18-4

inches to allow the use of a ring compressor on the

metal rings. A suitable sized screw-type hose clamp

will also serve to compress the rings for reassembly.

Care should be taken to avoid damaging the sealing

surfaces while fitting the plug into the sleeve bore.

4. Once the bonnet is resting on the body, reinstall and

tighten the bonnet flange bolting fingertight.

5. Using the actuator, seat the plug two or three times

to center the seat ring.

6. Leaving the plug in the extended (or closed) posi-

tion, begin tightening the bonnet flange bolting in a

crisscross pattern that will keep the bonnet square

with the valve. Tighten the first bolt 1/6turn, then

tighten the bolt directly opposite 1/6turn.

7. Continue tightening all bolting until the bonnet is

firmly seated, metal to metal, in the body. This can

be easily felt through the wrench.

8. Slowly stroke the plug up and down to check the

alignment of the plug with the attenuator. If binding,

sticking or scraping noises are heard, stop stroking

valve immediately. Disassemble the valve to deter-

mine noise and to detect possible damage.

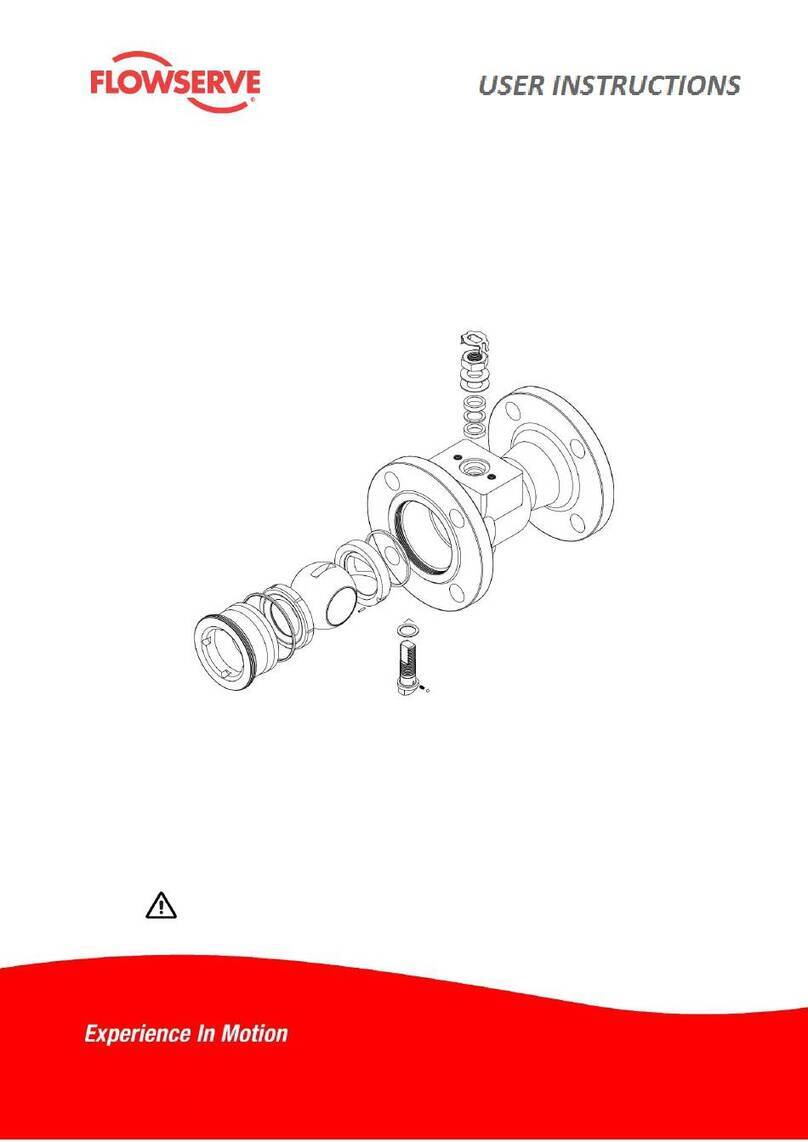

6. Lift the actuator bonnet and plug assembly from

body, taking care not to damage the sleeve bore or

plug head.

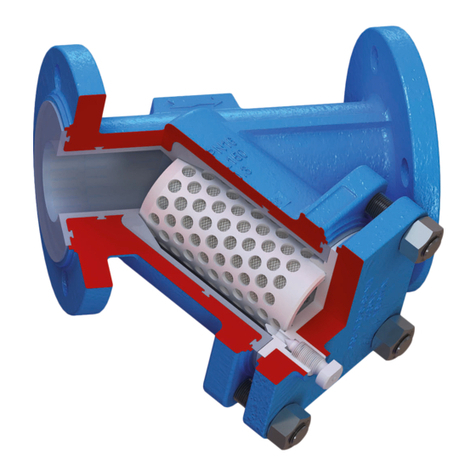

7. Remove the sleeve attenuator, seat ring and gaskets

from the body.

8. The attenuator may now be cleaned according to

established industry methods. If uncertain as to

which methods to use with a particular attentuator

and application, refer to factory.

Reassembling Pressure-balanced

MegaStream

Refer to Figure 2 and proceed as follows:

1. Install new seat gasket and reinstall seat ring.

NOTE: All gaskets should be replaced whenever

the valve is disassembled.

2. Install attenuator and sleeve. Replace bonnet and

sleeve gaskets, and plug seals.

3. Lower the actuator, bonnet and plug assembly

squarely into the sleeve bore. If Teflon seals are

used, the plug may remain retracted. With metal

piston ring seals, the plug must be extended a few

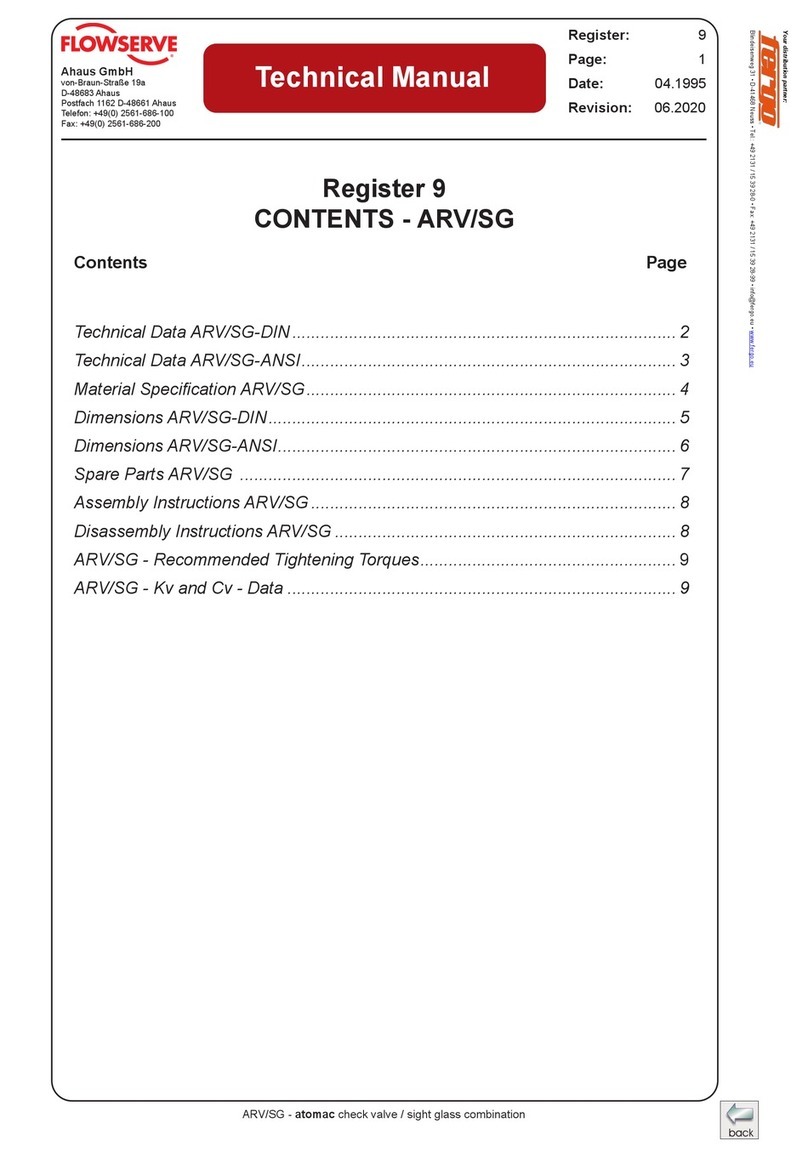

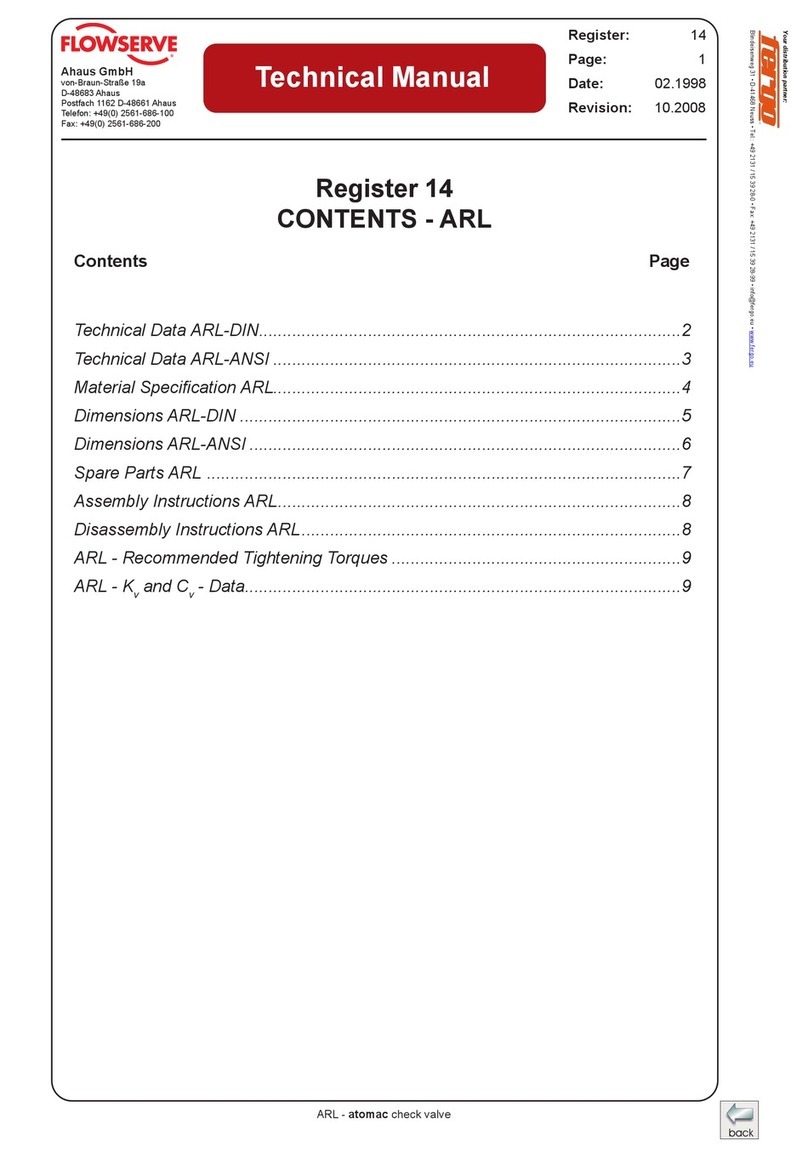

Problem Probable Cause Corrective Action

Jerky 1. Galling or scoring between 1. Superficial scoring or galling may be removed with a light application

stem travel plug and pressure-balanced of emery cloth; if more serious damage exists, contact factory

sleeve CAUTION: Trim parts are machined to close tolerances which are essential

for correct functioning of the valve; attempting to remove deep scratches

could result in high leakage rates or improper functioning of valve.

2. Overtightened packing 2. Adjust the packing box nuts to slightly over finger-tight (over-tightening

will cause excessive packing wear and high stem friction)

3. Service temperature exceeds 3. Reconfirm service conditions and contact factory

operating parameter of trim design

4. Inadequate air supply 4. Check for leaks in air supply or instrument signal system; tighten any

loose connections and replace any leaky lines

5. Malfunctioning positioner 5. Refer to positioner maintenance instructions

Excessive 1. Insufficiently tightened 1. Refer to “Reassembly” section for correct tightening procedure

leakage bonnet flange bolting

2. Worn or damaged seat ring 2. Disassemble and replace or repair seat ring (for correct procedure on

remachining seat, see Maintenance Instructions 1)

3. Worn or damaged plug seals 3. Disassemble and replace plug seals

4. Worn or damaged gaskets 4. Disassemble and replace gaskets

5. Inadequate actuator thrust 5. Check for adequate air supply to the actuator; if supply is okay, reconfirm

service conditions and contact factory.

6. Incorrectly adjusted plug 6. Refer to Maintenance Instructions 1 for correct plug adjustment

Restricted 1. Dirty attenuator 1. Disassemble and clean attenuator, using established industry

flow cleaning methods

2. Incorrectly adjusted limit- 2. Check stroke limiting device and correct, if necessary

stop or handwheel

Excessive 1. Improper flow direction 1. Check installation for flow direction under the seat; reinstall, if necessary

noise 2. Excessive pressure drop 2. Check design service conditions

3. Jerky or improper stemtravel 3. See corrective action under “Jerky stem travel”

4. Throttling too close to the seat 4. Recommended throttling should be 5 percent or more open

5. Loose parts 5. Check all external bolts and nuts for tightness; if noise is internal,

disassemble, check for damaged, scored parts or missing seat gasket

Troubleshooting MegaStream Control Valves

Flowserve and Valtek are registered trademarks of Flowserve Corporation.

FCD VLAIM018-05 ©1999 Flowserve Corporation. Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611