9

6.1 Wiring instructions

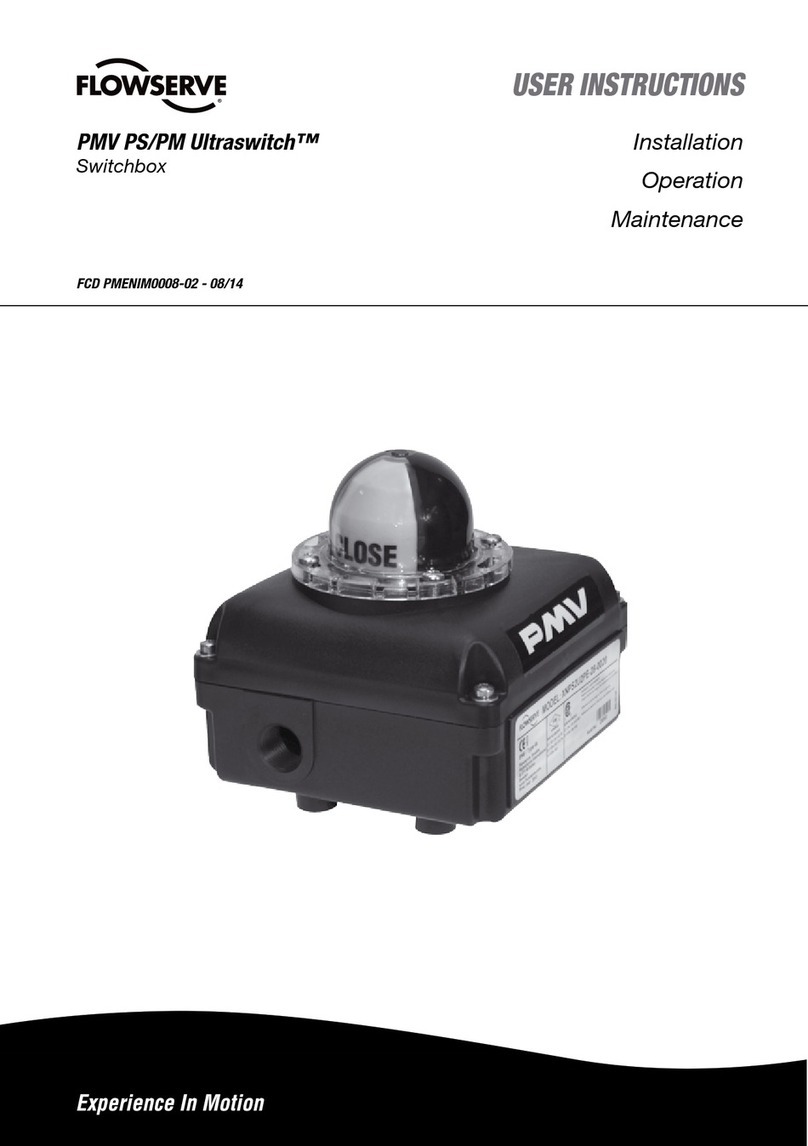

• Perform all wiring according to the

wiring diagram found on the label in the

housing (see picture) and instructions

given below.

• Make sure that the ground wire is

correctly connected

• Seal unused entries with proper and

suitable conduit plugs.

The WS/WM Ultraswitch™ enclosures feature pre-

wired switches. All user connections are made at a

numbered terminal strip. Both external and internal

grounding locations have been provided for use

in installation. A wiring diagram is located on the

product label and indicates which terminal number

corresponds to which switch contact: normally open,

normally closed, common, etc. Follow the wiring

diagram, and electric code to connect switches to

your system.

For field wiring: ensure that any excess wire lengths

or loops are routed away from any moving parts

and are short enough, or secured to ensure a 1/4”

clearance between the wire and the inside surface of

the switchbox cover.

Note: for all magnetically tripped proximity switches,

the top switch should only be used to indicate the

clockwise position: the bottom switch should only be

used to indicate the counter-clockwise position. Any

deviation from these settings may result in erratic

indication.

Solenoids may also be wired through the WS/WM

Ultraswitch™ enclosure. At least two auxiliary

terminals are included as standard.Wire the solenoid

to auxiliary terminals, then connect power leads to the

opposite terminal side. Be sure to properly ground the

solenoid at the provided ground terminal.

WS UltraSwitch™ Series enclosures include two 1⁄2”

NPT conduit entries and the WM Series includes two

M20x1.5 conduit entries.

Caution!

• Proper and suitable conduit plugs must be

installed in unused conduit entries before putting

the unit into service.

• Installation must be according to National

Electric Code, local codes, local certificates and

manufacturer’s instructions in all cases. Environ-

mental seals must be used to protect ingress of

water through the conduits.

• Prevent electrostatic build-up for safe use. The

enclosure of theWS/WM Ultraswitch™ switch box

is made of PA6/PA66 and any impact or friction

caused by external objects should be avoided to

prevent electrostatic build-up.

Wiring diagram inside

Internal and external grounding

Terminal strip

FCD PMENIM0010-02 - 06/19