Flowplant 320 Series Use and care manual

320 SERIES

Quick Reference Service Guide –Rev 2

INDEX

1) TECHNICAL SPECIFICATION

2) SCHEMATICS

3) WIRING DIAGRAM

4) WATER DIAGRAM

5) HYDRAULIC DIAGRAM

6) OPERATOR QUICK START GUIDE

7) SPARES LIST

8) SERVICE SCHEDULE

9) TROUBLESHOOTING

10) TELERADIO PAIRING

11) ALARM FAULT CODES

REVISION

DESCRIPTION

REFERENCE

SIGNED

DATE

0

FIRST ISSUE

N/A

JHS

04/09/19

1

RELEASE DAY UPDATES

JHS

2

SPARES UPDATE

SAS

06/04/21

1) TECHNICAL SPECIFICATION –320 SERIES

Engine …KUBOTA D1105

Pump …SPECK NP25

Flow …54 LPM / 45 LMP

Pressure …3000 PSI / 2500 PSI

Weight …500 KG

Dimensions …1250MM LONG X 1200MM WIDE X 1190MM HIGH

Hose Size …½” 91.44 M – 055-021 (STANDARD)

Hose Reel …HYDRAULIC

Radio System …TELERADIO 433 MGHZ CAN OPEN TG2

Tank Capacity …

400 / 650 L

Voltage …12 V DC

Control System …MURPHY MPC-20

Suggested Accessories …SEE SPEC SHEET

Jet Sizes Approximate …SEE JET SIZER

2) SCHEMATICS –320 SERIES

REMOVABLE

GRP CANOPY

CANOPY SUPPORT

CANOPY LATCHES

CANOPY LATCHES

ENGINE COOLER

GUARD

WATER FILTER

TANK FILL

400 LITRE

WATER TANK

HYDRAULIC TANK

HOSE FEED GUIDE

INLET HOSE

REEL

HOSE REEL

BATTERY

ENGINE PUMP

CONTROL VALVE

JUMP JET

HYDRAULIC DIVERTER

VALVE

MPC CONTROL

PANEL AND

ENCLOSURE

DIESEL TANK

ANTIFREEZE TANK

DRAIN

VALVE

GEARBOX

PRESSURE SENSOR

ANTI FREEZE VALVE

AIR FILTER

EXHAUST OUTLET

STARTER MOTOR

ALTERNATOR

OIL FILTER

SUMP PLUG

OIL PRESSURE SWITCH

FAN BELT

DIP STICK

OIL FILL

THERMOSTAT

MANUAL

LIFT PUMP

FUEL INLET

THROTTLE

FUEL SOLENOID

MAGNETIC PICK UP

LOCATED ON FLYWHEEL HOUSING

FUEL RETURN

GLOW PLUG

CONNECTION

3) WIRING DIAGRAM –320 SERIES

* FINE

MACHINING

FABRICATION

UNMACHINED

* MEDIUM

MACHINING

Flowplant Group Ltd.

Gemini House, Brunel Road, Churchfields, Salisbury, Wiltshire. SP2 7PU England.

Tel:

+44 (0) 1722 325424 Fax: +44 (0) 1722 411329

* FINE

MACHINING

FABRICATION

UNMACHINED

* MEDIUM

MACHINING

Flowplant Group Ltd.

Gemini House, Brunel Road, Churchfields, Salisbury, Wiltshire. SP2 7PU England.

Tel:

+44 (0) 1722 325424 Fax: +44 (0) 1722 411329

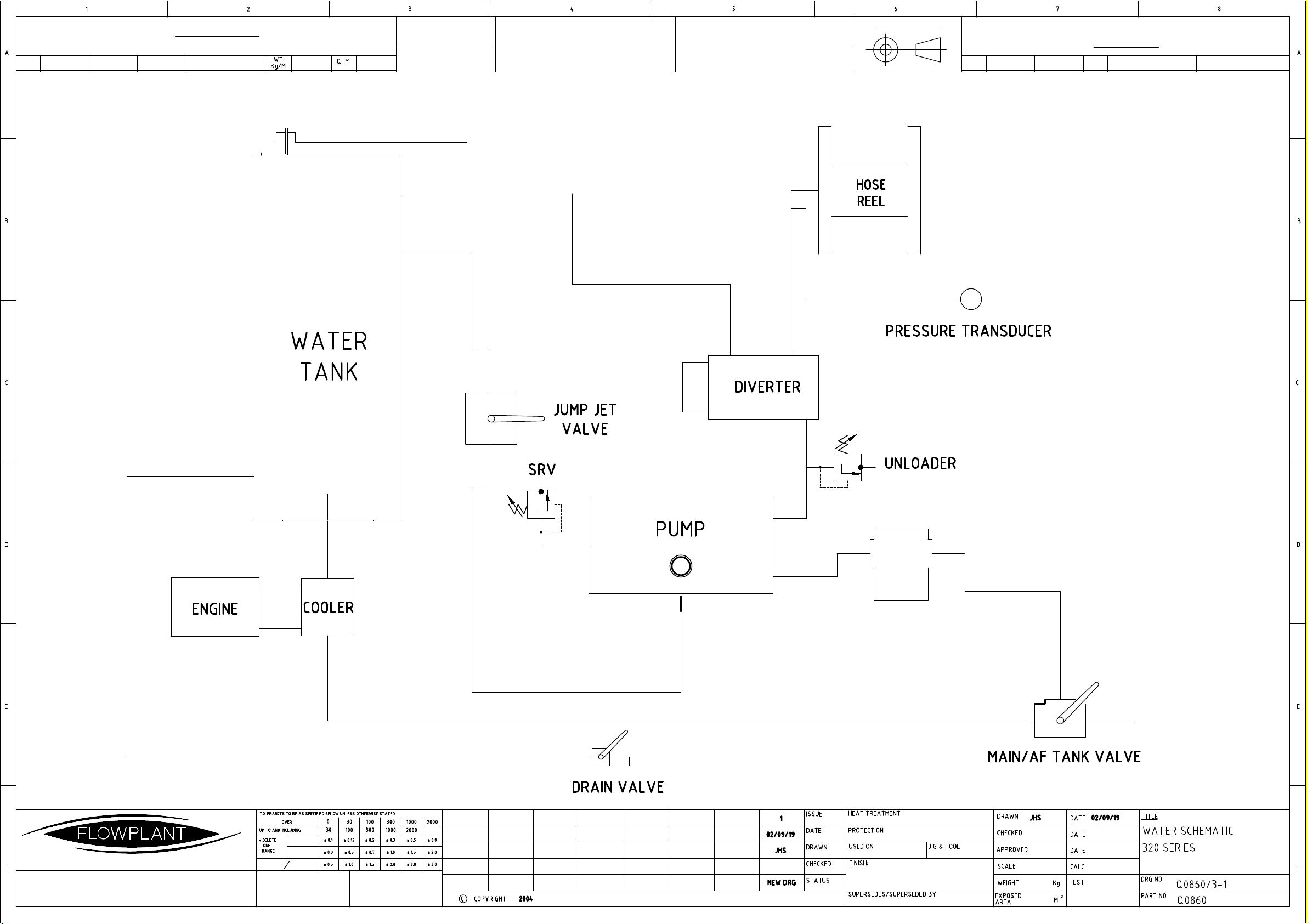

4) WATER DIAGRAM –320 SERIES

INFORMATION FOR ESTIMATION OF WEIGHT AND COST ONLY

MATERIAL LIST

ITEM PART NO. MATERIAL SPEC SIZE mm Kg

LENGTH TOTAL WT

PARTS LIST

ITEM PART No. DRG. No QTY DESCRIPTION REMARKS

A B C D E F G H J K

L M N P R S T U V W

X Y Z

Gemini House, Brunel Rd, Churchfields,

Salisbury, Wiltshire, England. SP2 7PU

Tel: (01722) 325424 Fax: 01722 411329

ALL DIMENSIONS IN MILLIMETRES

GEOMETRICAL TOLERANCES TO BS 308

ANGULAR DIMS TO BE WITHIN:-

MACHINED ± 0.5°, BENDING ± 2°

THREADS: BSP, TO MED. FIT. B.S. 2779

ISOMETRIC TO 6g / 6H

FABRICATION

UNMACHINED

* MEDIUM

MACHINING

* FINE

MACHINING

SURFACE ROUGHNESS: 1.6 MICRONS Ra

CONCENTRICITY TO WITHIN 0.2 T.I.R.

M/C RADII 1.5

DRILLED HOLES +0.13/-0.00

HOLE CENTRES TO BE ± 0.2

REMOVE ALL BURRS & SHARP EDGES.

DO NOT SCALE

IF IN DOUBT ASK !

MANUFACTURERS UNABLE TO COMPLY MAY

SUBMIT ALTERNATIVES WHEN QUOTING.

ALL DRAWINGS NOT TO THE LATEST

ISSUE ARE TO BE DESTROYED.

Flowplant Group Ltd.

Flowplant Group Ltd.

THIS DRAWING IS CONFIDENTIAL AND IS SUPPLIED

ON THE EXPRESS CONDITION THAT IT IS NOT

COPIED OR COMMUNICATED TO OTHER PERSONS

OR COMPANIES WITHOUT WRITTEN PERMISSION

FROM FLOWPLANT GROUP LTD.

Third angle projection

L E A D E R S I N C L E A N I N G T E C H N O L O G Y

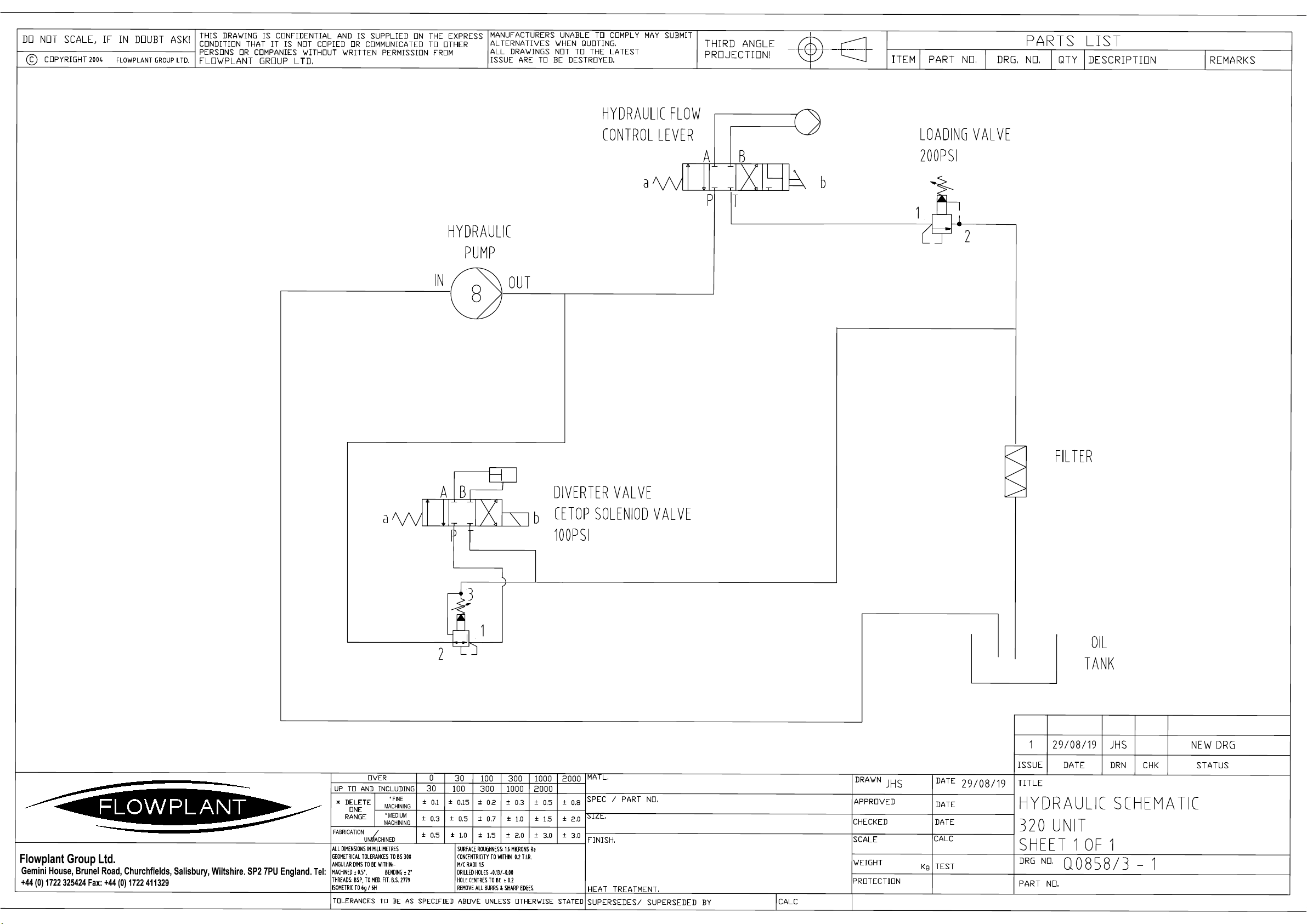

5) HYDRAULIC DIAGRAM –320 SERIES

* FINE

MACHINING

FABRICATION

UNMACHINED

* MEDIUM

MACHINING

Flowplant Group Ltd.

Gemini House, Brunel Road, Churchfields, Salisbury, Wiltshire. SP2 7PU England.

Tel:

+44 (0) 1722 325424 Fax: +44 (0) 1722 411329

2

1

2

1

3

6) OPERATOR QUICK START GUIDE

–320 SERIES Desilter

START UP

1) Perform all daily checks as detailed in service schedule and manual.

2) Ensure vehicle handbrake is applied. Connect to water supply.

3) Feed the end of the high-pressure hose through the hose trace.

4) Ensure the high pressure hose is in a safe position, preferably in sight.

5) Switch the master rocker switch to the on position (1).

6) Enter the 4 digit PIN using arrows and return button.

7) Press the green start button. The engine will start automatically, and idle.

JETTING

8) Adjust speed using RPM+ or RPM- buttons, to medium revs (i.e 1600 RPM).

9) To divert water to the high pressure (or back to tank) hose press yellow spray button .

10) Then readjust the speed to increase or reduce pressure.

RADIO CONTROL

11) Press the radio button on the main controller. The display will show “remote enabled”.

12) Pull out the red button on the base of the remote control handset.

13) Adjust speed / pressure using RPM+ “HI” and RPM- “LO” buttons.

14) To divert water to the high pressure (or back to tank) hose press yellow spray button .

SHUT DOWN

15) Adjust speed using RPM+ or RPM- buttons, to medium revs (i.e 1600 RPM).

16) Reduce the RPM to the idle speed using the RPM- / “LO” buttons.

17) Divert the water to tank using the button

18) Engine speed will automatically reduce to idle.

19) Press the red engine stop button to stop the engine.

20) To turn off the whole unit, switch the master rocker switch to the off position (0).

EMERGENCY / RAPID SHUT DOWN

21) Depress either the emergency stop button located on the unit next to the control system,

or (if in use) depress the emergency stop button on the base of the remote contol handset.

AUTOMATIC SHUT DOWN

22) The engine and unit as a whole will automatically shut down if the monitoring and control

system detects a malfunction or operating issue.

The below notes are to add in the understanding and navigation of the screens contained within the

Murphy MPC-20 Controller. MPC-20 Screen Display Sequence: -

Powering up the display screen: -

NB…when the E-stop circuit is activated, all power will be blocked to the control panel.

To power up the control panel, ensure the E-stop button is deactivated with the twist lock out.

switch the power on by pressing the master rocker switch located on the RHS, below the main

control panel to the 1 position. The three LED lights on the RHS of control screen will come on to

indicate that they work then screen will now power up and will prompt the entering of a passcode.

The three LED’s will indicate the following.

RED …Shutdown Alarm active

Amber …Warning Alarm

Green …Auto Mode

The screen will also indicate any alarm state that would prevent unit operation (i.e. water tank

empty) the screen will indicate the alarm and that it needs to be acknowledged and silenced by

pressing the enter/return button. Also, a STOP indication symbol will appear in the lower RHS of

screen, and the red LED on the control panel will be on and will prevent engine start.

To enter a passcode

NB…Normally when first switched on, the digit to the far RHS is highlighted.

1. Press enter/return on the control cursors to move highlighted digit to the far LHS

2. Press the up arrow on control cursors to advance digital to the required number

3. Press enter/return to select that digit and move to the next digit

4. Repeat the process until all four digits are entered

5. Press enter/return and the screen will then show the main screen

6. Indicating the flowplant logo, unit pressure, set temperature, engine RPM and engine status.

Passcodes: -

There are two passcodes that are used on this the MPC-20 controller.

•2010…Entree level passcode, give a basic entree level to the most basic of operation i.e.

operational screens

•1111…Low security level passcode, gives a more interactive entry level giving means of

changing minor settings, dates and times etc.

To enter a passcode level first press the main screen/passcode button. Then enter the required

passcode using the procedure listed above.

NB…The entree level code must have been entered before secondary levels and the engineering

level can be selected.

Display Screen’s: - (passcode…2010)

On entering this passcode, the following operational screens and accessible…

NB…these screens are only status displays and not settings that can be changed

NB…To navigate and access required screen, press the up/down arrow buttons to move through

the list of screens until the desired screen is indicated. Then press enter/return button

To navigate within the screen use of up/down arrows to move through screen list, then press the

enter/return button to access the parameter settings.

Press the return button to exit parameter settings or press the passcode button to return to main

home screen.

1. Main Screen...Indicating flowplant logo, unit pressure (Bar), engine RPM and engine status, with

a pressure indicating percentage bar along the bottom of the screen.

2. Operational Screen…12 box screen indicating the operational state of the unit

Box 1…Actual RPM…Display’s the actual RPM of the engine.

(via the signal from the magnetic pickup)

Box 2…Target RPM…Display’s the required set RPM of the unit.

(set by the operator via the speed up/down cursor button)

Box 3…Engine Battery… Display’s the voltage within the battery and the battery charging

voltage.

Box 4…Run Hours…Display’s the current run hours for the unit.

Box 5…Engine Status…Display’s the operational status of the engine, (i.e., Loaded,

Spindown, Stabilise, Stopped)

Box 6…Status Time…Display’s the countdown status of not active operations?

(countdown for 30mins)

Box 7…Remote…Display’s the operational state of the remote system. (i.e. Remote

Disabled, Remote enabled)

Box 8…Water…Display’s the operational state of the jetting sequence (i.e. OFF/ON)

Box 9…Time…Display’s time (Rear time)

Box 10…Date…Display’s Date (Rear Date)

Box 11…Unit Pressure…Display’s unit operating pressure (Displayed in Bar)

Box 12…Not Used…

3. Digital Input Status Screen…Indicates the operational status of the digital inputs received by

the controller. (when unit in non-operational state)

DI 1 Disabled Open

DI 2 Disabled Open

DI 3 Disabled Open

DI 4 Tank Empty Neg

DI 5 Disabled Open

DI 6 Low Oil Pressure SW Neg

4. Relay Status Screen…Indicates the status of the internal solid-state relays within the control

panel. (when unit in non-operational state)

R1 Crank Off

R2 Fuel Off

R3 Pre-Heat Relay Off

R4 Water Diverter Solenoid Off

R5 Not Used Off

R6 Not Used Off

5. Analog Input Status Screen…Indicates the status of the Analog signals received by the

controller. (when unit in non-operational state)

AI 1 Disabled

AI 2 Disabled

AI 3 Flowplant Water Pressure

AI 4 Engine Temperature

AI 5 Disabled

AI 6 Disabled

AI 7 Disabled

AI 8 Disabled

6. System Info Screen…Indicates general system info,

(i.e. time, day, date, P/N number, Serial Number, etc.)

Display Screen’s: - (passcode…1111)

On entering this passcode, the following setting screens and accessible…

NB…these screens allow access to minor level settings that can be changed

NB…To navigate and access required screen, press the up/down arrow buttons to move through

the list of screens until the desired screen is indicated. Then press enter/return button

To navigate within the screen use of up/down arrows to move through screen list, then press the

enter/return button to access the parameter settings.

Press the page back (enter Pic) button to exit parameter settings or press the home/passcode

button (enter pic) to return to main home screen.

1. First level Setting Screen…indicating the following setting screens for the unit

Flowplant Settings…allows access to the ‘Start Alarm Silence’ settings

System…allows access to the ‘Date/Time’ and the ‘Backlight’ settings.

Engine Settings…no access to these settings on this level entree

Advanced Engine Settings…no access to these settings on this level entree

Flowplant Settings…

Start Alarm Silence…

Start Alarm Silence…

Start alarm silence on…will silence the start-up siren (default is siren on)

Display Actual Temperature…

Display Actual Temperature…Displays actual temperature on main temperature screen

Hide Actual Temperature…Hides actual temperature on temperature screen (default)

System…

Date/Time…

Time…

Date…

Backlight…

Brightness…

Other manuals for 320 Series

2

This manual suits for next models

2

Table of contents

Other Flowplant Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Alfalaval

Alfalaval GJ Tote Blast Station instruction manual

IPC Eagle

IPC Eagle HighPure HP 0 instruction manual

AU Tool

AU Tool CT150 user manual

Alfalaval

Alfalaval Toftejorg SaniJet 25 instruction manual

Silvercrest

Silvercrest SRB 6 A1 384456 2107 Operating instructions and safety instructions

e.ziclean

e.ziclean Cyclosteam P310 manual