FLS FlowX3 F9.20 User manual

F9.20 Battery Powered Flow Monitor

INSTRUCTION MANUAL

EN 05-03

Table of Contents

1. Introduction…………………………………………………………………. 3

1.1. Safety Instructions………………………………………………………………. 3

1.2. Unpacking…………………………………………………………………………. 3

2. Description………………………………………………………………….. 4

2.1. Design……………………………………………………………………………... 4

2.2. Technical Features……………………………………………………………… 4

2.3. Connection to FlowX3 Sensors………………………………………………. 4

3. Specifications………………………………………………………………. 5

3.1. Technical Data…………………………………………………………………… 5

3.2. Dimensions………………………………………………………………………. 6

4. Installation………………………………………………………………….. 7

4.1. Panel Installation……………………………………………………………….. 7

4.2. Wall Installation…………………………………………………………………. 8

4.3. Compact Installation…………………………………………………………… 8

4.4. Wiring……………………………………………………………………………... 9

5. Operational Overview…………………………………………………….. 11

5.1. Keypad Functions………………………………………………………………. 11

5.2. General Operation Flowchart…………………………………………………. 11

6. View Level…………………………………………………………………... 13

7. Menu Directory Level……………………………………………………… 13

7.1. Free access (no password required)………………………………………… 14

7.2. Password protected access…………………………………………………… 14

F9.20 BatteryPowered Flow Monitor

1

8. Menu and Edit Level………………………………………………………. 15

8.1. Calibration Menu…………………………………………………………………… 15

8.1.1. Unit………………………………………………………………………………. 15

8.1.2. K-Factor…………………………………………………………………………. 16

8.1.3. Inftot Backup……………………………………………………………………. 16

8.4. Options Menu……………………………………………………………………….. 17

8.4.2. Filter……………………………………………………………………………… 17

8.4.3. Flow Decimal Point…………………………………………………………….. 18

8.4.4. Total Decimal Point…………………………………………………………….. 18

8.4.7. Menu PWD……………………………………………………………………… 19

8.4.8. Restot PWD…………………………………………………………………….. 19

8.4.9. K-Factor Calculate……………………………………………………………… 20

9. Troubleshooting……………………………………………………………. 21

9.1. Display messages………………………………………………………………….. 21

10.K-Factor Tables…………………………………………………………….. 22

11.Ordering Data………………………………………………………………. 23

F9.20 BatteryPowered Flow Monitor

2

1. Introduction

1.1. Safety Instructions

General Statements

Do not install and service the instrument without following the Instruction

Manual.

Unit installation and wiring connections should only be performed by qualified

staff.

Do not modify product construction.

Installation and Commissioning Statements

To clean the unit, use only chemical compatible products.

1.2. Unpacking

Please verify that the product is complete and without any damage. The following

items must be included:

• F9.20 Battery Powered Flow Monitor

• Instruction Manual for F9.20 Battery Powered Flow Monitor

• Instruction Manual for F3.00 Flow Sensor (only for F9.20.XX Compact Battery

Powered Flow Monitor)

F9.20 BatteryPowered Flow Monitor

3

2. Description

2.1. Design

The FLS FlowX3 F9.20 Battery Powered Flow Monitor is equipped with two long life

lithium batteries and it integrates the power supply for the sensor. It is designed to

show on the LCD display flow rate and totalized flow volume with no external power

supply required. One of the two totalizers is resettable while the other is non-resettable

and it is used to permanently record volume consumption. Self explaining calibration

menus allow a customized setup of all measuring parameters and the state of the art

electronic design ensures long-term reliable and stable indications. The high flexibility

is maximized with only one packaging for compact pipe mount, panel or wall

installation.

2.2. Technical Features

2.3. Connection to FlowX3 Sensors

FlowX3 Sensors

FlowX3

Monitor

F3.00.H

F3.00.C

F3.01.H

F3.01.C

F3.15.H*

F3.30.H*

ULF.H

ULF.R

ULF3.15*

ULF3.30*

F111.H

F111.C

F9.20 X X X X

* with Output Kit mounted

F9.20 BatteryPowered Flow Monitor

4

3. Specifications

3.1. Technical Data

General

Associated flow sensor:

• FLS FlowX3 Coil effect with frequency output

• FLS FlowX3 Reed effect

Materials:

• Case: PC

• Panel gasket: Neoprene

• Wall & Field gasket: EPDM

• Keypad: 5-button silicone rubber

Display:

• 3 line LCD: 2 x 12 alphanumeric lines + 1 icon line

• Update rate: 1 second

Enclosure: IP65 front

Electrical

Supply Voltage: 2 x 3.6 Volt Lithium thionyl chloride battery, 2.8 Ahr

Battery life: nominal 5 years

Sensor Input (Frequency):

• Sensor power: 3,6 Volt

• Range: 1 to 500 Hz

Environmental

Operating temperature: -5 to +60°C (23 to 140°F)

Storage temperature: -10 to +80°C (14 to 176°F)

Relative humidity: 0 to 95% non condensing

Standards and Approvals

Manufactured under ISO 9002

CE rating according to:

- Immunity: EN50082-1

- Emission : EN61000-6-2

- Low Voltage Directive : EN61010

F9.20 BatteryPowered Flow Monitor

5

3.2. Dimensions

Compact Mount

Panel Mount

Wall Mount

F9.20 BatteryPowered Flow Monitor

6

4. Installation

The battery powered flow monitor is available just in one packaging for compact field

version, panel or wall installation. The compact field version is mounted on top of the

sensor using the compact mounting kit (F9.KC1), the panel version is installed using the

panel mounting kit (F9.KP1), while the wall mounting version is fixed with the wall

mounting kit (F9.KW1).The mounting kits can be ordered directly connected to the monitor

or separately and then simply installed on it.

4.1. Panel Installation

The panel mounting version consists of the monitor and the mounting bracket kit

F9.KP1 with gasket for IP65 watertight panel installation. The monitor perfectly fits into a

standard ¼ DIN panel cutout.

1. Cut out the panel: the F9.20

requires a panel opening of

90,5 x 90,5 mm (3,563” x

3,563”). ¼ DIN punches are

recommended, alternatively a

jigsaw or another cutting tool

may be used.

2. Recommended minimum

clearance between panel

cutouts is 28 mm (1.1”) as

illustrated.

3. Place gasket on the instrument

and install into the panel. Be sure

the panel gasket is properly

seated against the panel and

around the instrument case.

4. Slide the metal bracket over the

back of the instrument. Press the

bracket against the inside of the

panel to perfectly fix the

instrument in place.

To REMOVE: press the clips outward while pulling the bracket away from the

instrument panel. Do not allow the instrument to fall out of the panel opening: it

may be helpful to secure the instrument temporarily with tape from front.

F9.20 BatteryPowered Flow Monitor

7

4.2. Wall Installation

The wall mounting version consists of the monitor and the wall mounting kit. The

F9.KW1 kit includes the plastic adapter with gasket for IP65 watertight wall installation

and the fixing screws.

1. Fix the wall mounting kit to a solid wall

using the included screws.

2. Pull the electrical cables through

liquid tight connectors.

3. Make wiring connections according to

wiring diagrams.

4. Secure carefully the F9.20 to the wall

mounting kit using the included

screws until finger tight.

5. Assemble the front cover.

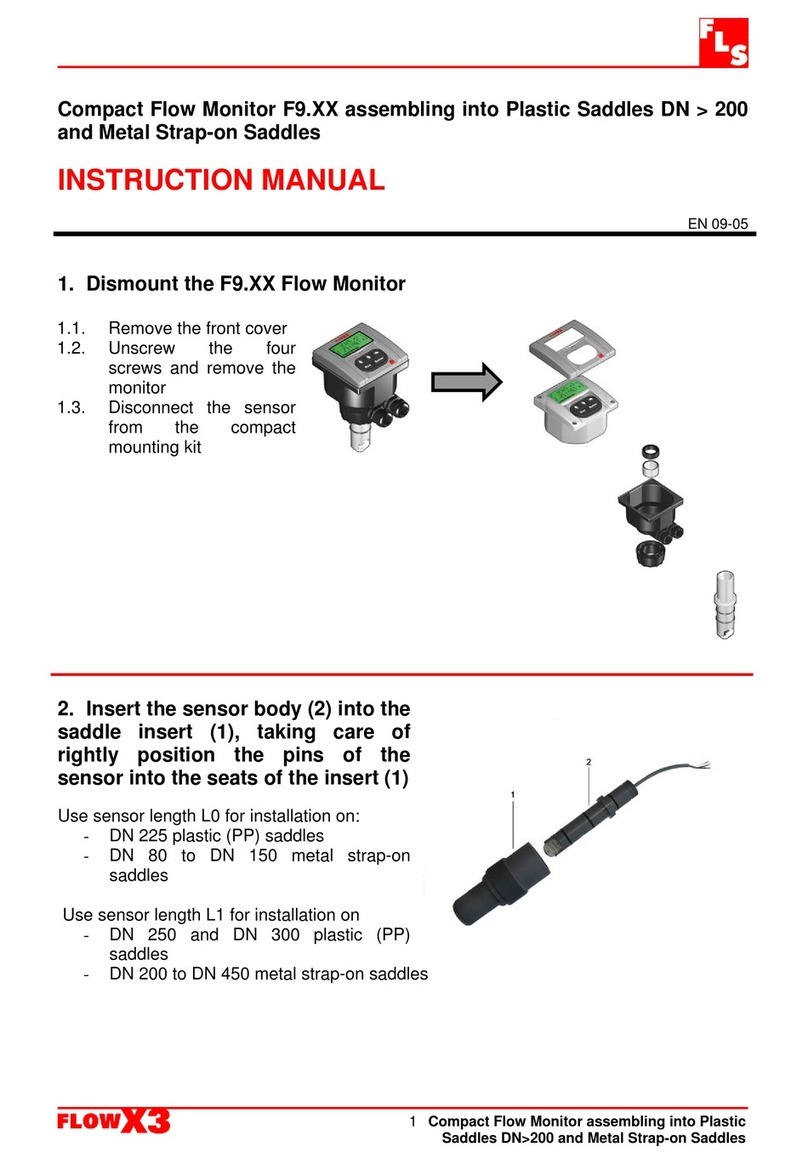

4.3. Compact Installation

The compact mounting kit F9.KC1 includes the

compact plastic adapter with gasket for IP65

watertight installation, the sensor gasket, the

compact cap, the locking ring and four fixing screws.

1. Assemble the sensor gasket in the proper

2. ate the sensor gasket with a silicone

3. and

4.

5. ugh liquid tight

6. connections according to

7. he F9.20 to the compact

8. e front cover.

seat.

Lubric

lubricant. Do not use any petroleum based

lubricant that may damage the gasket.

Add the compact cap to the sensor

insert the sensor into the plastic adapter

making sure the alignment tabs are seated

in the fitting notches.

Lock the sensor to the adapter: screw

completely the locking ring.

Pull the electrical cables thro

connectors.

Make wiring

wiring diagrams.

Secure carefully t

mounting kit using the included screws until

finger tight.

Assemble th

F9.20 BatteryPowered Flow Monitor

8

4.4. Wiring

ll wiring connections to F9.20 are made via removable terminals. Flow sensor

eneral recommendation

Terminals accept 26 to 12 AWG (0.08 to 2.5 mm2)

S tips and tin bare ends to

ggested when connecting more than one wire to a single terminal.

with the screw until

Wall Installation

proper external diameter for the liquid tight

nal diameter between 2-7 mm (0.079-0.276”)

”)

ear Terminal View

attery Replacement

ure to save the current totalizer in permanent memory

A

terminals are orange, all other terminals are green.

G

trip around 10 mm (0.4”) of insulation from the wire

avoid fraying.

Ferrules are su

Remove the upper part of the terminals for an easy cabling.

Insert wire tip or ferrule completely into the terminal and fix

finger tight.

Compact or

Use electrical cables with the

connector:

PG11: exter

PG13,5: external diameter between 5-12 mm (0.197-0.472

R

B

• Perform the proced

Battery indication appears

on the display when battery

voltage is low

before battery replacement. Refer to section 8.1.3. Inftot Backup

• Replace the batteries on the rear side of the instrument

ispose of the worn out battery properly! Ask to local authorities.D

F9.20 BatteryPowered Flow Monitor

9

Sensor Wiring Diagram

3.00.C IP68 or F3.01.C (compact version) F3.00.C IP65 flow sensor connection

LFXX.R flow sensor connection

• Maximum cable length is 16 m (52.8 ft).

F

flow sensor connection

U

F9.20 BatteryPowered Flow Monitor

10

5. Operational Overview

he FlowX3 F9.20 battery powered flow monitor, like all members of X3 Line, features a

5.1. Keypad Functions

The five push buttons of the keypad are used to navigate display levels and modify

he function of each button may change according to display level; please refer

T

digital display and a five-button keypad for system set-up, calibration and operation. This

section contains a description of the keypad functions and the general operation flowchart

of the instrument.

settings.

T

to following table:

View Scroll through Scroll through S

m

--------- Go to Menu

D litems items

elect items

arked with > irectory Leve

items items

Enter menu for

editing

---------

throu

items items em for editing Directory

or a flashing

digit

or a flashing

digit

Scroll right

through

shing digi

without saving settings

Level Function

Menu Directory Scroll through Scroll through Return to View

Menu Scroll gh Scroll through Enter menu

it

Return to Menu ---------

Edit Modify an item Modify an item

fla ts

Return to Menu Save new

5.2. General Operation Flowchart

The F9.20 battery powered flow monitor features four different levels as shown in the

View Level: this is the default level. After instrument set-up, all measured

u Directories for different set-

correct

each item in a Menu can be viewed and

eters can be set, modified and saved at this

following flowchart illustrating the basic navigation concepts.

values. Refer to section 6. View Level for details.

Menu Directory Level: there are two different Men

up and calibration. Refer to section 7. Menu Directory Level for details.

Access to this level can be free or password protected. Entering the

password allows direct access to next levels and to all editable items in all

menus, until a return to View Level.

Menu Level: the current setting for

selected for editing at this level.

Edit Level: all instrument param

level. Refer to section 8. Menu and Edit Levels for details.

F9.20 BatteryPowered Flow Monitor

11

F9.20 BatteryPowered Flow Monitor

12

F9.20 BatteryPowered Flow Monitor

13

6. View Level

• During normal operation, the flow monitor is in View Level displaying all measured

values.

• If the flow monitor is in a different level and no activity occurs for more than 3

minutes, it will return to View Level.

• To select the item you want displayed, press UP or DOWN arrows.

• Changing display indication does not affect or interrupt instrument operation

and calculation.

Description

Flow rate and resettable totalizer value

Resettable totalizer and flow rate value

Permanent totalizer value

Flow rate value

Resettable totalizer value. Press the RIGHT arrow key

to reset. If locked, you will need to enter the password

first. Lock or unlock the total reset in Option Menu (refer

to section 8.4.8. Restot PWD for details)

7. Menu Directory Level

Access to this level can be free or password protected. Entering the correct password

allows direct access to next levels and to all editable items in all menus, until a return to

View Level (refer to section 8.4.7. Menu PWD to select password protected access).

Four different menus are available to fully set-up the F9.00 flow monitor and transmitter.

These menus are separated in two different Menu Directories.

In terms of getting started and making measurements, Calibration Menu is the most

important menu in the F9.00 and it is the only one included in the first Menu Directory.

Output Menu, Simulation Menu and Option Menu are included together in the second

Menu Directory.

7.1. Free access (no password required)

7.2. Password protected acc

ess

F9.20 BatteryPowered Flow Monitor

14

8.

8.1. Calibration Menu

The F9.20 basic settings are made in this menu:

8.1.1. Unit

Set the engineering units for the instant flow rate and the total flow rate.

All the options available are displayed on the LCD.

The instrument will

automatically convert

the values of the two

totalizers in the new

engineering units.

To set K-Factor

To set flow rate and

totalizer Engineering Units

Menu and Edit Levels

F9.20 BatteryPowered Flow Monitor

15

he monitor and transmitter how to convert the input frequency

om the flow sensor into a flow rate. The K-factor is unique to the sensor model and to

the pipe size and material.

Refer to section 10. K-Factor Tables for the correct v

Limits: 000.01 to 99999 (the K-Factor cannot be set to 0)

8.1.3. Inftot Backup

The totalizer value can be stored in permanent memory whenever desired.

The procedure must be

performed before

batte

8.1.2. K-Factor

Set the K-Factor to tell t

fr

alue.

ry replacement.

F9.20 BatteryPowered Flow Monitor

16

.2. Options Menu

8.2.1. Filter

eraging level

to dampen LCD

indication, output and

relay response.

OFF: no dampening

effect, near instantaneous

response.

To select the averaging level of

LCD, output and relay response

To set the flow rate decimal

point position

To set the totalizer decimal

point position

To set ON or OFF password

protection to enter Menu Levels

reset totalizer

To perform automatic

calculation of K-Factor

8

To set ON or OFF password

protection to

Select the av

F9.20 BatteryPowered Flow Monitor

17

8.2.2. Flow Decimal Point

et the decimal point

pplication.

ns:

.XXXX ; XX.XXX ;

Set the decimal point

position to get the best

resolution for the

application.

Select one of the

following options

XXXXXXXX.XX

S

position to get the best

solution for there

a

Select one of the

llowing optiofo

X

X

X

XX.XX ; XXXX.X ;

XXXX.

8.2.3. Total Decimal Point

XXXXXXXXX.X

XXXXXXXXXX.

F9.20 BatteryPowered Flow Monitor

18

8.2.4. Menu PWD

Set

pro

Dir

lev

NOTE: the standard password is and it cannot be modified.

Se

pro

tot undesired

res

OTE: the standard password is and it cannot be modified.

ON the Menu PWD to

tect access to Menu

ectory Level and next

els.

.2.5. Restot PWD8

t ON the Restot PWD to

tect the resettable

alizer from

et operations.

N

F9.20 BatteryPowered Flow Monitor

19

8.2.6. K-Factor Calculate

Option used to perform automatic calculation of K-Factor by measuring the volume filled

into a tank. This to get the highest accuracy possible.

Press ENTER to start calculation.

Switch on a pump or open a valve.

F9.2

the s

When the tank is full, switch off the

pump or close the valve. Press

ENTER to stop calculation. F9.20

stops counting pulses from the

sensor.

Enter the volume (in liter) of fluid

filled into the tank.

F9.20 is calculating the new

K-F

0 starts counting pulses from

ensor.

actor.

Successful K-Factor

calculation. Press ENTER to

accept new K-Factor or ESC

to return without saving.

F9.20 BatteryPowered Flow Monitor

20

Table of contents

Other FLS Measuring Instrument manuals