Panasonic RS-790S User manual

Other Panasonic Measuring Instrument manuals

Panasonic

Panasonic EYFR02 User manual

Panasonic

Panasonic KW1M-H User manual

Panasonic

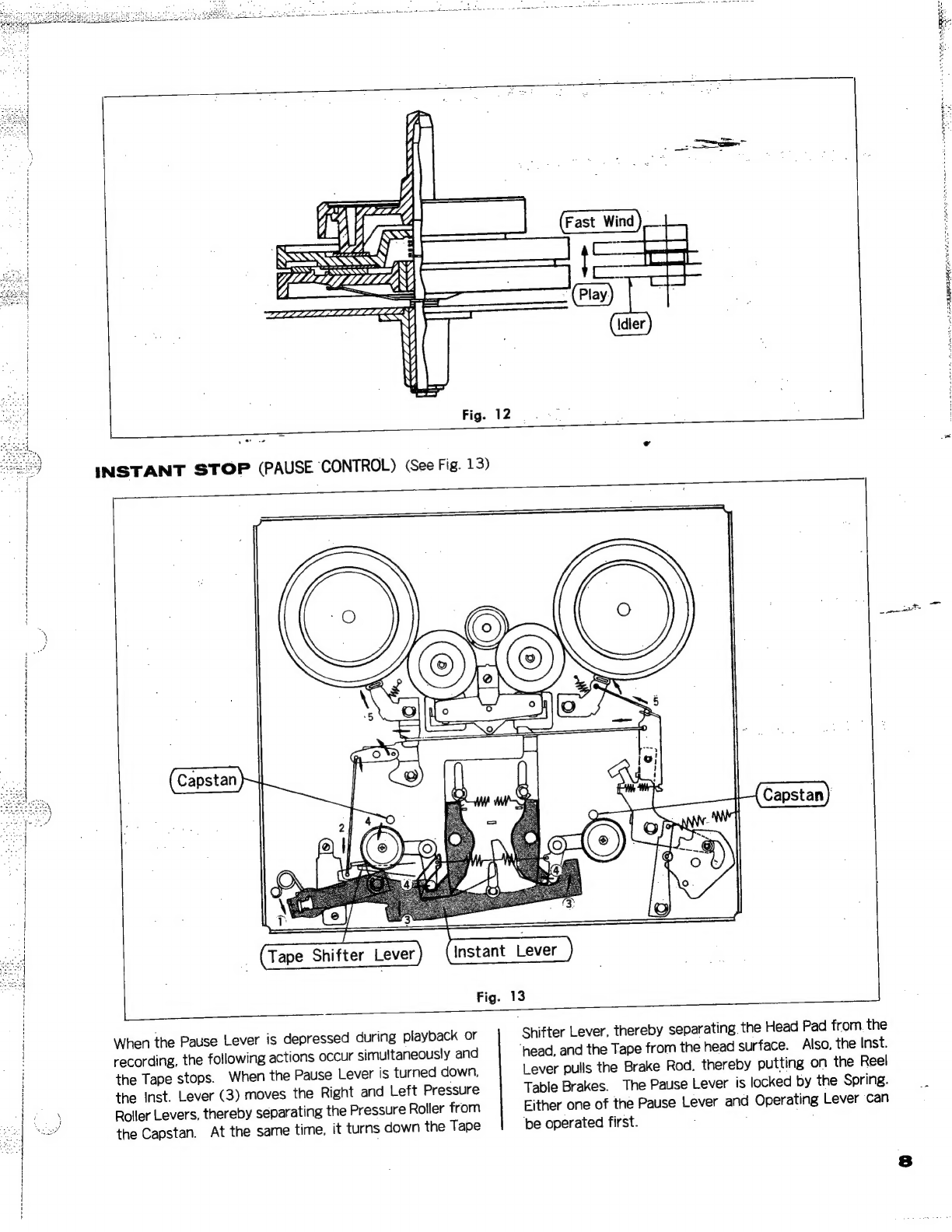

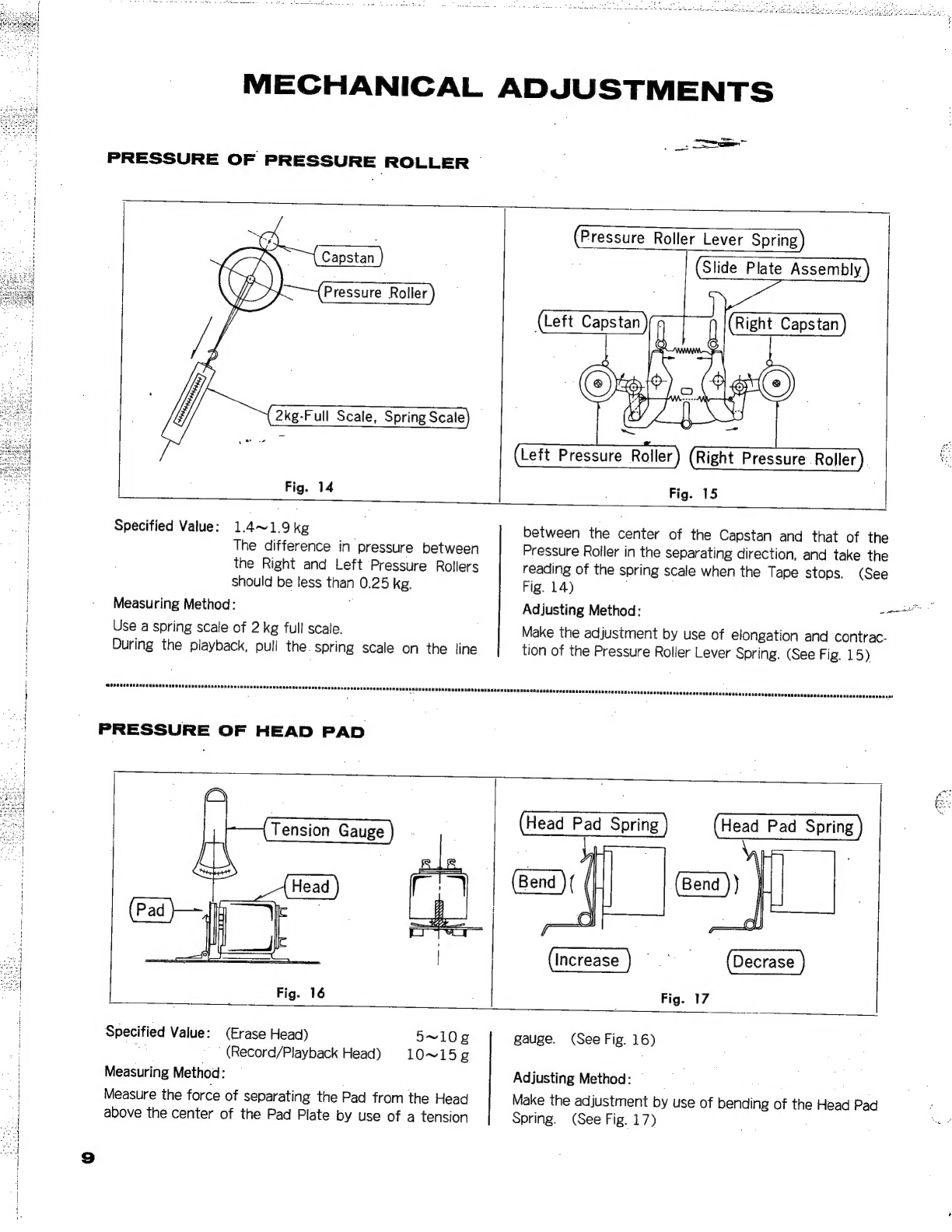

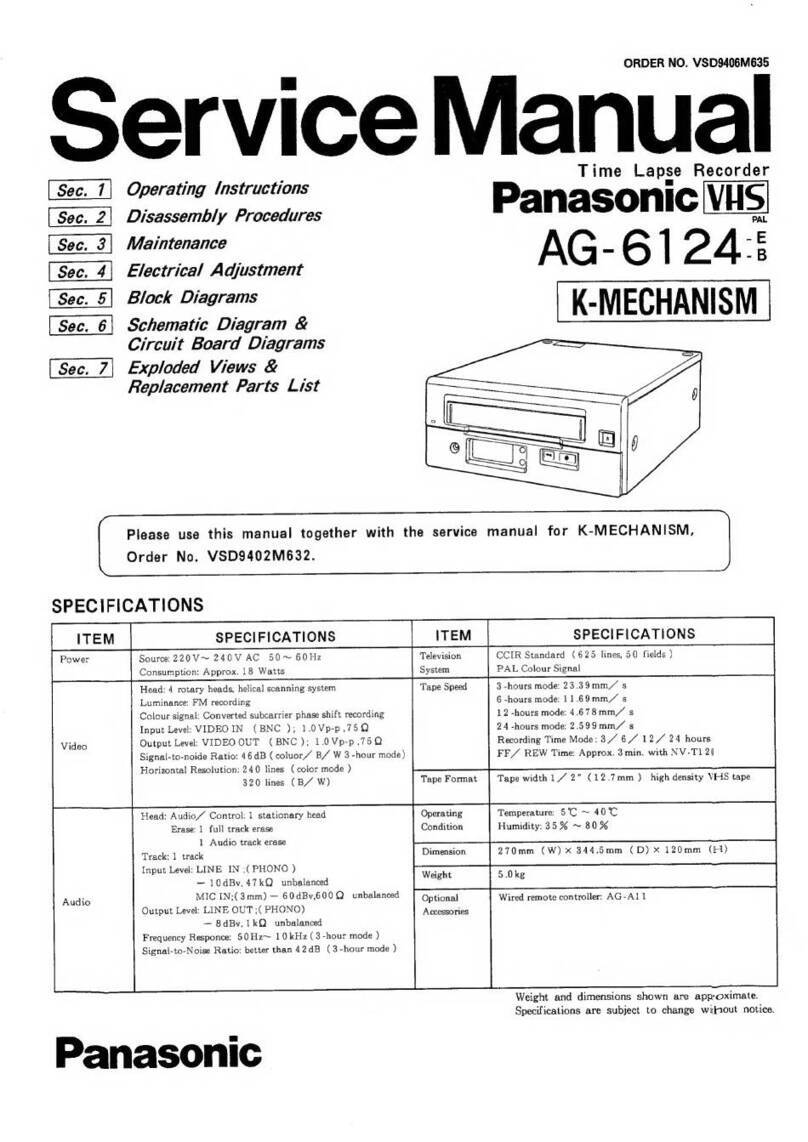

Panasonic AG6124 User manual

Panasonic

Panasonic KW9M Eco-Power Meter User manual

Panasonic

Panasonic KW9M Eco-Power Meter User manual

Panasonic

Panasonic PV-V4524S User manual

Panasonic

Panasonic WJ-NV300K/GJ User manual

Panasonic

Panasonic AJ-PG50EJ User manual

Panasonic

Panasonic RRQR100 - IC RECORDER User manual

Panasonic

Panasonic FZ-VNP001U User manual

Panasonic

Panasonic KW9M Eco-Power Meter User manual

Panasonic

Panasonic ShowStopper PV-SS2710 User manual

Panasonic

Panasonic DMR-HW220 User manual

Panasonic

Panasonic LP-GS Series User manual

Panasonic

Panasonic Omnivision PV-V4600 User manual

Panasonic

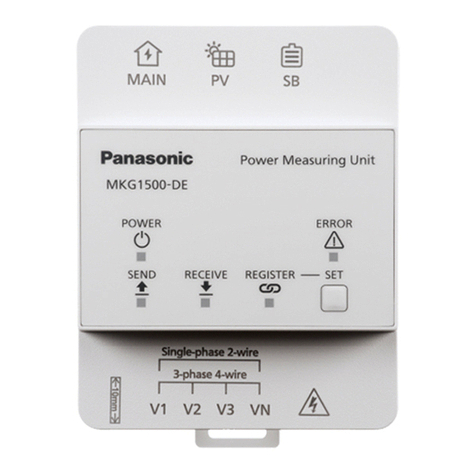

Panasonic MKG1500-DE User manual

Panasonic

Panasonic AG-RT850P User manual

Panasonic

Panasonic KW4S User manual

Panasonic

Panasonic WJHD500 - DIGITAL DISC RECORDE User manual

Panasonic

Panasonic LP-400 Series Use and maintenance manual