JAPD

EM-1687 Rev.1

P. 3 / 5

operating the Programming Unit.

In MONITOR mode (Maintenance Switch = 0), the unit is in normal

operation: repeating measuring, calculating and renewing the out-

put signal. In this status, the status indicator LED is flashing in

constant intervals of approx. 3 Hz (ON : OFF = 1 : 1). You can

monitorinput%,output%andoperatingstatus,variousparameters,

etc. on the Programming Unit.

The PROGRAM mode (Maintenance Switch = 1) is used when you

change various parameters concerning measuring, calculation and

output. Inthisstatus,thestatusindicatorLEDisflashinginconstant

intervalsofapprox.1.5Hz(ON:OFF=1:1). Inthetransitionperiod

fromMONITORtoPROGRAMmode,theLEDflashesapprox.in1.5

Hz but in different intervals (ON : OFF = 1 : 3), which indicates that

the unit is still processing the last cycle of measuring.

In PROGRAM mode, the unit stops measuring and renewing the

outputsignal. Theoutputisheld,butyoucanoutputaspecificvalue

for simulation and testing.

Whenalltheprogramchangeisover,be suretoreturn thetransmit-

ter to MONITOR mode. The modification will be lost if you turn off

power supply to the transmitter without doing this.

EXPLANATIONS OF TERMS & FUNCTIONS

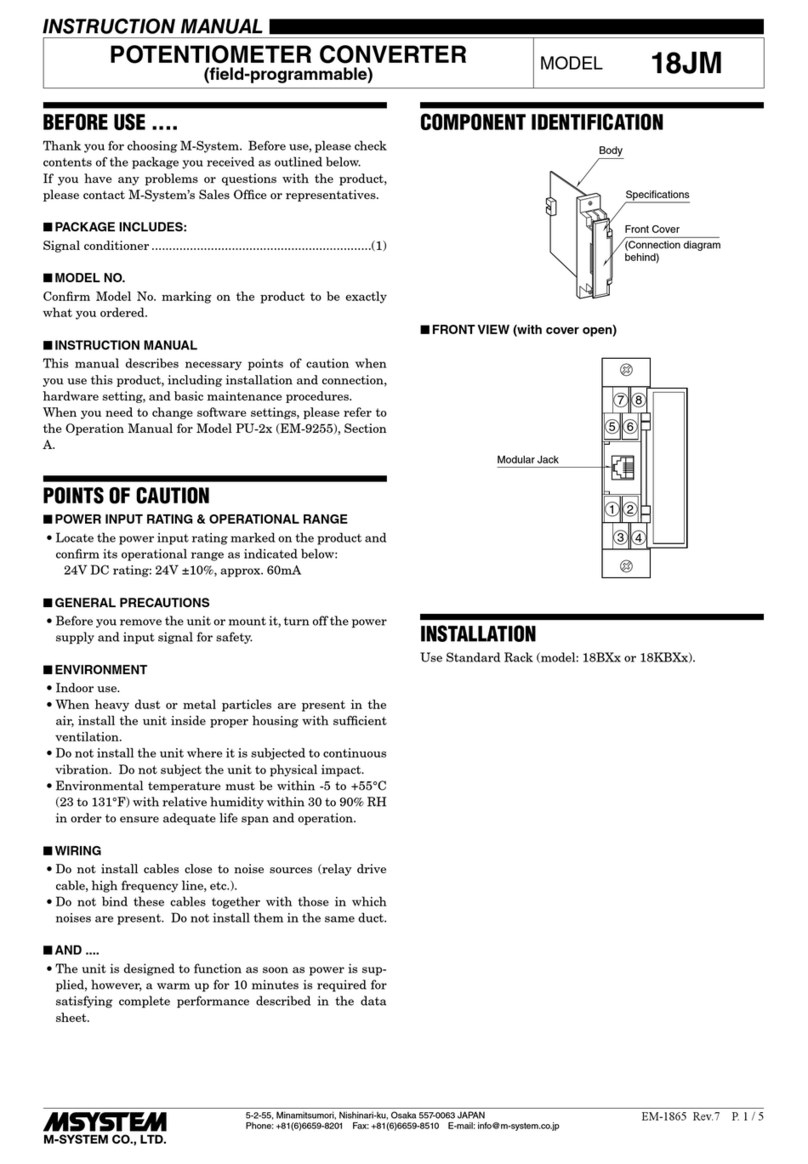

■ BASIC OPERATION

After the power is turned on, the JAPD accesses and checks the

data stored in its non-volatile memory. When there is no abnormal-

ity, it starts measuring.

The input signal, processed through the analog input circuit and

convertedintofrequency,iscomparedwiththepreset0%(zero)and

100%(span)inputvalues(as calibrated at the factory)todetermine

the input value. Then the signal is compared with the preset 0%

(zero)and100%(span)outputvaluesandconverted proportionally

into an frequency output.

Whenthecomparedresultisoutofthenormaloperationalrange,the

output is limited to a value -15% or +15% of the full-scale.

The input is sampled according to the sampling time (default 200

ms), and the output is renewed every this cycle.

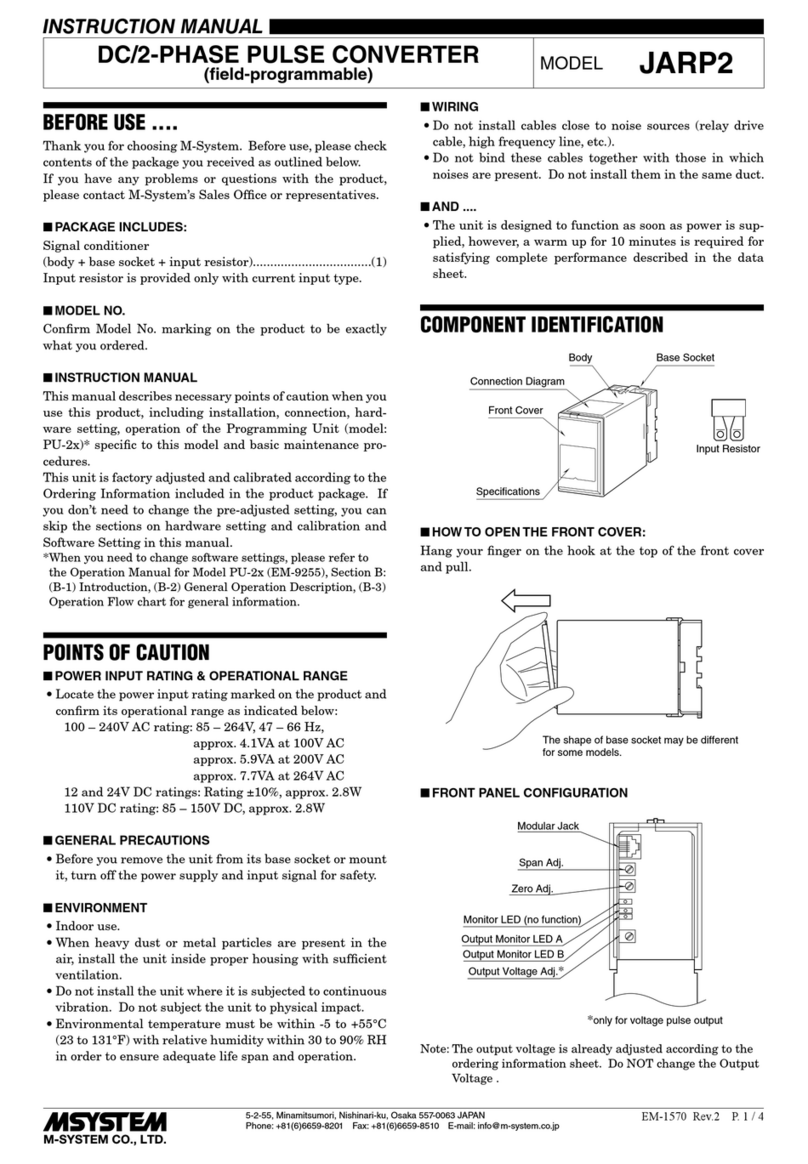

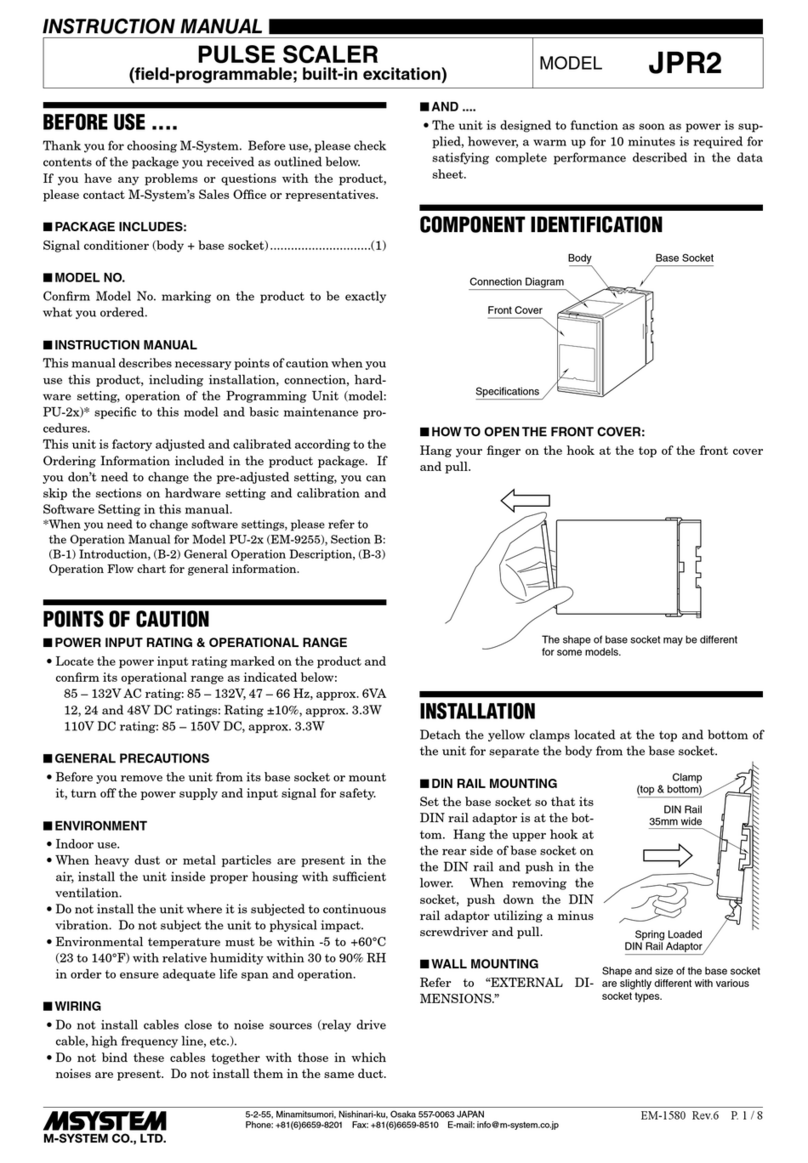

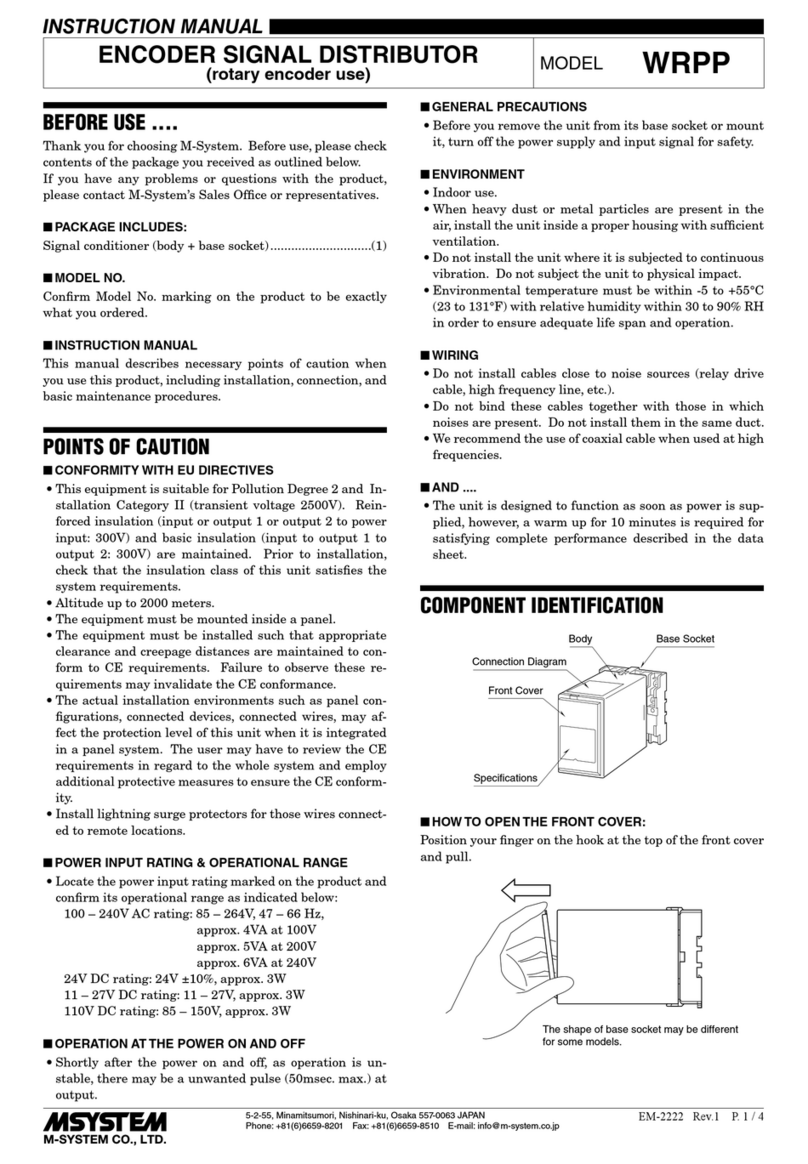

■ OPERATION MODE AND MAINTENANCE SWITCH

There are two operation modes: MONITOR mode and PROGRAM

mode.

Whenthepowersupply is turned on, theunitstartsup in MONITOR

mode. However, you can switch from one mode to another by

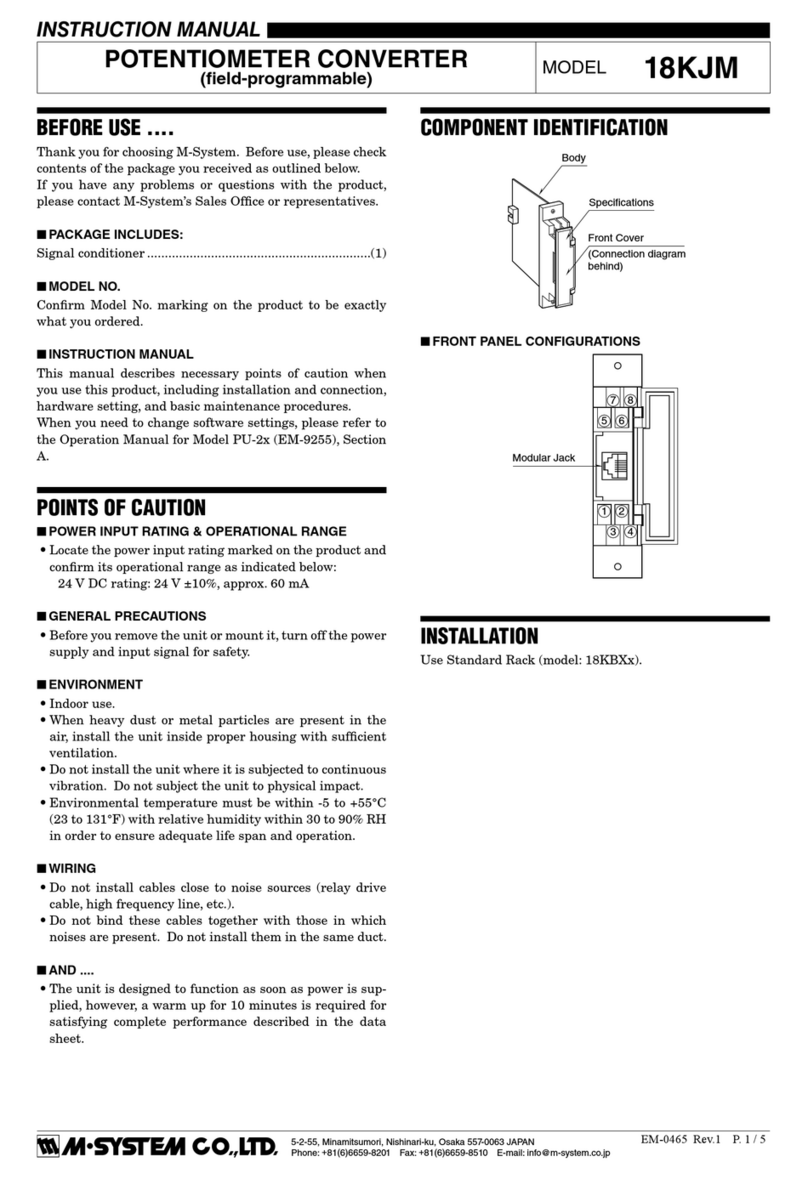

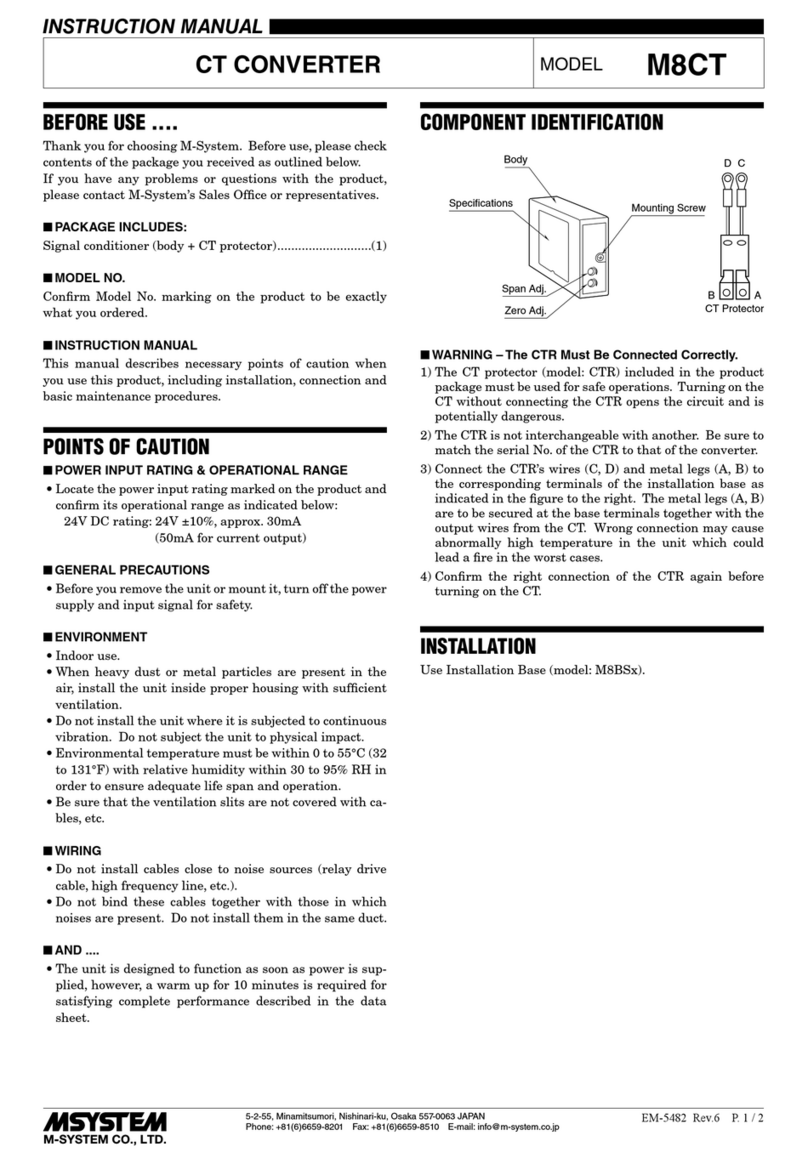

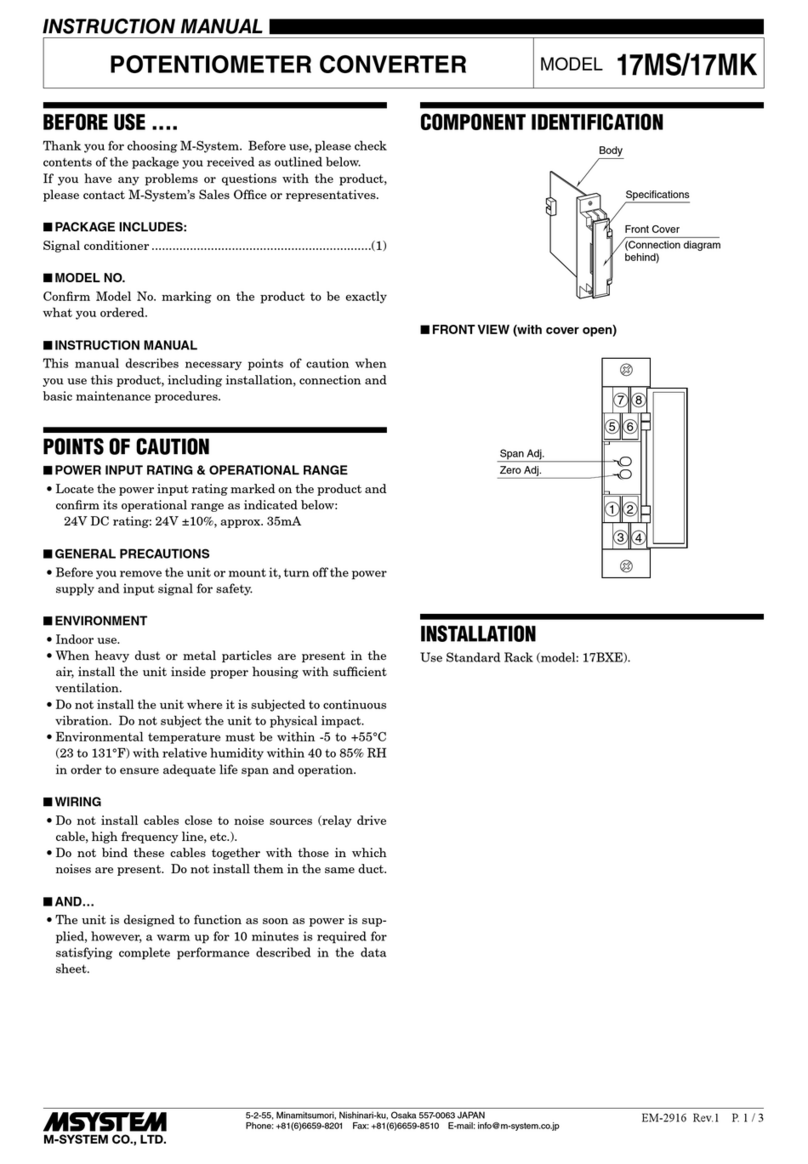

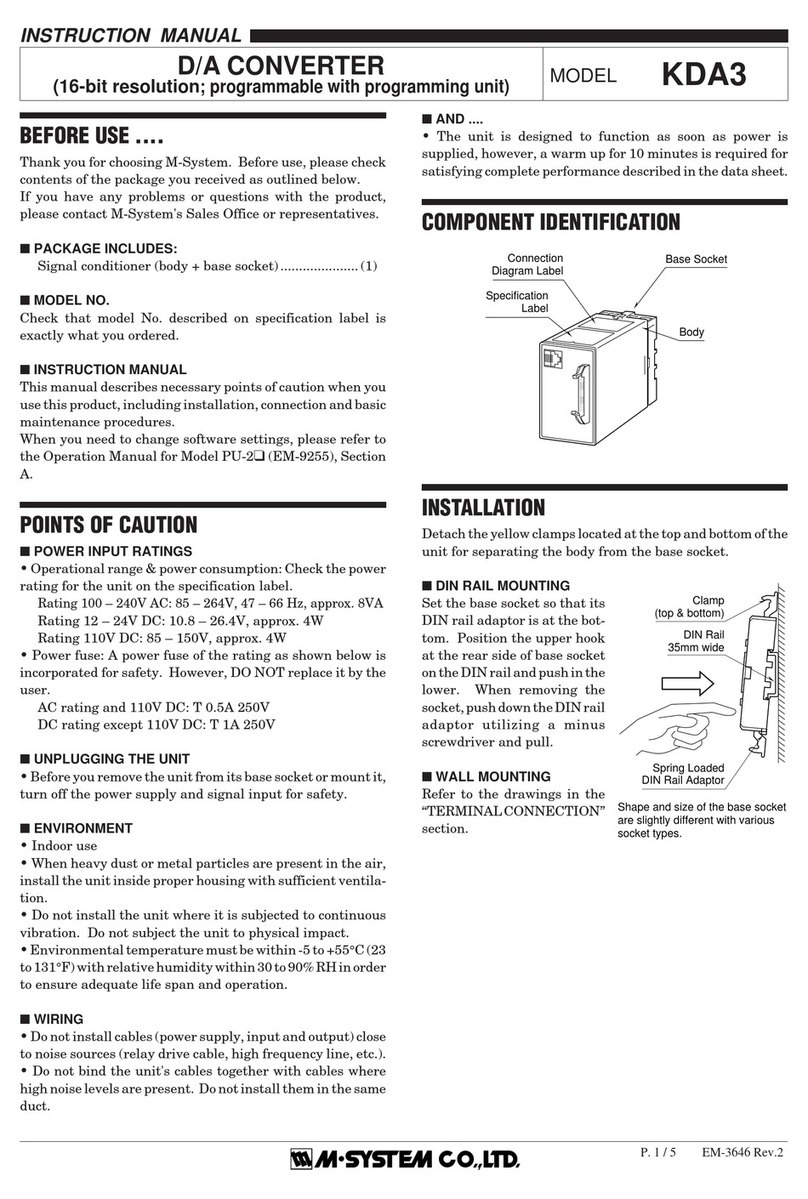

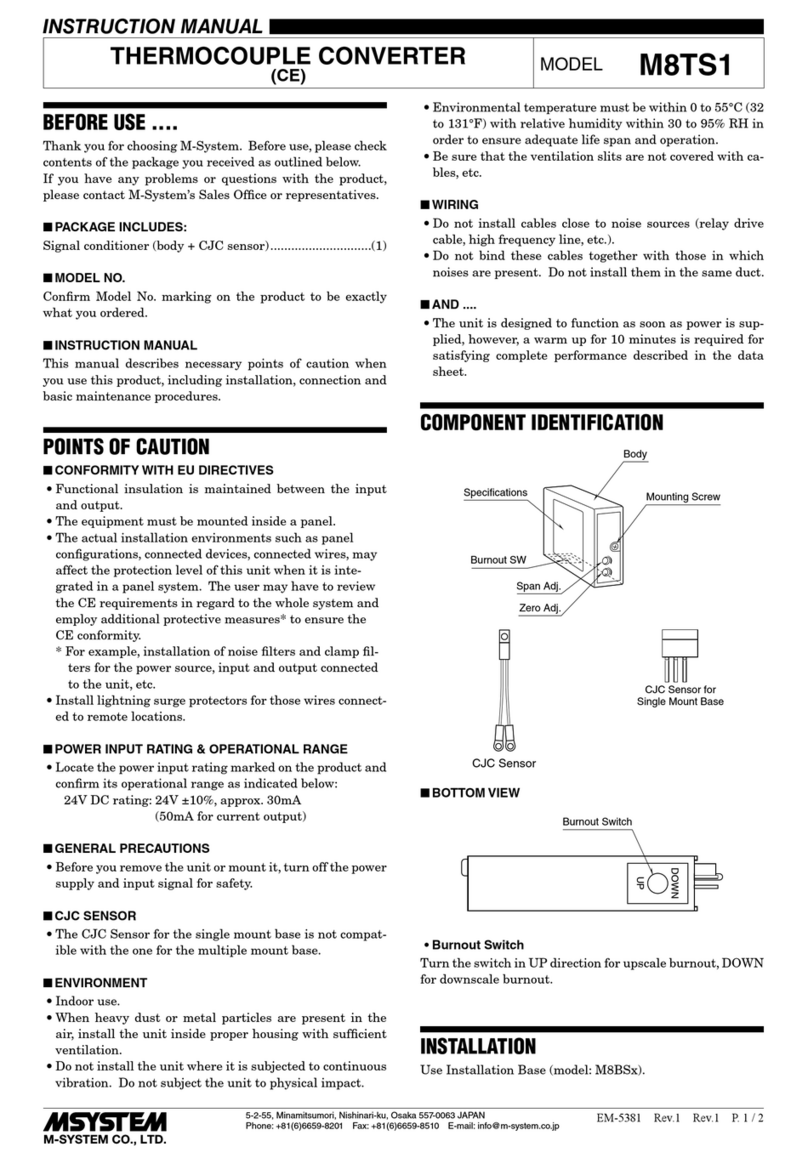

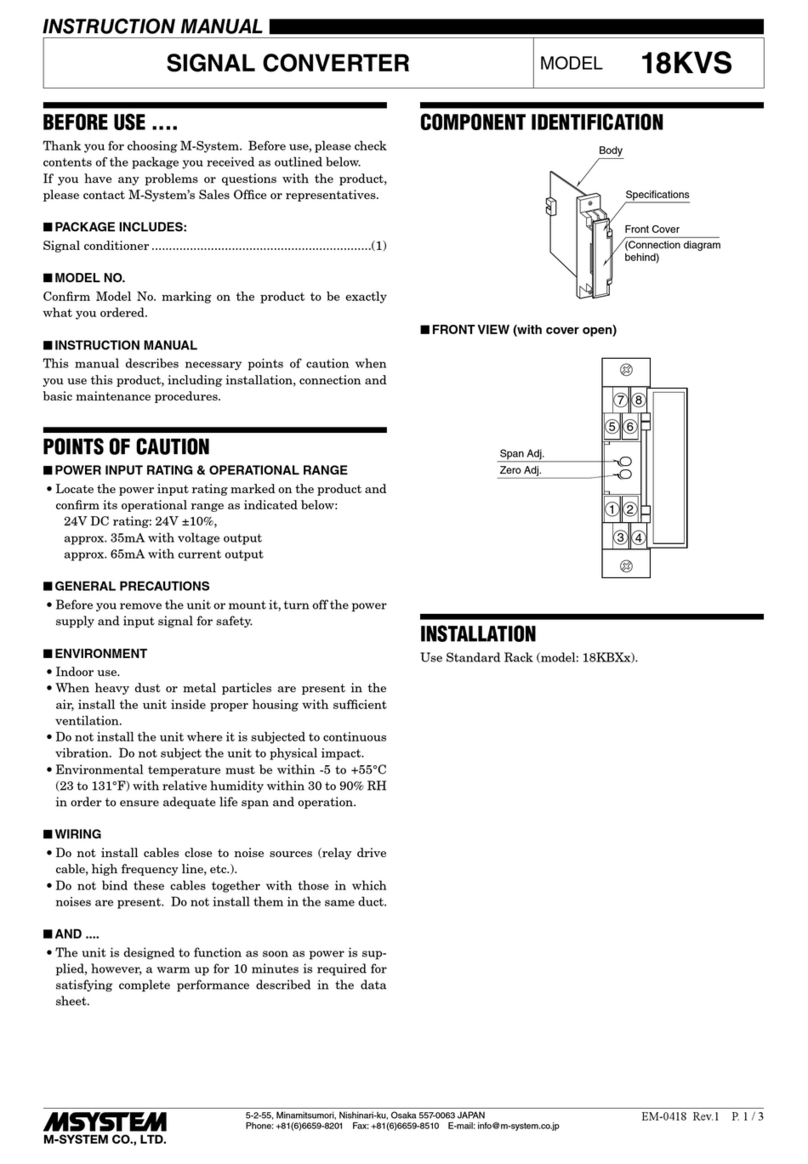

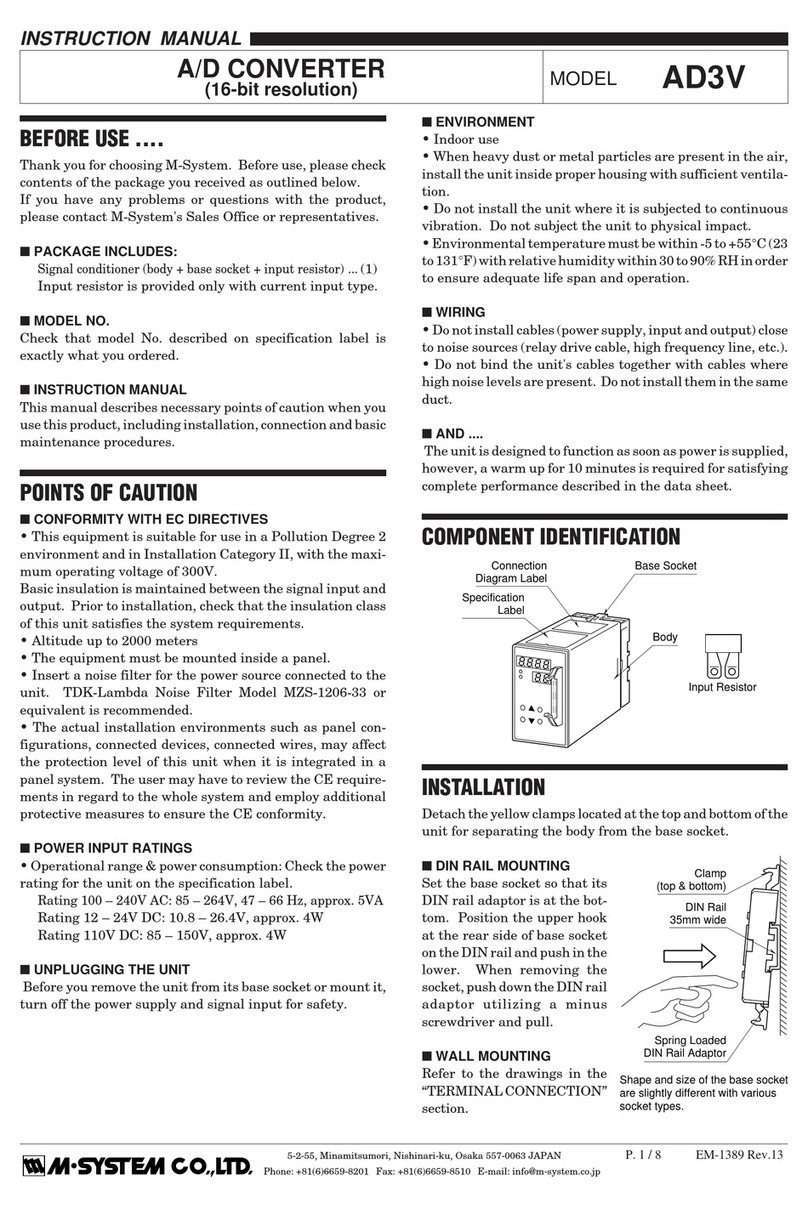

■ STATUS INDICATOR LED

TheCPUstatusisindicatedbydifferentblinkingpatternsofthefront

indicator LED. 1 pattern cycle is divided in 16 ON or OFF periods,

each of which lasts for 320 millisec.

In the figure to the right, ●●means that the light is OFF, while ●

meansthatit isON. TheON-OFF pattern changesfromthe leftend

to the right in 320 millisec. duration.

There are more of these patterns which are not shown here,

however, when the last one shown in the figure to the right or some

other pattern is indicated, contact M-System.

The anomaly report is available also on the display of the Program-

ming Unit. Refer to its manual for detailed information.

MONITOR MODE

Measuring Processing

Monitor. Parameters

Available

Monitor. Measuring

Value Available

PROGRAM MODE

Measuring Stopped

Changing Parameters

Available

Output Simulation

Available

Maintenance Switch = 1

Maintenance Switch = 0

Parameters Saved

in the Nonvolatile Memory.

Power

Turned ON

FLASHING PATTERNS IN NORMAL CONDITIONS

Program mode

Monitor mode, abnormality in the analog input circuit.

Monitor mode, normal input status

FLASHING PATTERNS IN ABNORMAL CONDITIONS

Monitor mode, parameters are destroyed or functioning in default values.

Monitor mode, parameters are destroyed and impossible to recover.