WARRANTY - Our goods come with guarantees that cannot be excluded under the Australian

Consumer Law. You are entitled to a replacement or refund for a major failure and for

compensation for any other reasonably foreseeable loss or damage. You are also entitled to

have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

To present claims under this warrantly, please contact your place of purchase or

contact Fluidmaster Holding Australia Pty Ltd.

Warranty excludes incorrect installation. Warranty on Replaceable Silicone Outlet

Washer is subject to water conditions and fair wear and tear.

IN NEW ZEALAND Call 09 415 5585

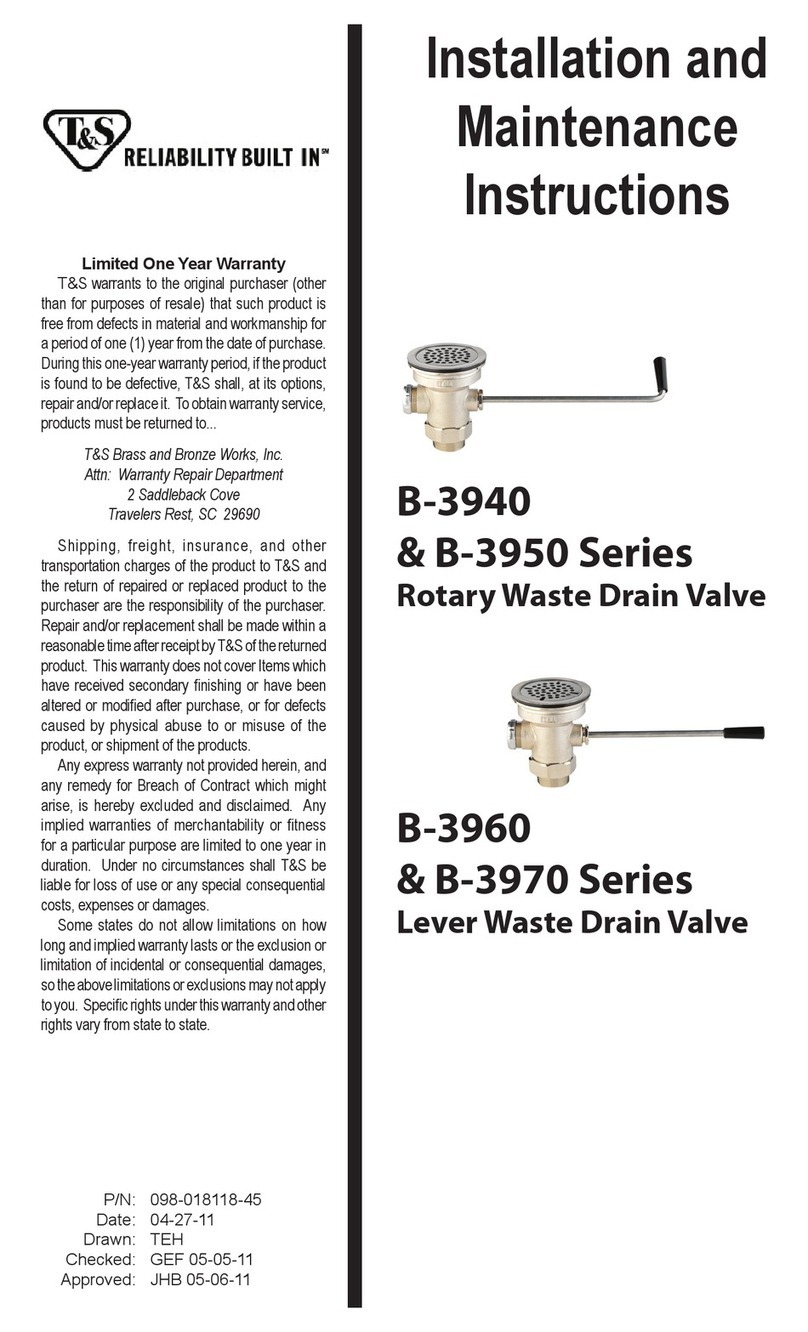

Replacement Silicone

Outlet Washer

Part # 56-01

Wedge Flush Pipe

Washer

Part # 56-02

Flush Pipe

Locking Collar

Part # 56-03

Tank to Bowl Gasket (Foam)

For Close Coupled Only

Part # 56-04

Tank to Bowl Gasket (Rubber)

For Close Coupled Only

Part # 6100

OTHER REPLACEMENT PARTS AVAILABLE SEPARATELY

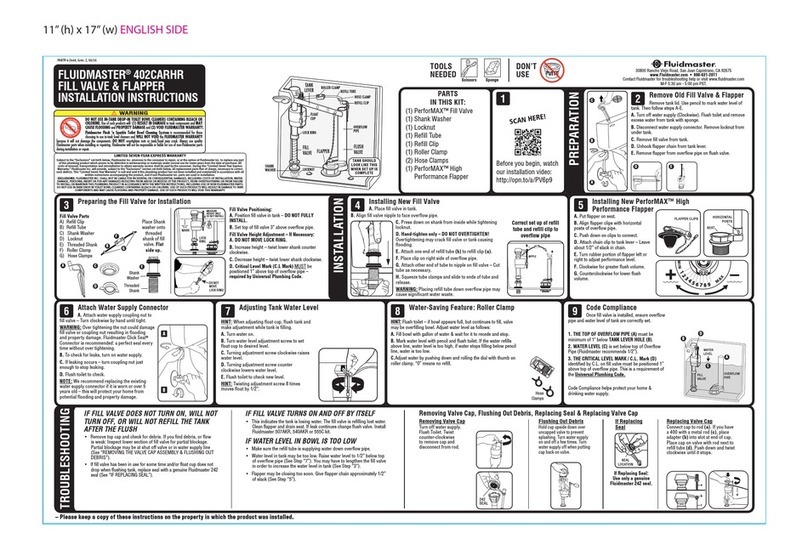

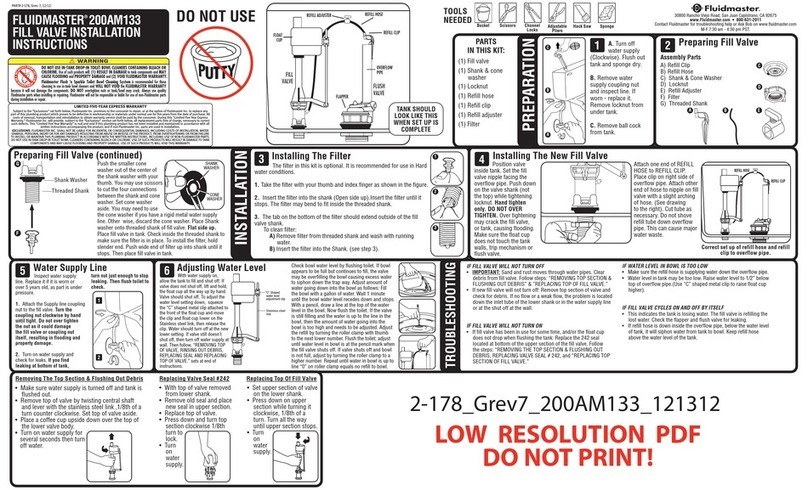

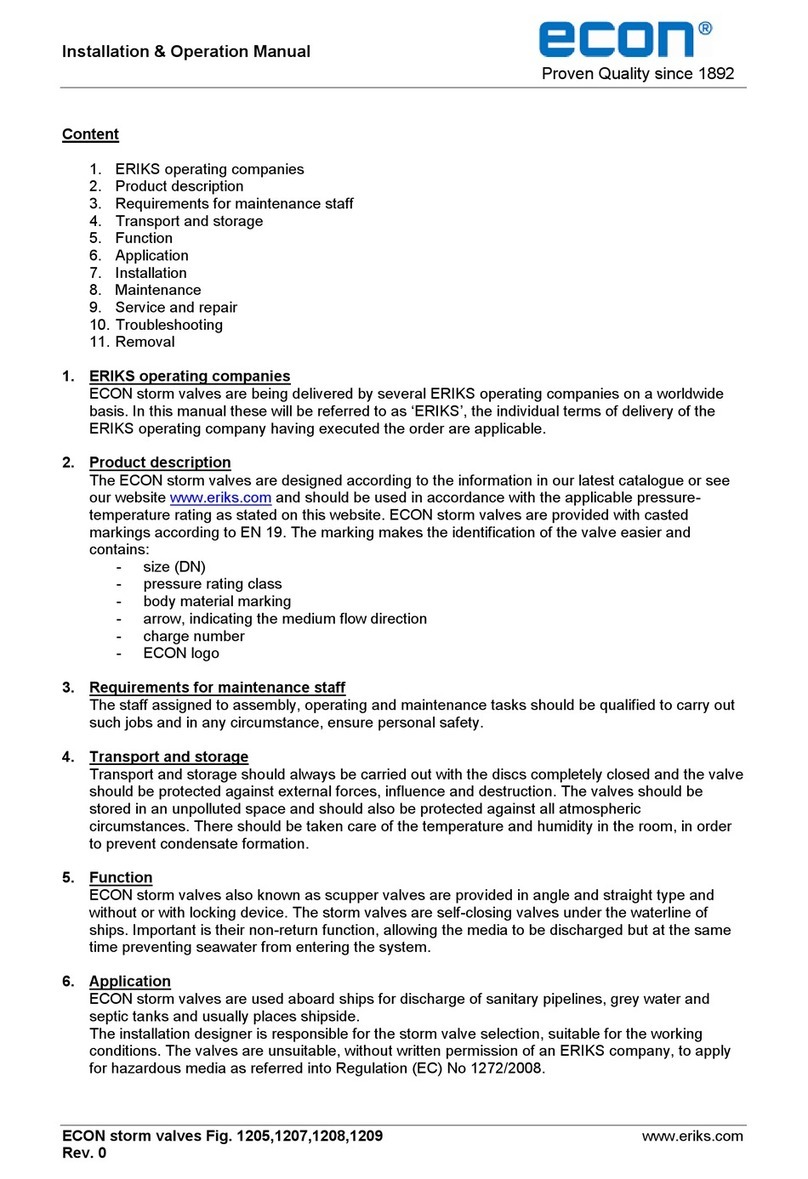

Maximum water level within the cistern tank should be no higher than 20mm below the top of the outlet

valve overflow tube. The overflow tube may be raised or lowered depending on the maximum required level

of water for a full flush, however the overflow height must always be 25mm below the critical level (CL)

marked on the Inlet Valve to ensure an Air Gap.

Fill tank with additional 3 litres (6 Litre total), for

6/3L Flush or Fill Tank with additional 11/2 Litres

(4.5 Litre total) for 4.5/3L Flush then mark the

top of Water Level. This is your Full Flush,

adjust the Full Flush Tab to set this volume.

(For older 9/4.5L flush toilet cisterns, use 4.5L

to set half flush mark and add 4.5L on top of

half flush volume to achieve 9L full flush volume

mark)

To establish water levels, pour in 3 litres of

water, then press full flush. This will establish

the residual water level mark, then add 3 litres

on top of the residual water and mark the top of

the water level. This is your 3 litre volume.

Adjust half flush tab on the side to flush 3 litres.

Close Coupled Cisterns:

Place rubber gasket on

pan hole and centre the

tank onto the washer.

Where required, place

bolts downwards in bolt

holes and tighten.

Wall Mount Cisterns: Connect the existing

flush pipe to the base of the outlet valve and

hand tighten the nut. Ensure the flush pipe nut

washer is in good condition.

Please retain instructions for future reference.

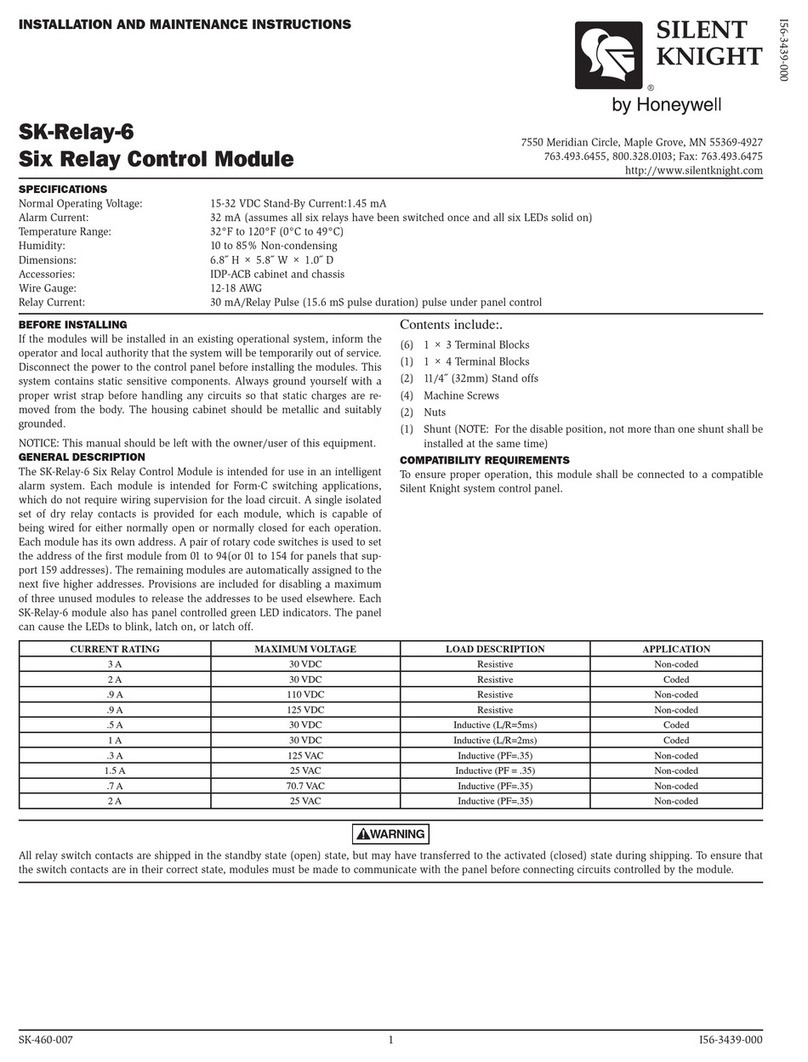

FLUIDMASTER®

560AU OUTLET VALVE

INSTALLATION INSTRUCTIONS

PART# 5-3309, Grev. 3, 08/17

Fluidmaster 560AU Outlet Valve Suits Flush Volumes:

4.5 Litre / 3 Litre

6 Litre / 3 Litre

9 Litre / 4.5 Litre

DO NOT USE IN-CISTERN DROP-IN TOILET BOWL

CLEANERS CONTAINING BLEACH OR CHLORINE.

Use of such products will: (1) RESULT IN

DAMAGE to Cistern components and MAY CAUSE

FLOODING and PROPERTY DAMAGE and (2) VOID

FLUIDMASTER WARRANTY.

DO NOT overtighten nuts or cistern/bowl may

crack. Always use quality Fluidmaster parts when

installing or repairing. Fluidmaster will not be

responsible or liable for use of non-Fluidmaster

parts during installation or repair.

WARNING

10B10A

NB: Shank length may be cut to

suit Close Coupled Cisterns

Fluidmaster Holding Australia Pty Ltd

5B/100 New Street

Ringwood, Victoria 3134

Australia

Phone: +61 (03) 8870 2555

Toll Free: 1 800 931 166

Email: salesau@fluidmaster.com

Website: www.Fluidmaster.com.au

1312

11