......................................................................................................................................15

4.4. A/D Status (Performance Test)..................................................................................................................18

4.5. Setup of Digital I/O.....................................................................................................................................18

4.6. Bus Interface Setup ...................................................................................................................................19

4.7. Bus Addressing via Setup Switch..............................................................................................................20

4.8. Back up Settings and Calibration Data......................................................................................................20

5. FAD-40 / FAD-40MB WITH RS-485 INTERFACE.......................................................21

5.1. Front View of FAD-40 (MB) .......................................................................................................................21

5.2. Electrical Connections ...............................................................................................................................22

5.3. RS-485- and Modbus-RTU-Interfacing......................................................................................................22

5.4. Setup and Calibration ................................................................................................................................22

5.5. BSI Data Structure (for FAD-40 and FAD-40MB only)..............................................................................23

5.6. Modbus RTU (for FAD-40MB only)............................................................................................................27

5.7. Modbus Data Structure (for FAD-40MB and FAD-40EN only)..................................................................27

6. FAD-40PB WITH PROFIBUS INTERFACE ................................................................30

6.1. Front View of FAD-40PB ...........................................................................................................................30

6.2. Electrical Connections ...............................................................................................................................31

6.3. Profibus and RS-232C Interfacing.............................................................................................................32

6.4. Setup and Calibration ................................................................................................................................32

6.5. Profibus Setup ...........................................................................................................................................32

6.6. Profibus and Profinet Data Structure (for FAD-40Px only)........................................................................33

7. FAD-40PN WITH PROFINET INTERFACE.................................................................37

7.1. Front View of FAD-40PN ...........................................................................................................................37

7.2. Electrical Connections ...............................................................................................................................38

7.3. Profinet Interfacing.....................................................................................................................................39

7.4. Setup and Calibration ................................................................................................................................39

7.5. Profinet / Ethernet Setup ...........................................................................................................................39

7.6. Profibus and Profinet Data Structure (for FAD-40Px only)........................................................................40

8. FAD-40EN WITH ETHERNET INTERFACE................................................................41

8.1. Front View of FAD-40EN...........................................................................................................................41

8.2. Electrical Connections ...............................................................................................................................42

8.3. Ethernet Interfacing ...................................................................................................................................43

8.4. Setup and Calibration ................................................................................................................................43

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 2 of 55

8.5. Ethernet Setup...........................................................................................................................................43

8.6. Modbus Data Structure..............................................................................................................................43

9. FAD-40CO WITH CANOPEN INTERFACE.................................................................44

9.1. Front View of FAD-40CO...........................................................................................................................44

9.2. Electrical Connections ...............................................................................................................................45

9.3. CANopen Interfacing .................................................................................................................................46

9.4. Setup and Calibration ................................................................................................................................46

9.5. CANopen Setup.........................................................................................................................................46

9.6. CANopen Data Structure (for FAD-40CO only).........................................................................................47

10. ERROR TABLE...........................................................................................................51

11. DIAGNOSTICS............................................................................................................52

12. INDEX..........................................................................................................................53

RIGHTS AND LIABILITIES

All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, mechanical, photocopying, recording, or otherwise, without the prior written permission of Flintec

GmbH

No patent liability is assumed with respect to the use of the information contained herein. While every

precaution has been taken in the preparation of this book, FLINTEC assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of the information contained

herein.

The information herein is believed to be both accurate and reliable. FLINTEC, however, would be obliged to be

informed if any errors occur. FLINTEC cannot accept any liability for direct or indirect damages resulting from

the use of this manual.

FLINTEC reserves the right to revise this manual and alter its content without notification at any time.

Neither FLINTEC nor its affiliates shall be liable to the purchaser of this product or third parties for damages,

losses, costs, or expenses incurred by purchaser or third parties as a result of: accident, misuse, or abuse of

this product or unauthorized modifications, repairs, or alterations to this product, or failure to strictly comply with

FLINTEC operating and maintenance instructions.

FLINTEC shall not be liable against any damages or problems arising from the use of any options or any

consumable products other than those designated as Original FLINTEC Products.

NOTICE: The contents of this manual are subject to change without notice.

Copyright © 2010-2011 by Flintec GmbH, 74909 Meckesheim, Bemannsbruch 9, Germany

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 3 of 55

1. SAFETY INSTRUCTIONS

CAUTION READ this manual BEFORE operating or servicing this equipment. FOLLOW

these instructions carefully. SAVE this manual for future reference. DO NOT allow untrained

personnel to operate, clean, inspect, maintain, service, or tamper with this equipment.

ALWAYS DISCONNECT this equipment from the power source before cleaning or performing

maintenance. CALL FLINTEC ENGINEERING for parts, information, and service.

WARNING ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THIS EQUIPMENT.

EXERCISE CARE WHEN MAKING CHECKS, TESTS AND ADJUSTMENTS THAT MUST BE

MADE WITH POWER ON. FAILING TO OBSERVE THESE PRECAUTIONS CAN RESULT

IN BODILY HARM.

WARNING FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT TO

PROPERLY GROUNDED OUTLET ONLY. DO NOT REMOVE THE GROUND PRONG.

WARNING DISCONNECT ALL POWER TO THIS UNIT BEFORE REMOVING THE FUSE

OR SERVICING.

WARNING BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC

COMPONENTS OR INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT

ALWAYS REMOVE POWER AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY

CONNECTIONS OR DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE

PRECAUTIONS COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE

EQUIPMENT OR BODILY HARM.

CAUTION OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE

DEVICES.

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 4 of 55

2. INTRODUCTION

2.1. Overview

The type FAD-40 A/D Converter Series consists of powerful and economic state-of-the-art instruments for static

and dynamic weighing applications plus force and torque measurements including digital I/O control.

Each instrument of the series converts the analogue low level signal from a load cell or a strain gauge sensor to

a digital high-resolution and high-accuracy signal and transmits the digital data to an external PLC or PC

system. As a special feature the instruments can switch between unipolar and bipolar input range without

affecting the external resolution. Digital I/O ports give further possibilities to extend the bus system with I/O

control in the cabinet and fast response setpoint output from the weighing instrument.

The type FAD-40 A/D Converter Series comprises various instruments for different industrial bus systems:

FAD-40 A/D Converter

only with RS485 interface

FAD-40PB A/D Converter with

Profibus DP interface

FAD-40EN A/D Converter with

Ethernet TCP/IP interface

FAD-40MB A/D Converter with

Modbus RTU interface

FAD-40PN A/D Converter with

Profinet interface

FAD-40CO A/D Converter with

CANopen interface

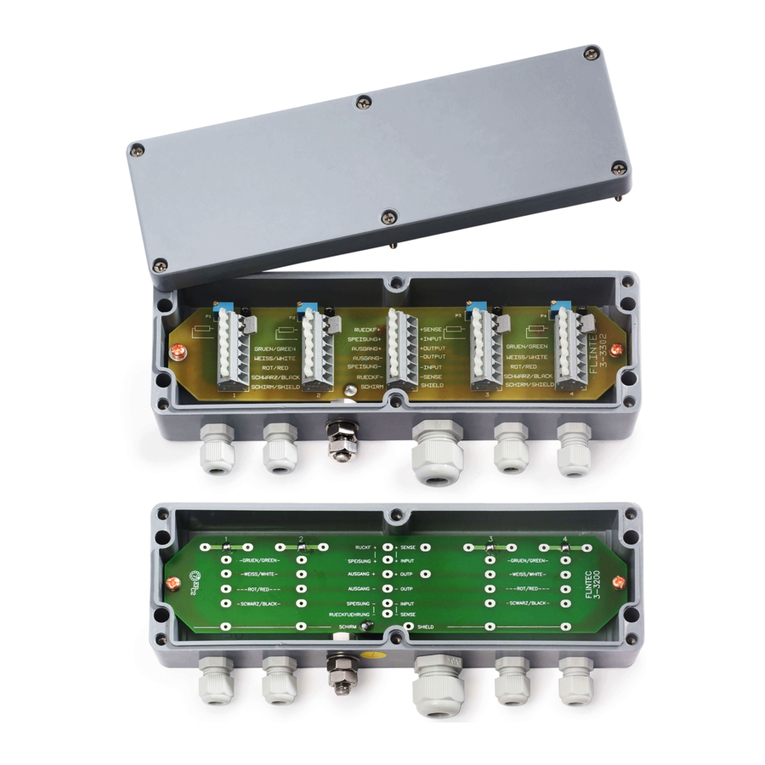

Figure 3.1 –FAD-40 A/D Converter series instruments

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 5 of 55

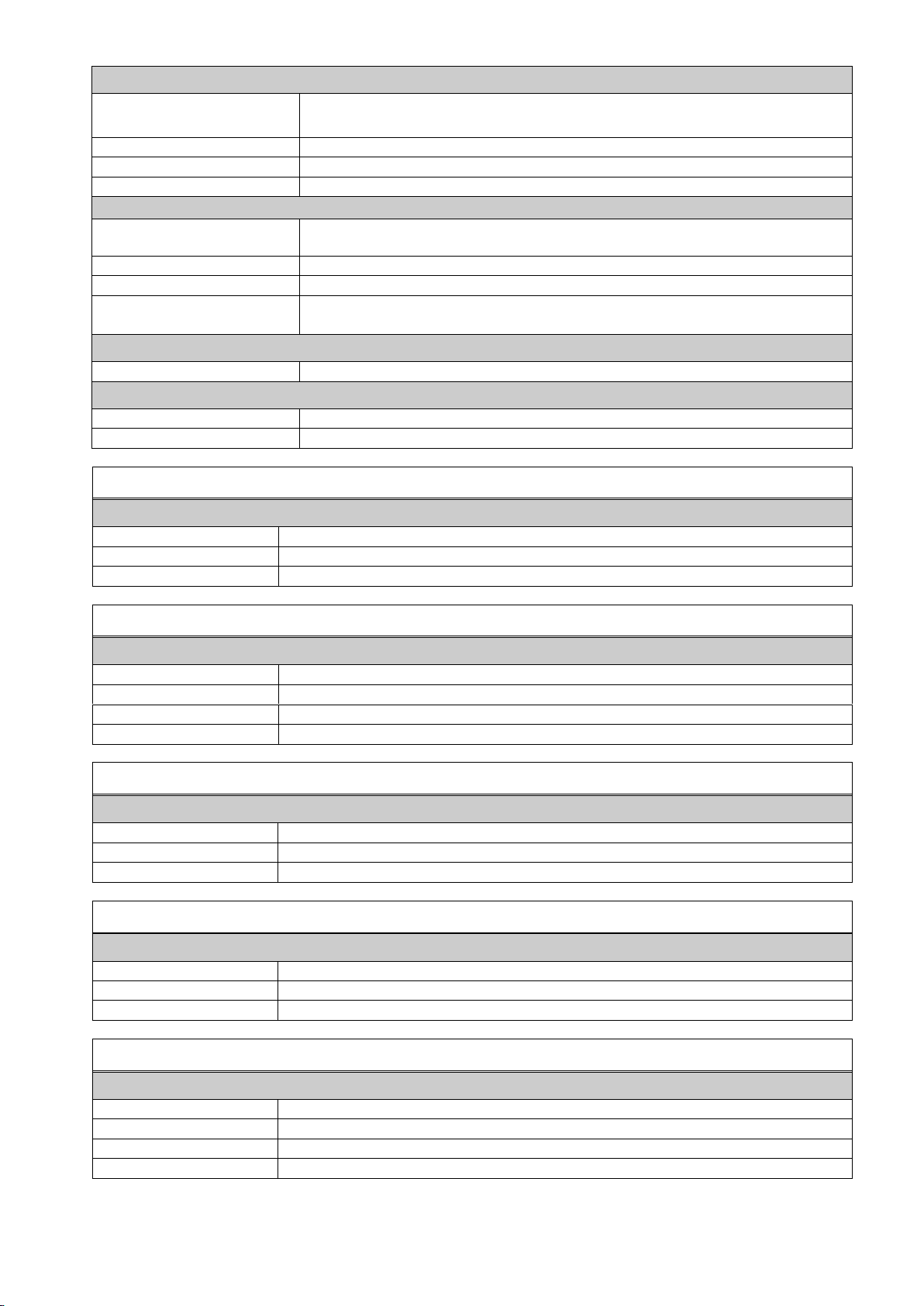

2.2. Key features and Specifications

Key Features

FAD-40

FAD-40MB

FAD-40PB

FAD-40PN

FAD-40EN

FAD-40CO

Bipolar signal input in Force and Count modes

Yes

Yes

Yes

Yes

Yes

Yes

500 to 100 000 counts external resolution at calibrated data

Yes

Yes

Yes

Yes

Yes

Yes

Unipolar 1 million and bipolar 2 million counts is adjusted and filtered

to external resolution in count mode

Yes

Yes

Yes

Yes

Yes

Yes

High internal resolution up to 8 million counts

Yes

Yes

Yes

Yes

Yes

Yes

Up to 800 conversions per second

Yes

Yes

Yes

Yes

Yes

Yes

2 digital inputs/outputs + 1 additional digital outp. (configurable)

Yes

Yes

Yes

Yes

Yes

Yes

Standard Serial interface RS-232C

No

No

Yes

Yes

Yes

Yes

Serial interface RS-485A

Yes

Yes

No

No

No

No

Modbus RTU interface

No

Yes

No

No

No

No

Profibus DP-V1 interface

No

No

Yes

No

No

No

Profinet interface

No

No

No

Yes

No

No

Ethernet (Modbus TCP/IP) interface

No

No

No

No

Yes

No

CANopen interface

No

No

No

No

No

Yes

BSI data interface

Yes

Yes

No

No

No

No

Bus address selection by setup switch (from 0 to 7)

Yes

Yes

Yes

No

No

Yes

Setup by Flintec xFace PC software

Yes

Yes

Yes

Yes

Yes

Yes

Auto-zero tracking and auto-zero at power-up

Yes

Yes

Yes

Yes

Yes

Yes

Motion detection

Yes

Yes

Yes

Yes

Yes

Yes

Zeroing and Taring by bus commands

Yes

Yes

Yes

Yes

Yes

Yes

Adaptive digital filter for fast and stable reading

Yes

Yes

Yes

Yes

Yes

Yes

Up to 6 load cells (350 Ω) or 18 load cells (1100 Ω)

Yes

Yes

Yes

Yes

Yes

Yes

Electronic calibration (eCal) without test weights

Yes

Yes

Yes

Yes

Yes

Yes

Zero and Span calibrations over bus interface

Yes

Yes

Yes

Yes

Yes

Yes

Zero adjustment

Yes

Yes

Yes

Yes

Yes

Yes

Span adjustment with test weights

Yes

Yes

Yes

Yes

Yes

Yes

Span adjustment with temporary zeroing for unloaded tanks

Yes

Yes

Yes

Yes

Yes

Yes

Power-on testing with setup switch

Yes

Yes

Yes

Yes

Yes

Yes

24 V DC power supply (11 to 28 V DC input voltage range)

Yes

Yes

Yes

Yes

Yes

Yes

Specifications

A/D Converter:

A/D converter type:

24 bit Delta-Sigma radiometric with integral analog and digital filters

Analog input range:

0 mV to +18 mV ( unipolar ) ; - 18 mV to +18 mV ( bipolar )

Linearity:

< 0.0015 % FS

Temperature coefficient:

< 2 ppm/°C

Min. input per vsi

0.1 μV/d (non approved)

Conversion rate:

Up to 800 measurement values per second

Internal resolution:

Up to 8 million counts

External resolution

Up to 100 000 counts (weight value, force, torque) respective

1 million raw counts (unipolar) respective 2 million counts (bipolar)

Calibration and Weighing Functions:

Calibration:

Electronic calibration without test weights (eCal) or calibration by test weights

Digital filter:

10 step programmable adaptive filter

Weighing functions:

Tare, zero, auto zero tracking, motion detection, auto-zero at power-up, save

tare at power-off, increased resolution

Load cells:

Excitation:

5 V DC at 58...1200 Ω, max. 100 mA

Number of load cells:

Up to 6 load cells à 350 Ω or 18 load cells à 1100 Ω in parallel

Connection:

4- or 6-wire technique, cable length 250 m/mm² for 6-wire connection

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 6 of 55

Communication and Setup:

Serial interface

RS232C with 9600 baud (8,N,1);

for FAD-40 and FAD-40MB: RS485 with up to 57600 baud (8N1, 7E1, 7O1)

Other interfaces

Depends on instrument type

Response time

< 4 ms (delay after each read or write command)

Setup and calibration

By PC software via RS232C respective RS485, backup data stored on PC

Digital Inputs + Outputs

2x configurable I/O

Selectively configured as input (10...26 V DC) or

open collector output (24 V DC, max. 100 mA)

1x additional output

Open collector output (24 V DC, max. 100 mA)

Input functions

Zero, tare, clear tare or control input to communication interface

Output functions

Setpoint output with / without hysteresis, tolerance band output or control

output from communication interface

Power supply:

DC power supply

10 to 28 VDC, < 200 mA, not galvanically isolated

Environment and Enclosure:

Operation temperature:

Between -10 °C and +40 °C at maximum 85% RH max, non-condensing

Enclosure and protection

Polyamide, for DIN-rail mounting, IP20

Instrument with RS485 interface: Type FAD-40

Communication:

Serial interface RS485

1200 to 57600 baud (8N1, 7E1, 7O1), bus capability up to 31 units

Communication mode

Requested

Dimensions & weight

99 x 22.5 x 114.5 mm (L x W x H), weighs appr. 110 g

Instrument with Modbus RTU interface: Type FAD-40MB

Communication:

Serial interface RS485

1200 to 57600 baud (8N1, 7E1, 7O1), bus capability up to 31 units

Communication mode

Requested or Modbus RTU

Address range

1...31

Dimensions & weight

99 x 22.5 x 114.5 mm (L x W x H), weighs appr. 110 g

Instrument with Profibus DP interface: Type FAD-40PB

Communication:

Profibus DP-V0 + DP-V1

9,6 kbit/s to 12 Mbit/s (automatic), galvanically isolated interface

Address range

1...126

Dimensions & weight

99 x 45 x 114.5 mm (L x W x H), weighs appr. 150 g

Instrument with Profinet interface: Type FAD-40PN

Communication:

Profinet

100 Mbit/s (full duplex), galvanically isolated interface

IP settings

DHCP or manual setup by PC software

Dimensions & weight

99 x 45 x 114.5 mm (L x W x H), weighs appr. 150 g

Instrument with Ethernet TCP/IP interface: Type FAD-40EN

Communication:

Ethernet TCP/IP

10 Mbit/s (full duplex), galvanically isolated interface

IP settings

Manual setup by PC software

Dimensions & weight

99 x 45 x 114.5 mm (L x W x H), weighs appr. 150 g

Other

Web client interface

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 7 of 55

Instrument with CANopen interface: Type FAD-40CO

Communication:

CANopen V.2.0

10 kbit/s...1 Mbit/s (automatic), galvanically isolated interface

Address range

1...126

Dimensions & weight

99 x 45 x 114.5 mm (L x W x H), weighs appr. 150 g

2.3. Housing

FAD-40 instruments come within a polyamide housing sealed to IP20. They are prepared for mounting on NS

37/7 or NS 35/15 standard DIN rails (see drawings).

22,5 mm

45 mm

99 mm

114,5 mm

View A

View B

Side view

View A: FAD-40, FAD-40MB

View B: FAD-40PB, FAD-40PN, FAD-40EN, FAD-40CO

Figure 3.2 –Dimensions

2.4. Accessories

2.4.1. Accessories supplied with the instrument

The following accessories are supplied together with the instrument. If any part

is missing, please contact your supplier.

FAD-40

FAD-40MB

FAD-40EN

FAD-40PB

FAD-40PN

FAD-40CO

4-pin and 5 mm pitch plug, light gray

1

1

2

2

2

2

7-pin and 3.81 mm pitch plug for load cell cable, black

1

1

1

1

1

1

6-pin and 3.81 mm pitch plug for Digital I/O and RS-485, black

1

1

3-pin and 3.81 mm pitch plug for Digital I/O, green

1

1

1

1

Installation CD (xFace software, technical documentation)

1

1

1

1

1

1

Table 3.1 –Accessories supplied with instrument

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 8 of 55

3. INSTALLATION

PRECAUTION: Please read this manual carefully before you install the instrument. If you apply all

recommendations in this chapter you will increase the reliability and long term performance of your system.

3.1. Recommendations

3.1.1. Control Cabinet Design

Warning: Please follow the following warnings for designing the control cabinet which will increase the

reliability of your system.

The control cabinet should be designed therefor the A/D converters can operate safely. The panel should be

placed in a clean area, without getting direct sun light if possible, with a temperature between -10 ºC and +40

ºC, humidity not exceeding 85% non-condensing. All external cables should be installed safely to avoid

mechanical damages.

FAD-40 instruments are very low level signal measuring instruments. To avoid electrical noise, the instruments

should be separated from equipment that produces electrical noise. Preferably use a metal cabinet against

radio frequency interference, to protect against electromagnetic disturbance the cabinet shall be connected to

ground. Keep the load cell cable trays separated from others, if possible. If there is noise-generating equipment

such as heavy load switches, motor control equipment, inductive loads etc., please be careful against the EMC

interference in the cabinet. If possible protect FAD-40 instruments by a Faraday cage or install them in a

separate section or install them far away from this kind of equipment. Install parallel reverse diodes to the DC

inductive loads like relays, solenoids etc. to minimize voltage peaks on the DC power lines.

3.1.2. Cabling

All cables coming to the control cabinet shall be shielded. Please use separate cable trays for these low signal

level cables. Distance from load cell cables, interface cables and DC power supply cables to power line cables

shall be 50 cm at minimum.

3.1.3. Mechanical Installation

After designing the control panel and installing DIN rails according to the recommendation in this chapter, place

the FAD-40 instruments on the DIN rail Be sure that the mechanical installation of the instruments is done

properly.

3.2. Electrical Connections

Warning: Please always remember that FAD-40 instruments are very low voltage measuring instruments. Your

control cabinet design and proper installation increases the reliability and the performance of the instrument.

Please do not forget that the instrument must be powered off before inserting or removing any peripheral

connector. All required electrical connections should be done as described below.

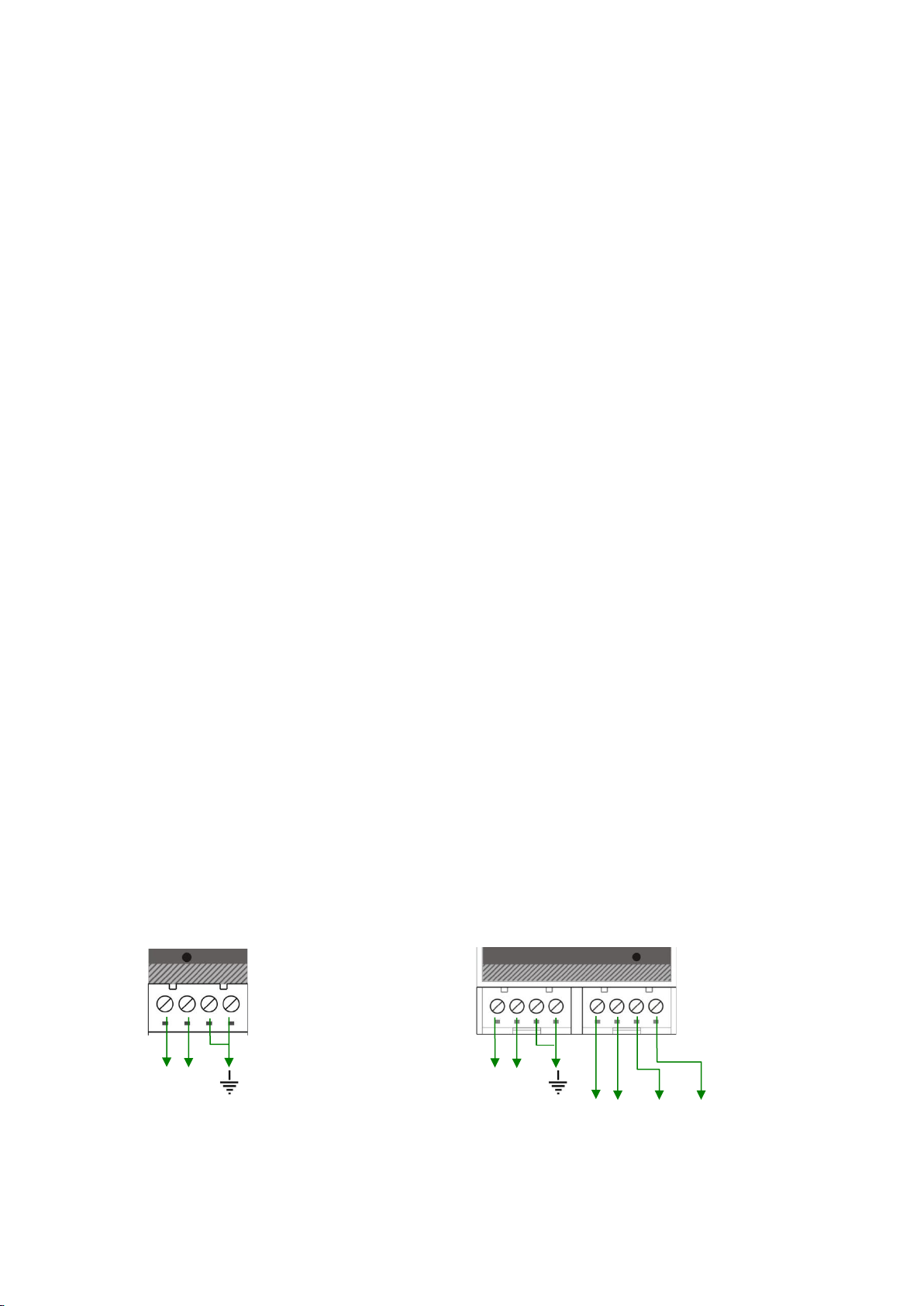

3.2.1. Power Supply and Grounding

The power supply voltage of the instrument shall be between 12 V DC and 28 V DC. The current consumption

of the power supply will be calculated by multiplying 0.2 A and the quantity of instruments. The pin configuration

of the 24 V DC power supply connector located at the bottom front of the instrument is shown below in

figure 4.1.

FAD-40 and

FAD-40MB

(front view)

FAD-40EN,

FAD-40PB,

FAD-40PN and

FAD-40CO

(front view)

24V 0V

24V 0V

TX RX GND Shield

Warning: Do not forget to connect the Shield pin to the reference ground.

Figure 4.1 –The pin layout of 24 V DC connectors

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 9 of 55

The quality of the instrument’s ground will determine the accuracy and the safety of your measuring system. A

proper ground connection is needed to minimize extraneous electrical noise effects on the measurement. A

poor ground can result in an unsafe and unstable operation. It is important that the instrument should not share

power lines with noise-generating equipment such as heavy load switching, motor control equipment, inductive

loads, etc. If the condition of the power line in the plant is poor, prepare a special power line and grounding.

Before interfering the instrument, turn off the power and wait at least for 30 seconds.

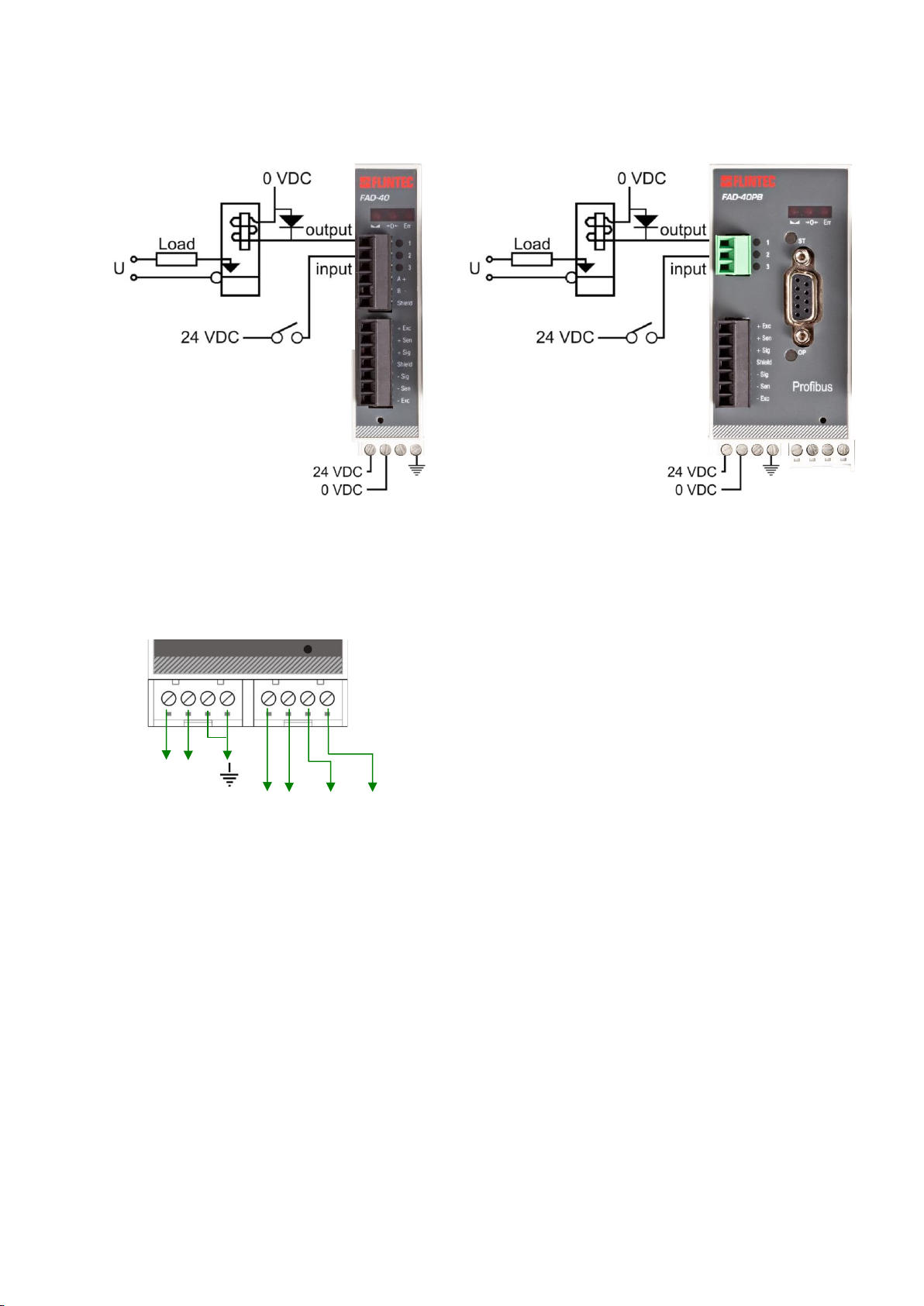

3.2.2. Load Cell Connection

To avoid damages, the load cell wiring should be made carefully before energizing the instrument. Load cell

connection details are shown below in figure 4.2. In 4-wire installations the sense and excitation pins with the

same polarity should be short circuited at the connector side. If you have a junction box in your system, use a 6

wire cable between FAD-40 and the junction box, and short circuit these pins at junction box for better

performance.

Load Cell

Connector

4 wire LC connection

6 wire LC connection

WARNING: Connect the load cell cable shield to the reference ground or the

shield pin of the load cell connector.

Figure 4.2 –Load cell connection

When you use a junction box and one or more load cells with 4 wires you have to short-circuit the excitation

(Exc) and sense wires (Sen) the same polarity as show on the figure 4.21.

Junction box 6 Wire-cable FT-10 Indicator

Bridges

4W-Load cell

Shield

Shield

+ Exc

+ Sig

- Sig

- Exc

Shield

Figure 4.21 –4 wires load cell connection via connection box

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 10 of 55

3.2.3. Digital I/O Connection

FAD-40 instruments have the digital I/O connectors on the instrument’s front. I/O1 is always an output, I/O2 and

I/O3 can be configured for input or output. The I/O connection diagram is shown in Figure 4.3

Figure 4.3 –Digital I/O connection

3.2.4. Serial Interface RS232

You can use the serial interface RS232 with the xFace software for configuration and adjustment.

FAD-40EN,

FAD-40PB,

FAD-40PN and

FAD-40CO

(Front view)

24V 0V

TX RX GND Shield

Figure 4.4 –The pin layout of RS232 connector

3.2.5. Communication Interface

Please refer to the corresponding chapter:

FAD-40 (RS485)

see chapter 6.2

FAD-40MB (Modbus RTU)

see chapter 6.2

FAD-40PB (Profibus)

see chapter 7.2

FAD-40PN (Profinet)

see chapter 8.2

FAD-40EN (Ethernet and Modbus TCP)

see chapter 9.2

FAD-40CO (CANopen)

see chapter 10.2

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 11 of 55

3.3. Commissioning

PRECAUTION: Please read this manual carefully before energizing the instrument. Perform the commissioning

operation according the procedure given in this chapter. Only trained persons are allowed for cleaning,

commissioning, checking and servicing of the instrument. The interference of untrained person may cause

some unwanted damages or injuries.

Before energizing the instrument, please make the required mechanical and electrical installations. After power

on, you have to setup your FAD-40 instrument before you can start to use the bus interface.

Install the xFace software onto your PC as described in chapter 5 Setup. The xFace software is used for setup,

calibration and testing of FAD-40 instruments.

After you have successfully checked the performance of the instrument with xFace, you can begin to use the

instrument in your application.

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 12 of 55

4. SETUP

PRECAUTION: Please read this manual carefully before energizing the instrument. Perform the commissioning

according the procedure given in chapter 4.3. Only trained person are allowed for commissioning, checking,

cleaning and servicing of the instrument. The interference of untrained person may cause some unwanted

damages or injures.

FAD-40 series instruments are setup and calibrated by the xFace software supplied with the instrument.

The instruments shall be setup in the sequence described below before you can use the bus interface.

•Install the xFace software onto your PC

•Connect your PC with the instrument over the serial interface (RS232 respective RS485)

•Setup and calibrate the instrument

•Check the performance of the instrument

4.1. Installation of the xFace Software

Please follow following steps to install the xFace software:

•Close all applications on your PC

•Insert the CD that contains the xFace software into the CD-ROM drive

•Double click “Setup.exe” to start the installation. The setup Wizard is displayed.

•Follow the menus in the setup wizard step by step.

•After finishing the installation, the Setup Wizard will inform you about the success of the software

installation. Click the OK button.

•After closing the Setup Wizard you can start to use the xFace software.

Typ FAD-30

Typ FAD-40: Select one of the FAD-40

models and press OK button.

Typ MCS-08

Figure 5.1 –xFace type selector window

4.2. Connection to the xFace Software

The connection between FAD-40 and the xFace software is done via the RS485 serial port or the RS-232C

service port for all models. Alternatively Ethernet (for FAD-40EN only) can be used for this connection. You can

purchase a suitable PC connection cable as an accessory from Flintec (Refer to chapter 3.4.2).

After running the xFace software select the FAD-40 model you use (see figure 5.1.). Select the PC’s

communication port within the Connection settings menu in the tools tab (see figure 5.2) and click the connect

icon. After the communication between FAD-40 and your PC has successfully started the traffic light of the

connect icon turns from red to green.

Protocol: Select the setup port of the instrument. FAD-40 and FAD-40MB

instruments can be setup over RS-485. Other models can be setup over RS-

232C.

Com Port: Select the communication port of the PC

Address: Select the RS-485 address, if RS-485 is selected

Baud rate: Select the RS-485 baud rate, if RS-485 is selected

Setting: Select the RS-485 communication port setting, if RS-485 is selected

Figure 5.2 –xFace Connection Settings

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 13 of 55

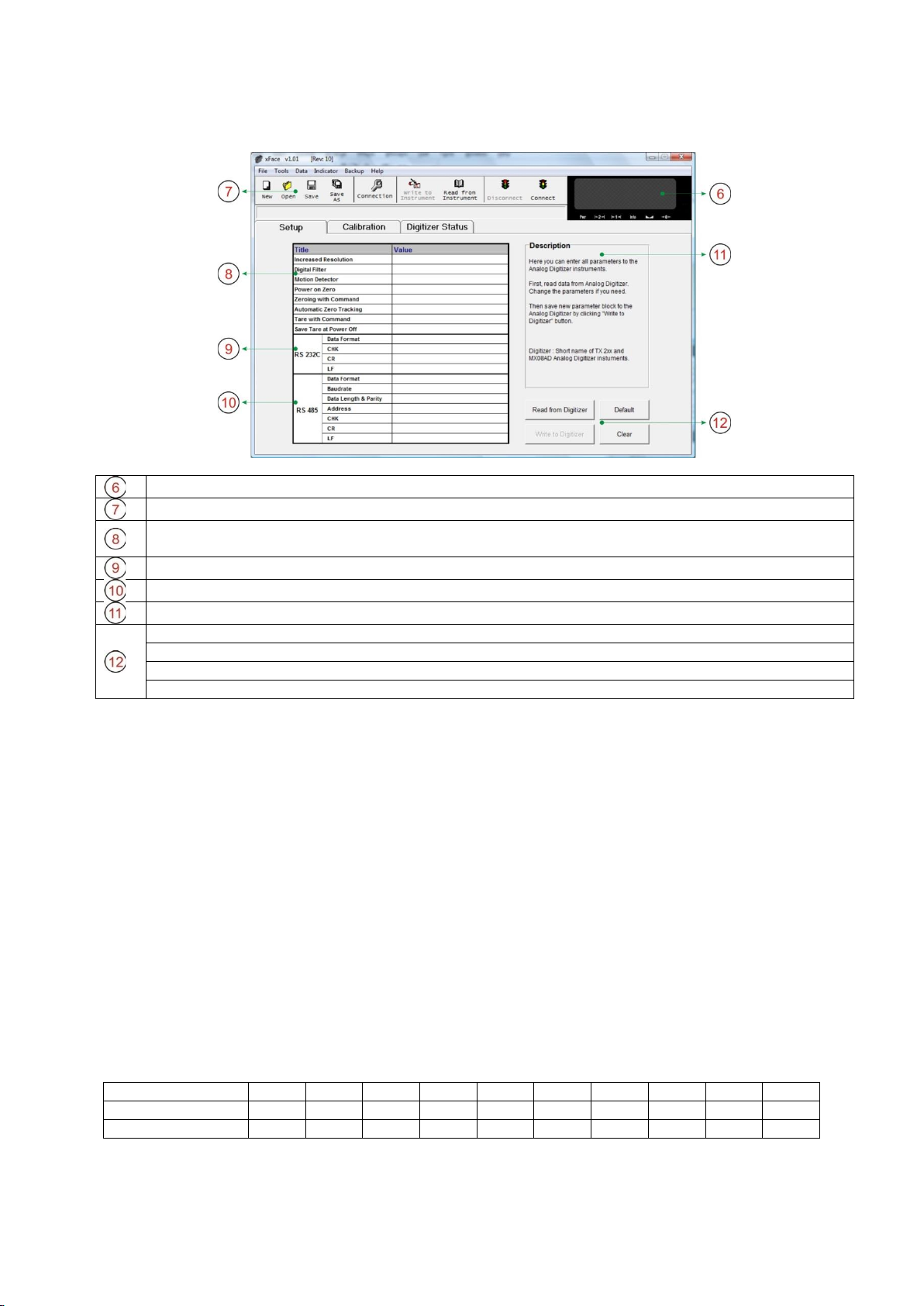

4.3. Setup and Calibration

WARNING: Read this manual carefully before you setup and calibrate the instrument. This will increase the

performance of your weighing system by applying proper setup and calibration.

Visual Weight Display: Displays the weight, count or force value

Toolbox: Contains shortcuts of some special commands

A/D Converter Parameters: This block allows the user to setup the A/D Converter’s parameter

related to the operation mode. Refer to chapter 5.3.1

RS-232C: RS-232C serial port communication settings (not for FAD-40 and FAD-40MB)

RS-485: RS-485 port communication settings. (FAD-40 and FAD-40MB only)

Description: This block provides some clear-text explanations

Read from A/D Converter: Click this button to read the parameter settings from the instrument

Write to A/D Converter: Click this button to save the parameter settings to the instrument

Default: Click this button to load the factory default settings

Clear: Empties the parameter settings

Figure 5.3 –FAD-40 Setup Parameters

For entering the parameter values enter the setup tab, adjust the parameter settings and then write this data to

the A/D Converter. After changing parameter settings the instrument always requires a re-calibration.

4.3.1. Scale Parameters

In the setup menu the scale parameters of FAD-40 can be viewed, changed or saved to the instrument. These

parameter settings are:

Increased External Resolution

For service purposes this parameter enables the 10 times higher resolution of the weight value than the defined

interval in weighing and force mode. Increased resolution must be disabled for use in normal operation (Not

available in Count Mode). Default setting: ‘Disable’.

Digital Filter

Environmental noise like bounding forces, air flow, vibration, motor control instruments etc. may disturb the load

cell signal. The selection of proper filter settings determines how quickly the system will react to the load cell

signal.**Load cell signal digital filtering is done according to this parameter settings. The settings can be

changed from 0 (fastest settling) to 9 (slowest settling). Default setting: ‘7’.

Setting

0

1

2

3

4

5

6

7

8

9

Values/s

1600

800

400

200

100

100

100

50

50

50

Settling time [ms]

80

140

250

180

300

420

380

620

720

1800

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 14 of 55

Motion Detection

This parameter defines the motion detection window which determines a stable weighing. If motion detection is

not required, this parameter can be disabled. The available motion detection window values are:

Weighing and Force Mode:

Disable

± 0.3e

± 0.5e (default setting)

± 1e

± 2e

Count Mode:

Disable

± 60

± 100 (default setting)

± 200

± 400

Power On Zero

This parameter enables automatic zeroing after powering on the instrument. The automatic zeroing is only

done if the total zero drift from the calibrated zero signal is in the defined zeroing window. This zeroing window

will be defined in the percentage of the scale capacity.

Disable (default setting)

± 2%

± 10%

To avoid unwanted zeroing at power on this parameter should be disabled or carefully set up in applications

like silo weighing, tank weighing and automatic weighing applications. If the weight is not within the power on

zeroing range, the instrument is powered on without zeroing (Not available in Count Mode).

Zeroing by Key (Zeroing Range)

Zeroing of the scale is performed if the difference between load cell signal value and unloaded load cell signal

value at the calibration is in the selected percentage of the scale capacity. Zeroing can be done by zeroing

command when the scale is stable. Zeroing can be done by zeroing command when the scale is stable.

The available zeroing ranges in the percentage of the scale capacity are:

Disable

± 2% (default setting)

± 20%

± 40%

Auto Zero Tracking

AZT automatically re-adjusts the scale to zero for compensating defined small deviations around the center of

zero. AZT only works within the defined zeroing range and stops working if this range is left.To avoid unwanted

zeroing this parameter should be disabled or carefully set up in applications like silo weighing, tank weighing

and automatic weighing applications (Not available in Count Mode). The available AZT window values are;

Disable (default setting)

± 0,5e

± 1e

± 3e

Tare

If this function is enabled, the weight is tared when the tare command is received. Additional conditions for

taring are positive gross weight and no motion. Multi-taring is possible with FAD-40 series (Not available in

Count Mode). Default setting: ‘Enable’.

Save Tare at Power Off

If this function is enabled, the tare value is stored at power off and the instrument starts up in Net mode at

power on (Not available in Count Mode). Default setting: ‘Enable’.

4.3.2. RS-485 Serial Interface Setup

Data Format

This parameter defines the serial communication port data format for RS-485. The available data formats are:

Disable:

Port will be disabled. Select “Disable” if this port is not used.

BSI

(default setting for FAD40)):

Communicates in BSI data format as a slave.

Refer to chapter 5.9 for details.

Modbus RTU

(default setting for FAD-40MB)):

Modbus RTU communication (for FAD-40MB only).

Refer to chapter 5.11 for details

NOTE: xFace automatically connects to the instrument whatever the data format is. After xFace is

disconnected, the instrument returns to operate with the last saved data format.

WARNING: Disable this interface if it is not used to increase the interfacing performance.

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 15 of 55

Checksum

The checksum can be enabled or disabled within BSI data format. The checksum calculation can be found in

the related data format description. Default setting: ‘Enable’.

Carriage Return (CR)

Carriage Return can be enabled or disabled within Continuous output data format. Default setting: ‘Enable’.

Line Feed (LF)

Line Feed can be enabled or disabled within Continuous output data format. Default setting: ‘Enable’.

The RS-485 setup is done by the xFace software as described in this chapter. Select the Setup tab after xFace

has established a connection with your instrument. The Setup tab (see figure 5.3) includes all RS-485 settings.

Baud Rate

One of the following baudrate will be selected for the RS-485 communication port.

1200

2400

4800

9600 (default setting)

19200

38400

57600

Data Length and Parity

The data length and parity can be selected as 8 None 1 (default), 7 Odd 1 or 7 Even 1.

Address of A/D Converter

The address range is 01 (default) to 31. If you enter 0, the instrument will operate without address data.

Modbus RTU Setup (for FAD-40MB only)

RS-485 Data Format: ‘Modbus RTU’,

RS-485 Data Length & Parity: ‘8 none 1’,

RS-485 Address: ‘01’ to ‘31’

4.3.3. Scale Build and Calibration

Scale build, operation mode selection and scale calibration is performed in the calibration tab of xFace as

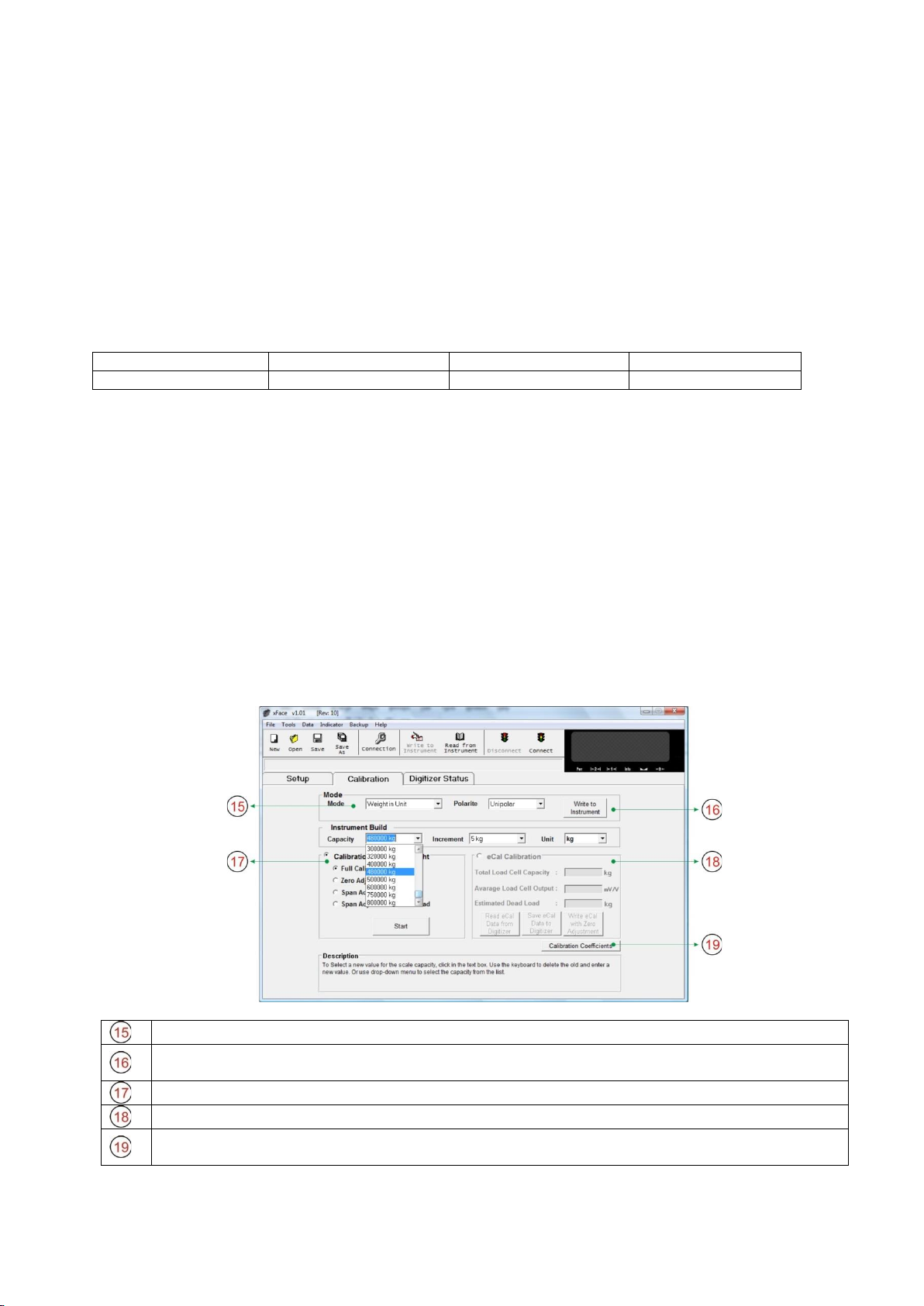

shown in figure 5.4. Please follow the procedure in the sequence as described in the following chapters.

Mode: Here the user selects the operation mode and the polarity.

Write to A/D Converter: Click this button to save the operation mode and polarity to A/D

Converter.

Calibration block: This block allows the user to calibrate with test weights.

eCal Calibration: This block allows the user to calibrate without test weights.

Calibration Coefficients: This function allows the user to restore a calibration if the calibration

coefficients have been noted before.

Figure 5.4 –Calibration

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 16 of 55

Mode Selection

FAD-40 instruments have three operation modes which are:

Count Mode:

Filtered and normalized ADC count data will be transmitted in this mode. The

calibration is performed at the PLC, if any.

Weighing Mode:

Unipolar weight data in calibrated weighing unit will be transmitted. This mode is

compatible to OIML R76 and EN 45501.

Force Mode:

Bipolar or unipolar force measurement data in calibrated force unit will be transmitted.

Select the scale operation mode and the polarity. Then click the “Write to A/D Converter” button to save your

mode selection. The default calibration of FAD-40 instruments is Count Mode and 10 mV unipolar input signal

range. If you select the Count Mode, there is no scale build and instrument calibration. Each FAD-40 instrument

is adjusted for high accuracy during the production. The FAD-40 input signal ranges and their external

resolutions are shown in Table 5.1.

Input signal range

Input Signal level

Polarity

External resolution

0 to 5 mV

5 mV

Unipolar

1 million counts

-5 to 5 mV

Bipolar

2 million counts

0 to 10 mV

10 mV

Unipolar

1 million counts

-10 to 10 mV

Bipolar

2 million counts

0 to 15 mV

15 mV

Unipolar

1 million counts

-15 to 15 mV

Bipolar

2 million counts

0 to 18 mV

18 mV

Unipolar

1 million counts

-18 to 18 mV

Bipolar

2 million counts

Table 5.1 - Count Mode, Input Signal Ranges and External Resolution

Select the input signal level and polarity for high external resolution. Write your mode selection to the

instrument by clicking “Write to A/D Converter” button. Jump to the chapter 5.4.

Scale Build

The scale capacity, the increment and the unit have to be introduced to the FAD-40 instrument before you can

perform a calibration in Weighing or Force mode.

Capacity:

To select a new value for the scale capacity, click in the text box.

Use the keyboard to enter a new value, or use the drop-down menu.

Increment:

Use the drop-down menu to select the increment.

Unit:

Select the unit

The scale calibration can be performed by using test weights or by electronic calibration (eCal).

Calibration by Test Weights

This calibration method performs zero and span calibrations using test weights. For accurate calibration the test

weight value should not be less than 1/10 of the scale capacity.

Figure 5.5 –Calibration by test weights

Please note that the scale build values should be entered before you start the calibration.

Select “Full Calibration” for performing a complete scale calibration. Click the “Start” button. Unload the scale

for performing the zero calibration and click the “Yes” button. The virtual display will show the [WAIT] message

during the zero calibration. During the zero calibration the scale must be stable. Approximately 5 seconds later

the span calibration window will be displayed. Load the scale and enter the loaded test weight value, then click

the “OK” button. The scale must be stable during the span calibration. Approximately 5 seconds later the new

calibration settings are saved automatically.

If any error occurs during the calibration an error message warns you. Click the “Yes” button to reload the

previous values or click the “No” button to use the new settings.

You can adjust the zero or the span of your scale without performing a full calibration. Additionally the “span

calibration to the unloaded scale” feature is another tool of FAD-40 instruments for after-sale services.

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 17 of 55

Zero Adjustment

If your scale has a residual zero drift you may perform a zero adjustment only. Select “Zero Adjustment” and

press the “Start” button. Then the zero calibration window will be displayed. Unload the scale and click the “OK”

button. The [WAIT] message appears on the virtual display during the zero adjustment. Approximately 5

seconds later the zero adjustment will be finalized.

Note:Zero adjustment is also performed over the bus interface. Refer to the data structure of the related bus

interface.

Span Adjustment

If your scale has a span drift, you may perform a span adjustment only. After selecting “Span Adjustment” and

pressing the “Start” button, enter the test weight value; place the test weights on the scale and press the “Yes”

button. The [WAIT] message appears on the virtual display approximately for 5 seconds while the span

calibration is being performed. After finalizing the span adjustment, the instrument will save the span

coefficients automatically.

Note:Span adjustment is also performed over the bus interface. Refer to data structure of the related bus

interface.

Span Adjustment under Load

This feature is being used to perform a span adjustment without unloading the scale. This operation is

especially used for the span adjustment for non-empty tanks to make a span adjustment without emptying the

tank. After selecting “Span Adjustment under Load” press the “Start” button. The temporary zeroing message

appears on the monitor. This means the instrument will determine the existing load as the temporary zero. If the

scale is stable press the “Yes” button. The [WAIT] message appears on the virtual display approximately for 5

seconds to determine the temporary zero. Then the span calibration window will be displayed. Load the scale

and enter the loaded test weight value, then click the “OK” button. The scale must be stable in this period.

Approximately 5 seconds later, the new calibration settings are saved automatically.

Please refer to the chapter 5.4 A/D Converter Performance Test).

Electronic Calibration (eCal)

eCal allows to perform a calibration without using test weights. FAD-40 is adjusted during production for

increased eCal accuracy. The calibration will be done based on the scale capacity, the total load cell capacity,

the load cell output and the estimated dead load. If the conditions are convenient for zero calibration, you may

perform automatic zero adjustment instead of entering an estimated dead load.

Figure 5.6 –eCal Calibration

After selecting eCal calibration enter the following values as:

Total Load Cell Capacity: Enter the total load cell capacity in kg as shown in the example below.

Example: If the weighing system has 4 pcs 1000 kg load cells, then enter 4000 kg.

Average Load Cell Output: Enter the load cell output in mV/V. If the weighing system has more than one load

cell, calculate the mean value of the load cells output as indicated in the certificates of the individual load cells.

Example: If the load cell outputs are LC1: 2.0010, LC2: 1.9998, LC3:1.9986 and LC4:2.0002, the mean value

will be LC output = (2.0010 + 1.9998 + 1.9986 + 2.0002) ÷ 4 = 1.9999 mV/V.

Estimated Dead Load: Enter the estimated dead load value of the weighing system in kg. You may perform a

zero adjustment in convenient time for exact dead load compensation. After pressing “Save eCal Data to

Converter” these data will be transferred to the instrument and eCal will be finalized.

If the scale is empty and you want to make an automatic zero adjustment instead of entering an estimated dead

load, then press the “eCal with Zero Adjustment” button for starting the zero calibration. The display will show

the [WAIT] message during the zero adjustment for approximately 5 seconds. In this period the scale must be

unloaded and stable. The eCal calibration coefficients are saved automatically.

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 18 of 55

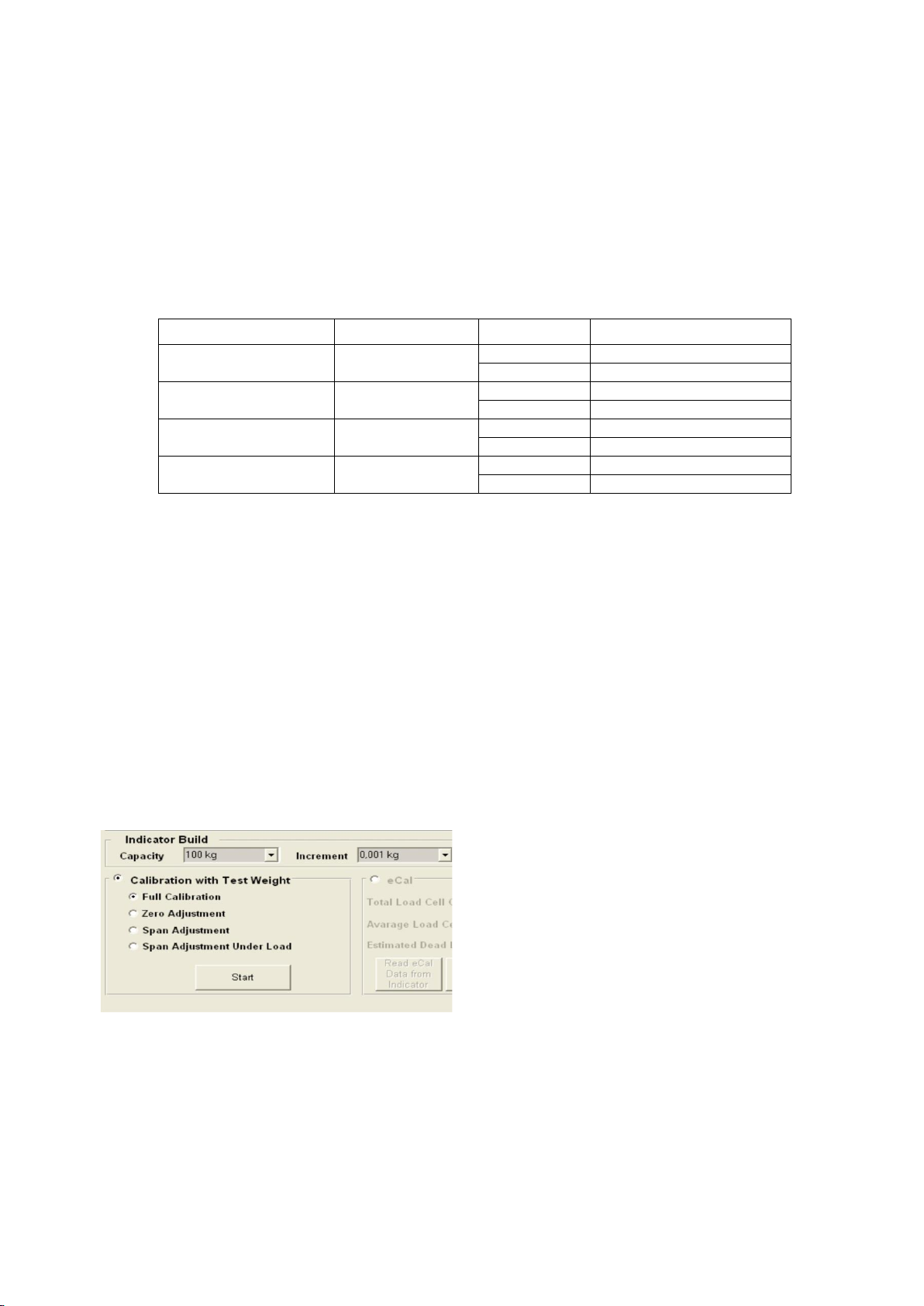

4.4. A/D Status (Performance Test)

The scale performance test should be performed before you install the bus connection. The tests are linearity,

repeatability and eccentricity. You can follow the test at the virtual display and/or status tab which show the

measurement data, the instrument data and the software version. For convenience keys for Taring, Zeroing

and Clear are located in this tab.

Figure 5.7 –A/D Status

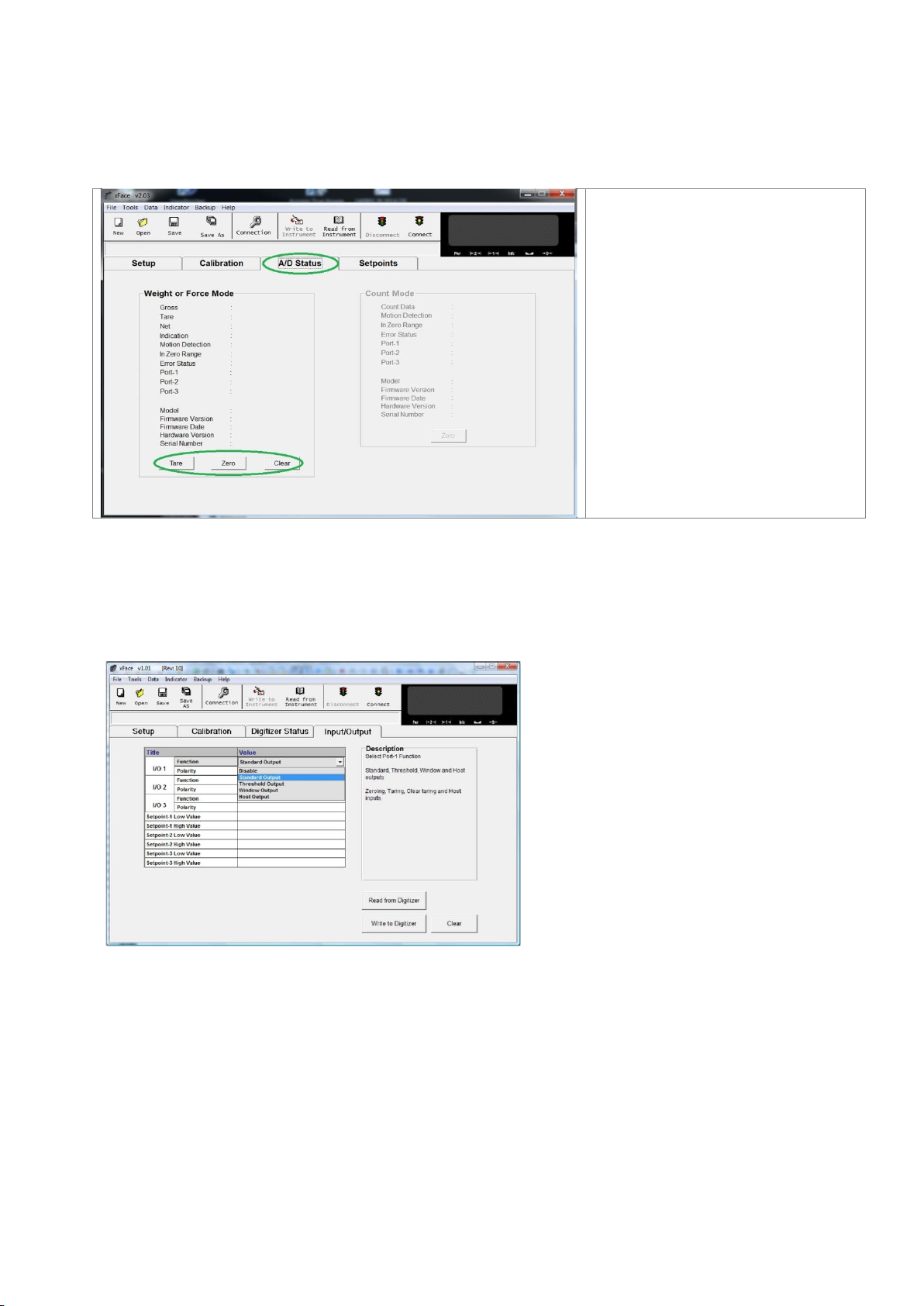

4.5. Setup of Digital I/O

FAD-40 instruments have 3 digital I/O channels. I/O1 is always an output, I/O2 and I/O3 can be configured for

input or output. The I/O connection diagram is shown in Figure 4.3

I/O1:

Select function and polarity

for I/O1 (output only)

I/O2:

Select function and polarity

for I/O2

I/O3:

Select function and polarity

for I/O3

Setpoint entries: Enter setpoints.

Setpoint 1 for I/O1, setpoint 2 for I/O2

and setpoint 3 for I/O3.

Figure 5.7 –Digital I/O Setup

FAD-40 Technical Manual, Rev.2.1.0; February 2022 Page 19 of 55

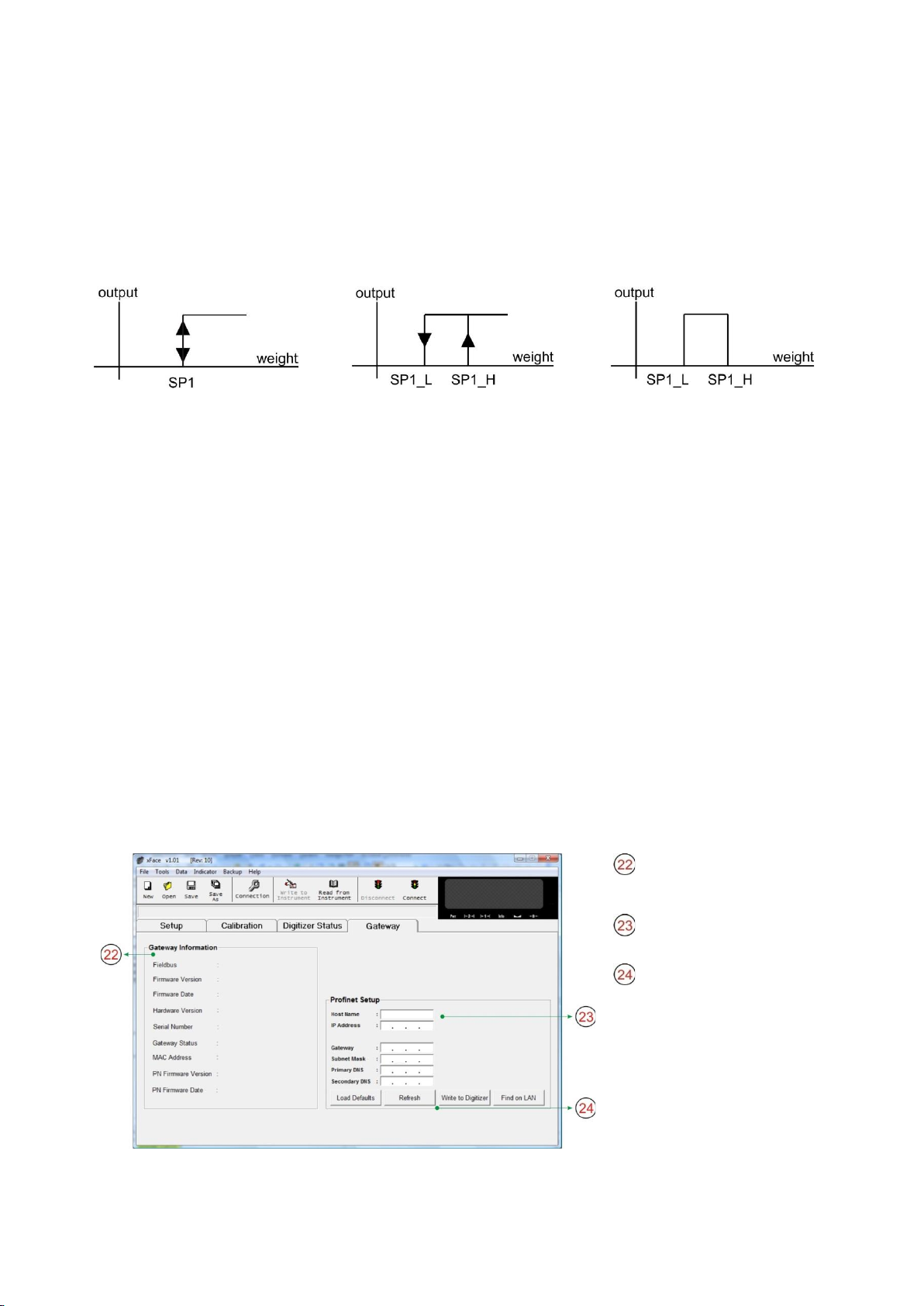

Setup of Digital Output Function

I/O1, I/O2 and I/O3 can be set up with the output functions described below.

Standard output

(Setpoint without hysteresis):

Only one value is entered. The

output state is forced active (active

high or active low, selectable) when

the weight is higher than the

setpoint SP1, else the output is

passive.

Setpoint with hysteresis:

2 values are entered. The output

state is forced active when the

weight gets higher than the higher

setpoint value SP1_H. The output

state drops to passive state when

the weight gets lower than the

smaller setpoint value SP1_L.

Tolerance band:

2 setpoint values are entered. The

output is active when the weight is

between these two setpoints

(SP1_L and SP1_H).

Host Output: Output controlled over field bus commands. Refer to related field bus data structure.

Disable: The ouput will be disabled.

I/O Polarity: The output polarity can be defined for active high (default) or active low (inverses the output).

Enter the setpoint values for the selected output function. Host output needs no setpoint value. Click “Write to

Converter” to save the changes.

Setup of Digital Input Function

I/O2 and I/O3 can be set up with the input functions described below:

Zeroing

The input zeros the scale.

Taring

The input tares the scale.

Clear Tare

The input clears the tare memory.

Host Input

Input controlled over field bus commands. Refer to related field bus data structure.

Disable

The input will be disabled.

I/O Polarity

The input polarity can be defined for active high (default setup) or active low (inverses the input).

4.6. Bus Interface Setup

FAD-40 instruments have a bus interface and these parameters have to be setup before the bus will be

connected. Bus communication settings are done in the Gateway tab.

Bus communication parameters and their descriptions can be found in the related instrument chapters.

Gateway Information:

Gives the user info about

the bus interface

Communication setup:

Network parameters

Load Defaults: Loads the

default values

Refresh: Reads the

settings from the instrument

and updates the window

Write to Converter: Saves

and activates the settings to

the instrument

Find on Network: Search

for the instrument on the

network

Figure 5.8 –Bus Interface Setup

This manual suits for next models

7

Table of contents

Other Flintec Media Converter manuals