fluid-o-tech ROTOFLOW User manual

08/09 Ed., Rev. B Page 1of 16

Fluid-O-Tech

PUMP TECHNOLOGY AT ITS BEST WWW.FLUID-O-TECH.COM

Office: 161 Atwater St., Plantsville, CT 06479 Phone: (860) 276-9270 Fax: (860) 620-0193

“ROTOFLOW”

ROTARY VANE PUMP

REBUILD MANUAL

08/09 Ed., Rev. B Page 2of 16

Contents

1) Materials Needed

2) Disassembly

3) Inspection

4) Reassembly

5) Testing

6) Rebuild Specifications

CAUTION: Proper safety precautions should always be observed. Always

wear proper eye protection when working.

08/09 Ed., Rev. B Page 3of 16

Materials Needed

# 1) Internal Retaining Ring Pliers/Spanner Wrench

Pliers with the capacity to remove a 2” internal retaining ring,

or spanner wrench if your pump has a screw-on cap.

# 2) Arbor press

Arbor press with at least 12“ of clearance underneath the ram.

# 3) Metal Rod

Rod to press out the shaft. It should be about .4” in diameter.

# 4) Bearing puller

Bearing puller for 11 mm ID bearings. Alternatively,

you can use a shallow tapered pin to press the

bearing out from the inside.

08/09 Ed., Rev. B Page 4of 16

# 5) Metal Rod

Rod to press out the washer and counterface.

It should be about 3/4“ diameter.

# 6) Plastic Rod

Short length of plastic rod for pressing the counterface in place.

Nylon is ideal, and should be about 1.1”. The end should be flat

and squared.

# 7) Plastic tube

Plastic tube to press the seal onto the shaft. It should have a flat,

square end with an ID of about .475” and an OD greater than

about 1”.

# 8) Tweezers

These are not required, but make putting the pins in

the rotor much easier.

08/09 Ed., Rev. B Page 5of 16

# 9) Metal Tube

Tube to press the bearing onto the shaft. This can be any

squared off metal tube with an ID of .440” and an OD greater than

m1.25”. Note that this tube must contact the inner and outer ring of

the bearing, otherwise the bearing could be damaged upon install.

# 10) Blocks or supports

Blocks or supports to hold the pump when pressing pieces in or out.

# 11) Repair kit

Repair kit for the Fluid-O-Tech rotary vane

pump you plan to repair.

08/09 Ed., Rev. B Page 6of 16

Disasse bly

1) If your pump has a retaining ring on the cap, use the retaining ring pliers to remove the

ring. Supporting the pump under the arbor press and using the ram to apply pressure aids in

removal of the retaining ring, and can help prevent it from flying off.

If your pump has a sticker on the cap and no retaining ring, remove the sticker. You will see

two small holes on the outer edge and one larger hole in the center. Support the pump in a

vise, and using the spanner wrench in the two outer holes, unscrew the cap counterclockwise.

2) Remove the stainless cap (retaining ring version) or stainless cover (screw-on cap version),

and then remove the o-ring underneath. Sometimes the cap/cover is too difficult to remove by

hand, and a tiny, flathead screwdriver can help to pry the cap free from the o-ring underneath.

3) Flip the pump over and support it on its rim. It should be held several inches above the

work surface of the arbor press, otherwise it will be difficult to fully press the rotor out. Make

sure nothing is obstructing the graphite flanges and rotor from being pressed out. The shaft

of the pump should be positioned directly inline with the ram of the press.

4) Press down on the pump rotor with the arbor press until you hit the bearing. Then you will

need to press the rotor the rest of the way out with the small metal rod (material #3). At this

point the rotor, front flange, vanes, and pins should be out of the pump. Sometimes additional

parts will have come out, but the proceeding steps are still required.

5) Next, you will need to remove the ball bearing. If you have a bearing puller, use it to

remove the ball bearing. If not, insert a slightly tapered pin (one end slightly larger than

11mm and one end slightly smaller) from the inside of the pump, through the seal, and into

the bearing. Support the pump with the bearing facing down, but make sure the bearing is not

obstructed from being pushed out. Then press the bearing out with the tapered pin from the

inside.

08/09 Ed., Rev. B Page 7of 16

6) Once the bearing is out, support the pump again on its rim with the bearing end facing up,

making sure nothing is obstructing components from being pushed out of the body. Now use

the metal rod (material #5) to press out the washer, counterface, and any remaining pieces.

Be sure that the rod presses only on the washer, and not on the small retaining ring or lip.

The pump body should now be empty, with only the small retaining ring and ball bearing o-

ring left inside. These are normally reused.

08/09 Ed., Rev. B Page 8of 16

Inspection

Once disassembled, the reusable components of the pump will need to be inspected for

damage. This includes the body, the rotor and the bypass.

1) Pump Body:

Check the pump body for dents on or around the rim that may impair the insertion of the new

graphite. The rim or ports are the most likely areas for a pump to be dented, and dents can

crack graphite as it is being inserted or keep fittings from screwing in the ports. If the body is

dented, try tapping it out carefully with a hammer if possible. Sometimes a file can be used to

take down the remaining high points. If the ports look damaged, running a tap through the

threads sometimes cleans them up. Also check the body for dirt or debris which could keep

the pump from being assembled properly, or damage the pump when put back into service.

The body should be thoroughly washed out before proceeding.

2) Bypass:

The bypass acorn nut can be removed to check the condition of the bypass valve and seat.

Remove the nut and components, and start by checking the bypass valve. The tapered

portion on it which seats against the hole should be smooth and have very little or no wear on

it. Check the edge of the hole that the valve seats in. This should also be smooth and free of

wear or erosion. If either of these is worn, this could prevent the pump from priming properly,

and/or reduce the flowrate out of the pump. If the valve is worn, it should be replaced. If the

valve seat is worn, the body may not be reusable. If the damage looks minor and the body is

brass, you can try “reseating” it. Drop a 3/8” steel ball bearing into the hole and using the rod

(material #3) hit it several times with a hammer. This can sometimes smooth out the hole

enough to make it reusable.

3) Rotor:

The rotor should have a smooth surface finish. A rough surface will wear out the graphite

quickly as the rotor spins. A nicked or dented slot will prevent the vanes from sliding in and

08/09 Ed., Rev. B Page 9of 16

out, and/or wear the graphite quickly. First, visually inspect the rotor for surface finish, nicks,

or scrapes. If it appears in good shape it should be tested. Run a new vane through each

slot by hand. It should slide freely through each slot. Assemble the rotor with the vanes,

pins(if applicable), liner, and flanges. The rotor should spin smoothly and easily by hand. If it

feels like its scraping the graphite, or if it becomes particularly difficult to turn through part of

the revolution, the problem needs to be addressed before proceeding. Separate the rotor

from the graphite and look for scrape marks as an indication of where the problem lies.

Sometimes the rotor can be salvaged if it’s just a very small nick or galled particle causing the

issue. Try carefully using a file to smooth the area causing the problem. Retest the rotor in

the graphite. If it seems smooth, proceed to the next step.

08/09 Ed., Rev. B Page 10of 16

Reasse bly

1) Before beginning to reassemble the pump, make sure all the pump parts and your work

area are clean. The clearances of the pump are very tight, and even small particles can

damage the pump or keep it from functioning properly. Carefully refer to the parts diagram to

ensure the proper selection and orientation of all parts.

2) Start by assembling the graphite and rotor. Locate the rear flange. Use the parts diagram

to verify that you have the correct flange, as the front and rear flange look similar. Insert the

long shaft end of the rotor through the hole in the center of the flange.

3) Hold the assembly with the shaft pointing straight down. Locate the two pins (these are

used in all 70-400 series pumps, and in only Viton versions of the 500-1000 series pumps).

Verify that they are both the same length. Using tweezers, insert the two pins into the center

of the rotor, perpendicular to each other. The flat sides of the pins should be touching each

other (070-400 series).

4) Locate the 4 vanes. Insert one vane in each slot of the rotor, being careful not to knock the

pins out. Make sure that the radiused or chamfered edge faces outward.

5) Locate the liner and place it over the rotor, either side facing up, but making sure that the

alignment pin notch matches the rear flange.

6) Now locate the front flange. Place the front flange over the top of this assembly using the

parts diagram to verify the orientation.

8) Now take the rotor/graphite assembly and put it with the front flange down on the base of

your arbor press. Center the shaft with the ram.

08/09 Ed., Rev. B Page 11of 16

9) Sometimes pushing the seal over the shaft in the next few steps can be difficult. It helps to

wet the seal and shaft with water, or even better, ethyl alcohol prior to doing this. The same

applies to the counterface which will be inserted later. Do not use any type of grease or oil to

install the seal or counterface. This can result in the shaft slipping in the seal during use,

which will rapidly wear the rubber, and cause the pump to leak. The seal is meant to stay in

the correct location on the shaft by friction.

10) Locate the seal. Position the seal on top of the rotor shaft with the graphite end facing

upwards. Using the plastic tube (material #7), press the seal over the shaft to the proper

depth. Use caution slipping it over the machined edges on the tip of the shaft, as they can

scrape the seal if not careful. The distance from the rear flange to the graphite ring of the

seal, while under pressure from the plastic tube, is 21mm, +/- .1mm. The seal will spring up a

little bit higher than this when pressure is taken off of the seal.

11) Now you will want to set the graphite/rotor assembly aside, and locate the stainless

washer and the counterface. Position the pump body on the table with its bearing end facing

down. Place the washer inside the body so that it rests on top of the small internal retaining

ring or shoulder. Wet the area around the washer and the counterface with ethyl alcohol to

make the installation easier. Next, place the counterface, with the white ceramic side facing

up, above the washer. It will need to be pressed in with the plastic rod (material #6), either by

hand or carefully with the arbor press. It is important to seat the counterface carefully and

uniformly. The stainless steel washer behind the counterface should no longer move around

freely.

12) Now take the graphite/rotor assembly and support it ¼ to ½” off the arbor press work

surface, with the seal facing upwards. Support it by the graphite, and not the tip of the rotor,

and make sure nothing is in the way of the body’s rim sliding beyond the bottom edge of the

front flange. The two holes on one side of the graphite assembly should face to the right (3

o’clock position). Now locate and insert the alignment pin into the alignment notches on the

top of the graphite (12 o’clock position). Sometimes water will help it stay in place.

08/09 Ed., Rev. B Page 12of 16

13) Take the pump body place it over the top of the rotor/graphite assembly, with the acorn

nut facing directly to the left and the ports facing upward (toward 12 o’clock). Locate the ball

bearing and position it in the hole on the top of the pump body. Using the metal tube (material

#10), press the body and bearing over the graphite/rotor assembly slowly and carefully,

guiding the graphite into the pump as you go. Continue pressing until the graphite is all the

way in and the bearing is flush with the pump body.

14) Flip the pump over on its shaft end. Make sure that the exposed flange is free of debris.

Locate the o-ring, and insert it into the groove in the graphite, running you finger over it in a

circle to ensure it is seated evenly. Place the cap or stainless cover over the o-ring. If the

pump uses a screw-on style cover, screw the cover on at this point. If it has a retaining ring

style cover, rest the large retaining ring on top of the cap. Position this under the arbor press

and rest the ram on the cap. While applying slight pressure, insert the retaining ring into the

groove using the retaining ring pliers. Once in the groove, apply a little more pressure with

the arbor press to allow the ring to further seat itself. It is then important to squeeze the ring

against the rim in several spots around the perimeter, with the pliers or some other similar

tool, in order to completely seat the retaining ring.

15) Now turn the pump by hand. It should offer some resistance, but feel smooth (the torque

should not be greater than 2.6 in.-lbs.). If it is very difficult to turn the pump by hand, it will

generally have to be disassembled, checked and then reassembled. This is often caused by

a tiny bit of debris getting stuck between the rotor and the flanges, or a not fully seated set of

graphite. Occasionally, a gentle tap on the end of the shaft with a hammer can fix the

problem, although not usually, and great caution must be exercised.

16) The last thing to do is change out the bypass o-ring, if your pump is equipped with a

bypass. If you don’t plan to test the bypass setting before putting the pump back into service,

make note of the position of the screw so that you can return it to the same position when you

are finished. Unscrew and remove the screw in the center of the acorn nut. You will see a

small o-ring at the head of the screw. Remove this o-ring and install the new one. Be careful

not to cut the new o-ring on the head of the screw, as it sometimes has a sharp edge. Screw

08/09 Ed., Rev. B Page 13of 16

the screw back into the acorn nut, returning it to the desired setting. If you want to test the

bypass setting, refer to the section “Testing” below.

08/09 Ed., Rev. B Page 14of 16

Testing

It is recommended that the pump be tested before being put into service, to ensure that the

pump was assembled properly and is running satisfactorily. The pump can be tested as

follows:

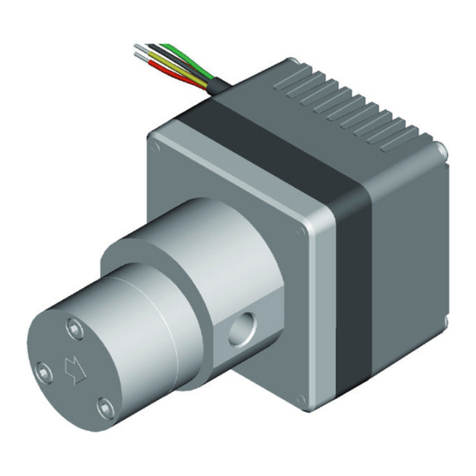

1) Connect the pump to a motor using the proper coupling and adapter if necessary (contact

Fluid-o-Tech for details, or visit www.fluidotech.com). Plumb the inlet of the pump directly to a

source of clean water, using tubing with an ID sufficiently sized for the flowrate of the pump.

Plumb the outlet of the pump to an inline pressure gauge, then to a ball valve, then to a flow

meter if one is available, then back to the reservoir of water (or drain if you are using a city

line). Be sure that no teflon tape or pipe dope enters the lines, as this can cause significant

damage to the pumps.

2) Turn the unit on and allow the pump to prime and rid the circuit of air. This shouldn’t take

too long, but if after a long period of time air still remains in the lines, check the following: the

fittings are sealed in the ports properly, the bypass is screwed on tightly and has a nylon

washer, the hoses in the tank are well below the surface of the water and not too close to

each other, and that there are no other leaks in the circuit. If the pump at any point begins to

make a buzzing noise, this is usually a sign of cavitation. To remedy, increase the inside

diameter of the inlet hose and/or shorten it’s length.

3) Once the pump is up and running, check for any obvious leaks. The important points to

examine are the cap, weep holes, bypass, and inlet and outlet. It is normal, on occasion, for a

few drops of liquid to come out of the weep holes on initial startup, especially if there is

residual ethyl alcohol in the cavity. This isn’t a problem unless it is a large amount or a

continuous drip. Next, take a reading on the flow meter. It should be a value close to the

flowrate listed on the corresponding data sheet for the particular pump and speed you are

using. Now close of the valve in the line to raise the pressure to about 100 psi. Re-check for

leaks and take another flow reading. Allow the pump to run for five or ten minutes. If after

08/09 Ed., Rev. B Page 15of 16

this the pump performs properly without leaking, it has been successfully rebuilt. If the cap

leaks, the cap o-ring and mating surfaces should be checked and replaced if necessary and

re-tested. If the pump leaks from the weep holes, the seal and counterface should be

checked and/or re-placed, then reassembled and tested.

4) The max bypass pressure can also be adjusted at this time if desired. This only applies to

those pumps equipped with an acorn nut on the inlet. It is advisable to turn the screw out until

it is flush with the acorn nut as a starting point. Before undertaking this procedure, make sure

that the equipment you are using is able to withstand at least the maximum pressure you will

be setting the bypass to. To test the max attainable pressure, close off the ball valve all the

way (while closely monitoring the pressure gauge to make sure it doesn’t go above 240psi)

and take a pressure reading. Turn the screw clockwise to increase the max pressure and

counterclockwise to decrease it. Be careful that you do not exceed 240 psi, the max rated

pressure for the pump. Set the max pressure to a point above the maximum operating

pressure, but below the maximum rated pressure for your system. Please note that the

bypass pressure should be set a minimum of 30 psi for 070-400 series and 60 psi for 500-

1000 series above the normal maximum operating pressure of your system. If the differential

is less than this, the bypass will potentially be damaged by overusing itself during normal

operation, and flowrate will suffer. The bypass is also not to be used as a flow or pressure

regulator. That will also wear the bypass rapidly. It is only designed to be used as a safety

valve in case of a system malfunction.

08/09 Ed., Rev. B Page 16of 16

Rebuilding Specifications

Liner Inside Diameters: 070 32.7mm

100 32.9mm

150 33.3mm

200 33.7mm

250 34.1mm

300 34.4mm

350 34.8mm

400 35.2mm

Pin Lengths: 070 16.2mm

100 16.2 mm

150 16.5mm

200 16.9mm

250 17.2mm

300 17.6mm

350 17.9mm

400 18.1mm

Max Shaft Torque: 2.6 in.-lbs.

Seal Depth: 21mm +/- .1mm

Ball Bearing: 11mm ID

30 mm OD

Table of contents

Other fluid-o-tech Water Pump manuals

fluid-o-tech

fluid-o-tech DGD Series User manual

fluid-o-tech

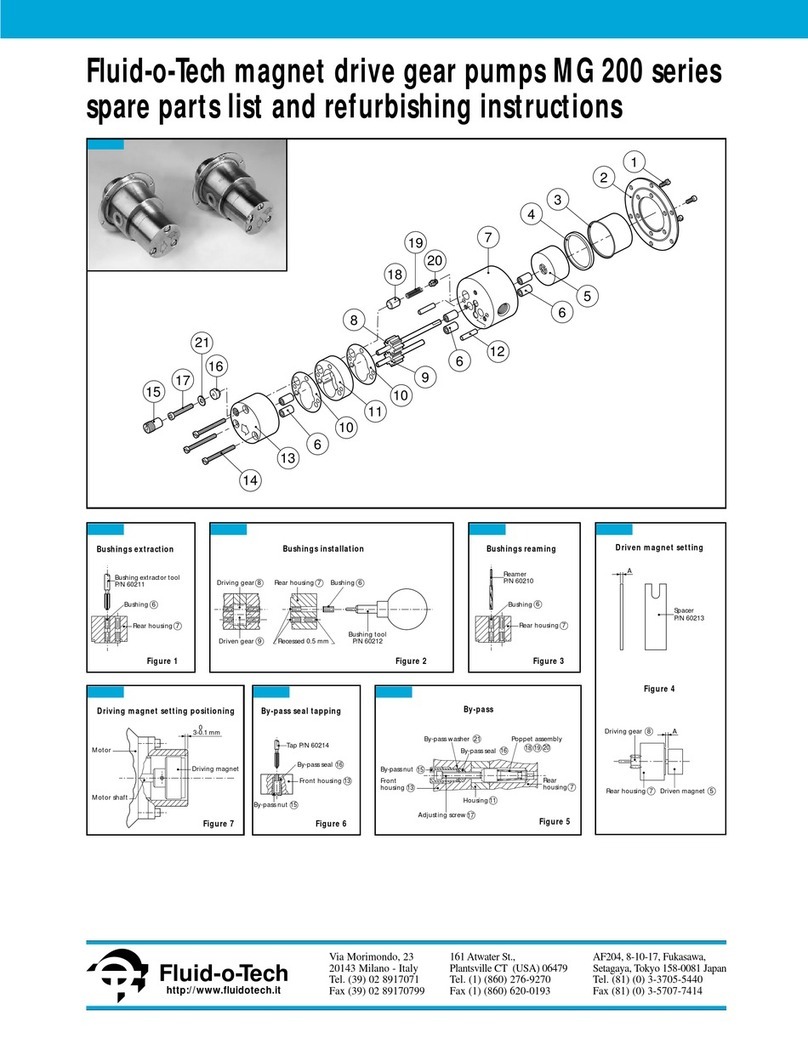

fluid-o-tech MG 200 Series User manual

fluid-o-tech

fluid-o-tech MG Series User manual

fluid-o-tech

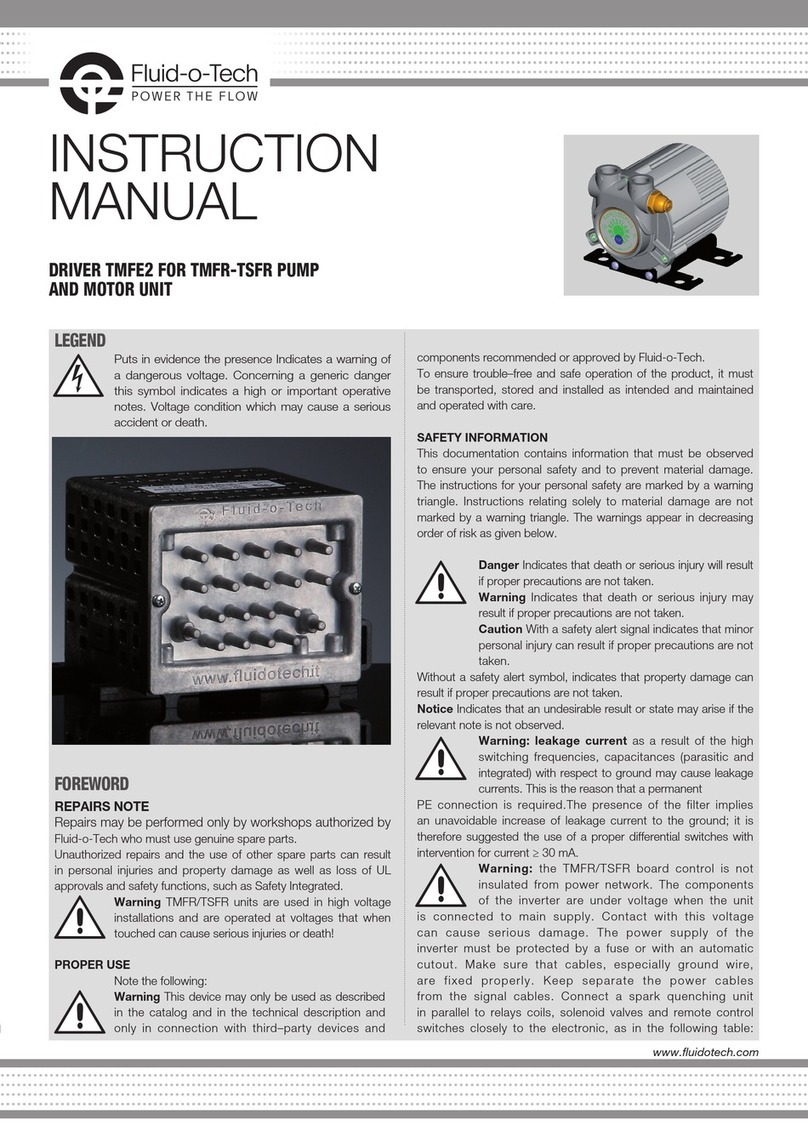

fluid-o-tech TMFR User manual

fluid-o-tech

fluid-o-tech MONO Series User manual

fluid-o-tech

fluid-o-tech MK series User manual

fluid-o-tech

fluid-o-tech FG Series User manual

fluid-o-tech

fluid-o-tech DGD PRO Series User manual

fluid-o-tech

fluid-o-tech TP30 Series User manual