VT Plus HF

Operators Manual

viii

Contents

Notices................................................................................................................................. i

All Rights Reserved............................................................................................... i

Restrictions and Liabilities ..................................................................................... i

Claims ................................................................................................................... i

Certification............................................................................................................ i

Obtaining Assistance............................................................................................. i

Manufacturing Location ......................................................................................... i

Safety Considerations..........................................................................................................ii

Warnings and Cautions .........................................................................................ii

Applicable Testing Standards .............................................................................................iv

Safety Requirements ............................................................................................iv

Electromagnetic Interference and Susceptibility ................................................... v

EC Directive 89/336/EEC Electromagnetic Compatibility .....................................vi

EC Directive 73/23/EEC Low Voltage (User Safety).............................................vi

Warranty ............................................................................................................................vii

Warranty Disclaimer...........................................................................................................vii

Contents ........................................................................................................................... viii

1 Overview

Introducing the VT PLUS HF ........................................................................................... 1-1

Optional Accessories ....................................................................................................... 1-2

Theory of Operation......................................................................................................... 1-2

Pressure Measurements ................................................................................... 1-2

Oxygen Measurements ..................................................................................... 1-4

Flow Measurements .......................................................................................... 1-4

Breath Detection................................................................................................ 1-6

Calculated Parameters ...................................................................................... 1-8

About This Manual........................................................................................................... 1-9

2 Installation

Unpacking and Inspection................................................................................................ 2-1

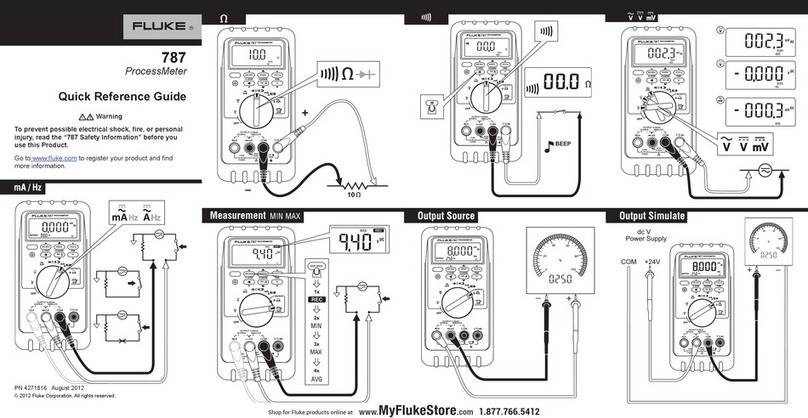

Connecting the VT PLUS HF........................................................................................... 2-2

Pneumatic Connections..................................................................................... 2-2

Quick Installation/Operations Guide .................................................................. 2-3

Bi-directional Flow Mode ................................................................................... 2-3

Uni-directional Flow Mode ................................................................................. 2-4

Inspiratory Testing............................................................................................. 2-4

Expiratory Testing.............................................................................................. 2-4

Attaching the Printer Cable .............................................................................................. 2-6

3 Keypad Functions

VT PLUS HF Keypad Functions ...................................................................................... 3-1

4 System Setup

Using the Setup Screen................................................................................................... 4-1

Settings............................................................................................................................ 4-2

Gas Settings...................................................................................................... 4-2

Gas Temperature .............................................................................................. 4-4

Ambient Temperature........................................................................................ 4-4

Relative Humidity............................................................................................... 4-4

Correction Mode................................................................................................ 4-5

Barometric Pressure Units................................................................................. 4-5

Barometric Pressure.......................................................................................... 4-5

Breath Detection................................................................................................ 4-6

Breath Detect Threshold.................................................................................... 4-6

Inspiratory versus Expiratory Tidal Volumes...................................................... 4-7