www.flowair.com |2

Table Of Contents

1. GENERAL INFORMATION........................................................3

2. TECHNICAL DATA ..................................................................... 3

2.1.CONSTRUCTION................................................................. 3

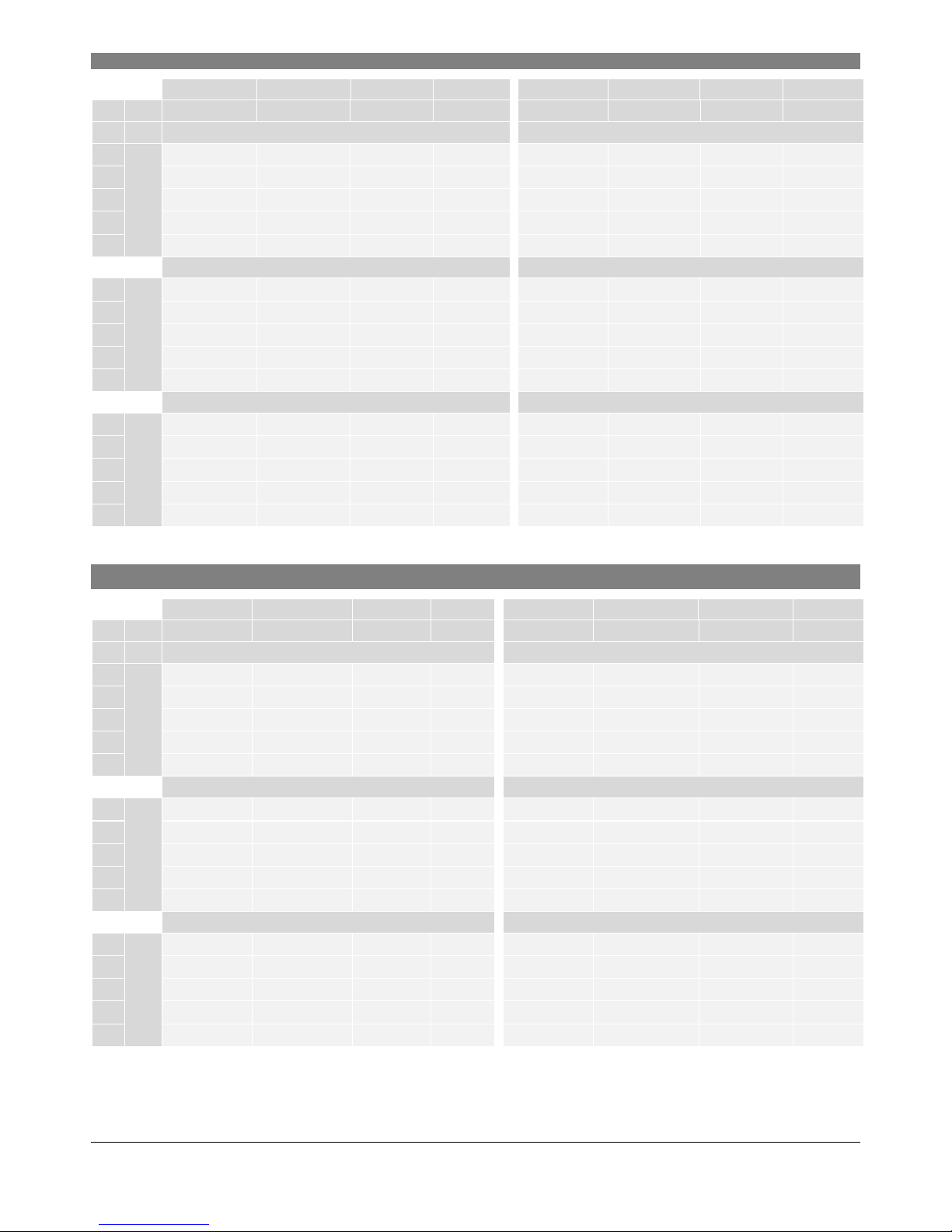

2.2.DIMENSIONS.......................................................................4

2.3.ACOUSTIC PRESSURE LEVEL...........................................4

2.4.AIR VOLUME........................................................................ 4

2.5.NOMOGRAM OF AIR FLOW SPEED...................................5

3. HEAT OUTPUT DATA ................................................................ 5

3.1. ELIS A-W-100.....................................................................5

3.2. ELIS A-W-150.....................................................................6

3.1.ELIS A-W-200.......................................................................6

4. INSTALLATION...........................................................................7

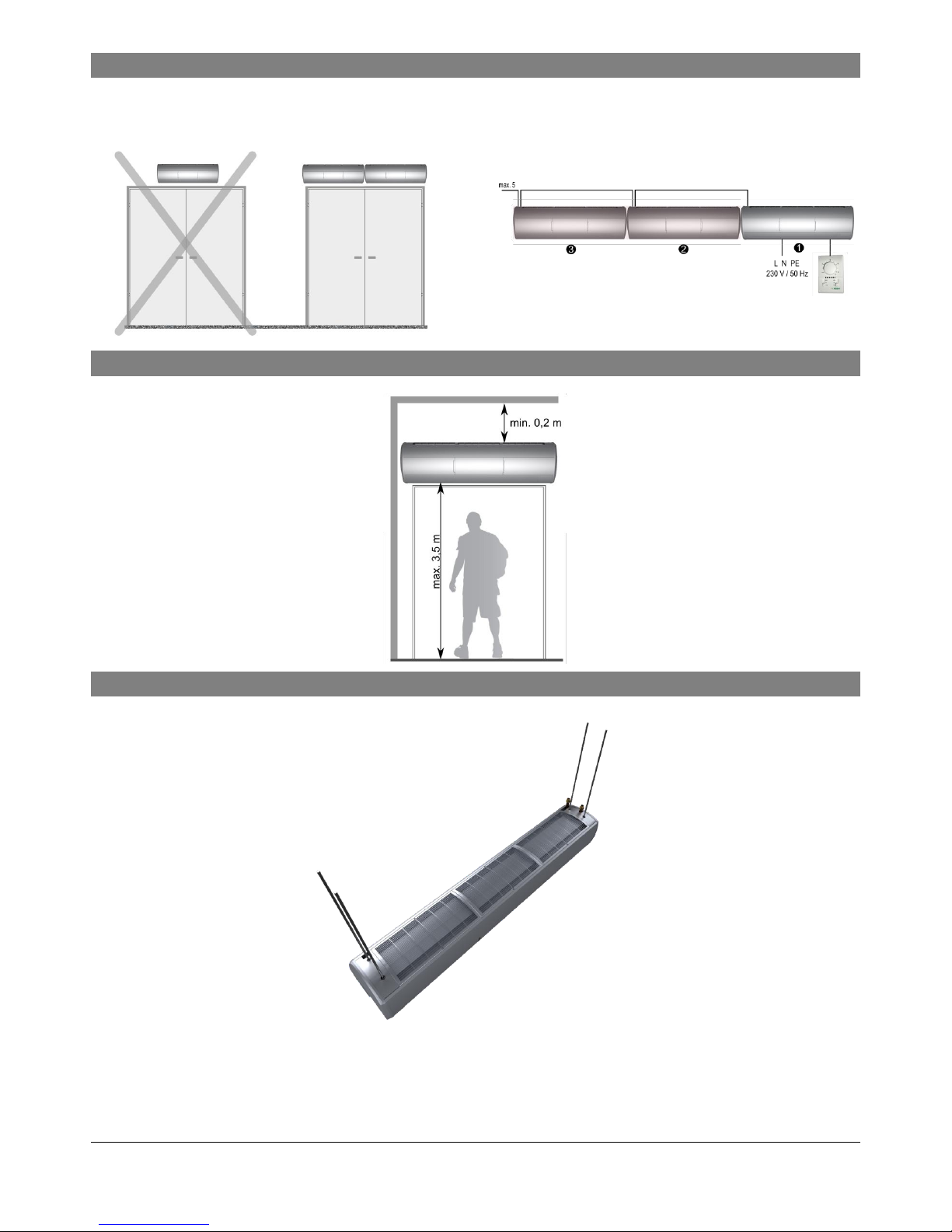

4.1.RECOMMENDATION OF MONTAGE DISTANCES..............7

4.2.MOUNTING BY RODS UNDER THE CEILING..................... 7

4.3.MOUNTING ON THE WALLS BY THE BRACKETS.............. 8

4.4.BRACKETS ..........................................................................8

4.5.STAGES OF INSTALATION.................................................9

5. CONTROL SYSTEMS..............................................................10

5.1.CONTROL ELEMENTS......................................................10

5.2 CONNECTING GUIDE........................................................ 11

5.3.CONTROL SYSTEM........................................................... 11

5.3.1. REGULATION TS –ELIS A-W/N WIRING

DIAGRAMS............................................................12

5.3.2 REGULATION TS –ELIS A-E WIRING DIAGRAMS12

5.3.3 REGULATION T-box - ELIS A-W/N WIRING

DIAGRAMS............................................................13

5.3.4 REGULATION T-box - ELIS A-E WIRING DIAGRAMS

………………………………………………………..13

5.3.5 CONTROL SYSTEM –MASTER-SLAVE

COMMUNICATION ................................................ 14

5.3.6 CONTROL SYSTEM –BMS CONNECTION......... 14

5.3.7. CONTROL SYSTEM –SETTING BMS ADDRESS14

5.3.8. DRV CONTROL SYSTEM –BMS REGISTERS....15

5.4.DOOR CONTACT INSTALLATION..................................... 16

6. GUIDELINES FOR CONNECTION WITH POWER SUPPLY.......16

7. GUIDELINES FOR CONNECTION WITH PIPELINE.................. 16

8. OPERATION............................................................................. 16

9. FILTERS REPLACEMENT........................................................ 17

10. CLEANING AND CONSERVATION.......................................... 17

11. SERVICE..................................................................................17

Thank you for purchasing the ELiS curtain. This operation

manual has been issued by the FLOWAIR GŁOGOWSKI

I BRZEZIŃSKI SP.J. company. The manufacturer reserves the

right to make revisions and changes in the operation manual at

any time and without notice, and also to make changes in the

device without influencing its operation

This manual is an integral part of the device and it must be

delivered to the user together with the device. In order to

ensure correct operation of the equipment, get thoroughly

acquainted with this manual and keep it for the future.

The devices may only be installed and operated in conditions

for which they have been designed. Any other application,

inconsistent with this manual, may lead to the occurrence of

accidents with dangerous consequences. Every effort must be

made in order to eliminate the possibility of improper use of the

device. Access of unauthorized persons to the device should

be restricted, and the operating personnel should be trained.

The manufacturer bears no responsibility for damage resulting

from incorrect installation, improper operating, or not getting

acquainted with the guidelines of the manufacturer manual.

RECOMMENDATIONS AND REQUIRED SAFETY

MEASURES

Get acquainted with this operation manual before

performing any works at the device.

The device may only be installed by qualified personnel

with adequate authorisations and skills.

In the building where ventilation causes underpressure, air

cutrain may have limited efficiency

When performing works at the device, remember about

your own safety.

During installation, electrical connection, connection to the

heating medium, start-up, repairs and maintenance of air

curtains, observe the commonly recognized safety

standards and regulations.