I-KOIL.KITINSTALLATION AND MAINTENANCE INSTRUCTIONS

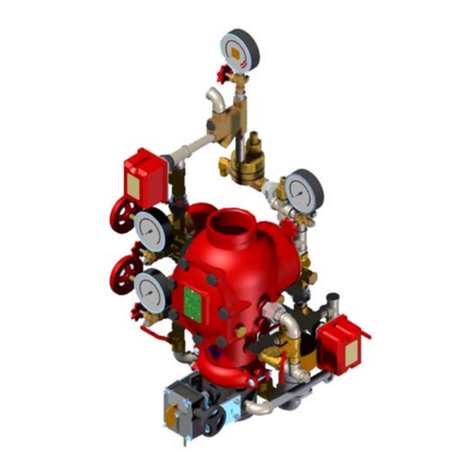

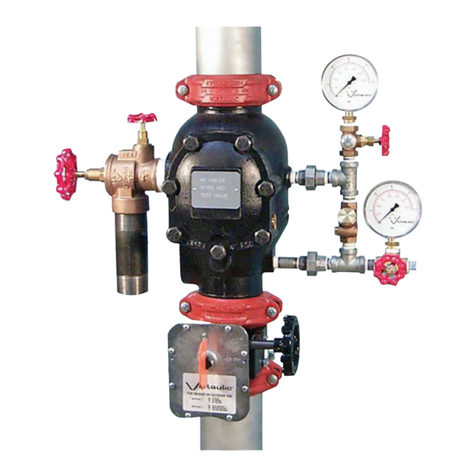

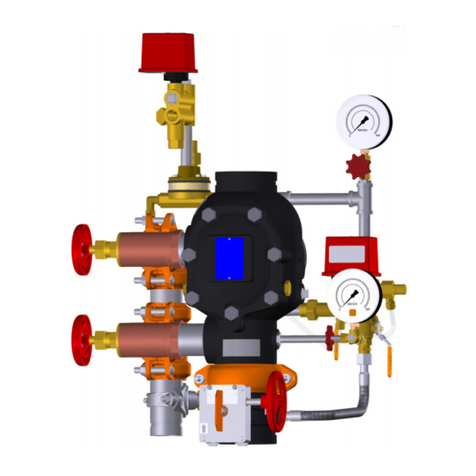

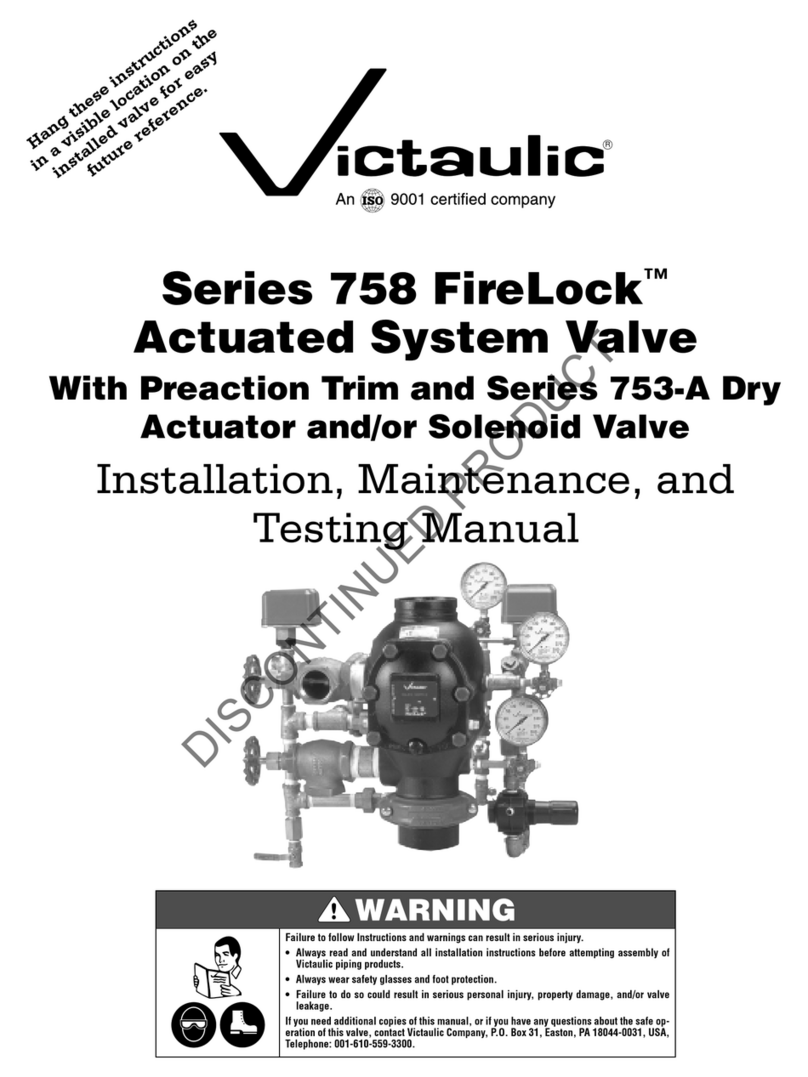

KOIL-KIT™Coil Pack – Series 799, Series 79V with ATC Valve,

Series 79B with Bypass, and Series 79A with Bypass and ATC Valve

For complete contact information, visit victaulic.com

I-KOIL.KIT 2954 REV F UPDATED 07/2014 Z004799001

VICTAULIC AND KOIL-KIT ARE TRADEMARKS OR REGISTERED TRADEMARKS OF VICTAULIC COMPANY AND/OR ITS AFFILIATED ENTITIES

IN THE UNITED STATES AND/OR OTHER COUNTRIES. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

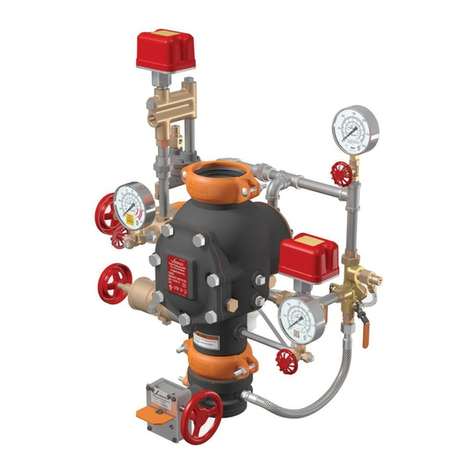

INSTALLING THE BALANCING VALVE DRAIN KIT

NOTICE

• System depressurization is not required for drain kit installation;

however, caution must be taken to ensure that the long pressure/

temperature (PT) port is not loosened prematurely.

*NOTE: New gaskets

must be used.

FLOW

Drainage

Nipple

Gasket*

Gasket*

Cover

Nut

The drain kit (part number K-000-786-CBV) for Series 786, 787, and

78K Balancing Valves is sold separately through Victaulic and comes

with two new gaskets, a drainage nipple, and a nut.

1. Remove the components from the long pressure/temperature (PT)

port, shown in the assembly drawings above. NOTE: The cover with red

holder will be re-used when the drain kit is installed.

2. Install the drain kit components, as shown in the drawing above. The

new gaskets (provided in the kit) must be installed to prevent leakage

from the port. Re-install the cover with red holder onto the nut.

3. Locate the recess under the cover. Insert a 5-mm allen key, and

apply 8 - 14 counterclockwise turns to drain from the PT port.

PRE-SETTING, BALANCING, AND MEASURING

Refer to the applicable installation and setting instructions for the valve

supplied with the KOIL-KIT™Coil Pack.

REPLACEMENT PART INFORMATION

WARNING

• Depressurize and drain the piping system before attempting to

perform any maintenance or replace any components.

Failure to follow this instruction could result in serious personal

injury and/or property damage.

The following parts are sold separately through Victaulic for KOIL-KIT™

Coil Packs. Contact Victaulic with any order requests or questions

regarding these parts.

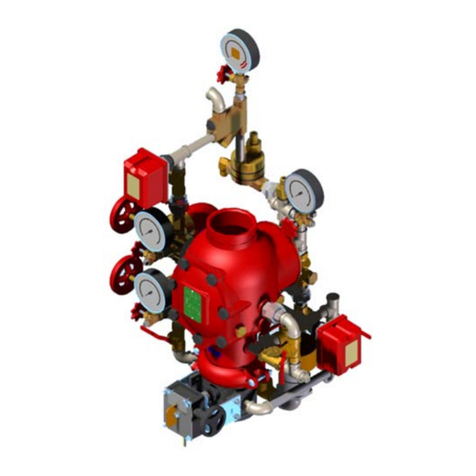

Hose-End Drain Assembly for Series 78Y Strainer/

Ball Valve Combination or Series 78T Ball Valve

(Part Number P-002-78Y-DRN for ¼-inch NPT or

P-004-78Y-DRN for ½-inch NPT)

The hose-end drain assembly is field-replaceable. Remove the existing

hose-end drain assembly from the drain valve adapter, and thread the

new assembly into the adapter. Use PTFE thread sealant tape or pipe

dope on the male threads that connect to the Series 78Y or 78T.

PT Ports for Series 78Y Strainer/Ball Valve

Combination, Series 78T Ball Valve, Series 78U

Union Port Fitting with Air Bleed, or Series

786/787/78K Balancing Valves

(Part Number P-002-78Y-PTP for 78Y/78T/78U

or K-000-740-003 for 786/787/78K)

The PT ports are field-replaceable. Remove the existing PT port(s), and

thread the new port(s) into the valve body. For Series 78Y/78T/78U:

Use PTFE thread sealant tape or pipe dope on the threads. For Series

786/787/78K: DO NOT use PTFE thread sealant tape or pipe dope on

the threads.

Air Vent for Series 78Y Strainer/Ball Valve

Combination, Series 78T Ball Valve, Series 78U

Union Port Fitting with Air Bleed

(Part Number P-002-78U-MAV)

The air vents are field-replaceable. Remove the existing air vent, and

thread the new air vent into the valve body. Use PTFE thread sealant

tape or pipe dope on the threads.

Port Extender for Series 78Y Strainer/Ball Valve

Combination, Series 78T Ball Valve, or Series 78U

Union Port Fitting with Air Bleed

2-inch/51-mm Length

(Part Number P-000-78Y-2XT)

4-inch/102-mm Length

(Part Number P-000-78Y-4XT)

In applications where KOIL-KIT™Coil Pack components will be

insulated, port extenders are available to extend the PT ports of the

Series 78Y or 78T or the air vent of the Series 78U to provide clearance

for 2 inches/51 mm or 4 inches/102 mm of insulation. Thread the port

extender into the existing PT ports or the existing air vent. Use PTFE

thread sealant tape or pipe dope on the threads. NOTE: Depending on

the configuration ordered, some KOIL-KIT™Coil Packs may be supplied

with this option factory installed.

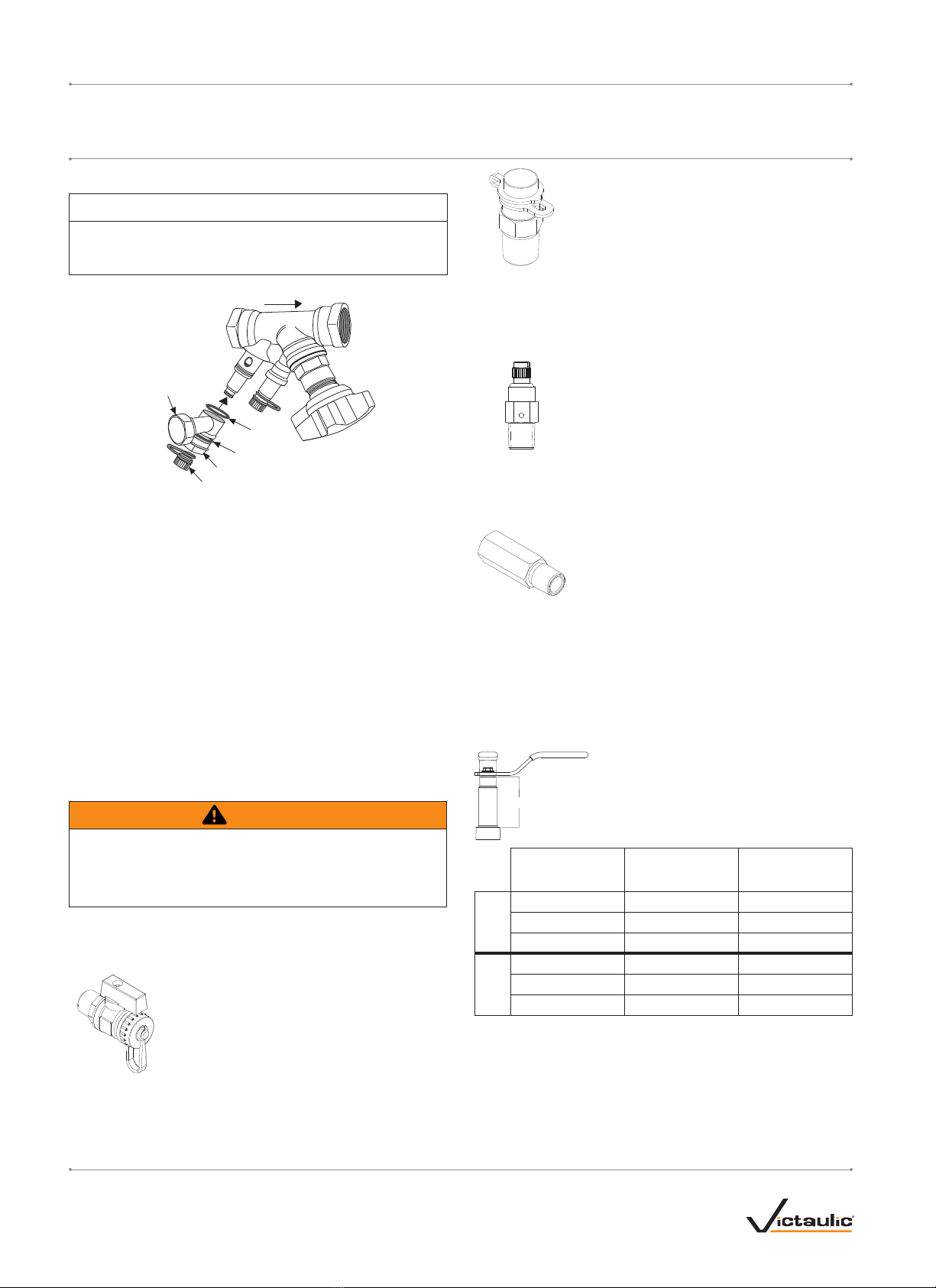

Handle Extension for Series 78Y Strainer/Ball

Valve Combination or Series 78T Ball Valve

Valve Inlet Size

inches

Part Code for

2-inch/51-mm

Handle Extension

Part Code for

4-inch/102-mm

Handle Extension

78Y

½ - 1 P-004-78Y-2HL P-004-78Y-4HL

1 ¼ - 1 ½ P-012-78Y-2HL P-012-78Y- 4HL

2P-020-78Y-2HL P-020-78Y-4HL

78T

½ - ¾ P-004-78Y-2HL P-004-78Y-4HL

1 - 1 ½ P-012-78Y-2HL P-012-78Y- 4HL

2P-020-78Y-2HL P-020-78Y-4HL

In applications where KOIL-KIT™Coil Pack components will be

insulated, the handle extension is available to extend the handle of the

Series 78Y or Series 78T valves to provide clearance for 2 inches/51

mm or 4 inches/102 mm of insulation. Remove the hex washer-head

screw from the handle assembly. Remove the handle assembly and

install the handle extension. Re-install the handle assembly onto

the handle extension by using the hex washer-head screw. NOTE:

Depending on the configuration ordered, some KOIL-KIT™Coil Packs

may be supplied with this option factory-installed.

Handle Extension