Table of Contents

Safety precautions ......................................................................................................... 1

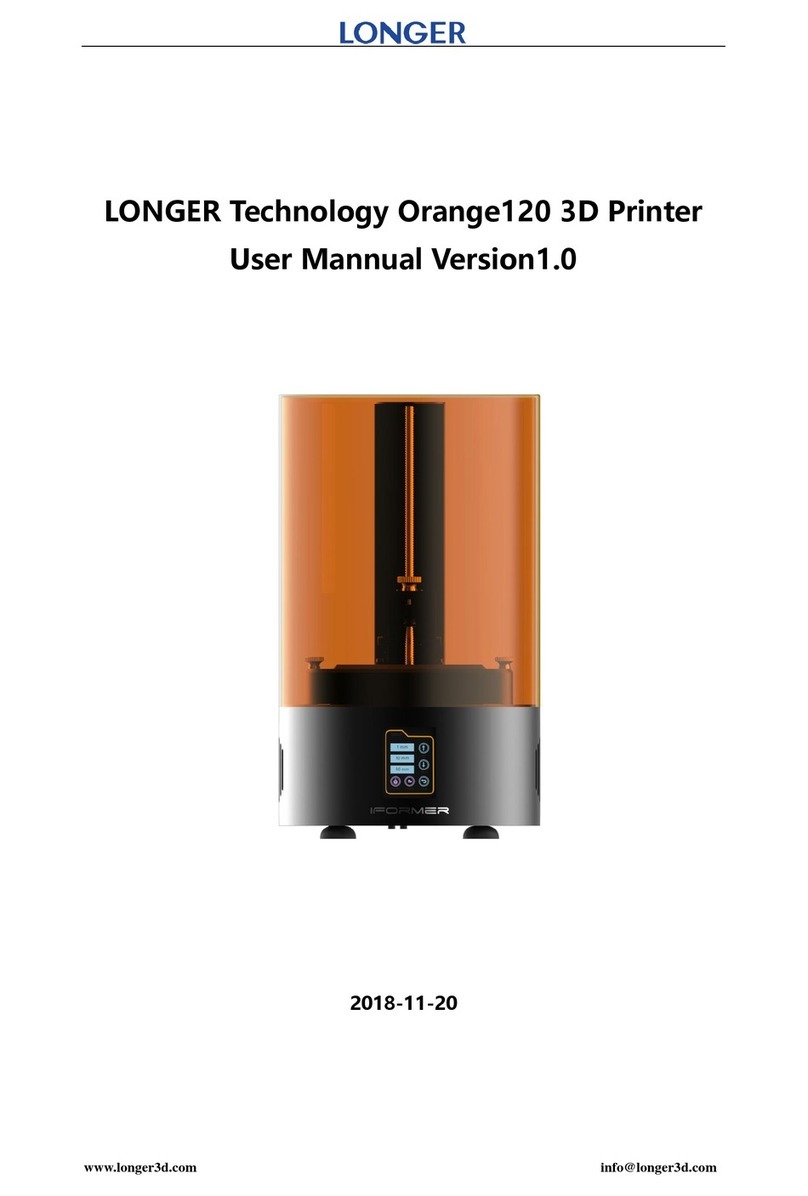

1. Product information ...................................................................................................3

1.1. Printer parameters ........................................................................................ 3

1.2. Packing list ..................................................................................................... 4

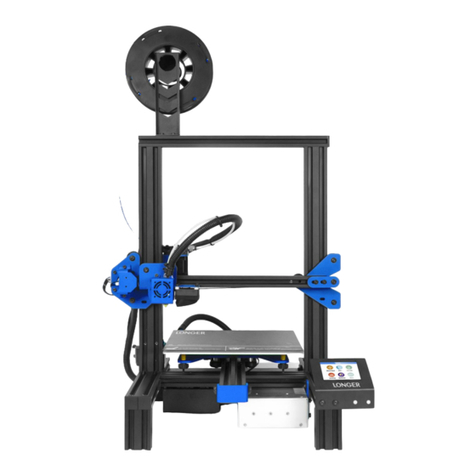

1.3. Printer overview ............................................................................................ 5

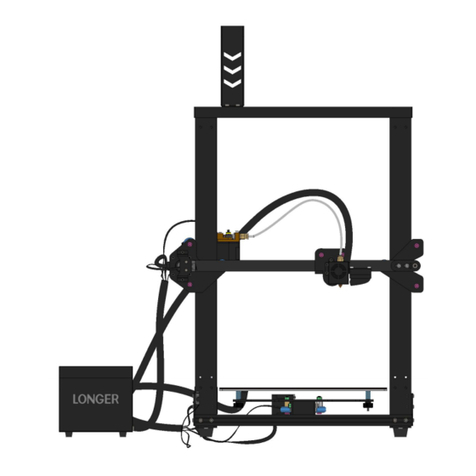

2. Printer assembly ........................................................................................................ 7

2.1. Unpacking the parts ...................................................................................... 7

2.2. Install frame and base ................................................................................... 8

2.3. Install holders of filament and sensor ........................................................... 9

2.4. Install auto level sensor and touch screen .................................................. 10

2.5. Connect the cables ...................................................................................... 11

2.6. Check the X and Y axis ................................................................................. 12

2.7. Leveling ........................................................................................................13

3. Machine operation ...................................................................................................15

3.1. Machine control interface description ........................................................ 15

3.2. Home interface ............................................................................................ 16

3.3. Move interface .............................................................................................17

3.4. Tune interface ..............................................................................................18

3.5. Filament interface ........................................................................................19

3.6. Leveling interface .........................................................................................20

3.7. File interface ................................................................................................ 22

3.8. Print interface .............................................................................................. 23

4. Installation and use of Cura software ...................................................................... 24

4.1. Software installation ....................................................................................24

Add the LK4 X 3D printer to Cura....................................................................... 25

4.3. Import the model ........................................................................................ 26

4.4. Slicing parameters....................................................................................... 27

4.5. Slice and save Gcode files ............................................................................28

4.6. Slice and preview .........................................................................................29

4.7. Print online .................................................................................................. 29

5. FAQ manual ..............................................................................................................32

5.1. How to update the firmware? ..................................................................... 32

5.2. How to solve a clogged nozzle? ...................................................................32

5.3. What to do if the hot bed can not be leveled?........................................... 33

5.4. How to solve filament does not adhered to the hot bed? .......................... 35

5.5. what to do if the printer can not be printed online? .................................. 36