MANUAL - PERISTALTIC PUMPS TP30 - 12/21 Ed.

Fluid-o-Tech reserves the right to alter the specifications indicated in this catalogue at any time and without prior notice.

pumps to ensure optimum perfomance. Using non-

original tubes may result in a different performance

or damage the pump by invalidating the applicable

warranties.

• Periodically, check that the pump is working properly

and that the tubing is in good conditions, especially

if aggressive or hazardous fluids are pumped which

may cause damage or risks.

• In case the TP30 pump handles dangerous or

aggressive fluids, before disconnecting it from the

circuit, make sure the fluid contained in it has been

removed or neutralized by using of appropriate

reagents.

GENERAL INFORMATION

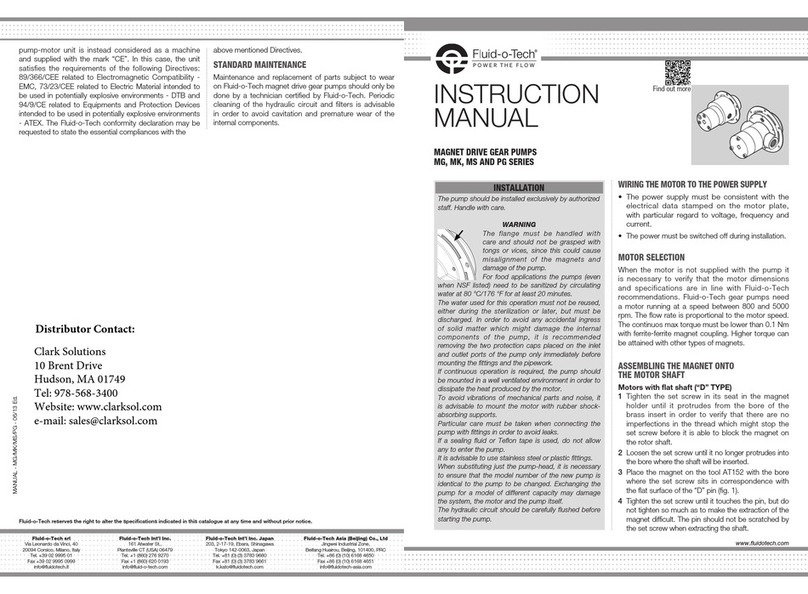

The Fluid-o-Tech TP30 Series is designed for use

in food, medical, laboratory and general industrial

applications. Before use, it is the responsibility of the

installer to ensure the tube materials are compatible

with the pumped media and that the environment is

suitable for the installation and operation of the product.

Electrical connections should be made by a suitably

qualified person. The power supplied to the pump

motor should be consistent with the design and rating

of the motor supplied. In case of doubt, please refer

to the factory quoting the model number and serial

number.

This pump is not suitable for direct use on human

beings. For food applications the pump needs to be

sterilized by an approved method appropriate to the

intended use. The pump should be mounted in a

well ventilated environment in order to dissipate the

heat produced by the motor. To avoid vibrations of

mechanical parts and noise, it is advisable to mount

the motor with rubber shock-absorbing supports.

Particular care must be taken when connecting

the tube connectors in order to avoid leaks. When

substituting tubing, it is necessary to ensure that the

pump housing and drive are compatible with any

change in specification. Exchanging the tube for a

different capacity or size may damage the system, the

motor and the pump itself. The hydraulic circuit should

be carefully flushed before starting the pump.

WARRANTY

Every new pump is guaranteed to be free of defects

when leaving the factory for a period of 12 months –

excluding tube – from the production date printed on

pump label. Fluid-o-Tech will repair or replace at its

judgement part or all of the product not conforming

to this warranty. Fluid-o-Tech’s responsibility under

this warranty is limited to the repair or replacement of

defective product returned to us on a D.A.P. basis,

providing that our analysis discloses that such part or

parts were defective at the time of sale.

The warranty is not recognized if:

• The instructions on how to handle, install or operate

the pump are disregarded.

• The pump has been disassembled or modified by

anyone other than a Fluid-o-Tech (or authorized by

Fluid-o-Tech) engineer or repaired with non original

components.

• Solid extraneous particles are found in the pump

drive mechanism or tube bed.

• Obvious signs of excess pressure are evident.

• The pump has been utilized for an application for

which it was not intended to be used where the

operating conditions and/or the pumped liquid were

incompatible with the pump itself and this application

has not been specifically approved by Fluid-o-Tech.

• Normal wear and tear is not covered by the present

warranty.

The adjustment or replacement of defective parts

made under this warranty will not extend the original

warranty period. The Purchaser/User is responsible for

the disposal or recycling of the product at end of its

use or lifetime. For more information on proper disposal

method, please contact Fluid-o-Tech Customer Care.

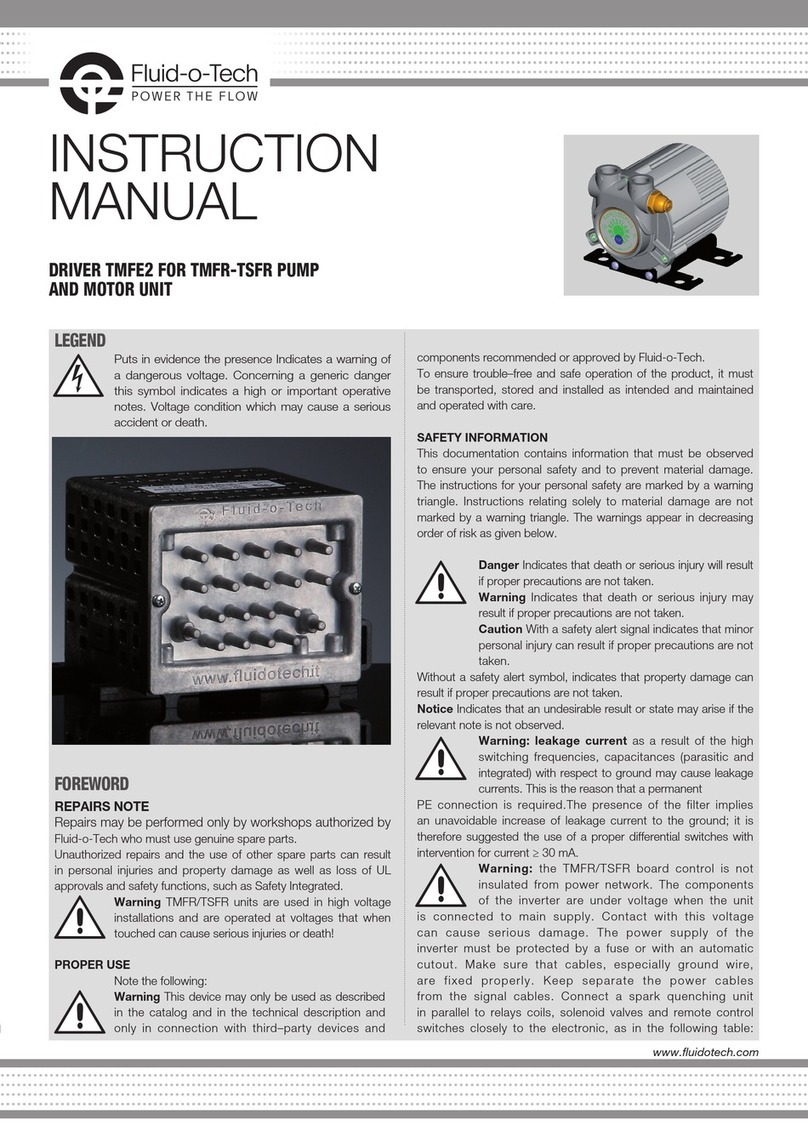

CERTIFICATIONS

The pump is assembled with a motor, the complete

pump-motor unit is considered as a machine and

supplied with the mark “CE”.

Different grades of tubes are available and they

satisfy the requirements of the following Directives:

D.M. 174/04 of the Health Ministry, of 6th April 2004,

on materials and devices that may be used in fixed

catching, treatment, adduction and distribution

installations of water destined for human use.

EC Regulation n.1935/2004 of the European Parliament

and the Council of 27th October 2004 on materials

and articles intended to come into contact with food

products and for which there are migration tests with

photo A as required by DM n.338 of 22nd July 1998

Encl.1 Chapter 1.

Fluid-o-Tech Int’l Inc.

161 Atwater St.,

Plantsville CT (USA) 06479

Tel. +1 (860) 276 9270

Fax +1 (860) 620 0193

Fluid-o-Tech Int’l Inc. Japan

2nd Floor, 4-3-8, Espoir Todoroki,

Todoroki, Setagaya, Tokyo 158-0082

Tel. +81 (0) (3) 6432 1812

Fax +81 (0) (3) 6432 1813

Fluid-o-Tech Asia (Shanghai) Co., Ltd.

2/F, Factory building 6 (1), No. 258, Zhijiang Road,

Fengxian District, Shanghai City, Z.P.: 201499 China

Tel. +86 (021) 67100 838

Fax +86 (021) 67100 605

Fluid-o-Tech srl

Via Leonardo da Vinci, 40

20094 Corsico, Milano, Italy

Tel. +39 02 9995 01

Fax +39 02 9995 0999