Flomec OM025 User manual

IMOMMED-0907

I N S T R U C T I O N M A N U A L

Models : OM025, OM040 & OM050

Flomec

Factory

1 / 19 Northumberland Road,

Caringbah NSW 2229, Sydney

AUSTRALIA

tel : +61 2 9540 4433

fax : +61 2 9525 9411

website : www.flomec.com.au

USA

916 Belcher Drive

Pelham, AL 35124

USA

Tel : +1 205 378 1050

Fax : +1 205 685 3001

Email : customerservice@trimecus.com

Website : www.

trimecus

.com

Distributed by:

Each meter has been calibrated on mineral oil

and will contain a small amount of oil residue.

The oil used is Castrol Diesel Calibration

Fluid 4113 (product code 055830).

Medium capacity positive displacement flowmeters

OVAL GEAR

SEE OVER

I

M

P

O

R

T

A

N

T

1 Index / contents

1.0 General Page

1.1 Overview 2

1.2 Operating principal 2

1.3 Model number information 3

1.4 pecifications 4

2.0 Installation

2.1 Mechanical installation 5

2.1.1 Orientation 5

2.1.2 Flow conditioning & locations 6

2.2 Electrical installation 6

2.2.1 Instrument cable 6

2.2.2 Hazardous area wiring 7

2.3 Pulse output selection for pulse meters 7

2.3.1 Hall sensor pulse output 7

2.3.2 Reed switch pulse output 7

2.3.3 Quadrature pulse output 8

2.3.4 ignal integrity verification 8

2.3.5 Bi-directional flow 8

2.4 Meters fitted with integral instruments 9

2.4.1 Meter calibration factor (K-factor or scale Factor) 9

3.0 Commissioning 10

4.0 Maintenance 10

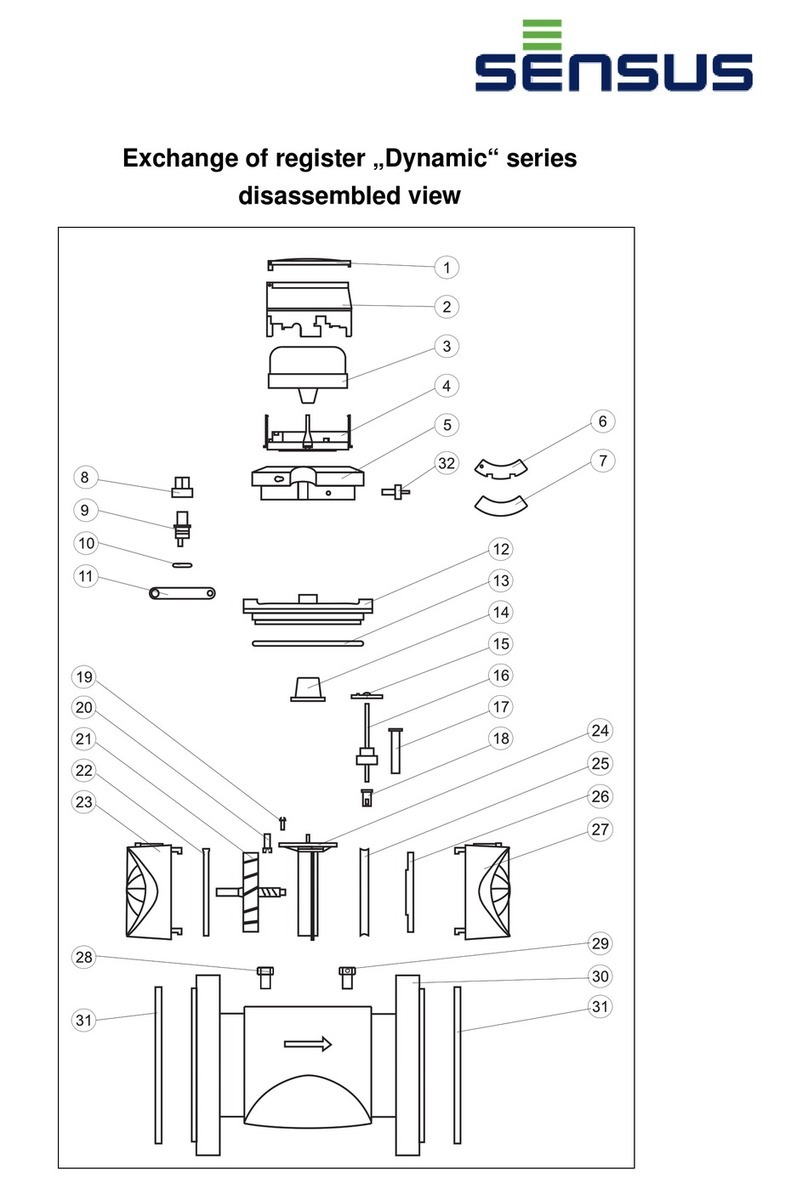

4.1 Disassembly of pulse meter 11

4.2 Disassembly of meters fitted with an instrument 11

4.3 Exploded view & spare parts 11 & 12

4.4 Inspection & exploded view 13

4.5 Re-assembly of meter 13

5.0 Fault Finding 14

5.1 Trouble shooting 15

General 2

General

1.1 Overview

The Oval gear meter is a precise positive displacement flowmeter incorporating a pair of oval geared rotors. These

meters are capable of measuring the flow of a broad range of clean liquids.

tainless teel flowmeters are suited to most water based products and chemicals and aluminum meters are

suitable for fuels, fuel oils & lubricating liquids.

The flowmeter is available as a blind meter with pulse output capable of interfacing to most monitoring and control

instrumentation or the meter can be fitted with or supplied with instruments such as totalisers, rate totalisers or

batch controllers.These instruments also have monitoring and control output options including 4-20mA, scaled

pulse, flowrate alarms and batch control logic (preset metering).

If your flowmeter is fitted or supplied with an instrument please also refer to the relevant instrument instruction

manual.

These flowmeters can be installed within hazardous areas by using the reed switch pulse output in Intrinsically

afe loops or fitting Intrinsically afe certified Instruments. Please consult the factory for the availability of

flameproof models.

1.2 Operating rinciple

The Oval gear are positive displacement flowmeters where the passage of liquid causes two oval geared rotors to

rotate within a precision measuring chamber and with each rotation a fixed volume of liquid is displaced passing

through the meter. Magnets embedded within the rotors initiate a high resolution pulse train output. The pulse

output can be wired directly to process control and monitoring equipment or can be used as an input to

instruments supplied with or fitted directly to the meter.

The benefits of this technology allow precise flow measurement and dispensing of most clean liquids irrespective

of their conductivity, with other liquid characteristics having nil or minimal effect on meter performance. This

metering technology does not require flow profile conditioning as required with alternative flow technologies

making the installation relatively compact and low cost.

O ERATION :

Liquid travels around the crescent

shaped chambers created by the

rotational movement of the rotors

l

iquid exits the

measuring chamber

liquid in transit

flow

l

iquid entering

measuring chamber

Model number information 3

pecifications 4

Model coding

15mm ( 1/2" )

25mm ( 1" )

40mm ( 11/2" )

50mm ( 2" )

Body material

AAluminum

S316 Stainless Steel

HHigh pressure stainless

Rotor material

Aluminum

Stainless steel

9Application specific

Bearing type

1Ceramic ( SS rotors )

4Hardened steel roller bearings ( Alum. rotors )

O-ring material

1Viton ( standard ) -15~+200ºC [ -5~+400ºF ]

2Ethylene Propylene Rubber -150ºC (300ºF) max.

3Teflon encapsulated viton

-150ºC (300ºF) max.

4Buna-N (Nitrile) -65~+100ºC (-53~+212ºF)

Temperature limits

-2120ºC ( 250ºF ) - see note 1

-5120ºC ( 250ºF ) - see note 2

Process connections

1BSP female threaded

2NPT female threaded

4ANSI-150 RF flanges

5ANSI-300 RF flanges

6PN16 DIN flanges

9Customer nominated

Cable entries

Code O with mechanical register options 03~6mm cable gland (B2/B3 options)

1M20 x 1.5mm

21/2" NPT

M o d e l N o. E x a m p l e

A 4 1 - 5 1 1 R2

Integral options

QP Quadrature pulse output

E1 Explosion proof ~ Exd

Q1 Exd with Quadrature pulse

B2 BT11 dual totaliser

B3 Intrinsically safe BT11 (I.S.)

R2 RT12 Flow Rate Totaliser

R3 Intrinsically safe

RT12

(I.S.)

E0 EB10 batch controller

M* = M1 litres, M2 gallons M* 3 digit mechanical reset totaliser

M* = M3 litres, M4 gallons M* 4 digit mechanical reset totaliser

SB Specific build requirement

(1) 120ºC (250ºF) rating of the pulse meter, 80ºC (180ºF) rating with BT, RT & EB options.

See temperature code 5 for higher temperature with BT, RT, & EB

(2) Cooling fin is fitted with integral instruments for operation between 80~120ºC (180~250ºF)

consult factory

OM015

OM025

4

5

IECEX & ATEX approved

flow rate, totals & all outputs

OM025

2 NPN open collector phased outputs

4

dc 2 stage batch controller

OM040

OM050

accum. & reset totals, pulse output

IECEX & ATEX approved

IECEX & ATEX approved

IECEX & ATEX approved

Specifications

Model prefix : OM015 OM025 OM040 OM050

Nominal size ( inches )

15mm

(1/2")

25mm

(1")

40mm

(11/2")

50mm

(2")

* Flow range ( litres / min ) 1 ~ 40 10 ~ 150 15 ~ 250 30 ~ 450

* Flow range ( SGM ) 0.26 ~ 10.6 2.6 ~ 40 4 ~ 66 8 ~ 120

Accuracy @ 3cp

Repeatability

Temperature range

Maximum pressure ( threaded meters )

aluminium 68 ( 1000 ) 68 ( 1000 ) 30 ( 440 ) 20 ( 300 )

316L stainless 100 ( 1500 ) 100 ( 1500 ) 100 ( 1500 ) 38 ( 560 )

high pressure stainless refer factory for options

Protection class

Recommended filtering

(minimum)

150 microns ( 100 mesh ) minimum

Electrical - for pulse meters (see also optional outputs)

Output pulse resolution : pulses / litre ( pulses / US gallon ) - nominal

Reed switch 83 ( 314 ) 27 ( 102 ) 13 ( 50 ) 6.5 ( 25 )

Hall effect 166 ( 628 ) 107 ( 405 ) 52.6 ( 200 ) 26 ( 99 )

Quadrature Hall option 166 ( 628 ) 53.5 ( 203 ) 26.3 ( 100 ) 13 ( 50 )

Reed switch output

Hall effect output (NPN)

Optional functions

Display flowrate, total (accumulative & resettable)

Preset batching 1 & 2 stage high speed batch control

IP65 3 digit reset mechanical totaliser 999.9 ltr/gal 9999 litres or gallons

IP65 4 digit reset mechanical totaliser 9999.9 ltr/gal 99999 litres or gallons

Mechanical Accum. totaliser capacities M1 & M2 (6 digit), M3 & M4 (8 digit)

Optional outputs

Flow 4 ~ 20mA, high & low flow rate alarms

Pulse scaled pulse (programmable) , pulse amplifier

* Maximum flow is to be reduced as viscosity increases, max. pressure drop 100Kpa (15psi)

± 0.5% of reading ( ± 0.2% with optional RT12 )

typically ± 0.03%

3 ire open collector, 5~24Vdc max., 20mA max.

30Vdc x 200mA max. (max. temp. shock 10ºC (50ºF) / min)

* Maximum flow on fuels may be maintained for intermittent periods of refuelling.

IP66/67 (NEMA4X), optional Exd IIB T6 or I.S.

-20ºC ~ +120ºC ( -4ºF ~ +250ºF )

bar ( PSI )

Installation 5

2.0 Installation

2.1 Mechanical Installation Prior to installing the meter check :

# The fluid is compatible with the meter materials of construction using appropriate information such as fluid

compatibility charts and site experience.

# Application and process conditions are compatible with the meter specifications. Minimum and max. flows are

within the meter specified range including any in-situ cleaning processes. When metering viscous liquids the

maximum allowable flow may need to be reduced to ensure the pressure drop across the meter does not exceed

100 kPa (1 Barg, 15 PSIG)

# Process temperature and pressure does not exceed meter ratings.

# The meter is not exposed to process temperatures and pressures that will cause the liquid medium to gasify

(flash) within the meter.

2.1.1 Orientation

The flowmeter MU T be mounted so that the rotor shafts are in a horizontal plane. This is achieved by mounting

the meter so that the terminal cover or integral instrument display, whichever is fitted, is facing in a horizontal

direction. Note the terminal cover or instrument display can be rotated in 90 degree increments to provide access to

the electrical entry and to allow the display orientation to suit the installation.

The meter will operate in the alternative orientation, however, it is likely its life & performance will be reduced as a

result of the gravity pull on the rotors.

Liquid can flow into the meter from either a horizontal or vertical direction. For vertical flow installations the most

common orientation is for the liquid to rise through the meter (i e travel from bottom to top) to assist in air or

entrained gas elimination. The meter operation is independent of the liquid flow direction thus there is no markings

for inlet or outlet.

6 Installation

2.1.2 Flow Conditioning and Locations

Strainer : It is recommended to IN TALL a 100mesh (150 micron) strainer immediately upstream of (prior to) the

meter. trainers are available from the factory.

Flow conditioning : The flowmeter does not require any flow conditioning, therefore straight pipe runs before or

after the meter are not required. If required, the pipe size about the meter can be altered to suit the installation.

Locations : The flowmeter is preferred to be fitted upstream of any flow control and/or shut off valve, this prevents

free discharge from the meter and minimizes the risk of drainage and air entrapment which can result in erroneous

readings or damage the meter on start up.

Process or safety critical meters should be installed in a by-pass section of pipe with isolation valves to enable the

meter to be isolated and serviced as required. A by-pass installation also allows purging of the system during

commissioning (see Commissioning).The meter must be appropriately rated and is typically located downstream

(on the discharge side) of the pump.

If mounted outdoors ensure a suitable watertight gland or plug is used to seal any open electrical entries. In humid

environments take precautions to avoid condensation build up within the electrical and/or instrument enclosure. It

is good wiring practice for conduits to be connected from the bottom of an entry port, in this way condensation will

gravitate away from any terminal housing.

Fluid state : Fluid entering the meter must remain a liquid at all times so protect the meter to avoid solidification or

gelling of the metered medium. If meters are to be trace heated or jacketed in any way the maximum temperature

rating of the meter must not be exceeded. ize the meter to avoid gasification of volatiles (flashing) within the

liquid due to the pressure drop experienced within the system or within the meter.

Hydraulic shock : If pressure surges or hydraulic shock of any kind is possible, the system upstream of the meter

must be fitted with a surge suppressor or pressure relief valve to protect the meter from damage. High frequency

flow pulsations can damage the meter. uch pulsations can be caused by the injection profile in diesel engines.

Most pulsations are removed with the installation of a suitable pulsation dampener.

2.2 Electrical Installation

2.2.1 Instrument Cable Twisted pair low capacitance shielded instrument cable 7 x 0.3mm (0 5mm2) should

be used for electrical connection between the flowmeter and remote instrumentation. The cable screen should be

earthed at the readout instrument only to protect the transmitted signal from mutual inductive interference.

The cable should not be run in a common conduit or parallel with power and high inductive load carrying cables as

power surges may induce erroneous noise transients onto the transmitted pulse signal or cause damage to the

electronics. Run the cable in separate conduit or with other low energy instrument cables. The maximum

transmission distance is typically 1000m (3300 Ft)

I N C O R R E C T

When i

nstalled incorrectly the weight

of the rotors will bear down on the

base of the measuring chamber.

C O R R E C T O R I E N T A T I O N S

Installation 7

2.2.2 Hazardous area wiring Intrinsically safe wiring including using the reed switch pulse output as simple

apparatus, wiring to an Intrinsically afe Instrument or wiring to the Exd explosionproof option( Exd IIB T4/T6 )

wiring techniques must be undertaken in accordance with the rules, regulations and requirements applying to the

territory in which the meter is being installed. The meters should only be connected by qualified staff, the qualified

staff must have knowledge of protection classes, regulations & provisions for the apparatus in hazardous areas.

If the flowmeter is fitted with an intrinsically safe instrument refer to the appropriate manual & I. . supplement for

wiring of the instrument inputs and outputs.

Earthing lugs are located within the terminal housing cover and on the meter body. Use a separate earth within the

cable making sure that the earth conductor does not come in contact with the cable shield / screen.

Use only high temperature cable at the flowmeter when the process temperature exceeds 85ºC.

2.3 ulse Output selection for pulse meters Two types of output are available on each meter, open collector

from Hall Effect sensors or reed switch contact. Each output type is linearly proportional to volumetric flow and each

pulse is representative of an equal volume of liquid.

2.3.1 Hall Effect Sensor ulse Output The Hall Effect ensor is a solid state 3 wire device providing a NPN

open collector output. It requires a dc voltage between 5~24Vdc to operate and is the recommended pulse output

for powered installations such as local or remote batching.

The pulse output between signal and -0V is a voltage square wave with the high level being the dc voltage

available at the open collector and the low level being -0V.

The receiving instrument must incorporate a pull up resistor ( typically greater than 10K ohms in most instruments )

which ties the open collector to the available dc voltage level when the Hall sensor is not energized. When

energized the open collector output is pulled to ground through the emitter (-0V).

2.3.2 Reed Switch ulse Output The reed switch output is a two wire normally open P T voltage free contact

ideal for installations without power or for use in hazardous area locations when Intrinsically afe (I. .) philosophy

is adopted. Note: when using the reed switch output the liquid temperature must not change at a rate greater than

10ºC per minute (50ºF per minute). In general the reed switch life will exceed 2 billion actuations when switching

less than 5Vdc @10mA as is the case when combined with the RT, EB or BT instruments.

8 Installation

2.3.3 Quadrature (QUAD) ulse Output The diagrams below apply when the meter is fitted with the

Quadrature pulse output option (two Hall Effect sensors arranged to give separate outputs out of phase with

one another)

The Quadrature output is typically suited to custody transfer applications where signal integrity verification is

required, it is also used for metering bi-directional flow.

2.3.4 Signal integrity verification Many fiscal transactions require the primary measuring device (flowmeter)

to have Quadrature outputs in order to detect any difference in the number of pulses from each input

( from & ) during delivery.

2.3.5 Bi-directional flow Combining the Quadrature feature and model PD1 pulse discriminator module

produces forward & reverse outputs both of which may be integrated to provide a “net” reading. The RT12 flow

rate totaliser will take both output & will perform the “net” flow function.

1

2

phase shift between

outputs

Quadrature

Pulse Output

1

2

common

to

1 & 2

VDC

+

0V

-

QUAD

NPN HALL EFFECT

REED Sw.

VDC

+

0V

-

QUAD

NPN HALL EFFECT

REED Sw.

Hall Effect NPN

open collector

Reed witch

contact closure

VDC

+

0V

-

QUAD

NPN HALL EFFECT

REED Sw.

PD1 Pulse

Discriminator

2

1

10

9

7

6

5

4

2

1

8~24Vdc

+

0V ground

-

Reverse flow

Forward flow

Installation 9

2.4 Meters fitted with integral Instruments If your flowmeter is fitted with an integral instrument such as a

totaliser, rate totaliser or batch controller then the pulse output from the meter has been factory wired to the flow

input of the readout instrument.

As a default the reed output is pre-wired and DIP switches set for a integral totaliser or rate/totaliser allowing self

powered operation of the instrument displays.

Also by default the open collector output from the Hall ensor is pre-wired and DIP switches set for a integral batch

controller allowing high speed, solid state operation of the model EB batch controller.

These defaults may vary at the customer request or for specific applications such as dual flow input or high or low

flow so if unsure remove the instrument bezel to check the wiring.

The output(s) and function(s) available from a meter fitted with an integral instrument depends on the model of the

instrument fitted and may include meter pulse repeater, prescaled pulse output, 4-20mA flow output, flowrate

alarms or single/dual stage batch control logic (preset controller)

Refer to the option in the meter model number and relevant instrument manual. Unless programming details were

provided at time of order the instrument program will contain factory default parameters. Integral instruments will

however be programmed with the relevant calibration factor (K factor or scale factor) for the meter.

Factory default settings can be found in the instrument instruction manual and it should be noted all output(s) are

turned OFF and if required need to be turned ON then programmed to suit the application requirements.

2.4.1 Meter Calibration Factor (K or scale Factor) Each flowmeter is individually calibrated and supplied with a

calibration certificate showing the number of pulses per unit volume (eg pulses per litre or pulses per USgallon)

Nominal figures are shown in the specification section of this manual.

Meters fitted with Integral Instruments will have the relevant calibration factor entered into the program of the

instrument. Please refer to relevant instrument manual for programming details.

10 Commissioning & Maintenance

3.0 Commissioning Once the meter has been mechanically and electrically installed in accordance with this

and any other relevant instrument manual(s) the meter is ready for commissioning.

The meter must NOT be run until the pipework is flushed of foreign matter, more often than not foreign matter is

present after pipework fabrication or modification, weld slag, grinding dust, sealing tape & compound &/or surface

rust are most common offenders.

Flushing can be undertaken by utilizing a by-pass or removing the meter from the pipework. If neither is practical

then the meter rotors must be removed prior to flushing (refer to Maintenance section of this manual for

disassembly)

After flushing or following long periods of shutdown the meter must be purged of air/vapour. This can be achieved

by allowing the liquid to flow through the meter at a slow rate until all air/vapour is displaced. Never run the meter

above its maximum flow or exceed 100kpa (1 bar, 15psi) pressure drop across the meter. Now the meter is ready

for its operation to be confirmed by ensuring correct indication or operation at the receiving instrument(s). Refer if

necessary to fault finding section of this manual.

4.0 Maintenance Adhering to the installation instructions in this manual should ensure your meter provides the

required operational performance. These are mechanical meters and a periodic maintenance and inspection

regime will maximize the operational availability of the meter.

The frequency of maintenance depends on the application factors including liquid lubricity and abrasiveness and

operational factors such as flowrate and temperature.

BEFORE undertaking meter maintenance ensure the following :

Associated alarm(s) or control output(s) are isolated so not to affect the process

Voltage supply is isolated from the meter

Liquid supply to the meter is closed off

The meter is depressurized and liquid drained from the meter

strainer

flowmeter

isolation valve

isolation valve

by-pass valve

Open downstream valve last

with

LCD

register

Maintenance 11

4.1 Disassembly of ulse meter (Refer Exploded View) If required to gain access to the meter terminals and

pulse output board, undo the 4 cap screws (10), remove the terminal cover (9) carefully to avoid putting strain on

the terminal connections. The pulse output board (6) can now be accessed and removed if necessary (screws 7).

If required to gain access to the oval geared rotors undo the 8 body screws (5), carefully pry the meter body apart

avoiding misplacing or damaging the O-ring (3) and rotors (2).

4.2 Dissassembly of meters fitted with an Instrument If the meter is fitted with an integral instrument the

instrument display assembly must be removed if required to gain access to the instrument terminal connections,

instrument battery or pulse output board. This is achieved by undoing the bezel screws and separating the display

assembly from its base. Do not stress or damage the wires that connect the display assembly to the meter output.

Take care not to misplace or damage O-ring(s).The pulse output board can now be accessed. To remove the pulse

output board, first undo the screws that fix the instrument base to the flowmeter.

12 Maintenance

4.3 SPARE PARTS

(refer to exploded view)

Item Description OM025 OM040 OM050

1 Body assembly with rotor shafts Part No.

aluminum 1401096 1401094 1401092

stainless steel 1401097 1401093

2 Rotor assembly set

aluminum rotors + bearings 1424071 1424111 1424099

stainless steel rotors + bearings 1424092 1424125 1524011

3Body O-ring (size BS153) (size BS245) (size BS253)

viton

( standard )

13031531

13032451

13032531

teflon 13031533 13032453 13032533

4 Meter cap

aluminum ith M20 conduit entry 1302047 1302160 1302088

aluminum ith 1/2" NPT conduit entry 1302164 1302161 1302167

stainless ith M20 conduit entry 1302165 1302166 1306025

stainless ith 1/2" NP T conduit entry 1302059 1302162 1306029

5 ap screw (M6 x 20) (M10 x 25) (M10 x 25)

stainless & aluminum bodies 130816103 130810104 130810104

6Pulse output board

standard pulse board 1412033 1412055 1412034

quadrature pulse board 1412039 1412040 1412040

7 Output board screw

M3 x 4 slot head 130803101

8Terminal cover O-ring

suit std. stainless cover

(BS132)

13031321

suit Exd aluminum cover

(BS032)

13030321

9 Terminal cover

IP66/67 standard cover

(SS)

1306030

Exd explosionproof cover

(alum.)

1306020-EX

10 Terminal cover screw

M5 x 16 130805101

11 Flange portion O-ring (size BS123) (size BS136) (size BS140)

viton 13031231 13031361 13031401

teflon 13031233 13031363 13031403

12 Flange portion screw (M8 x 25) (M10 x 30) (M10 x 30)

socket head 130808103 130810104 130810105

13 Flange portion refer diagram opposite

Recommended spare parts : Item 2 rotor assembly set

Item 3 body O-ring

Item 6 pulse output board

Maintenance 13

4.4 Inspection (refer Exploded View) Inspect O-rings for damage, chemical attack, deformity or any form of

deterioration.

Remove, inspect and clean the rotors, also check that the magnets have not been chemically attacked. Check the

measuring chamber for damage or scoring & redress if necessary, the rotor shafts should NOT be loose or able to

be rotated.

4.5 Re-assembly of meter (refer Exploded View) When re-installing the rotors all four magnets MU T be

visible when both rotors are in place. Both rotors will only engage correctly if fitted precisely at an orientation of 90

degrees to each other. Rotate the rotors slowly by hand to ensure they are correctly fitted at the same time check

the rotor shafts & rotor bearings for wear.

Fit the O-ring into the groove and assemble the two parts of the meter, the body & cap align with a location pin.

Fit the body cap screws (5) and tighten in a star sequence then torque in the same sequence to 3.5 Nm. This

sequence and procedure ensures the meter bodies are assembled correctly and evenly. Fit the pulse output board,

terminal cover or instrument as appropriate.

14 Fault finding

5.0 Fault Finding Pulse meters have two distinct sections: the mechanical wetted section housing the rotors

and the electrical section housing the pulse output board.

Meters fitted with integral instruments have these two sections plus the instrument.

The aim of fault finding is to trace the source of the fault to one of these sections.

If a fault is traced to an instrument section, refer to the relevant instruction manual.

Below are basic fault finding steps. Also refer to Trouble hooting Guide on following page.

Step 1 - Check application, installation and set up

Refer to Mechanical Installation section for installation and application factors that may effect the meter operation

including pulsation and air entrainment or incorrect meter selection including incorrect flow rate, temperature and

pressure or materials compatibility. Refer to Electrical Installation for correct wiring.

Step 2 - Check for blockages

The most common cause of fault/unsatisfactory meter operation, particularly for new or altered installations, is due

to blockage within the system or meter caused by foreign particles such as weld slag, sealing tape or compound,

rust, etc.

Step 3 - Ensure flow is present

No flow or lower than normal minimum flow may be attributed to a blocked strainer, jammed or damaged rotors

within the flowmeter, malfunctioning pump, closed valves or low liquid level in feeder tank.

Step 4 - Ensure oval gears within meter are rotating

Rotation of the oval gears can be heard by holding a screw driver blade to the meter body and pressing the handle

hard against the ear lobe. If necessary test the meter with the flow turned off and turned on to familiarize yourself

with the audible rotation signature.

Step 5 - Ensure pulses are being generated during flowing conditions

A multimeter is often not fast enough to distinguish the pulse train from the reed switch or Hall Effect sensor. An

oscilloscope will allow you to view the output pulse train. When viewing the Hall effect sensor pulse ensure a pull

up resistor is installed between the pulse output and the supply voltage (refer electrical installation).

Step 6 - Confirm Instrument Operation

If an associated instrument is connected to the flowmeter confirm its operation by simulating a pulse input onto the

flow input terminals. In most instances a contact closure on the flow input terminals is an adequate simulation.

Trouble shooting 15

Notes

5.1 TROUBLE SHOOTING

Symptom Solution

1. 1. Ground shield of signal cable

2. Re-route cable from high electrical energy sources

2. 1. Remove source of air or gas entrapment

2. Install an upstream air eliminator

3. 1. Increase back pressure on pump

2. Install a fast response one way check valve

3. Install a surge arrestor between pump & meter

4. Re-calibrate meter in situ to compensate for pulsations

5. Change pump style to smooth delivery type pump

1. Damaged or 1. Inspect, repair, clean or replace rotors

worn rotors

2. 1. Inspect measuring chamber for damage - repair

2. Check concentricity of rotor shafts within chamber

3. 1. Ground shield of signal cable

2. Re-route cable from high electrical energy sources

3. Check all electrical terminations & wires for continuity.

1. Rotors fouled 1. Check that rounded teeth are towards base of chamber

2. Check for obstruction due to foreign particles

3. Clean, repair or replace rotors

2. 1. See instructions for reassembly of meter with

particular emphisis on positioning of rotors & magnets

3. 1. Check terminal connections & solder joints

2. Ensure dc voltage is available at Vdc & 0v and

receiving instrument is fitted with a pull up resistor

3. Replace output board

1. 1. Check DIP switch settings & program data

2. Check terminal connections & electrical continuity

3. Repair / replace receiving instrument

Possible cause

Output signal

interference

Pulsating flow from

reciprocating style

pump

Damaged or worn

measuring

chamber

No output from

output board

Faulty receiving

instrument

Meter incorrectly

reassembled

Meter

readings

are high

Output signal

interference

Meter

readings

are low

Entrained air or

gas

No output

from meter

Not reading

on readout

instrument

This manual suits for next models

2

Table of contents

Other Flomec Measuring Instrument manuals

Flomec

Flomec QSE Series User manual

Flomec

Flomec TM Series User manual

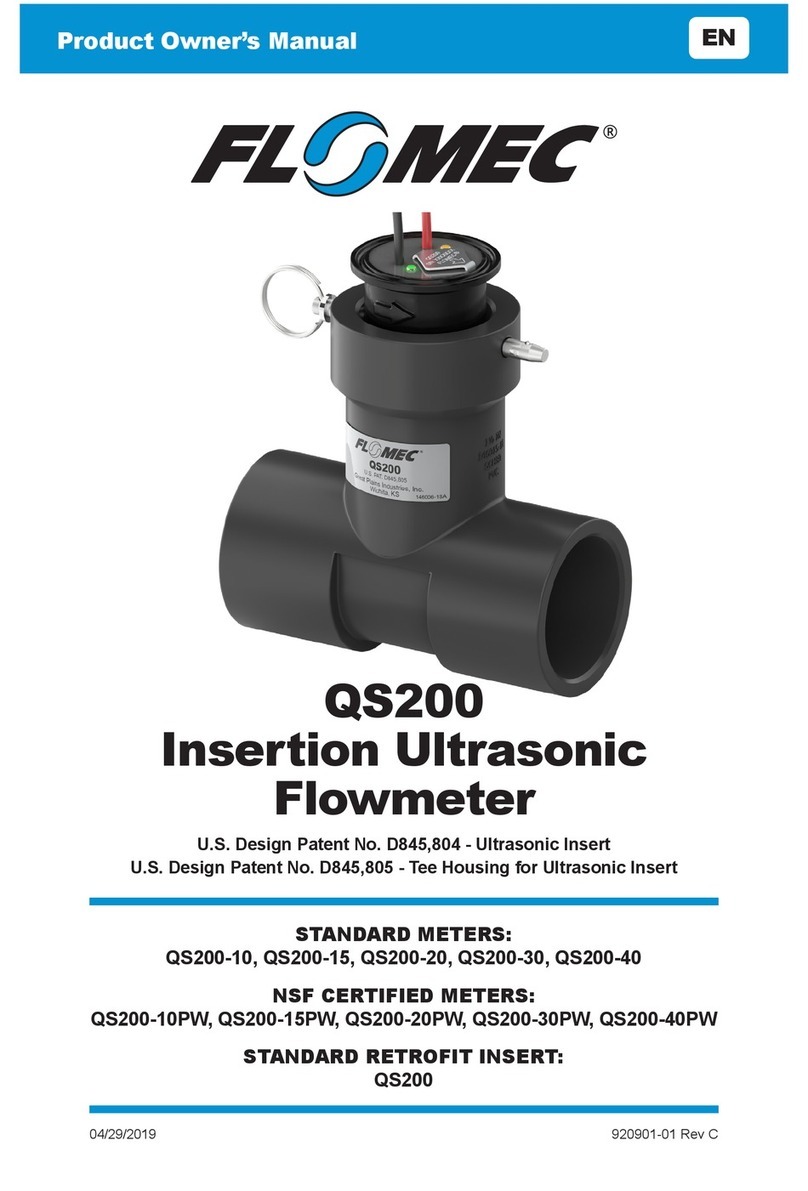

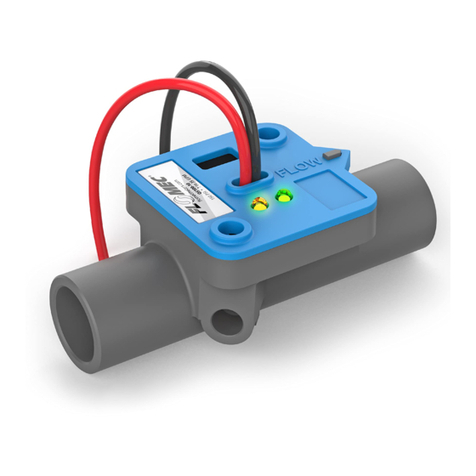

Flomec

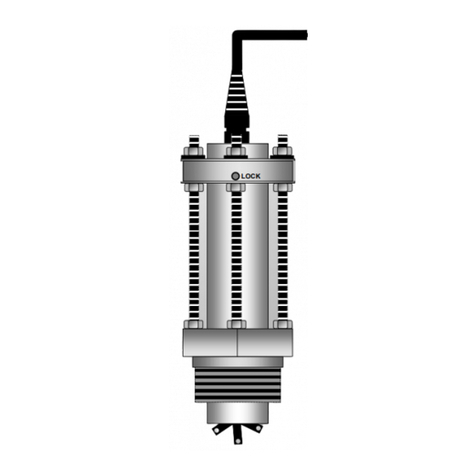

Flomec QS200 User manual

Flomec

Flomec QS200 User manual

Flomec

Flomec 490 User manual

Flomec

Flomec TM Series User manual

Flomec

Flomec QSE Series User manual

Flomec

Flomec LM51DN User manual

Flomec

Flomec TM Series User manual

Flomec

Flomec GPRO QM Series User manual

Flomec

Flomec Q9 User manual

Flomec

Flomec G Series User manual

Flomec

Flomec QS200 User manual

Flomec

Flomec G2 User manual

Flomec

Flomec Q9 User manual

Flomec

Flomec Oval Gear User manual

Flomec

Flomec QS100-10 User manual

Flomec

Flomec EGM Series User manual

Flomec

Flomec QS200 User manual

Flomec

Flomec D-40 User manual