VEB-53 Series Valves 1 Installation Guide

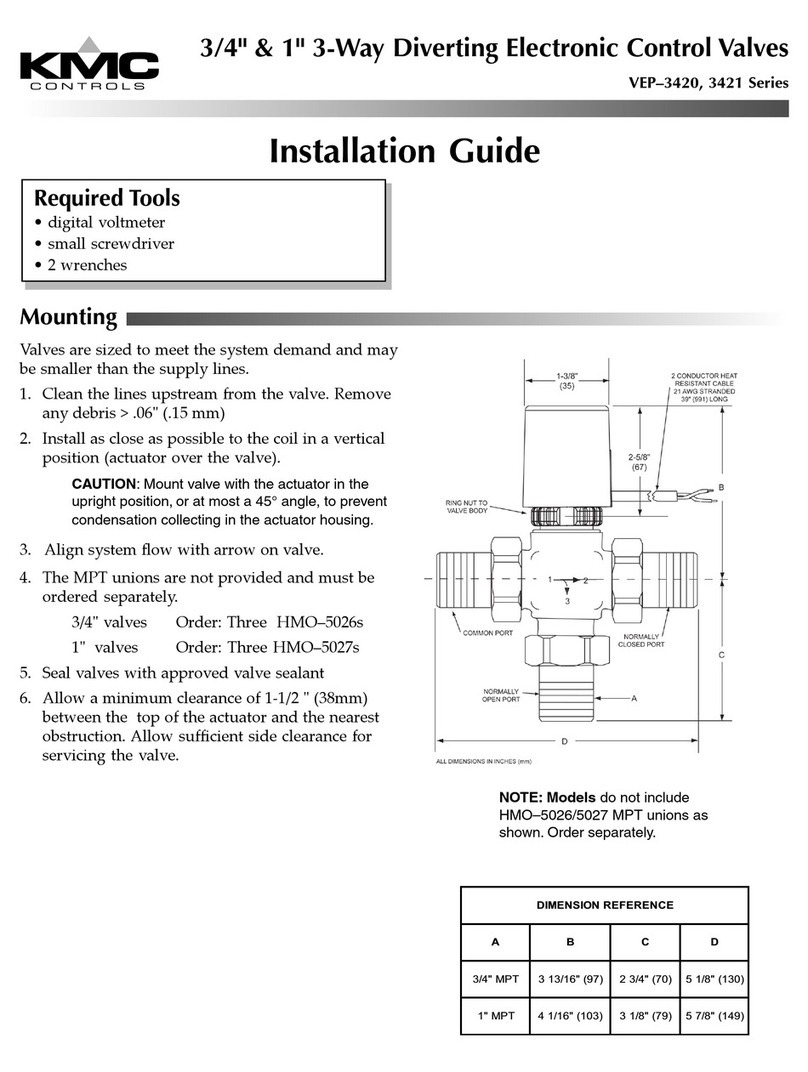

B

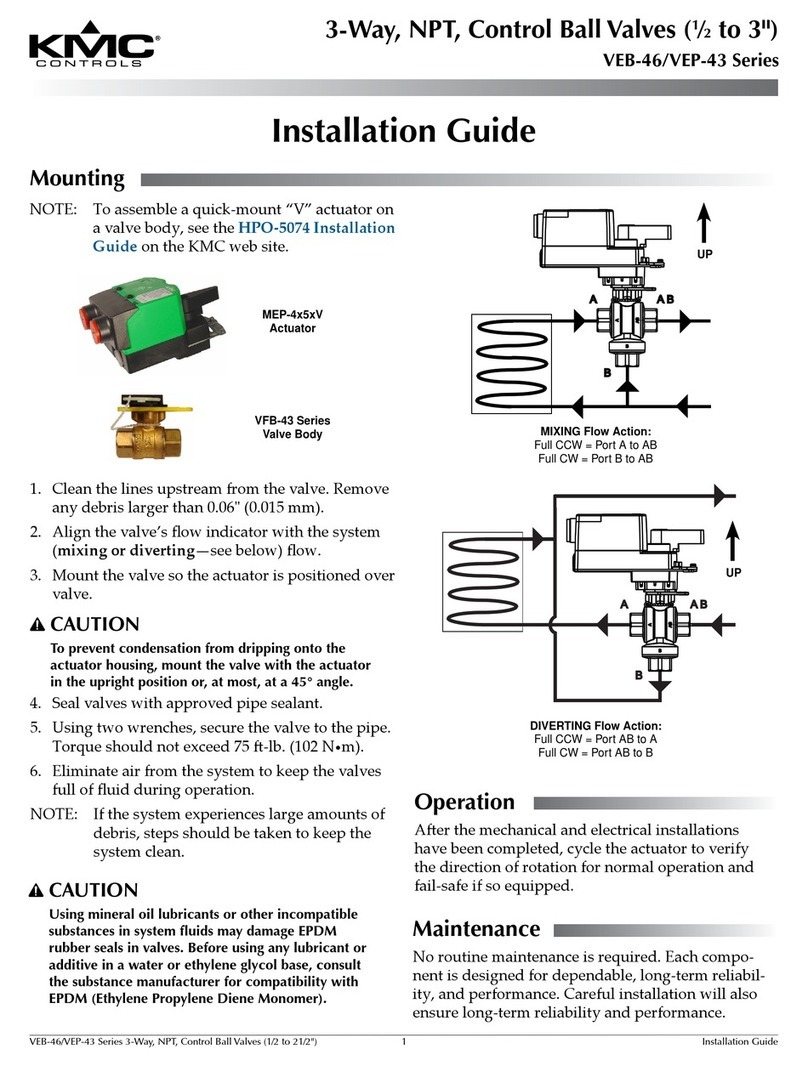

E

A

C

Full CW =

Valve Open

Full CCW =

Valve Closed

Size

A B

C

D

E

Weight

(lb.)

4"

11 9 13.75 9 17.75 70

5"

12.375 10 14.75 10 18 80

6"

13.875 11 15.625 11 18.875 95

D

Installation Guide

2-Way, Flanged, Control Ball Valves

VEB-53 Series

Mounting 1

Wiring 1

Operation 2

Maintenance 2

Accessories/Repair Parts 2

Models and Specifications 2 Mounting

1. Cleanthelinesupstreamfromthevalve.Remove

anydebris(weldingslag,pipescale,orother

contaminants)largerthan1/16inch(1.6mm).

NOTE: Ifthesystemexperienceslargeamounts

ofdebris,stepsshouldbetakentokeep

thesystemclean,suchas20meshstrainer

installedupstreamofthevalve.

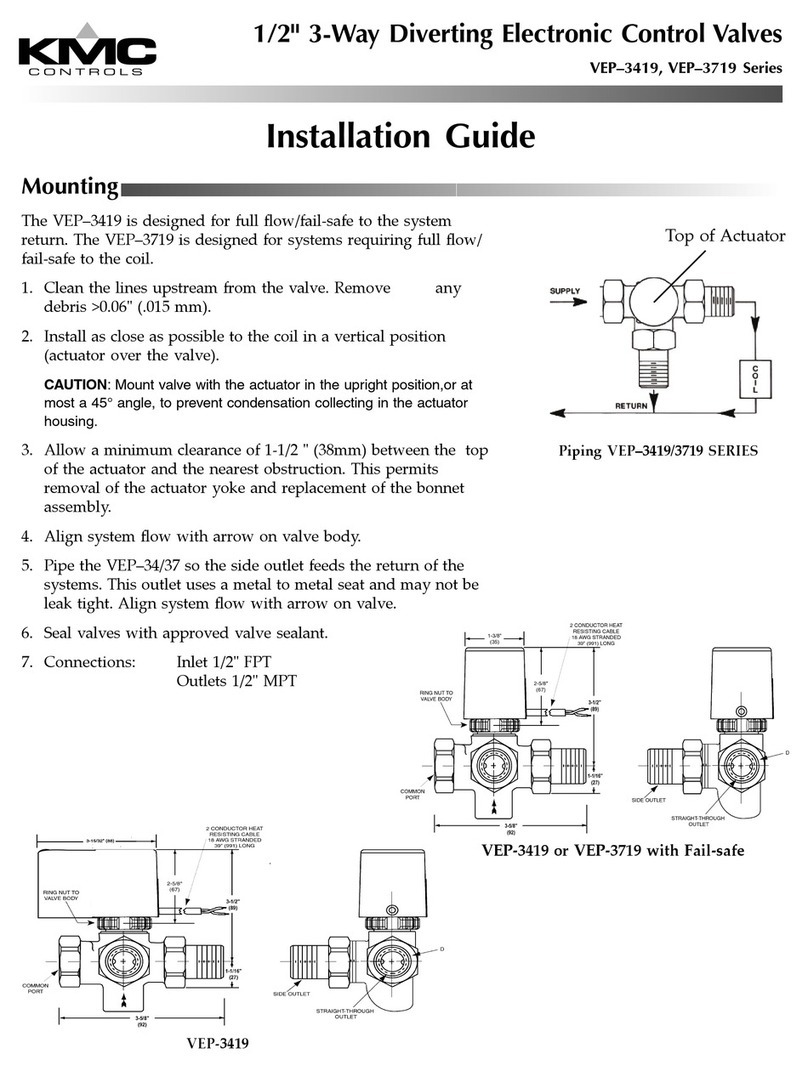

2. Alignthevalveassemblyaccordingtothesystem

owrequirements(seetheillustrationbelow).

3. Thevalvemaybemountedoneitherverticalor

horizontalpipelines.Onhorizontallines,mount

thevalvesotheactuatorispositioneduprightand

overthevalve.(Leavesucientroomonallsides

toservicetheactuatorandvalve.)

CAUTION

To prevent condensation from dripping onto the

actuator housing on horizontal lines, mount the

valve with the actuator in the upright position or, at

most, at a 45° angle.

4. Installapprovedangegaskets(notsuppliedby

KMCControls)andboltthevalvetothepipes.

5. Eliminateairfromthesystemtokeepthevalves

fullofuidduringoperation.

UP

(on horizontal

lines)

CAUTION

Using mineral oil lubricants or other

incompatible substances in system fluids may

damage EPDM rubber seals in valves. Before

using any lubricant or additive in a water or

ethylene glycol base, consult the substance

manufacturer for compatibility with EPDM

(Ethylene Propylene Diene Monomer).

Wiring

Wiringisdependentonthetypeofactuatorand

thedesiredoptionsthatareavailable.Consultthe

actuatormodellabelandthentherelevantsections

intheMEP-7200/7500/7800 Series Actuators

Installation Guidefordetailedinstructionsonthe

applicablewiring,feedbackselector,andactuator/

signalrangereset(auto-mapping)ofthevalve’s

actuator.