Flintec MCS-64 User manual

MCS-64

(Multi Channel System for Process Industry)

Manual MCS-64 with CANbus

Document no.G164-Rev4-GB

Manual MCS-64 Page 1

www.flintec.com

Exc-

Sen-

Sig-

Sig+

Sen+

Exc+

Exc-

Sen-

Sig-

Sig+

Sen+

Exc+

Exc-

Sen-

Sig-

Sig+

Sen+

Exc+

Exc-

Sen-

Sig-

Sig+

Sen+

Exc+

Logic in

Load

Cells

Logic out

C0123CC0123CC0123C C0123C

FLINTEC

www.flintec.com

BC

470uF

+HP

1234

ON DIP

R2

R1

Mt1

Mt27

Mt28

Mt2

J14

T6

T26

Exc-

Sen-

Sig-

Sig+

Sen+

Exc+

Exc-

Sen-

Sig-

Sig+

Sen+

Exc+

Logic in

Load

Cells

Logic out

C0123C C0123C

FLINTEC

www.flintec.com

Y

5

V+

0

5

1

6

9

BC

470uF

+HP

FUSE

5X20

FLINTEC Fl112081 B16

FLINTEC Fl112081B16

PWR

Com

6

5

4

3

2

1

0

PB Adresse

Profibus Connector

Act

PGM 86.1

PWR

Com

In 0

Out 0

Err

In 1

Out 1

In 2

Out 2

In 3

Out 3

LDM 88.1

PWR

Com

In 0

Out 0

Err

In 1

Out 1

In 2

Out 2

In 3

Out 3

LDM 88.1

PWR

Com

In 0

Out 0

Err

In 1

Out 1

In 2

Out 2

In 3

Out 3

LDM 88.1

PWR

Com

In 0

Out 0

Err

In 1

Out 1

In 2

Out 2

In 3

Out 3

LDM 88.1

PWR

Com

In 0

Out 0

Err

In 1

Out 1

In 2

Out 2

In 3

Out 3

LDM 88.1

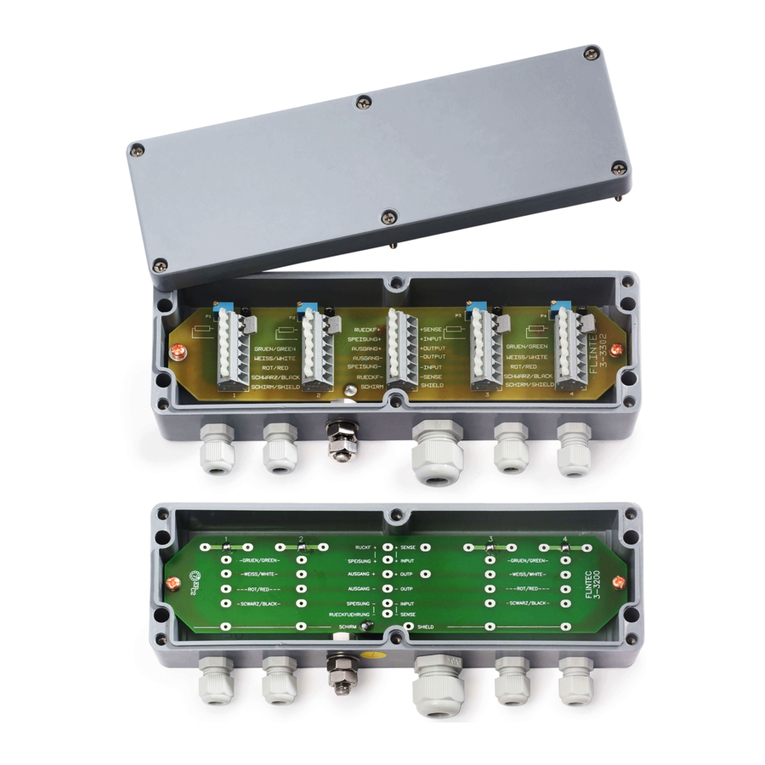

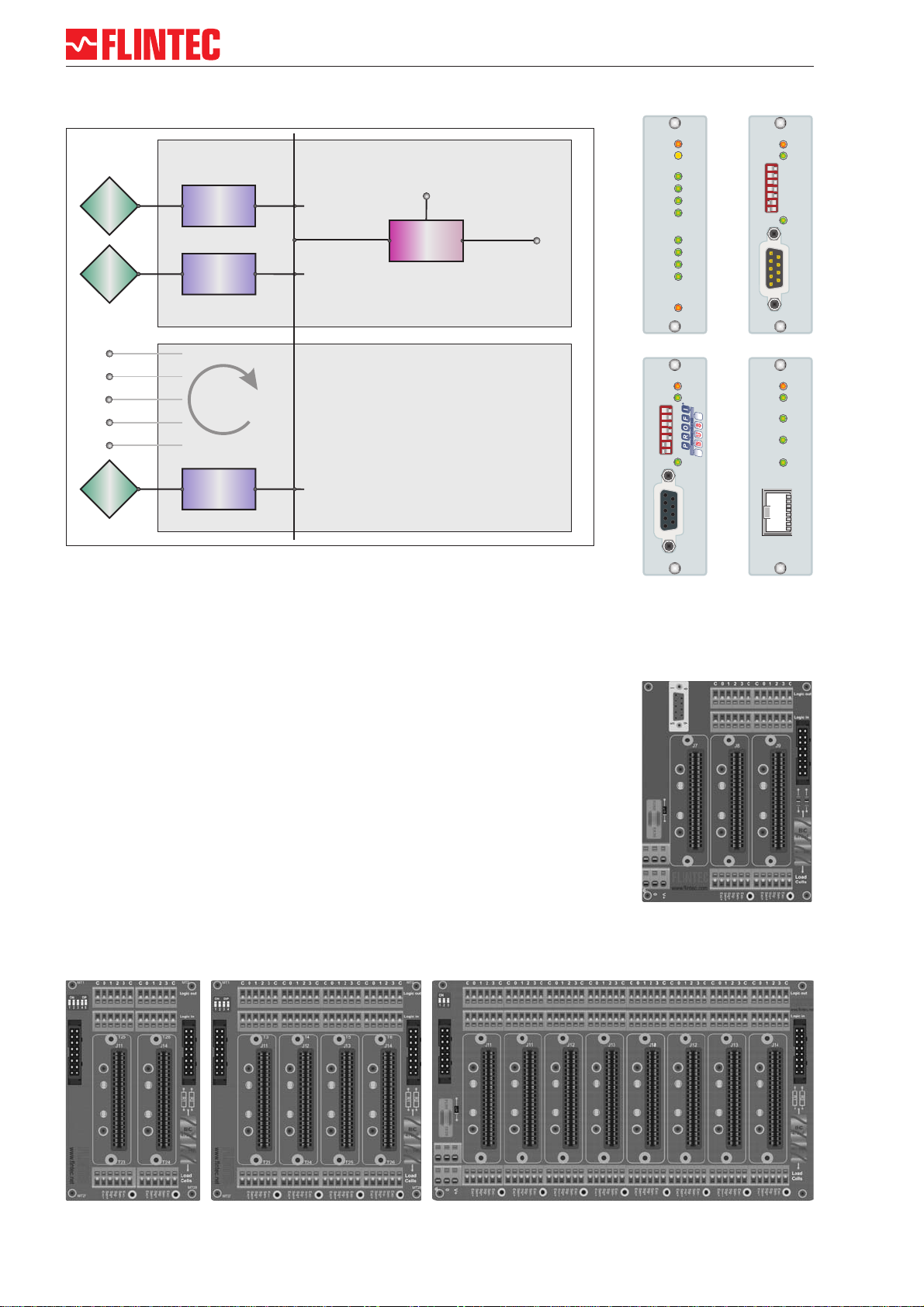

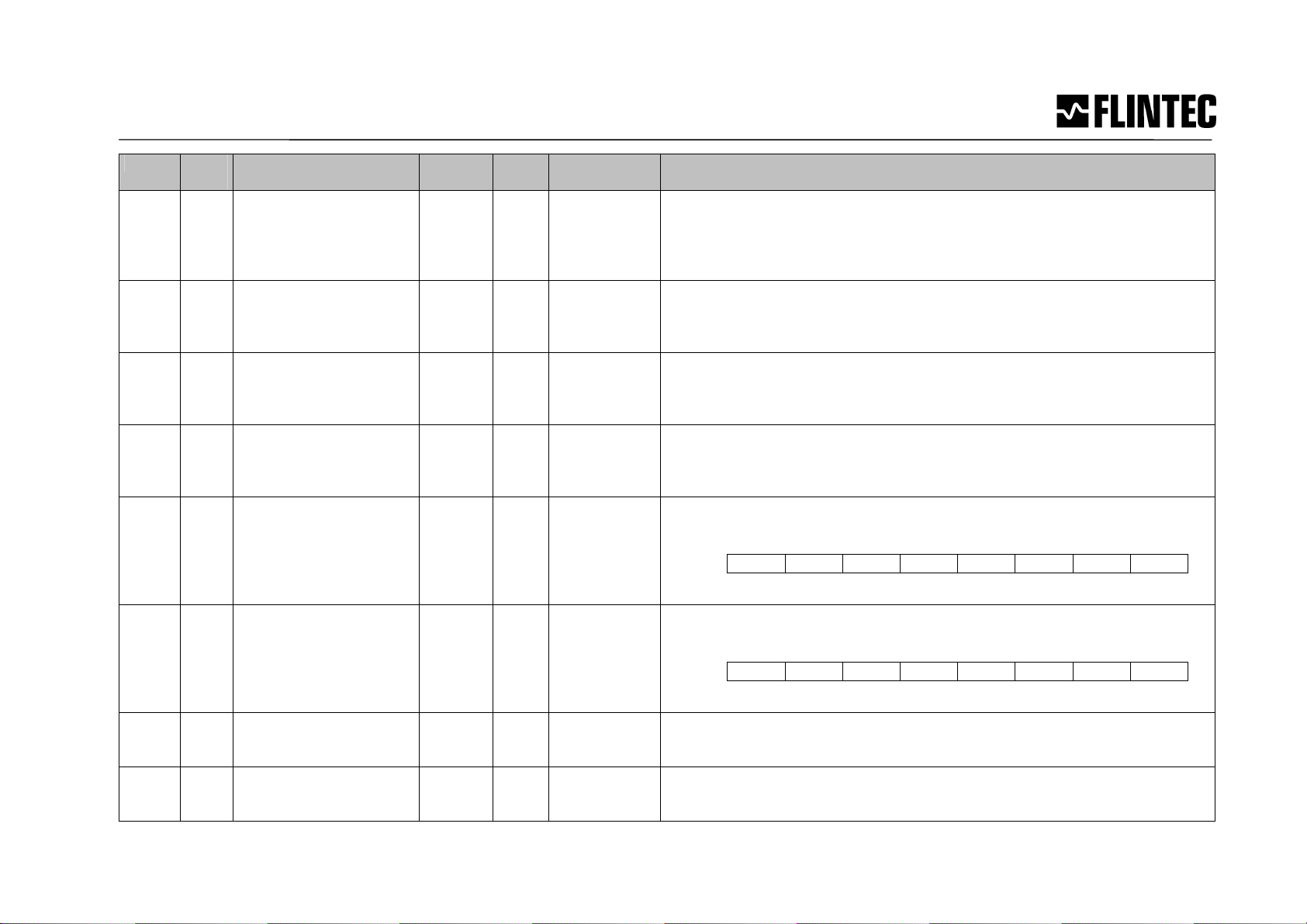

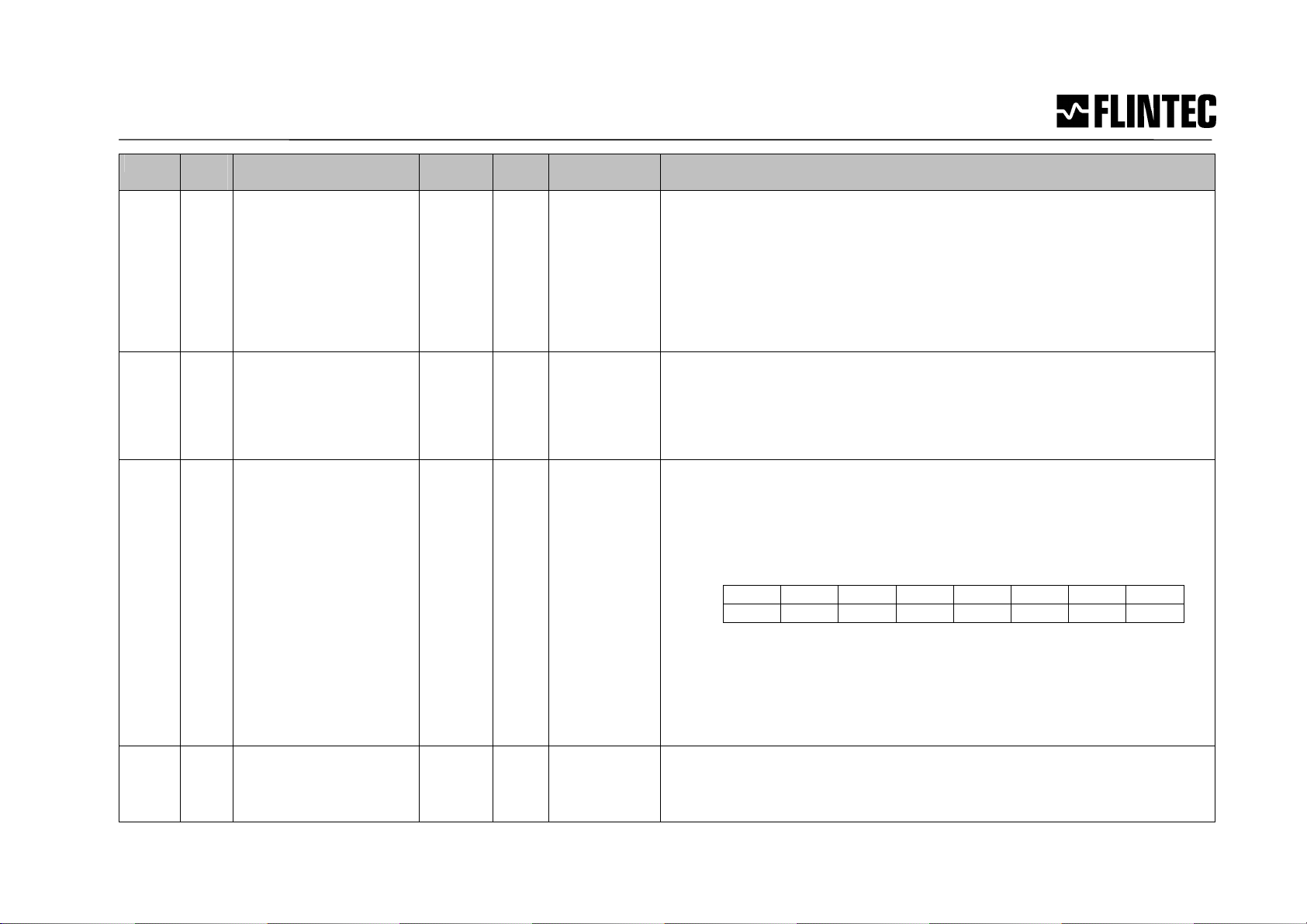

Example of MCS-64 with 5 channels and Profibus-Gateway

Page 2 Manual MCS-64

LDM 88.1

#1

Load Cell

#1

LDM 88.1

#2

Load Cell

#2

Gateway

Fieldbus

- Profibus (PGM 68.1)

- CANopen (CGM 85.1)

- Ethernet (EGM 87.1)

RS 232

Service-Port

RS485 - Bus

LDM 88.1

#64

Load Cell

#64

Base Board

MB 89.1

Extension Boards

MB 89.2

MB 89.3

MB 89.4

Components of MCS-64 in overview

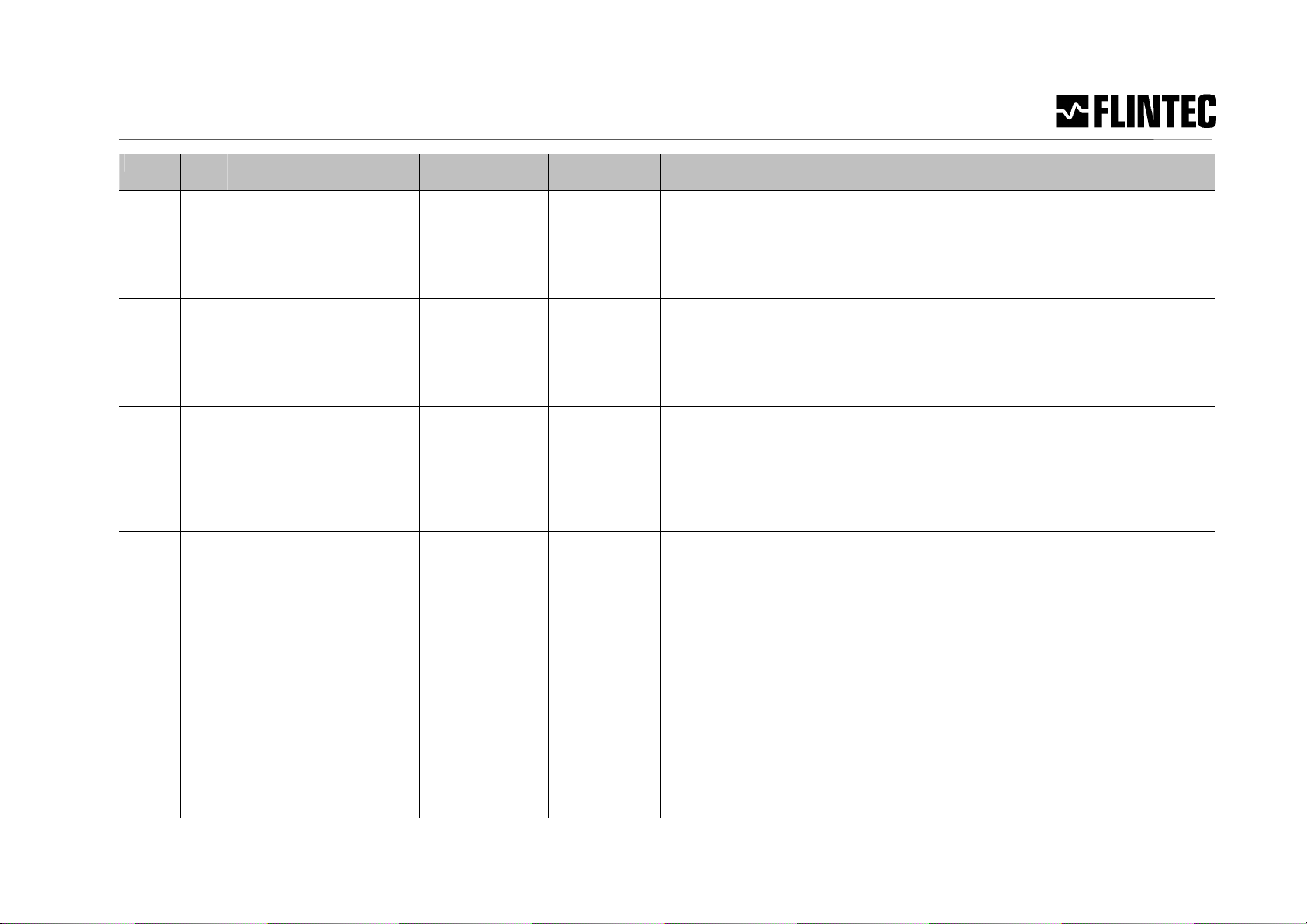

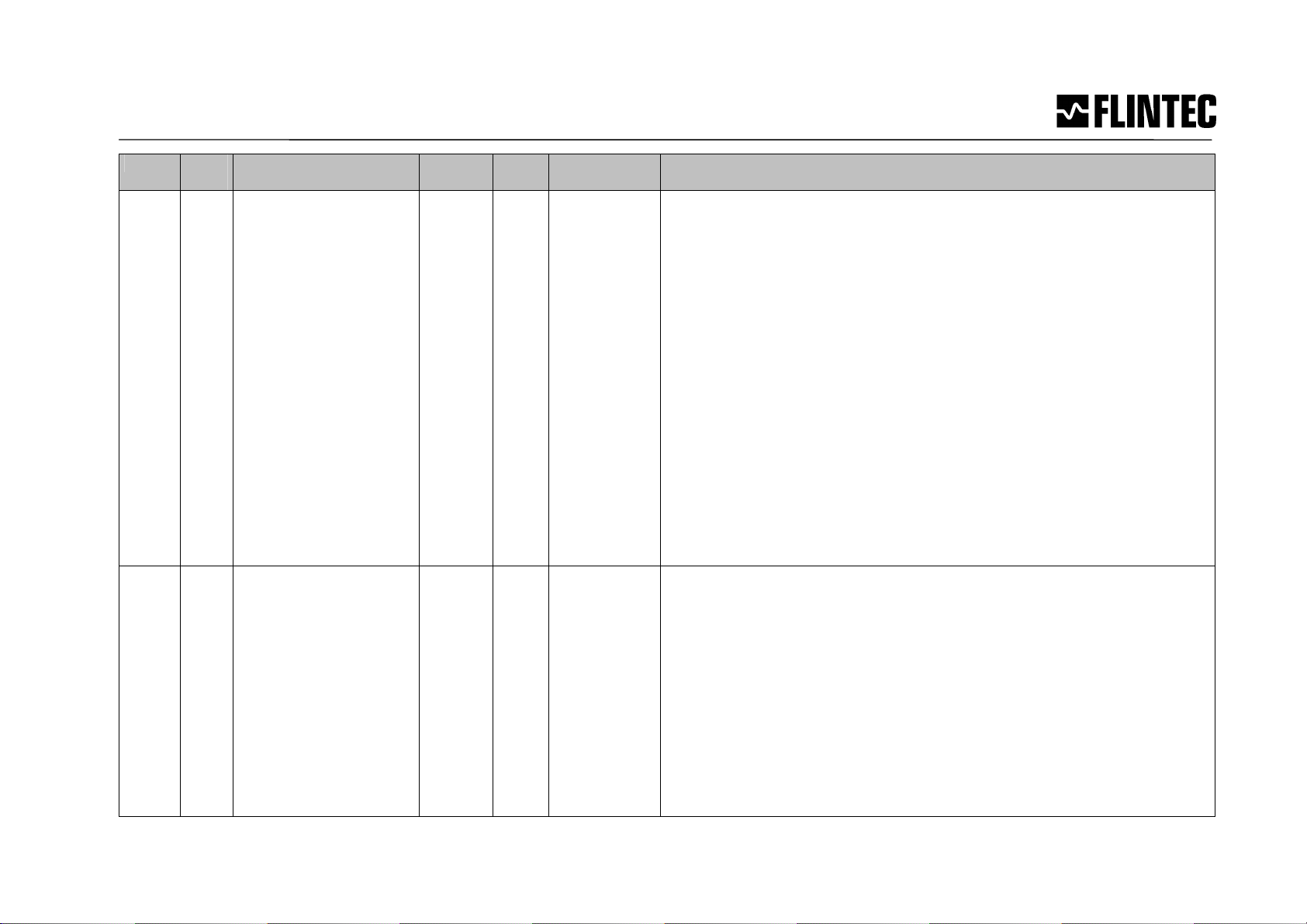

Components of MCS-64

All boards have the same technical features:

•Spring clips for load cell terminals in 6-wire-technique

•4 DI’s via spring clip terminal blocks

•4 DO’s via spring clip terminal blocks

•Header for ribbon cable to extension board

PWR

Com

In 0

Out 0

Err

In 1

Out 1

In 2

Out 2

In 3

Out 3

LDM 88.1

LDM 88.1

PWR

Com

6

5

4

3

2

1

0

PB Adresse

Profibus Connector

Act

PGM 86.1

PGM 86.1

PWR

Com

6

5

4

3

2

1

0

Bus Adresse

CANopen Connector

Act

CANopen

CANopen

CGM 85.1

CGM 85,1

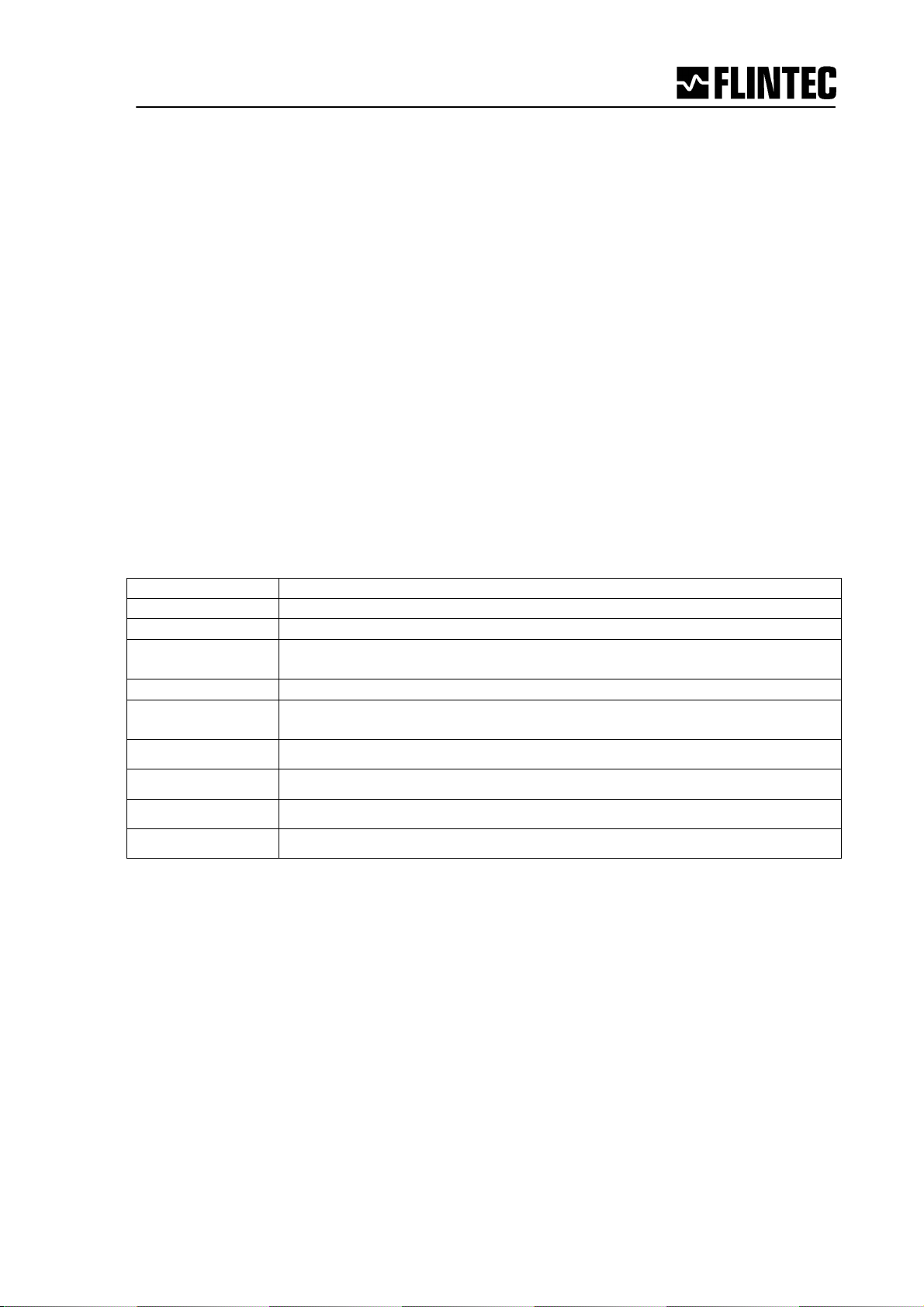

MB 89.1

Dim 104 x 135 mm

MB 89.3

Dim 129 x 135 mm

MB 89.2

Dim 79 x 135 mm

MB 89.4

Dimensions 229 x 135 mm

Base Board MB 89.1

•Slot for one Gateway CGM 85.1 / PGM 86.1 / EGM 87.1

•2 Slots for weighing processor LDM 88.1

•RS 232 Service port

PWR

Com

FD/CS

100Mbps

Link/Act

Ethernet TCP/IP

EGM 87.1

87654321

EGM 87,1

Extension Boards MB 89.2/.3/.4

•2/4/8 Slots for weighing processor LDM 88.1

Manual MCS-64 Page 3

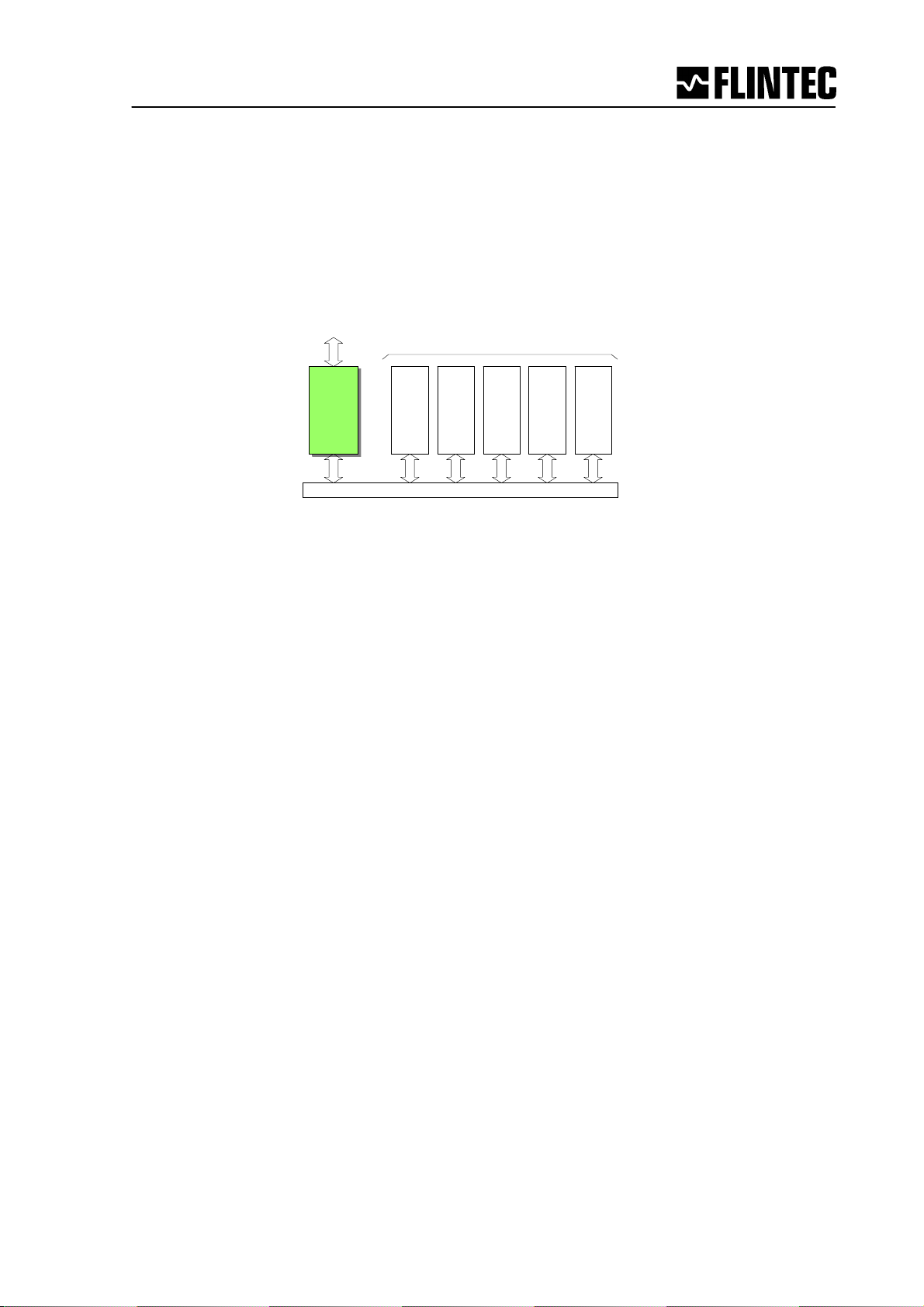

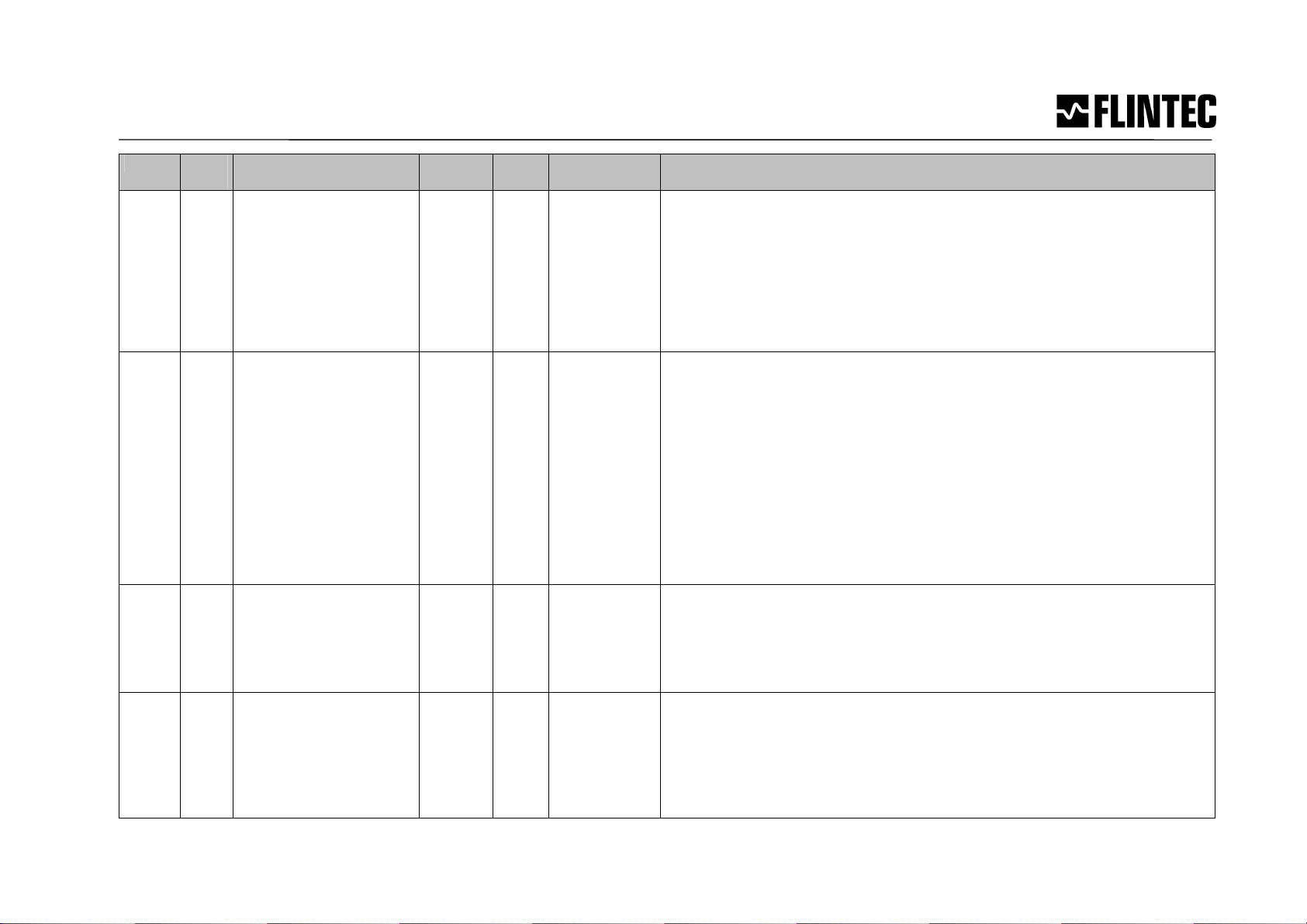

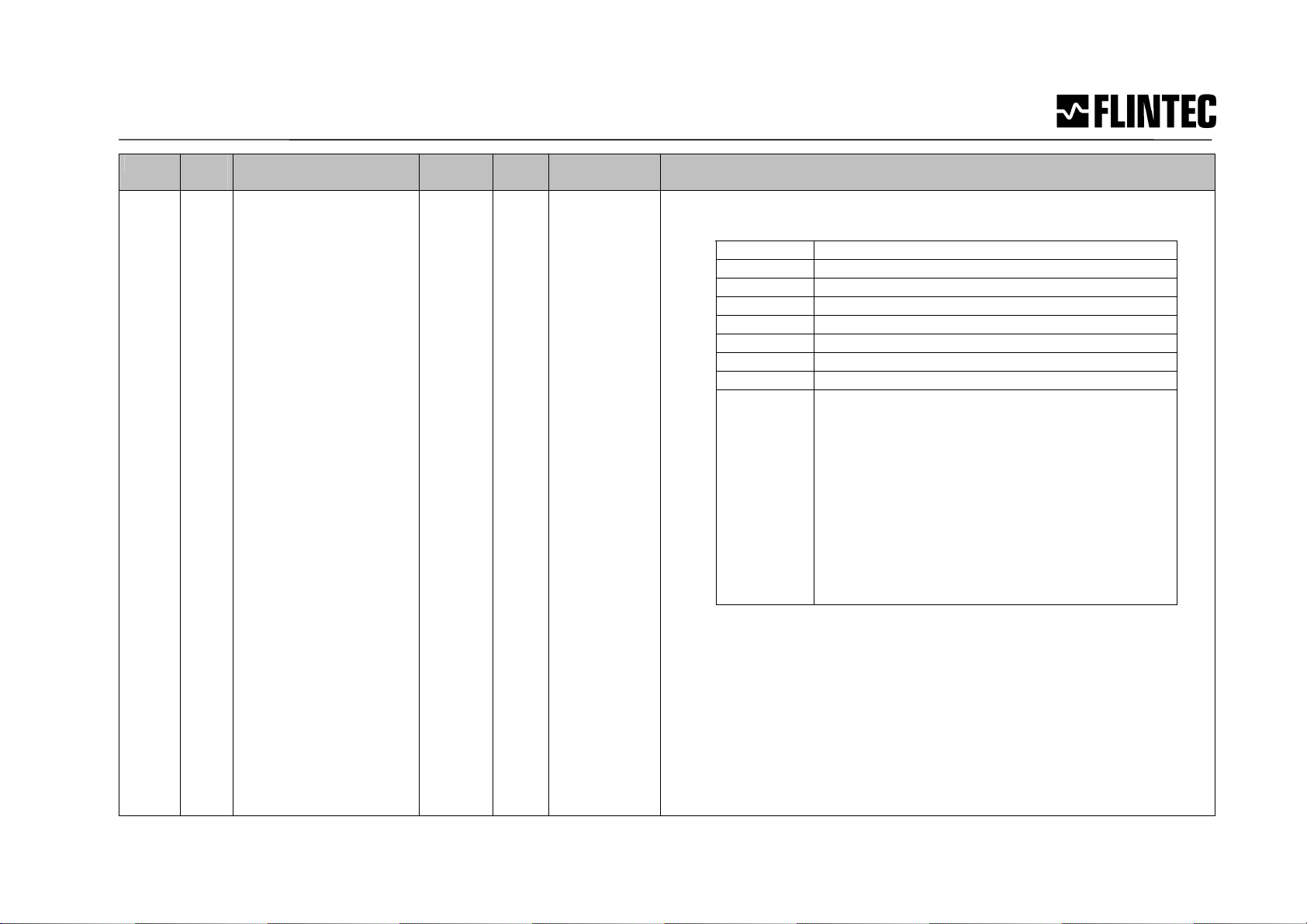

Linearity < 0.002 % FS

Excitation 5 V DC, load cells 100-2 000 Ohm, 6 wire technique

Analogue input range ±2.2 mV/V (bipolar)

Minimum input per vsi 0.05 mV per interval non approved

Resolution ±260 000 counts , ±18-Bit-A/D convertor

Conversion rate 2400 measurements per second intern

Digital Filter FIR Filter 2.5 ... 19.7 Hz or IIR Filter 0.25 ... 18 Hz; programmable in 8 steps each

Calibration software calibration and set up

Computer interface intern RS485/RS422, full duplex, 115 200 Baud, bus capability up to 64 devices

Weighing functions zero, gross, tare, net, filter etc.

Inputs 4 opto-isolated inputs, 10 ... 30 V DC max. 3 mA

Outputs 4 OC outputs, < 35 V DC, 500 mA

Temperature effects on zero 5 ppm/°K typ.; max. < 10 ppm/°K

on span 4 ppm/°K typ.; max. < 8 ppm/°K

Temperature range –10 °C to +50 °C (operating); –30 °C to +80 °C (storage)

Enclosure Aluminium, protection IP40

Dimensions 80 x 23 x 100 mm, with two M3 fixing screws for mounting on boards MB89.1/2/3/4

Power supply 12 ... 24 V DC ±10 %, < 60 mA,(reversed voltage, burst and ESD protected)

Power consumption 1,5 W max.

EMC CE 73/23/EEC; 93/98/EEC and 89/336/EEC

Computer interface via

Service Port MB 89.1

RS232C, 115 200 Baud

Vibration withstands 1.0 G operational; 2.5 G non-operational

LDM 88.1 Specifications

Weighing Processor LDM 88.1

PWR

Com

In 0

Out 0

Err

In 1

Out 1

In 2

Out 2

In 3

Out 3

LDM 88.1

LDM 88.1

The digital weighing processor LDM 88.1 is a load cell

digitizing unit for precise measuring of loads in motion.

•± 18 bit resolution (±260 000d)

•Excitation5VDC/50mA

•2 400 Measurements/s internal,

600 Measurements/s external

•mV/V calibration

•4DI’s

•4DO’s

•RS 485 bus, 115.2 kBaud

•Digital Filter (FIR and IIR)

•for static or dynamic weighing

processes

•3 Firmware versions

Load Cell

Low-Pass

Filter

Digital Filter

IIR- / FIR

ADC

- Net

- Gros

- Average

- Dose

Digital

Output /

Setpoint

1 ... 4

Digital

Input

1 ... 4

RS 485 / 230 kBaud

binary format

LDM 88.1

Remote Control Output

Start Filling Cycle

Trigger Signal

Page Manual MSC-64

4

Contents

Part A: CANopen ............................................................................................. pages 6 - 28

Part B: Commands ..........................................................................................pages 28 - 50

Part C: Components / Technics of System MSC-64 .......................................pages 51 - 60

1Introduction...........................................................................................................6

1.1 Identification and Scope......................................................................................6

1.2 Purpose...............................................................................................................6

1.3 Acronyms and Definitions ...................................................................................6

1.3.1 Acronyms........................................................................................................6

2System Detailed Design.................................................................................7

2.1 General ...............................................................................................................7

2.2 Backplane handling.............................................................................................7

2.3 CANopen ............................................................................................................8

3CANopen profile.................................................................................................9

3.1 The PDOs ...........................................................................................................9

3.2 Communication Profile......................................................................................10

3.3 Object Directory ................................................................................................10

3.4 Quick Start Guide..............................................................................................26

3.4.1 Process data objects.....................................................................................26

3.4.2 Service data objects......................................................................................27

4COMMANDS........................................................................................................28

4.1 System diagnosis Commands – ID, IV, IS ........................................................29

4.2 Calibration Commands – CE, CM, CI, DS, DP, CZ, CG AZ, AG, ZT, FD, CS ..30

4.3 Motion detection Commands – NR, NT ............................................................34

4.4 Filter setting Commands – FM, FL, UR.............................................................35

4.5 Set Zero/Tare and Reset Zero/Tare Commands – SZ, RZ, ST, RT..................37

4.6 Output Commands – GG, GN, GT, GS.............................................................39

4.7 Setpoint Commands - Sn, Hn, An.....................................................................40

4.8 Trigger Commands – SD, MT, GA, TE, TR, TL ................................................42

4.9 Trigger Special Commands– RW, TT, TS, DT, TW, TI, HT ..............................45

4.10 Communication setup Commands – AD & BR..................................................48

4.11 Save calibration, setup and setpoint parameters Commands – CS, WP, SS...49

4.12 Filling Commands – PD1 to PD21, DI, SC, AC, GD, DT, SD............................50

4.13 Loss in Weight Commands – PL1 to PL5, LC, LI, GF, GR, GM.......................51

4.14 Speed Estimation Multi-Channel System MCS-64 ...........................................52

Manual MCS-64 Page 5

5MCS-64 Components and Configuration.................................................. 53

5.1 Base Board MB 89.1 for 1 Gateway and 2 LDM 88.x ............................................ 53

5.2 Extension Board MB 89.2 for 2 LDM 88.x.............................................................. 54

5.3 Extension Board MB 89.3 for 4 LDM 88.x.............................................................. 55

5.4 Extension Board MB 89.4 for 8 LDM 88.x.............................................................. 56

5.5 Address setup guide extension boards for 1 – 16 channels .................................. 57

5.6 Address setup guide extension boards for up to 32 channels ............................... 58

5.7 Example Check Weigher Wiring ............................................................................ 59

5.8 Example Liquid Filling Wiring................................................................................. 60

5.9 LDM 88.1 - digital Input / digital Output - .............................................................. 61

5.10 Firmware Versions ................................................................................................. 62

5.11 Appendix ................................................................................................................ 62

Page Manual MSC-64

6

1 Introduction

1.1 Identification and Scope

This document describes the system design for a CANopen Gateway (CGM85) and up to 64

Load Cell Digitizing Module (LDM88.x) using the Flintec backplane system. It describes the

functionality of the backplane, the protocol used on the backplane and the CANopen profile

used to access the LDM88 modules via the CGM85 Gateway. It specifies the protocols and

logical format of the messages between the CANopen and the local backplane system.

1.2 Purpose

The purpose of this document is to specify functionality and performance of the Gateway and

the Load Cell Digitizing Modules (LDM88) with the available firmware versions (standard

88.183, filling 88.184, loss in weight 88.185).

1.3 Acronyms and Definitions

1.3.1 Acronyms

This section includes a list of all abbreviations and acronyms used throughout the document

in alphabetical order.

CAN Controller Area Network

CANopen A higher layer protocol using the CAN.

FAT Factory Acceptance Test – the preliminary test

Function A software entity that encapsulates some computations and can be used

without worrying about its implementation

PDO Process Data Object

Process A software entity that executes a computational entity, including modules

and functions.

RPDO Receive PDO

SAT Site Acceptance Test – the final test on site.

SDO Service Data Object

TPDO Transmit PDO

Manual MCS-64 Page 7

2 System Detailed Design

2.1 General

This software connects a CANopen network to the local backplane modules. The Gateway

transports commands and responses to and from the CANbus. It scans the LDM modules for

their status and then transmits this status information continuously to the CAN controller.

CANopen

ADAPTOR

CANopen

ADAPTOR

BACKPLANE

LDM and other IO

Up to 64 modules per backplane

CAN controller

CAN BUS

Figure 1- CANopen Gateway in context

2.2 Backplane handling

The Gateway must continuously scan the backplane modules. It keeps track of which

modules are present and those that are not. The Gateway communicates with 4 levels of

priority on the backplane.

The highest priority communication is initiated on direct commands from the CAN controller

either by accessing a SDO or by using RPDO3.

The second highest priority is given to LDM modules in the final filling stage. The Gateway

reports the end of filling for each module with a TPDO2 containing the module number,

module status, and for example the dosed weight.

The third priority is the normal module scan. The Gateway continuously transmits TPDO1

with the status information for each module.

At a very low priority the Gateway looks for backplane modules that aren’t recorded as

active, in order to re-establish communication with modules that may have been restarted to

recover from failure.

The Gateway always informs the CAN controller when a module fails, or comes back online.

Page Manual MSC-64

8

2.3 CANopen

The CANopen Gateway follows the CAN2.0B recommendations. It receives both 11-bit

identifiers, and tolerates 29-bit identifiers. It only transmits 11-bit identifiers.

The Gateway is always quiet on the CANbus until the NMT Start command is received,

except for the very first ‘node guard’ message.

When started, the TPDO1 is used to send current status information. The backplane is

scanned approx. 10 times per second. This gives 64 modules X 10 = 640 status messages

per second if all 64 modules are installed. The TPDO1 holds the Gateway status, the module

number, the module status and either net or gross weight, depending on the SDO selection.

The default is the Gross value. When filling is in progress the Gateway transmits a TPDO2

every time a module changes state to ‘wait for trigger’. This TDPO2 contains the module

number, the module status and the dosed weight. In Check Weigher applications the

TPDO2 is used to send triggered measurements.

With RDPO1 frames you can send simple commands without an acknowledgement. The

functions are: select Gross or Net value in TPDO1, Set or Clear System zero, Set or Clear

Tare.

With RPDO2 frames you can send Triggers or Stop triggers. For the filling application the

trigger can be used to start the Filling Cycle. On checkweigher applications the trigger can

start measurements and a stop-trigger will stop further internal retriggers.

In case of an overrun, error or failure an EMERGENCY message is sent to the CAN

controller indicating the nature of the error or failure.

EMERGENCY messages are transmitted when the CAN controller tries to set up a module

not present, or not functioning, or when a module fails to answer the normal backplane scan

or when a module comes back on-line.

RPDO3 and RPDO4 are ignored by the Gateway.

SDOs are handled according to profile and CANopen recommendation.

The NMT protocol will use the ‘node guarding’ method (no heartbeat), but are otherwise fully

implemented

The “SDO Block Download Protocol” may be implemented later.

Manual MCS-64 Page 9

3 CANopen profile

3.1 The PDOs

The status is sent constantly to the CAN controller. The TPDO1 is sent up to 320 times per

second. This has to cover all installed modules. With a 64 LDM installation this gives 5

measurement per second per LDM, a 32 LDM installation will give 10 measurements per

second per LDM. Speed could be increased with a 16 LDM installation to 20 measurements

per second per LDM (only possible with special firmware for Gateway).

The TPDO2 is sent every time a LDM finishes a filling cycle. It has the same format and

fields as the TPDO1 except it contains the DOSED NET weight.

The format of the TPDO1 and TPDO2 is:

32 bit 16 Bit 8 bits 8 Bit

Weight Module Status Module number Gateway

State

The first field is a single precision float value containing weight information,

Gross or Net values if it is a TDPO1, and the Dosed NET weight if it is a TPDO2.

The next 16 bit field contains the module status as described below:

$0001 - Under range,

$0002 - Over range,

$0004 - Not within Zero range (not yet implemented, zero),

$0008 - Exactly zero,

$0010 - No motion, still stand, steady state,

$0020 - Tare set,

$0040 - Preset tare (0=tare is measured, 1=tare is set by user),

$0080 - Invalid weighing (wire-break, A/D ref. out of range),

$0100 - Set-point 0 (source>limit),

$0200 - Set-point 1,

$0400 - Set-point 2,

$0800 - Set-point 3,

$1000 - Filling in progress,

$2000 - Filling has completed.

$4000 - Average ready,

$8000 - Cold start.

Module number is the module (LDM) from which the data originates (0..63).

Gateway state is the state of the CANopen Gateway itself. This field is formatted as

follows:

2 bit 2 Bit 4 Bit

cmd resp reserved

“cmd” is a modulo-4 counter that increments every time a command is received i.e.

every time a SDO is received by the Gateway. If the completion of the SDO setting

requires communication with a LDM on the backplane the user can monitor the “resp”

field to determine when the LDM has acknowledged the command.

“resp” is a modulo-4 counter that increments when a command has been processed

(and a result can be fetched). If a SDO has been received, it indicates when the

Gateway has finished processing the SDO.

Page Manual MSC-64

10

The CANopen SDOs is a confirmed service, and overrun does not occur if the CAN controller

only communicates with the Gateway in the PRE-OPERATIONAL state. When a SDO has

been received by the controller no further communication takes place until the service has

been acknowledged (or a timeout occurs). However, other types of communication may fill

the Gateways internal buffer storage. In this event, the Gateway will issue an Overrun

Emergency message.

3.2 Communication Profile

The parameters which are critical for communication are determined in the communication

profile.

This includes the data for manufacturer's product nomenclature, for identification, or the

parameters for object mapping.

Abbreviations used in Tables:

ro read only

rw read / write

wo write only

(read will not be regarded as an error, but returns undefined results)

UI8 Unsigned8

UI16 Unsigned16

UI32 Unsigned32

I32 Signed32

REAL32 32 bit IEEE754 floating point

VS Visible String

3.3 Object Directory

The object directory of the CAN communication module is described below:

Please look the following pages.

Manual MCS-64 Page 11

Communication Profile (Tables)

Index Sub-

index

Name Type Attri-

bute

Default-value Meaning

1000 0 Device Type UI32 ro 00030191H Device Type

<TBD>

1001 0 Error Register UI8 ro 0 0: No error

Bit 0: General error in Gateway Module

Bit 4: Error in CAN communication module

Bit 7: Manufacturer-specific error

1005 0 COB-ID Sync messg. UI32 rw 80H COB-ID of the SYNC object

1006 0 Communication cycle

Period

UI32 ro 3125 320 Hz TDPO1 rate (3125 uS)

100C 0 Guard Time UI16 rw 320 Cycle time in ms, set by the NMT Master or the configuration tool.

Index 100Ch and 100Dh are used if index 1017h is ero.

100D 0 Life Time Factor UI8 rw 3 Wait time is set by the NMT Master or the configuration tool.

100E 0 Node guarding identifier UI32 ro 0x700 +

NodeID

Node guarding identifier

1010 0

1

2

Number of elements

Save all

Save communication

UI8

UI32

UI32

ro

rw

rw

2

0

0

Number of Store parameters entries

Save everything that can be saved

Same as sub 01 but only CAN com. parameters are saved

1014 0 COB-ID Emergency

Message

UI32 ro 80H + NodeID

COB-ID of the Emergency Object

1017

0 Heartbeat Time UI16 rw 0 Producer Heartbeat time in ms. If index 1017h is non-zero the Heartbeat

protocol is used, otherwise the Node-guard protocol is used.

1018 0

1

2

3

4

Identity Object

Vendor ID

Product Code

Revision Number

Serial Number

UI8

UI32

UI32

UI32

UI32

ro

ro

ro

ro

ro

4 Number of entries

Vendor ID

Product Code

Revision Number

Serial Number

Manual MCS-64 Page 12

Index Sub-

index

Name Type Attri-

bute

Default-value Meaning

1400

0

1

2

Number of elements

COB-ID

Transmission type

UI8

UI32

UI8

ro

ro

ro

2

200H +

NodeID

FFH

Communication parameters of 1st Receive PDO

Determined using the CANopen minimum system ID assignment

procedure.

Asynchronous communication.

1401 0

1

2

Number of elements

COB-ID

Transmission type

UI8

UI32

UI8

ro

ro

ro

2

300H +

NodeID

FFH

Communication parameters of 2

nd

Receive PDO

Determined using the CANopen minimum system ID assignment procedure.

Asynchronous communication.

1402 0

1

2

Number of elements

COB-ID

Transmission type

UI8

UI32

UI8

ro

ro

ro

2

80000400H +

NodeID

FFH

Communication parameters of 3

rd

Receive PDO

Determined using the CANopen minimum system ID assignment procedure.

Asynchronous communication.

1403 0

1

2

Number of elements

COB-ID

Transmission type

UI8

UI32

UI8

ro

ro

ro

2

80000500H +

NodeID

FFH

Communication parameters of 4

th

Receive PDO

Determined using the CANopen minimum system ID assignment procedure.

Asynchronous communication.

1600

0

1

2

Entries in Rx PDO 1

1

st

Object: LDM #

2

nd

Object Cmd. Byte.

UI8

UI32

UI32

ro

ro

ro

2

20060108

20060308

Mapping parameters of the 1

st

Receive-PDO

Object is a bitwise command

:

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Cmd: SnG SnN ST RT SZ RZ

1601

0

1

2

Entries in Rx PDO 2

1

st

Object: LDM #

2

nd

Object Cmd. Byte.

UI8

UI32

UI32

ro

ro

ro

2

20060108

20060408

Mapping parameters of the 2

nd

Receive-PDO

Object is a bitwise command

:

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Cmd: TR TS

1602

0 Number of mapped

Entries in Rx PDO 3

UI8 ro 0 Mapping parameters of the 3

rd

Receive- PDO (disabled)

1603

0 Number of mapped

Entries in Rx PDO 4

UI8 ro 0 Mapping parameters of the 4

th

Receive-PDO (disabled)

Manual MCS-64 Page 13

Index Sub-

index

Name Type Attri-

bute

Default-value Meaning

1800

0

1

2

3

Number of elements

COB-ID

Transmission type

Inhibit Time

UI8

UI32

UI8

UI16

ro

rw

rw

rw

3

180H +

NodeID

FFH

10

Communication parameters of 1

st

Transmit PDO

Determined using the CANopen minimum system ID assignment procedure.

Asynchronous communication.

Transmit inhibit time of PDO in 100 µs steps. A repeated transmission of the

PDO is prevented within the defined interval of the inhibit time.

Cyclic sending of PDO value (default 640 times / sec.)

1801

0

1

2

3

Number of elements

COB-ID

Transmission type

Inhibit Time

UI8

UI32

UI8

UI16

ro

rw

rw

rw

3

280H +

NodeID

FFH

10

Communication parameters of 2

nd

Transmit PDO

Determined using the CANopen minimum system ID assignment procedure.

Asynchronous communication.

Transmit inhibit time of PDO in 100 µs steps. A repeated transmission of the

PDO is prevented within the defined interval of the inhibit time.

Event based sending of PDO value (when a dosed value is present)

1802

0

1

2

3

Number of elements

COB-ID

Transmission type

Inhibit Time

UI8

UI32

UI8

UI16

ro

rw

rw

rw

3

380H +

NodeID

FFH

10

Communication parameters of 3

rd

Transmit PDO

Determined using the CANopen minimum system ID assignment procedure.

Asynchronous communication.

Transmit inhibit time of PDO in 100 µs steps. A repeated transmission of the

PDO is prevented within the defined interval of the inhibit time.

Event based sending of PDO value (when Rx PDO 3 has been processed by

the system)

1803

0

1

2

3

Number of elements

COB-ID

Transmission type

Inhibit Time

UI8

UI32

UI8

UI16

ro

ro

ro

ro

3

80000480H +

NodeID

FFH

10

Communication parameters of 4

th

Transmit PDO

Determined using the CANopen minimum system ID assignment procedure.

Asynchronous communication.

Transmit inhibit time of PDO in 100 µs steps.

(not used, will not be transmitted)

Manual MCS-64 Page 14

Index Sub-

index

Name Type Attri-

bute

Default-value Meaning

1A00

0

1

2

3

4

Number of mapped

Entries in Tx PDO 1

1

st

Object

2

nd

Object

3

rd

Object

4

th

Object

UI8

UI32

UI32

UI32

UI32

ro

ro

ro

ro

ro

8

20000220H

20020110H

20020208H

20020308H

Mapping parameters of the 1

st

Transmit-PDO

32 bit IEEE754 floating point weight value.

Module Status

Module ID [0...63]. The current module scanned.

Gateway Status

1A01

0

1

2

3

4

Number of mapped

Entries in Tx PDO 2

1

st

Object

2

nd

Object

3

rd

Object

4

th

Object

UI8

UI32

UI32

UI32

UI32

ro

ro

ro

ro

ro

8

20010420H

20020110H

20020208H

20020308H

Mapping parameters of the 2

nd

Transmit-PDO

32 bit IEEE754 floating point, default: dosed net value.

Module Status

Module ID [0..63]. The current module scanned.

Gateway Status

1A02

0 Number of mapped

Entries in Tx PDO 3

UI8 ro 0 Mapping parameters of the 3

rd

Transmit- PDO (disabled)

1A03

0 Number of mapped

Entries in Tx PDO 4

UI8 ro 0 Mapping parameters of the 4

th

Transmit-PDO (disabled)

Manual MCS-64 Page 15

Index Sub-

index

Name Type Attri-

bute

Default-value Meaning

2000

0

1

2

3

4

5

6

Number of entries

Gross weight

Net Weight

Tare

Dosed weight

Dosed tare

Average weight

UI8

REAL32

REAL32

REAL32

REAL32

REAL32

REAL32

ro

ro

ro

ro

ro

ro

ro

6

Number of entries in command input array.

Weight values as 32 bit IEEE754 floating point.

2001

0

1

2

3

4

5

6

7

8

9

10

11

Number of entries

Gross weight

Net Weight

Tare

Dosed weight

Dosed tare

Average weight

A/D sample

H&B Device ID

H&B FW Version

Device Status

ADC Reference

UI8

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

ro

ro

ro

ro

ro

ro

ro

ro

ro

ro

ro

ro

11

Number of entries in info array.

Weight and info values as 32 bit signed integer

2002

0

1

2

3

Number of entries

1

st

Object

2

nd

Object

3

rd

Object

UI8

UI16

UI8

UI8

ro

ro

ro

ro

4

Number of objects in the dosed result.

Module Status

Module ID [0...63]. The module that finished a filling cycle.

Gateway Status

2003

0

1..16

Number of entries

Hardware ID bytes

UI8

UI8

ro

ro

16

Number of bytes in hardware identification array.

Manual MCS-64 Page 16

Index Sub-

index

Name Type Attri-

bute

Default-value Meaning

2004

0

1

2

3

4

5

6

Number of entries.

Save:

Analog output

Calibration

General set-up

Dosing parameters

Set-points

Loss in Weight

UI8

UI8

UI8

UI8

UI8

UI8

UI8

ro

wo

wo

wo

wo

wo

wo

5

LDM #

LDM #

LDM #

LDM #

LDM #

LDM #

Number of parameters.

Save LDM settings (Valid LDM # is [0..63].)

save analog output parameters,

save calibration settings,

save general set-up parameters,

save dosing setup parameters,

save set-point parameters.

save loss in weight parameters

2005

0

1

2

3

Number of entries

START filling process

ABORT filling process

TRIG filling cycle

UI8

UI8

UI8

UI8

ro

wo

wo

wo

3

LDM #

LDM #

LDM #

START filling process

ABORT filling process

TRIG the next filling cycle

2006

0

1

2

3

4

Number of entries

LDM select [0..63]

Factory Default

Direct command 1

Direct command 2

UI8

UI8

UI8

UI8

UI8

ro

wo

wo

wo

wo

4

LDM#

LDM#

Number of system entries.

Restores the factory defaults, if the TAC is enabled.

Direct bitwise command byte 1 to LDM

Direct bitwise command byte 2 to LDM

Commands bits are:

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Byte1 SnG SnN ST RT SZ RZ

Byte2 TR TS

Sng,SnN: select Gross or Net in PDO1(tx),

ST,RT: Set/Reset Tare,

SZ,RZ: Set/Reset Zero,

TR: Software trigger.

TS: Trigger Stop; stop triggered measurement(s).

2007

0

1

2

3

Number of entries

CAN speed

CAN address

LDM Scan end

UI8

UI8

UI8

UI8

ro

rw

ro

rw

1

2

DIP-SW

15

CAN parameters (changes take effect after restart)

1=1Mbit; 2=500Kbit; 3=250Kbit; 4=125Kbit; 5=50Kbit.

The CANopen address. (DIP-SW on MCS-64)

Last LDM module to include in the scan (default: 16 LDM modules).

Manual MCS-64 Page 17

Index Sub-

index

Name Type Attri-

bute

Default-value Meaning

2100 -

213F

for

LDM

0..63

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Number of entries.

1

st

Parameter

2

nd

Parameter

3

rd

Parameter

4

th

Parameter

5

th

Parameter

6

th

Parameter

7

th

Parameter

8

th

Parameter

9

th

Parameter

10

th

Parameter

11

th

Parameter

12

th

Parameter

13

th

Parameter

14

th

Parameter

15

th

Parameter

16

th

Parameter

17

th

Parameter

18

th

Parameter

19

th

Parameter

UI8

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

ro

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

19 Number of parameters.

Analog source

Analog high

Analog low

Filter setting

Filter Factor

Digital Outputs

Digital Inputs

Measuring Time

Filter mode

No-motion range

No-motion time

Digital outputs mask

Tare

Start Delay

Trigger Edge

Trigger Level

Update rate

Zero track (TAC protected)

∆Time

21FF

0

Number of entries.

As for 2100-2163

UI8 wo

Number of general parameters.

As for 2100 – 213F, except this is WRITE ONLY and the settings are

broadcasted to all LDMs.

Manual MCS-64 Page 18

Index Sub-

index

Name Type Attri-

bute

Default-value Meaning

2200 -

223F

for

LDM

0..63

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Number of entries.

1

st

Parameter

2

nd

Parameter

3

rd

Parameter

4

th

Parameter

5

th

Parameter

6

th

Parameter

7

th

Parameter

8

th

Parameter

9

th

Parameter

10

th

Parameter

11

th

Parameter

12

th

Parameter

13

th

Parameter

14

th

Parameter

15

th

Parameter

16

th

Parameter

17

th

Parameter

18

th

Parameter

19

th

Parameter

20

th

Parameter

21

st

Parameter

UI8

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

ro

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

19 Number of filling parameters.

Pre-fill mode

Correction factor for in-flight value in percent. Range: 0..50.

Zero check average time (in milliseconds)

Tare delay (in milliseconds)

Tare average time (in milliseconds) 0= Tare off

Delay after pre-fill (in milliseconds).

Blanking time (in milliseconds) after coarse valve shuts OFF

In-flight delay time (in milliseconds)

Dosed weight average Time (in milliseconds)

Zero tolerance (in increments).

Tare reference (in increments).

Tare tolerance (in increments).

Pre-fill level (in increments). Set-point for 1

st

pre-filling.

Fine-fill weight (in increments)

Filling weight (in increments).

In-flight value (in increments).

Pre-fill level (in increments). Set-point for 2

nd

pre-filling.

Fill timeout value (in milliseconds)

Underweight post fill time

Tare interval – the number of fillings per tare measurements

Bad rupture blanking

22FF

0

Number of entries.

As for 2200-2263

UI8

Ro

wo

17 Number of filling parameters.

As for 2200 – 223F, except this is WRITE ONLY and the settings are

broadcasted to all LDMs.

Manual MCS-64 Page 19

Index Sub-

index

Name Type Attri-

bute

Default-value Meaning

2300 -

233F

for

LDM

0..63

0

1

2

3

4

5

6

7

8

9

10

11

12

Number of entries.

Absolute gain

Absolute zero

Calibrate enable

Calibrate gain

Set calibration point B

Set calibration point A

Calibrate max

Calibrate min

Calibrate save

Calibrate zero

Decimal point

Display step size

UI8

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

I32

ro

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

rw

12 Number of calibration parameters.

Absolute gain calibrate (TAC protected)

Absolute zero calibrate (TAC protected)

Calibrate enable (enables TAC when the TAC is written)

Calibrate gain (TAC protected)

Set calibration point B

Set calibration point A

Calibrate max (TAC protected)

Calibrate min (TAC protected)

Calibrate save (TAC protected)

Calibrate zero (TAC protected)

Decimal point (TAC protected)

Display step size (TAC protect)

23FF

0

Number of entries.

As for 2300-233F

UI8

ro

wo

12 Number of calibration parameters.

As for 2300 – 233F, except this is WRITE ONLY and the settings are

broadcasted to all LDMs.

Manual MCS-64 Page 20

Index Sub-

index

Name Type Attri-

bute

Default-value Meaning

2400 -

243F

for

LDM

0..63

0

1

Number of entries

Dose Info

UI8

UI16

ro

ro

1

Read the dose info:

Bit value Meaning

$0001 Coarse valve open

$0002 Fine valve open

$0004 Dose program running

$0008 Not used

$0010 Not used

$0020 Not used

$0040 Tare out of range – no filling in this cycle

$0080 Zero out of range

$FF00 The High byte has the following interpretation:

- 00= Idle

- 01= Waiting for trigger(2

nd

trigger)

- 02= Bottle on, calculating tare

- 03= Pre-fill

- 04= Main Filling

- 05= Fine Filling

- 06= In-flight delay

- 07= Post fill calculations

- 08= Post Filling

Table of contents

Other Flintec Media Converter manuals

Popular Media Converter manuals by other brands

H&B

H&B TX-100 Installation and instruction manual

Bolin Technology

Bolin Technology D Series user manual

IFM Electronic

IFM Electronic Efector 400 RN30 Series Device manual

GRASS VALLEY

GRASS VALLEY KUDOSPRO ULC2000 user manual

Linear Technology

Linear Technology DC1523A Demo Manual

Lika

Lika ROTAPULS I28 Series quick start guide

Weidmuller

Weidmuller IE-MC-VL Series Hardware installation guide

Optical Systems Design

Optical Systems Design OSD2139 Series Operator's manual

Tema Telecomunicazioni

Tema Telecomunicazioni AD615/S product manual

KTI Networks

KTI Networks KGC-352 Series installation guide

Gira

Gira 0588 Series operating instructions

Lika

Lika SFA-5000-FD user guide