For dimensions of tool AT 152/1 refer to table 1.

OPERATING CONDITIONS

Ensure that the pump materials are compatible with

the pumped fluid. Fluid-o-Tech pumps are designed to

handlecleanwateratambienttemperature.

Any other fluid and/or operating condition need to be

tested and approved by the customer and verified by

Fluid-o-Tech. The maximum liquid temperature is 120

°C (248 °F). It is strongly recommended, especially for

theinlet,usingapipewithaninnerdiametersufficientto

handlethepump’scapacity.Thiswillavoidcavitationand

consequentfailure ofthe pump.The dischargepressure

mustnotexceed20bar/290psiinanyevent.

Thepipingonthedischargesideshouldthereforebeable

tohandleapressureof20bar(290psi).

Itisalsorecommendedinstallingafilterbeforethepump

capableofkeepingoutparticleslargerthan10μmwhich

could cause fast wear of the internal components, and

witha surface arealarge enough not to cause hydraulic

losses in the circuit. It is also important to check

periodically the filter cartridge. In order to keep the filter

under control, it is advisable to install a vacuum gauge

after the filter. In case the vacuum increases more than

0.1bar,thecartridgeshouldbecleanedorchanged.

For long pump life, the pumped fluid must not contain

solid particles. Although the magnet drive gear pumps

are self-priming, they should operate under wetted

conditions, as dry running will cause accelerated wear

oftheinternalcomponents.Adirtyfilteroraninsufficient

supply of water can cause cavitation and accelerated

wearoftheinternalcomponentsofthepump.

If the suction line is subject to low pressure or flow it

is recommended fitting a pressure/level switch before

the pump in order to switch the motor off when that

happens. It is also recommended to protect the system

from accidental overpressure with safety devices such

asapressurereliefvalveorapressureswitchconnected

tothemotor. It isnotadvisable to installsolenoidvalves

in the circuit; however, if necessary, the soleinoid valve

should only be installed after the pump. Solenoid valves

installedbeforethepumpshouldbeavoidedatalltimes.

The internal diameter should be appropriately sized for

thepumpcapacity.Inordertoavoidpressurespikesthe

solenoid valve should only be operated after the pump

has stopped, allowing a few seconds to go by after the

motor has been switched off. If the pump is equipped

with a relief valve (bypass), the valve will act, in case of

accidentaloverpressure, to limit the pressure,by means

orrecirculatinfthefluidinternally.

The relief valve is not a flow regulator, and should

notbeused as such.Ifused as aflowregulator, the

excess fluid will recirculate within the pump, through

thereliefvalve,andthepumpmayfail.

Themaximumdifferential pressure shouldbeat least

1 bar (14.5 psi) lower than the relief valve setting in

ordertoavoid fluid recirculationandtherefore lossof

capacityandultimatelyfailure.

Dueto magneticcoupling, thepump doesnot requirea

mechanical seal to prevent leakage. This eliminates the

usualproblemsassociated withtheuse ofa mechanical

seal. The maximun pressure varies with pump model

and speed. As the differential pressure deacreses the

flowratewillincrease.Beyondthevaluesspecifiedinthe

charts on page 4 of this leaflet where the performances

outside the grey area are attained with the rare earths

magnet, the torque that can be transmitted is limited

by the magnet strenght, and the coupling between the

motor and the pump is not guaranteed, therefore the

pump might stop. The coupling can be re-established

simply by switching off the motor, waiting until it is

completelystopped,andthenrestartingthemotoragain.

WARRANTY

Every new pump manufactured by Fluid-o-Tech is

guaranteed to be free of defects in workmanship and

materialwhenleavingthefactoryforaperiodof18months

from the production date printed on pump label, plus a

periodof6monthstocoverthewarehouseandtransittime,

orforaperiodofmaximum24monthsfromthepurchasing

date to the first product use. In no event shall this period

exceed24monthsfromdateoforiginalinvoice.

Fluid-o-Tech will repair or replace at our discretion part or

all ofthe productnotconforming tothis warranty.Fluid-o-

Tech’s responsibility under this warranty is limited to the

repair or replacement of defective product returned to us

onanDDPbasis,providingthatouranalysisdisclosesthat

suchpartorpartsweredefectiveatthetimeofsale.

Thewarrantyisnotrecognizedif:

• The instructions on how to handle, install or operate

thepumparedisregarded.

• The pump has been disassembled or modified by

anyone other than a Fluid-o-Tech (or authorized by

Fluid-o-Tech) engineer or repaired with non original

components.

• Thepumpgasbeenoperateddry,undercavitation.

• Solidextraneousparticlesarefoundinthepump.

• Obvioussignsofexcesspressureareevident.

• The pump has been utilized for an application for

which it was not intended to be used where the

operating conditions and/or the pumped liquid were

incompatible with the pump itself and this application

hasnotbeenspecificallyapprovedbyFluid-o-Tech.

• In case of pumps equipped with a relief valve, when

theoperatingpressurehasbeenlessthan1barbelow

thereliefvalvesetting.

• Normal wear and tear is not covered by the present

warranty

The adjustment or replacement of defective parts made

under this warranty will not extend the original warranty

period.

CERTIFICATIONS

NSFlistedpumpsavailablefordrinkableliquids.Forthe

modeldetails,pleaserefertotheofficialNSFwebsite

(directlinkavailableonwww.fluidotech.it)

The pump itself, without the motor, is not to be

considered as a machine, but only a component,

thereforethemark“CE”isnotapplicable.

Whenthepumpisassembledwithamotor,thecomplete

Fig. 1

Tool pin reference plane

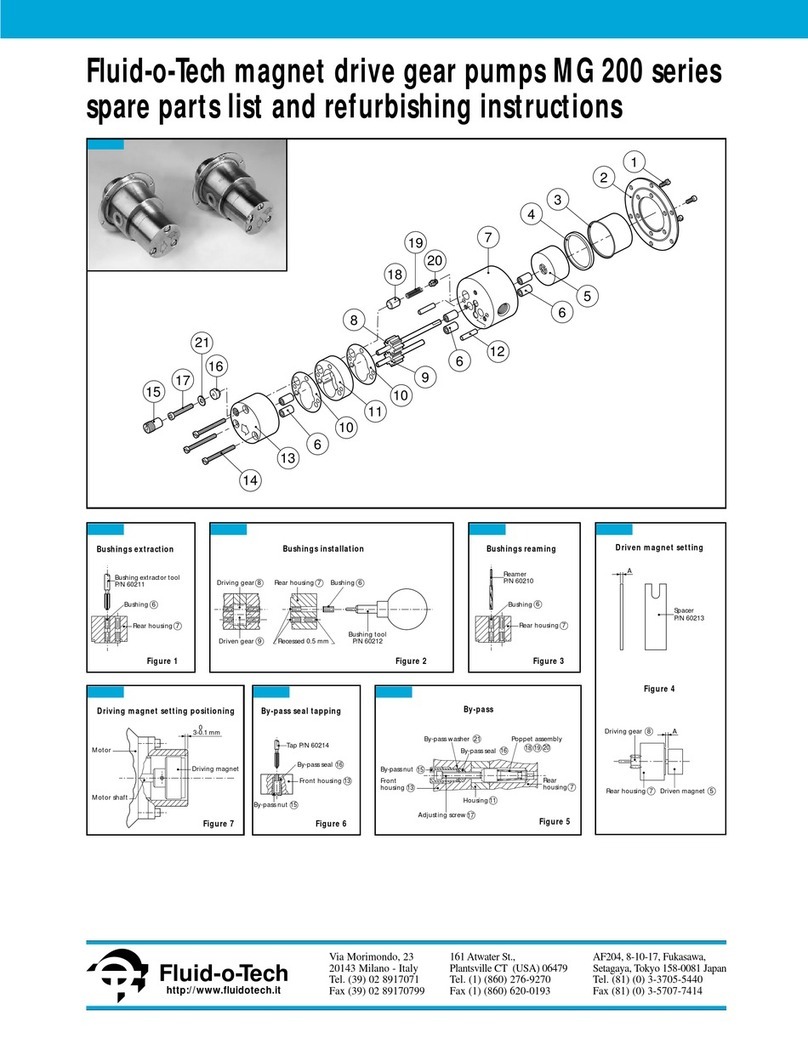

Fig. 2 - MGAF series driving magnets with “D” shaft

AT-152_1

Fig. 3 - MGAF series driving magnets with shaft key seat

AT-152_1

X

Tool AT-152_.. options (depending on pump series

and magnet type)

Pump series MG/MS MK

Magnet type MGAF MGAS MKAF MKAS

“X” dimension 3 3 3 6

(in mm)

Tool type AT-152_1 AT-152_2 AT-152_8

Tab. 1: Tool AT-152_..