FLOWTECH flowvent User manual

Table of contents

Popular Water Filtration System manuals by other brands

Oase

Oase Bitron C operating instructions

GÜDE

GÜDE GA 20l operating manual

Premier

Premier WP-2 LCV Installation, operation and maintenance manual

Keating Of Chicago

Keating Of Chicago Safe and Easy Filter owner's guide

SIBRAPE

SIBRAPE MINIFILTRO 10010006 installation manual

Kessel

Kessel Ecolift L Series Installation and operating instructions

3M

3M CS-451 Installation and instruction manual

Mitsubishi Electric

Mitsubishi Electric FBM Series installation manual

CF GROUP

CF GROUP VITALIA XEOT05 installation instructions

Bestway

Bestway Flowclear 58486 owner's manual

flamco

flamco FlexBalance EcoPlus C Series Installation and operating instructions

Toshiba

Toshiba TWP-TSR75SHKW instruction manual

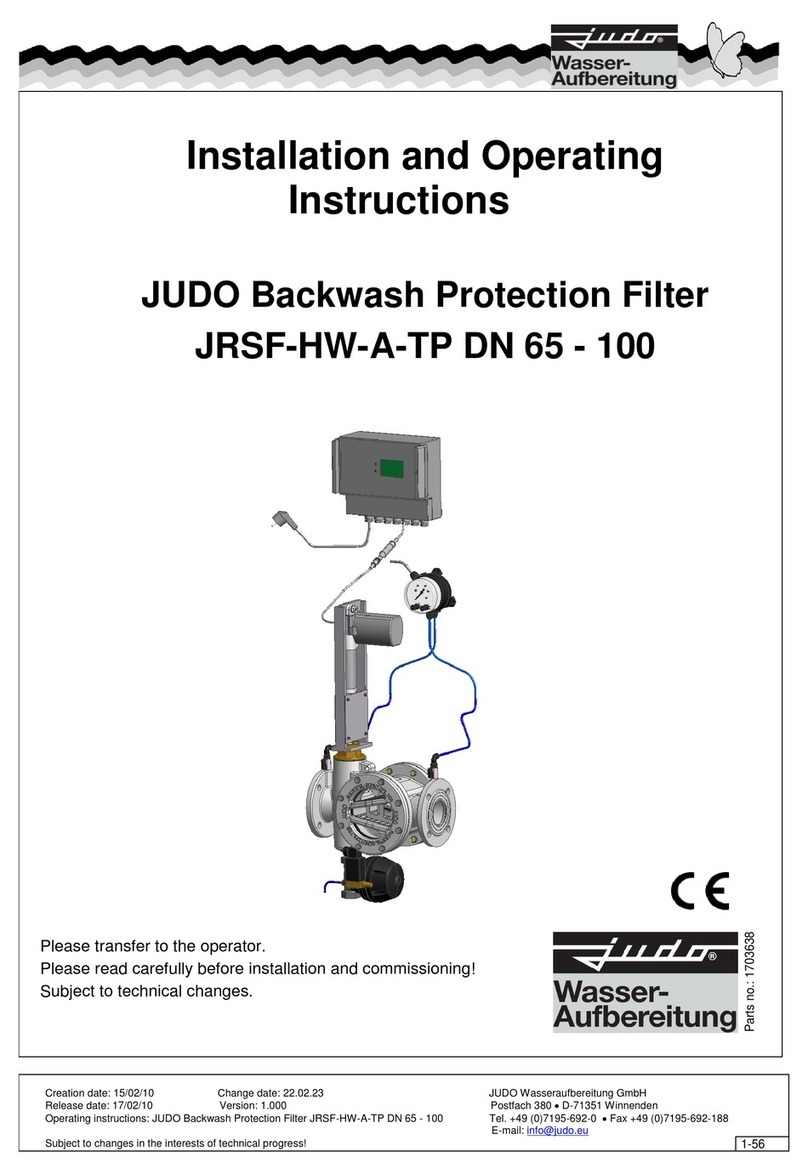

Judo

Judo JRSF-HW-A-TP DN 65 Installation and operating instructions

Purenex

Purenex RD-100 Installation & service manual

Fresh Water Systems

Fresh Water Systems Aqua Choice AOW2 Installation and user guide

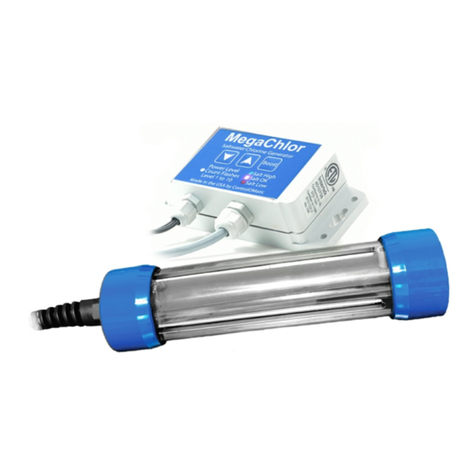

ControlOMatic

ControlOMatic MegaChlor Installation & operation manual

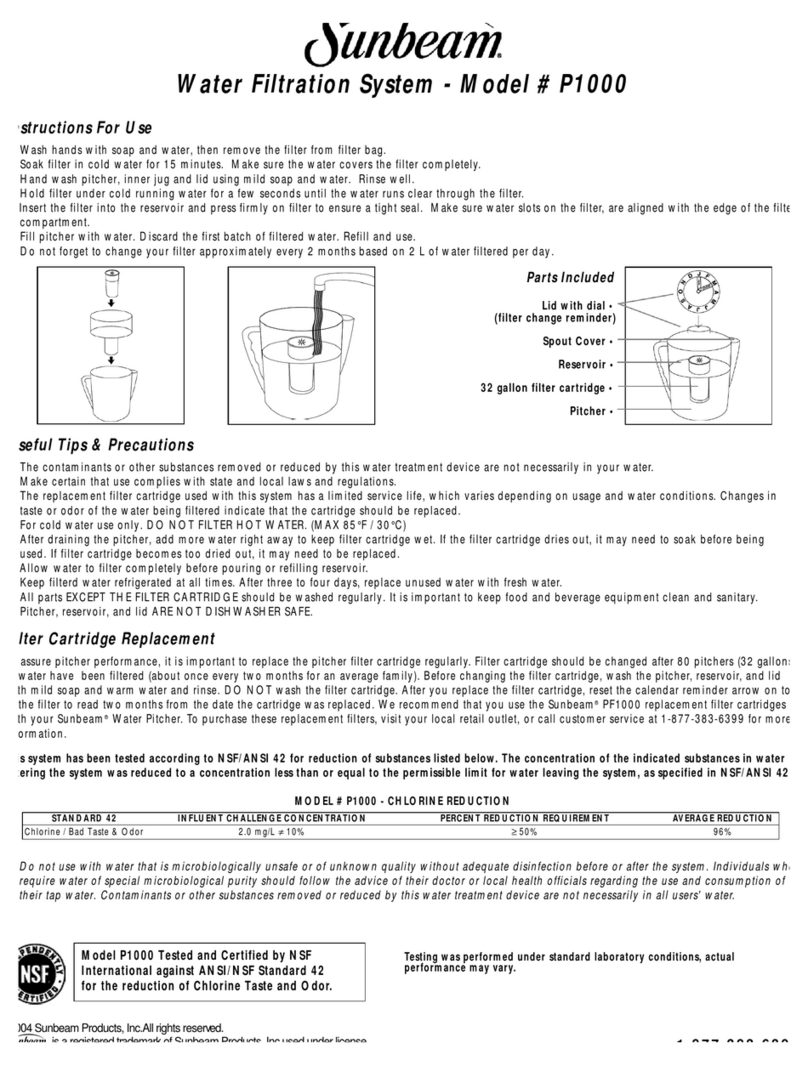

Sunbeam

Sunbeam P1000 Instructions for use

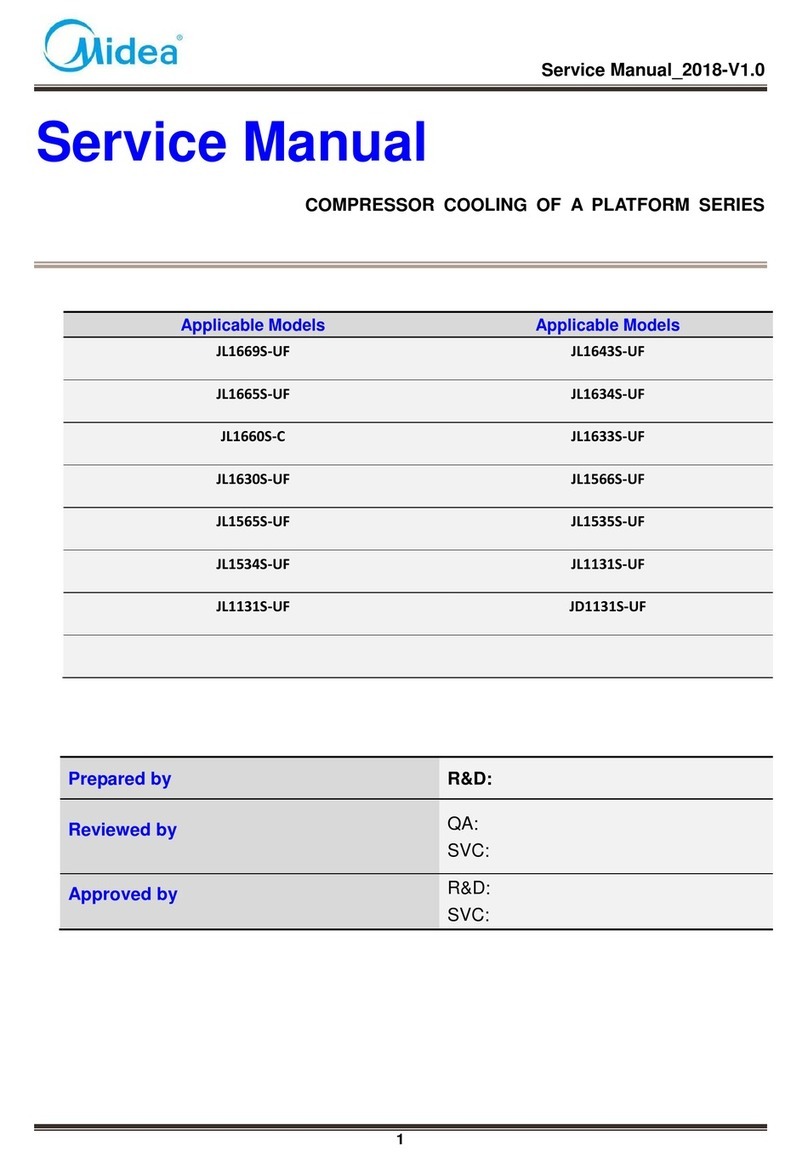

Midea

Midea JL1669S-UF Service manual