Valtek FlowTop General Service Valve FCD VLENIM8610A4 11/18

3

flowserve.com

1 Scope of Manual

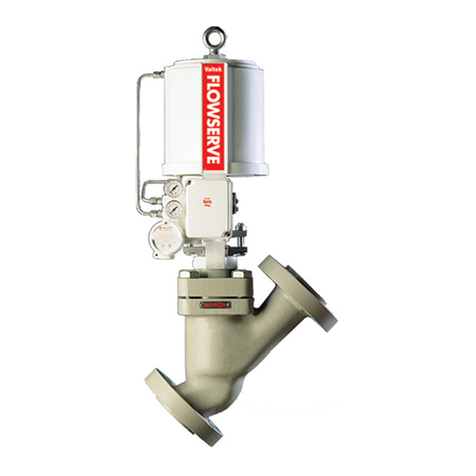

The following user information covers the Valtek FlowTop

general service control valve:

• English ASME Units - Class 150, NPS ½ - 6 - Type V746

• English ASME Units - Class 300, NPS ½ - 6 - Type V748

• Assembled with a pneumatic actuator

• Comes with or without ancillary equipment

2 Intended Use

WARNING

Control valves are pressure ves-

sels designed and rated for spe-

cific application conditions. Before installation, check the

serial number and / or the tag number to ensure that the

valve and actuator being installed are correct for the in-

tended application. Do not use the valve outside of its rated

design limits. Exceeding the design limits may cause haz-

ardous conditions including leakage of the process media

or rupture of the pressure boundary resulting in possible

process loss, equipment or environmental damage, or seri-

ous personal injury or death.

The specific product design data can be found on the valve’s

serial plate, data sheet and the calculation sheet (in acc. to the

IEC 60534-7:2010).

The Valtek FlowTop handles a wide variety of general service

applications, while offering high flow capacity. All sizes come

standard with unbalanced trim; for high pressure drop appli-

cations optional pressure balanced trim is available for NPS

size 3 to 6.

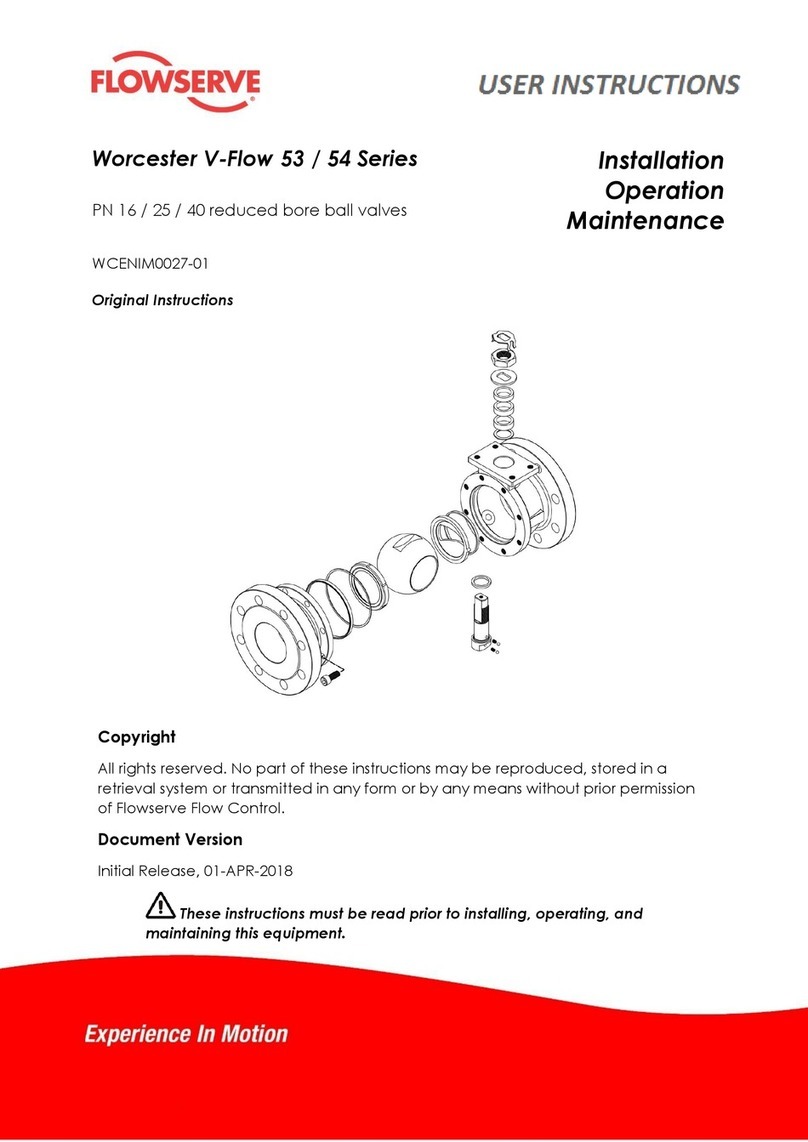

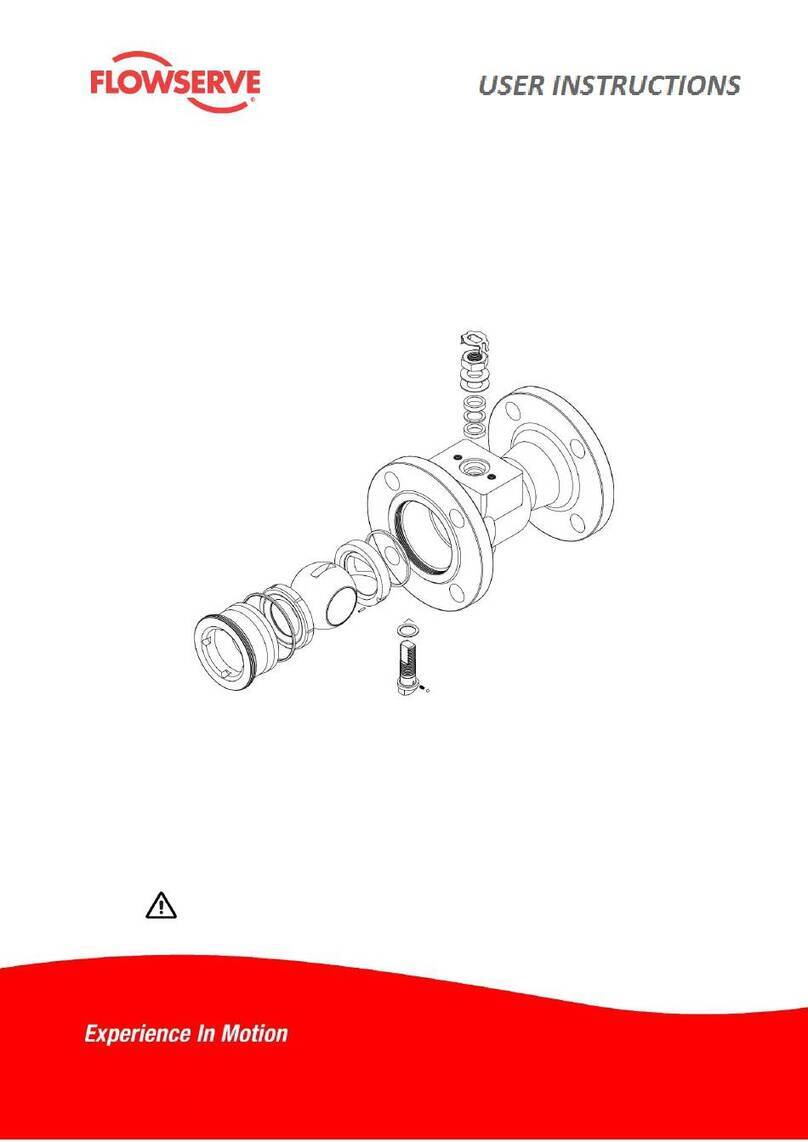

The Valtek FlowTop consists of the body, bonnet, trim,

and actuator. The valve is designed with a high level of in-

terchangeability allowing the user to assemble the greatest

possible number of variations from a minimum number of

components to match each application. There are five bon-

net designs: standard bonnet or extended bonnet (either as

unbalanced or pressure balanced), and bellows seal bonnets.

See Figure 1 and Figure 2.

The Valtek FlowTop is designed in compliance with EN

1349:2009 - Industrial Process Control Valves (DIN EN 1349

and VDE 0409-1349).

The Valtek FlowTop is designed for use in MODERATE and

WORLDWIDE environmental conditions, ambient tempera-

ture range -40°F to 180°F (-40°C to +82°C), air humidity up

to 93% non-condensing, air pollution up to 300 µg/m3, unless

restricted by the accessories.

The product offering may include optional ancillary equip-

ment, such as positioners, air-filter regulators, solenoid

valves, limit switches or boosters. Digital, I/P, or pneumatic

positioners can be mounted directly, with a mounting bracket

or according to NAMUR standards. Refer to the relevant man-

ufacturer‘s user instructions for information regarding other

ancillary equipment.

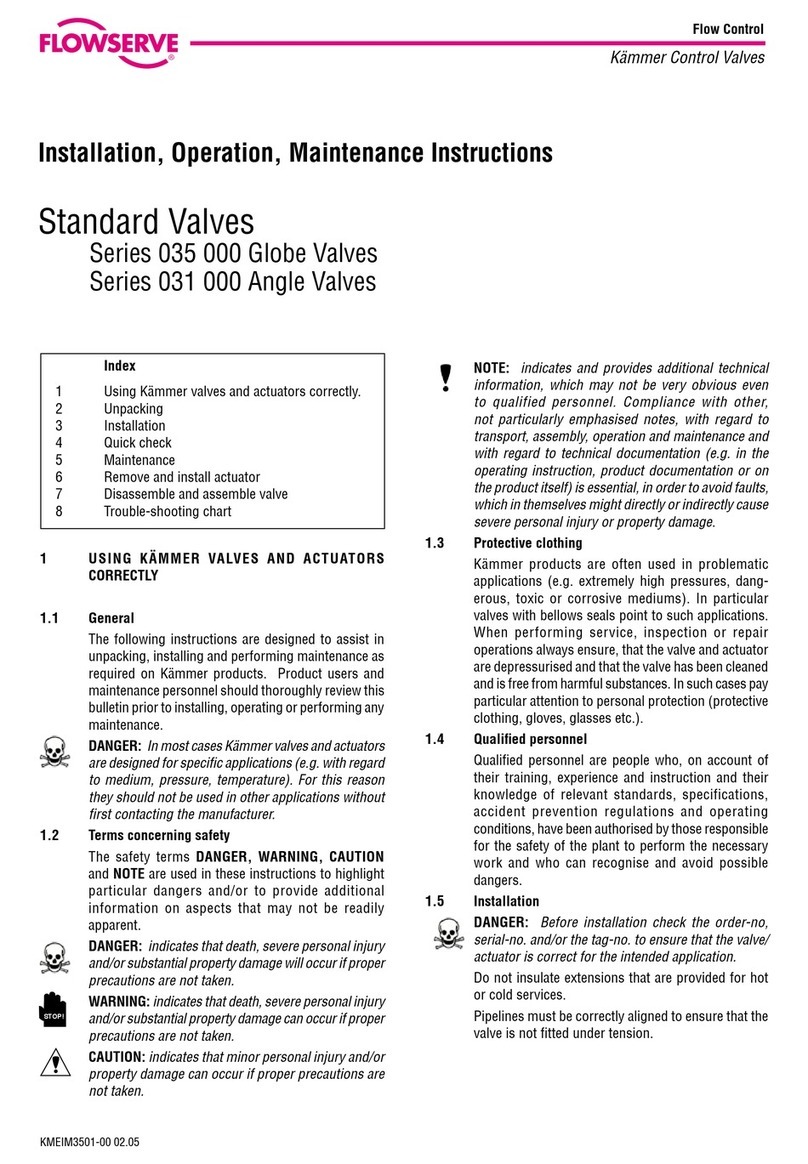

3 Product Identification

Each Valtek FlowTop (V746 and V748) control valve comes

with an attached serial plate which includes key information

specifically for each control valve:

Figure 3: Serial Plate (WW-design, WorldWide)

R

Made in Villach - Austria

Tag.No.

Kennzeichnung

Fabrikations Nr.

Serial No.

Type

Typ

DN

PN/Class

Gehaeuse / Atteste

Body / Certificate

Kegel

Plug

Seat

Sitz

Kvs / Cv

Innenteile

Trim

Antrieb

Actuator

S

Betriebstemperatur

Working Temperature

max.

Betriebsdruck

Working Pressure

Characteristic / Stroke

for Actuator

Arrangement

Supply

Sicherheitsstellung

< 30°

Druecke sind Ueberdruecke

Pressures are gauge pressures

Umgebungstemperatur

Ambient Temperature

max.

min.

Kennlinie / Hub

dp

fuer Antrieb

max.

Einbaulage

Besonderheiten

Specialities

Zuluft

Federlaufbereich

Spring Range

Failure Position

min. / max.

Figure 4: Serial Plate (EU-design, European Union)

The same serial number shown on the plate will appear on

all Valtek FlowTop data sheets, dimensional drawings, bills

of material, and spare parts lists. Other information located

on the serial plate is self-explanatory for the Valtek FlowTop

control valve.

You can download .pdf versions of the Valtek FlowTop docu-

mentation including a technical bulletin and user instructions

at www.flowserve.com. It is the user’s responsibility to keep

this and related documentation on file and accessible for the

Valtek FlowTop product.

4 Valtek FlowTop Modification

Valtek FlowTop control valves are generally delivered as tested

and assembled units, with factory-mounted actuators.